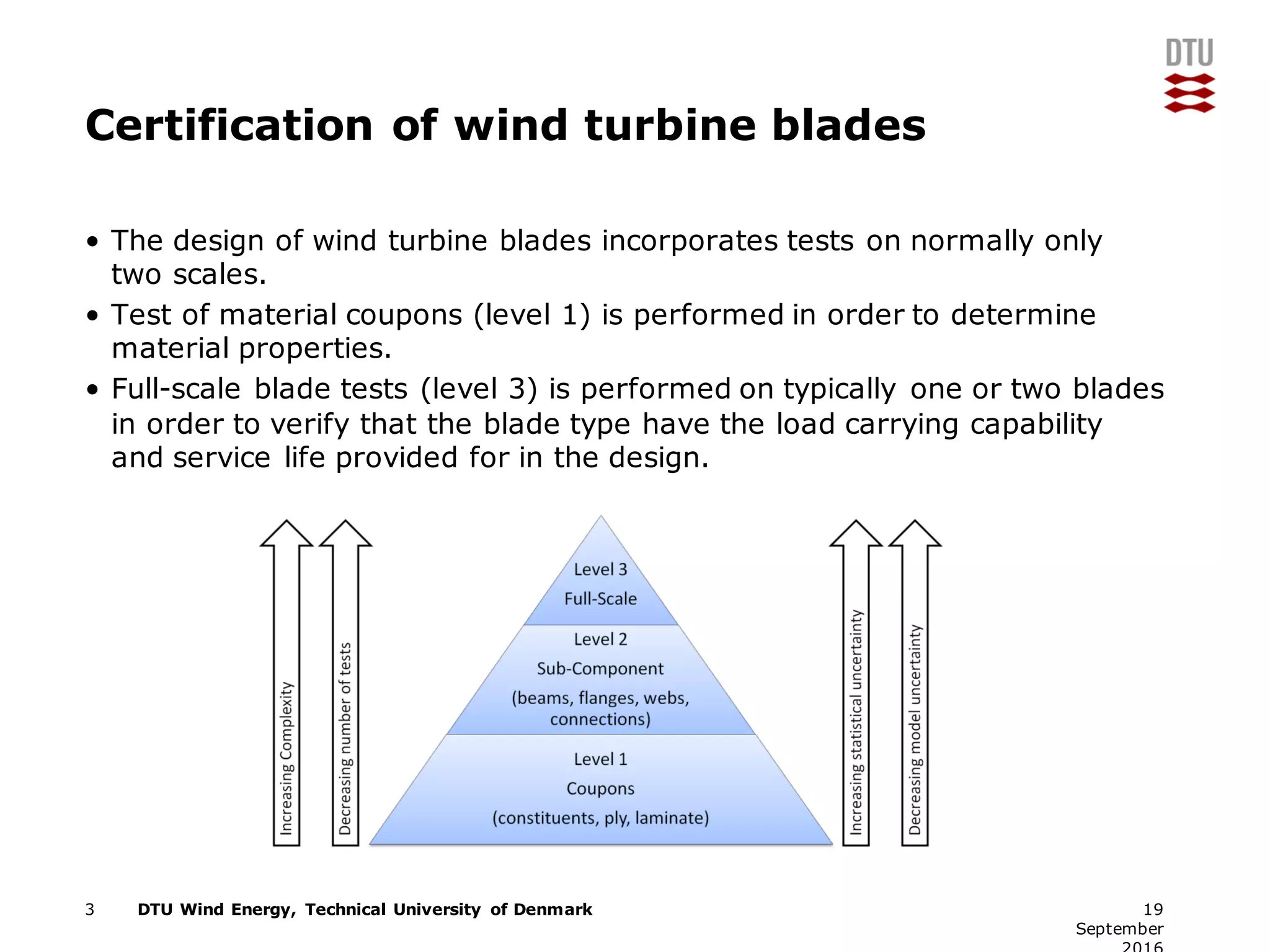

