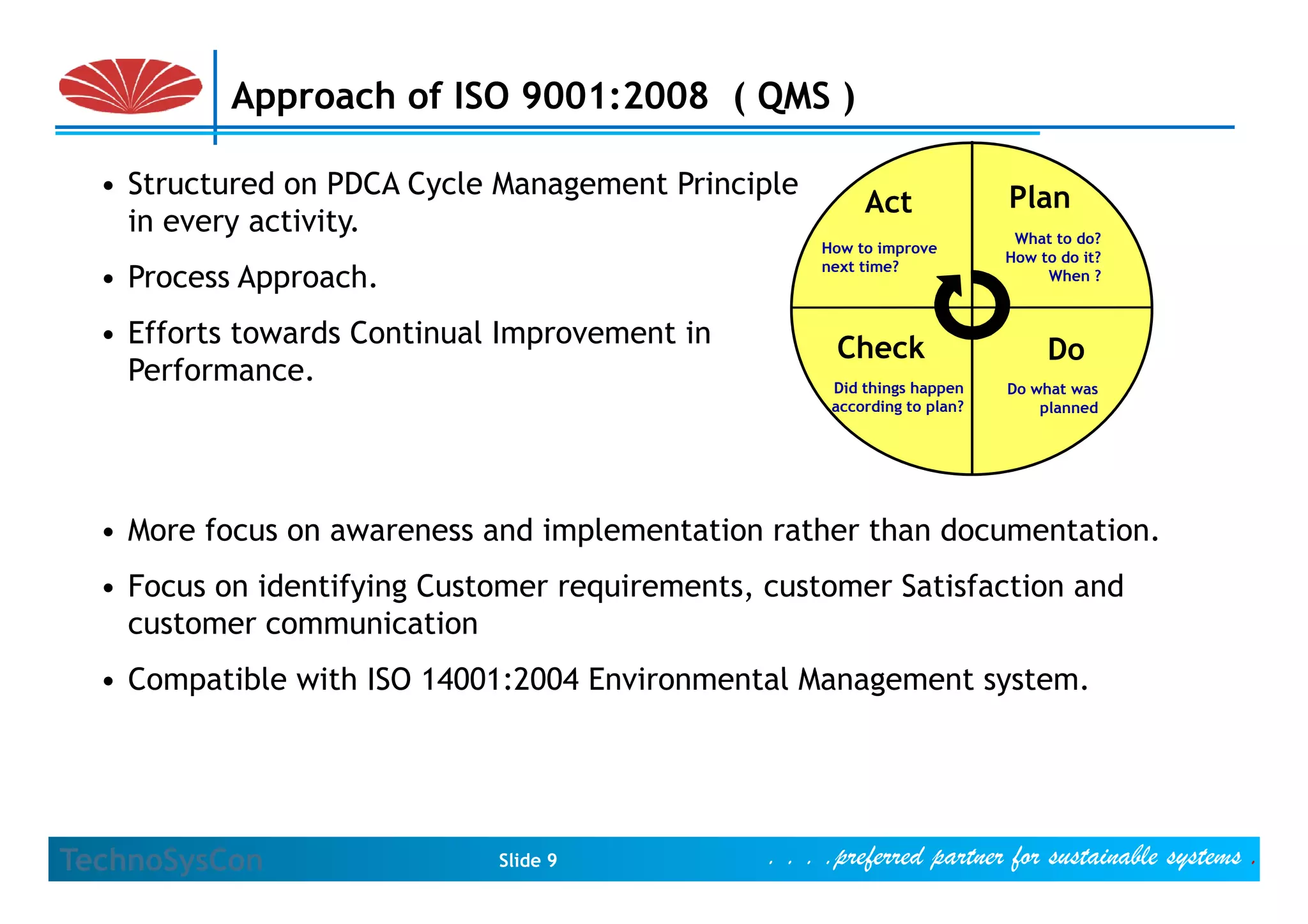

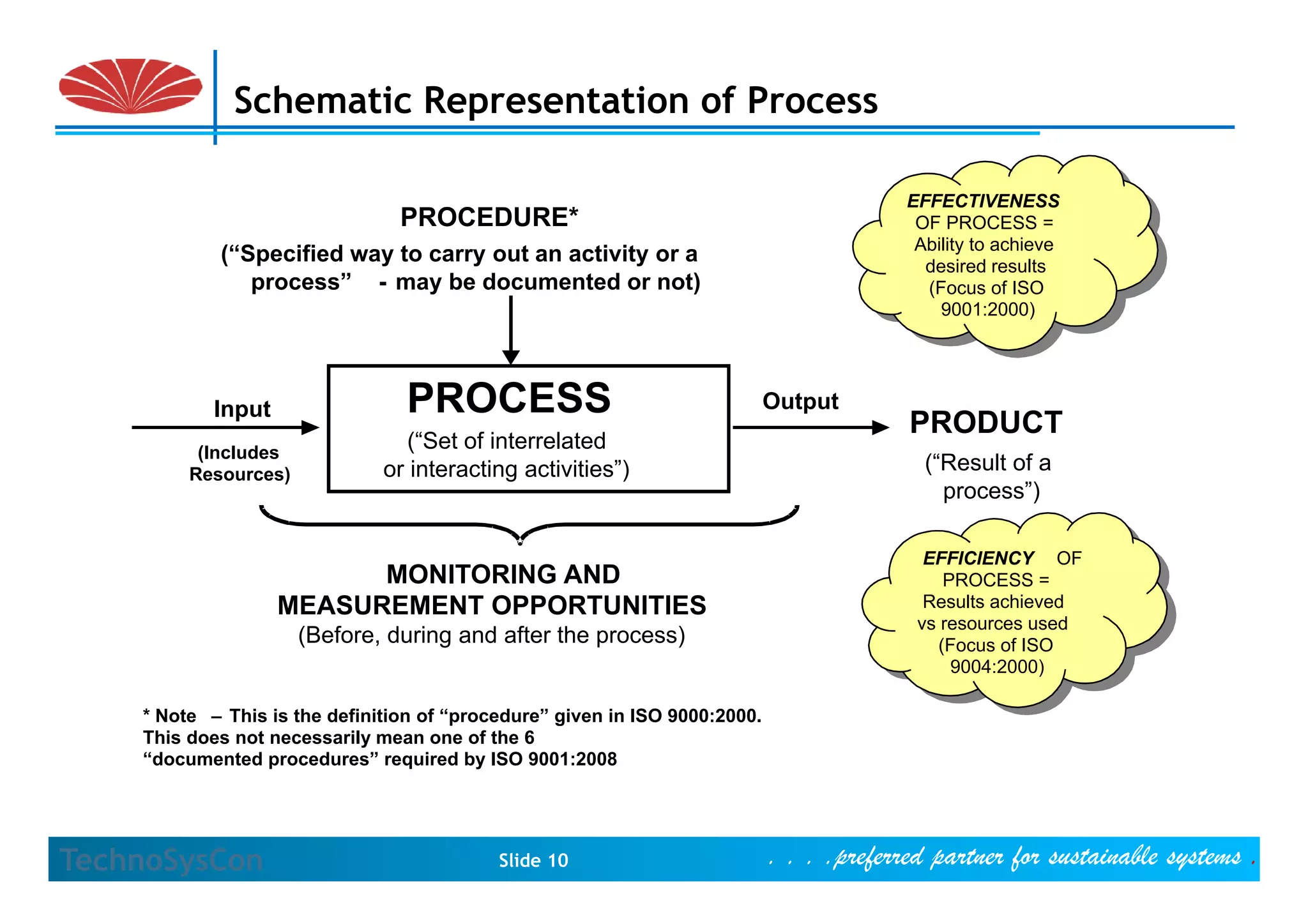

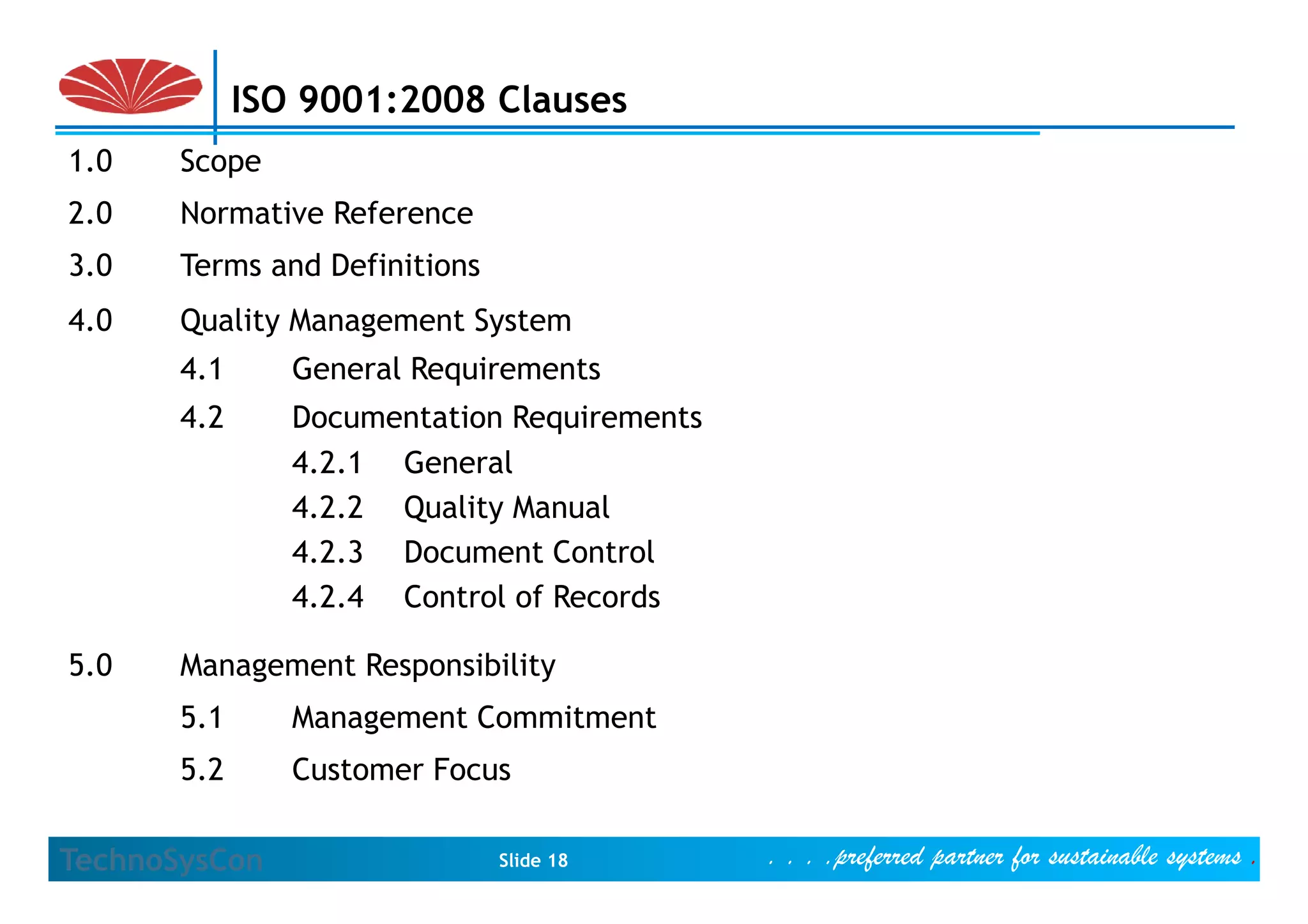

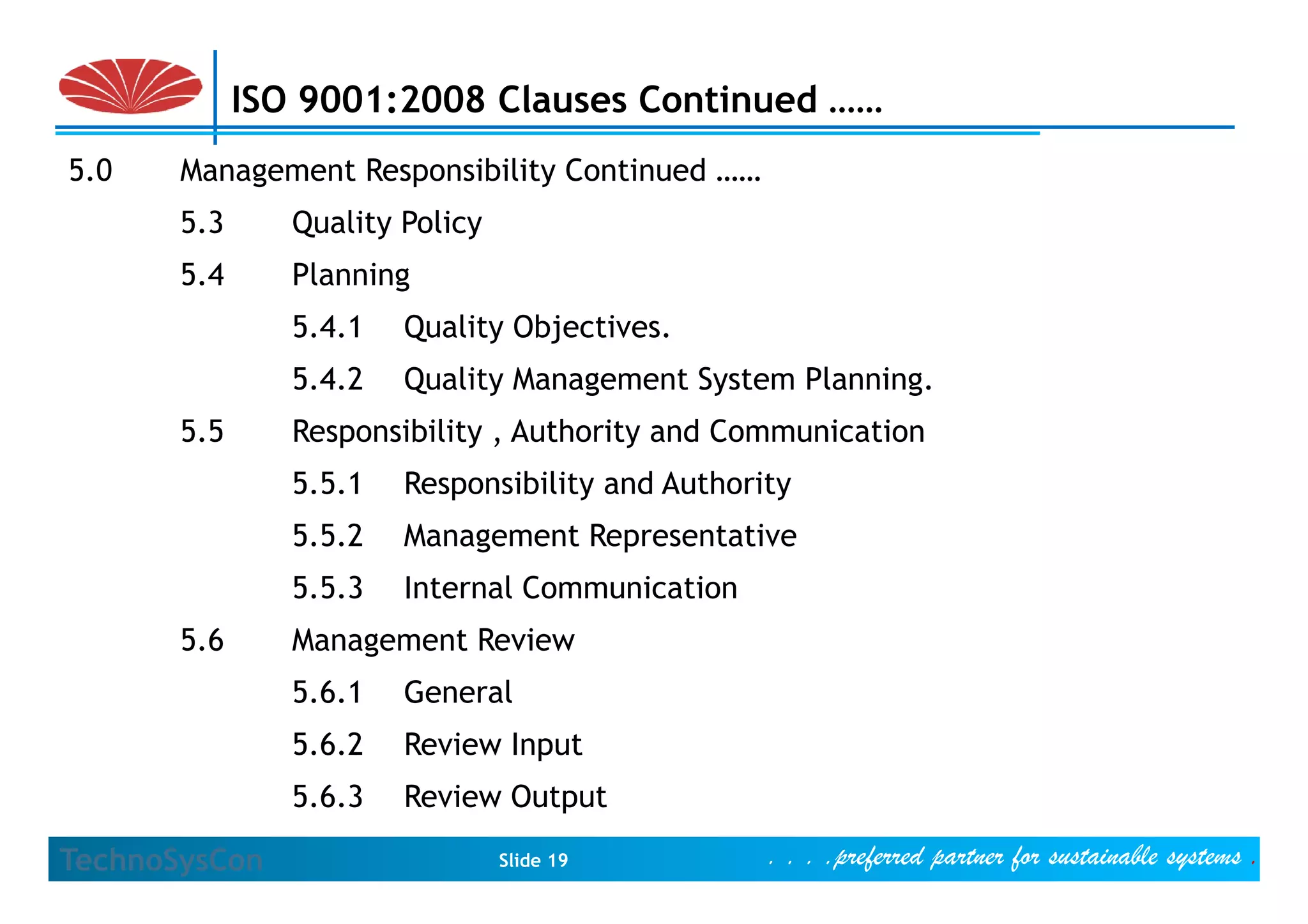

The document provides an overview of ISO 9001:2008 Quality Management System requirements. It discusses the evolution of quality systems, the history and development of ISO standards, and the key aims and principles of ISO 9001:2008. The document outlines the main clauses of ISO 9001:2008, including requirements for documentation, management responsibility, resource management, product realization, and measurement. It also discusses the benefits certification can provide organizations.