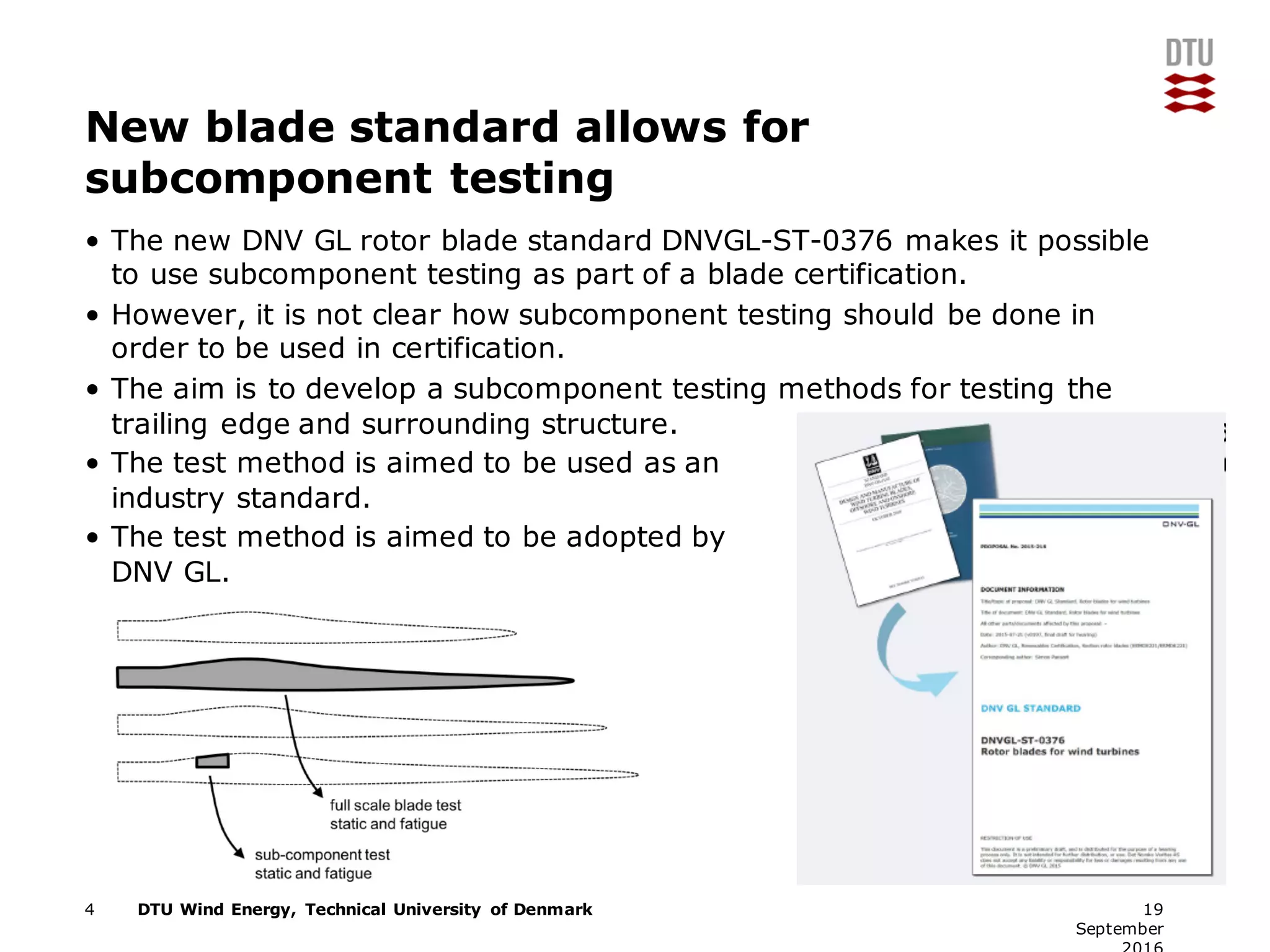

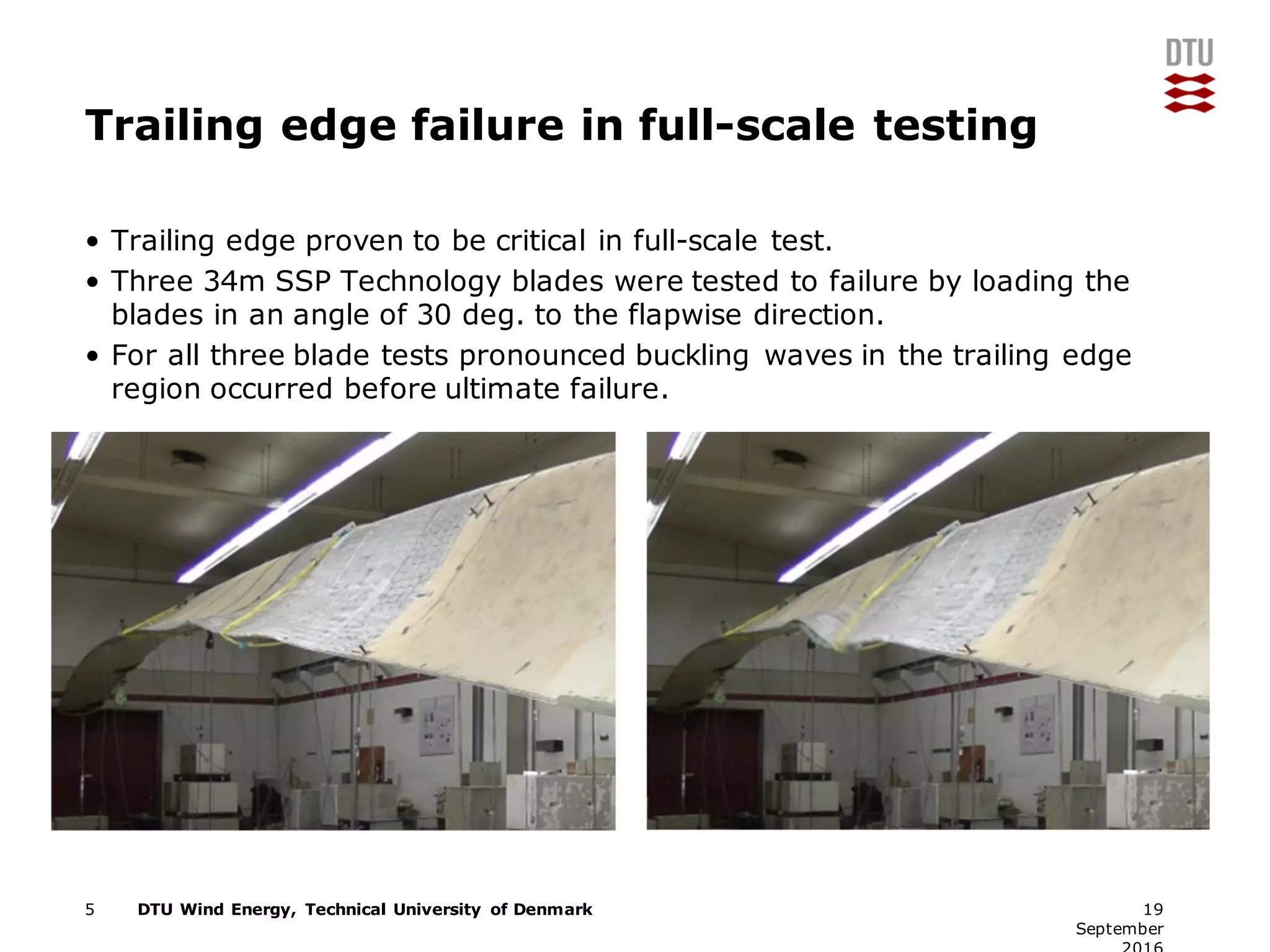

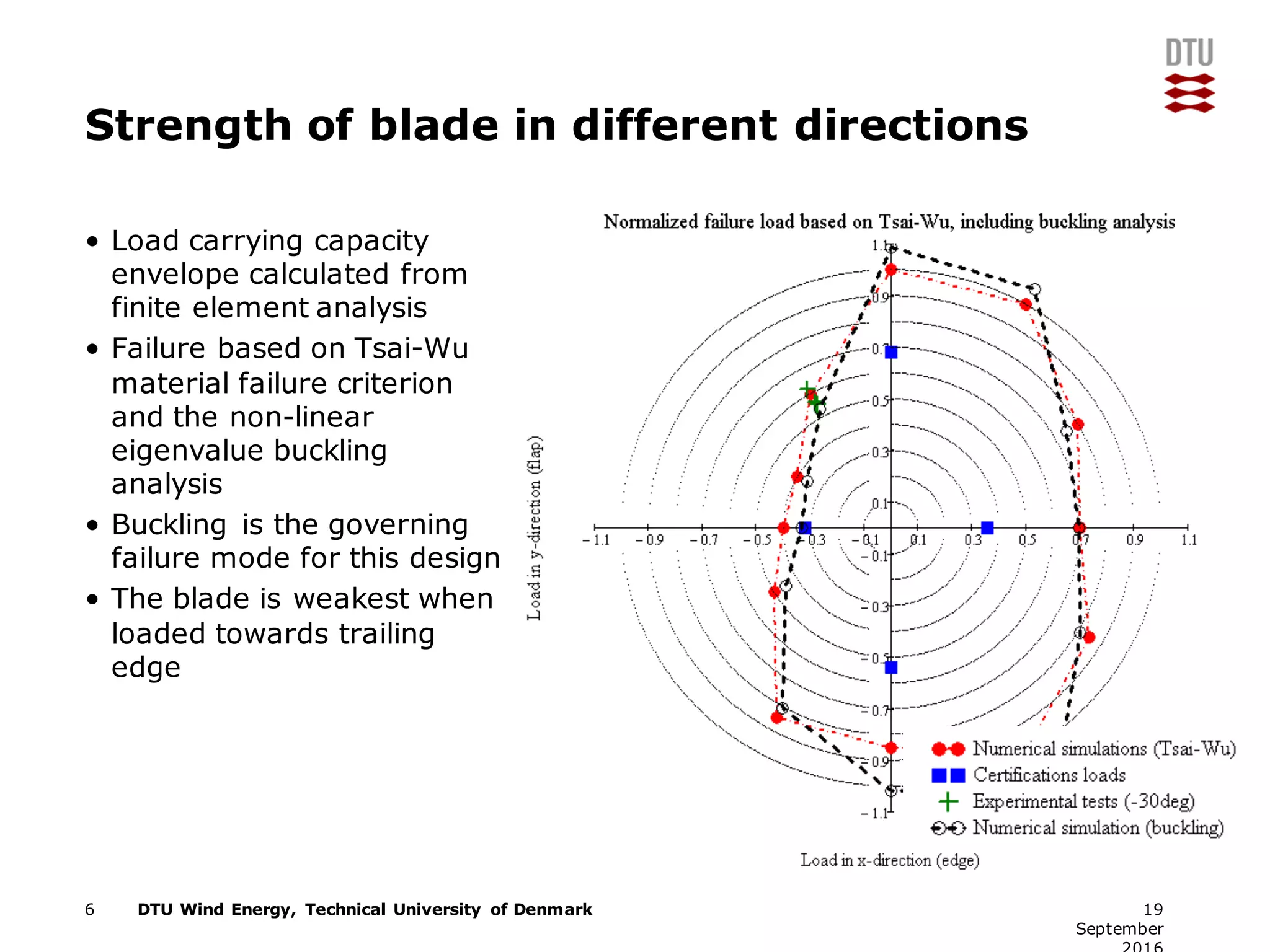

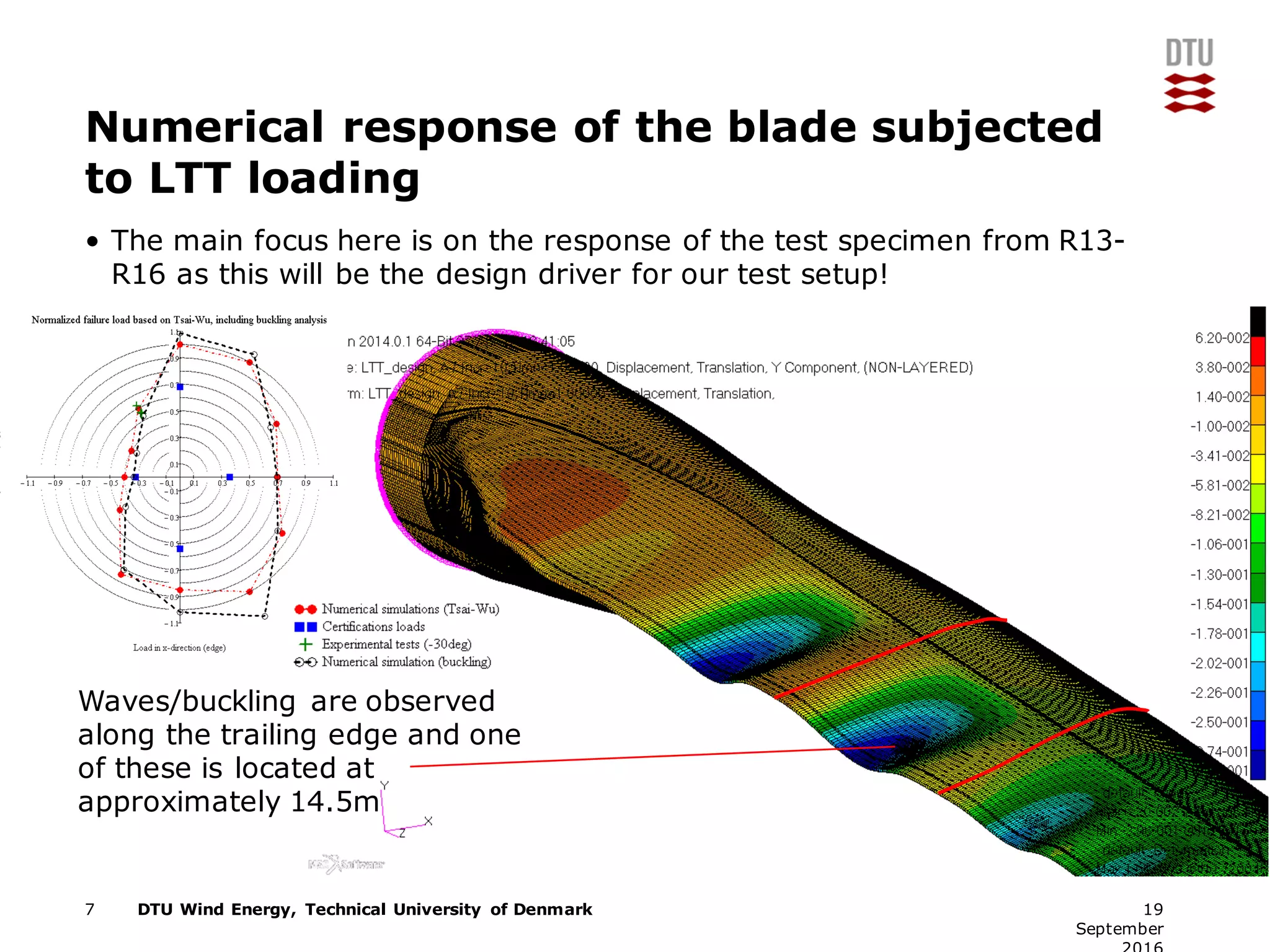

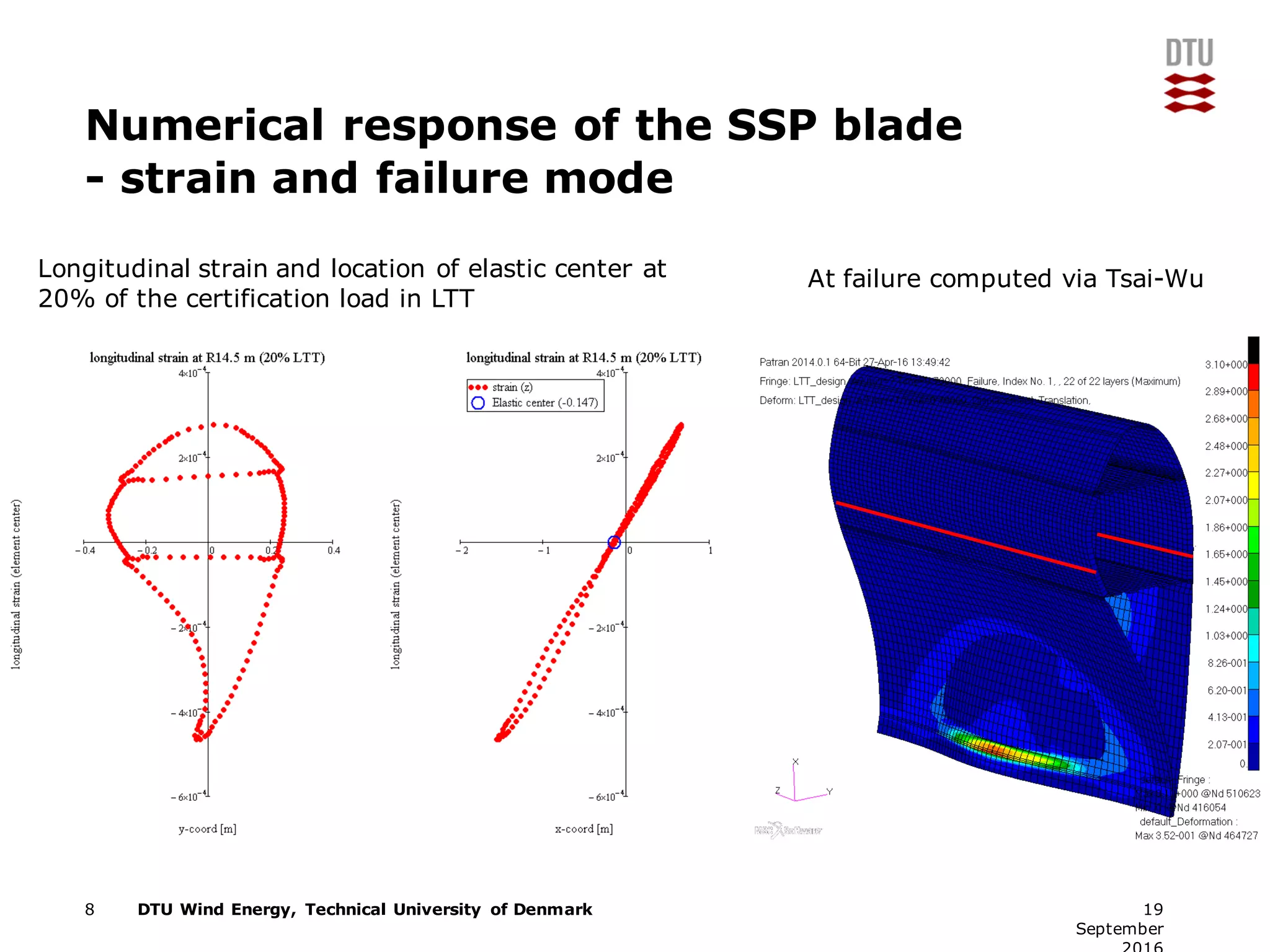

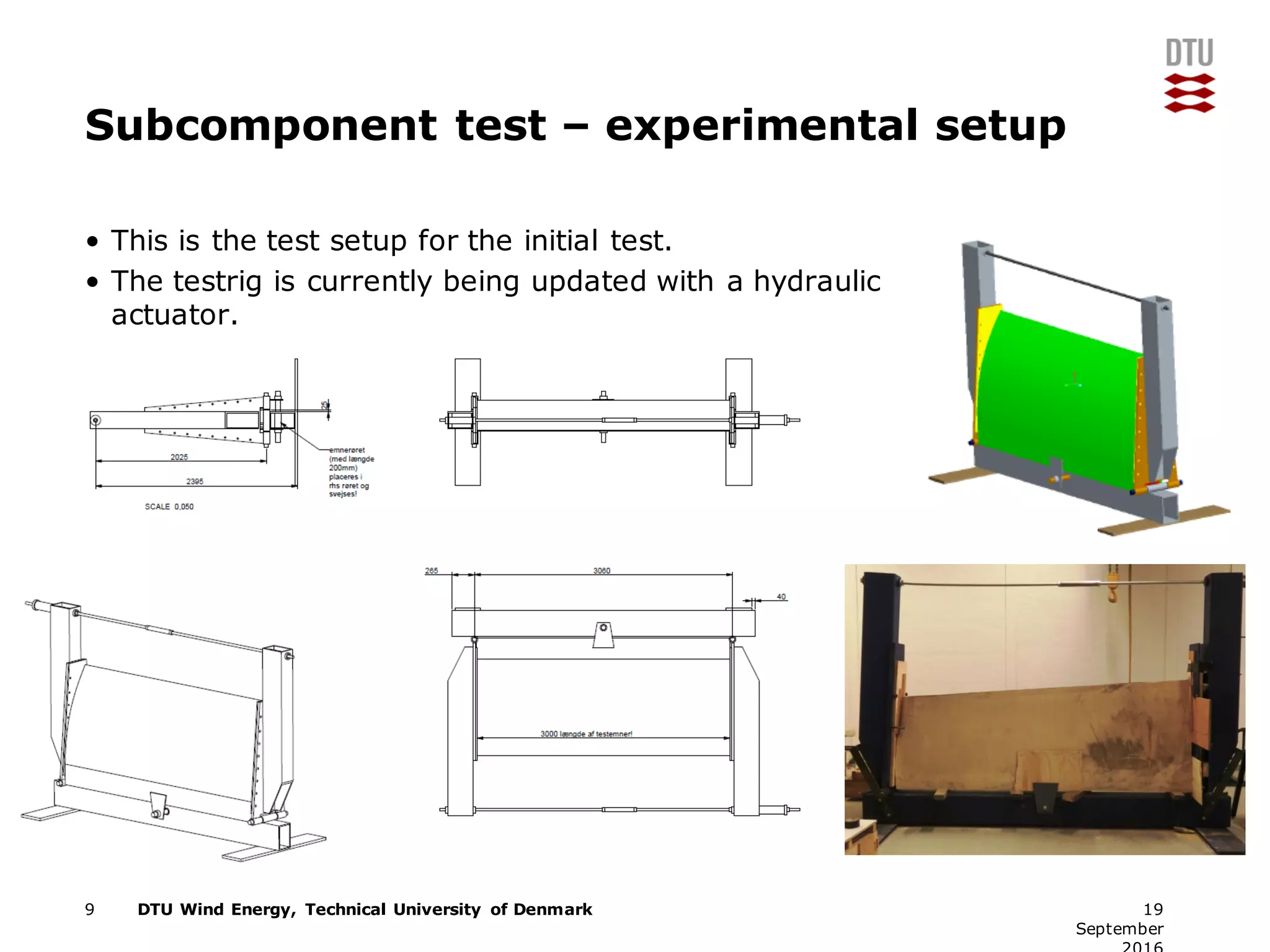

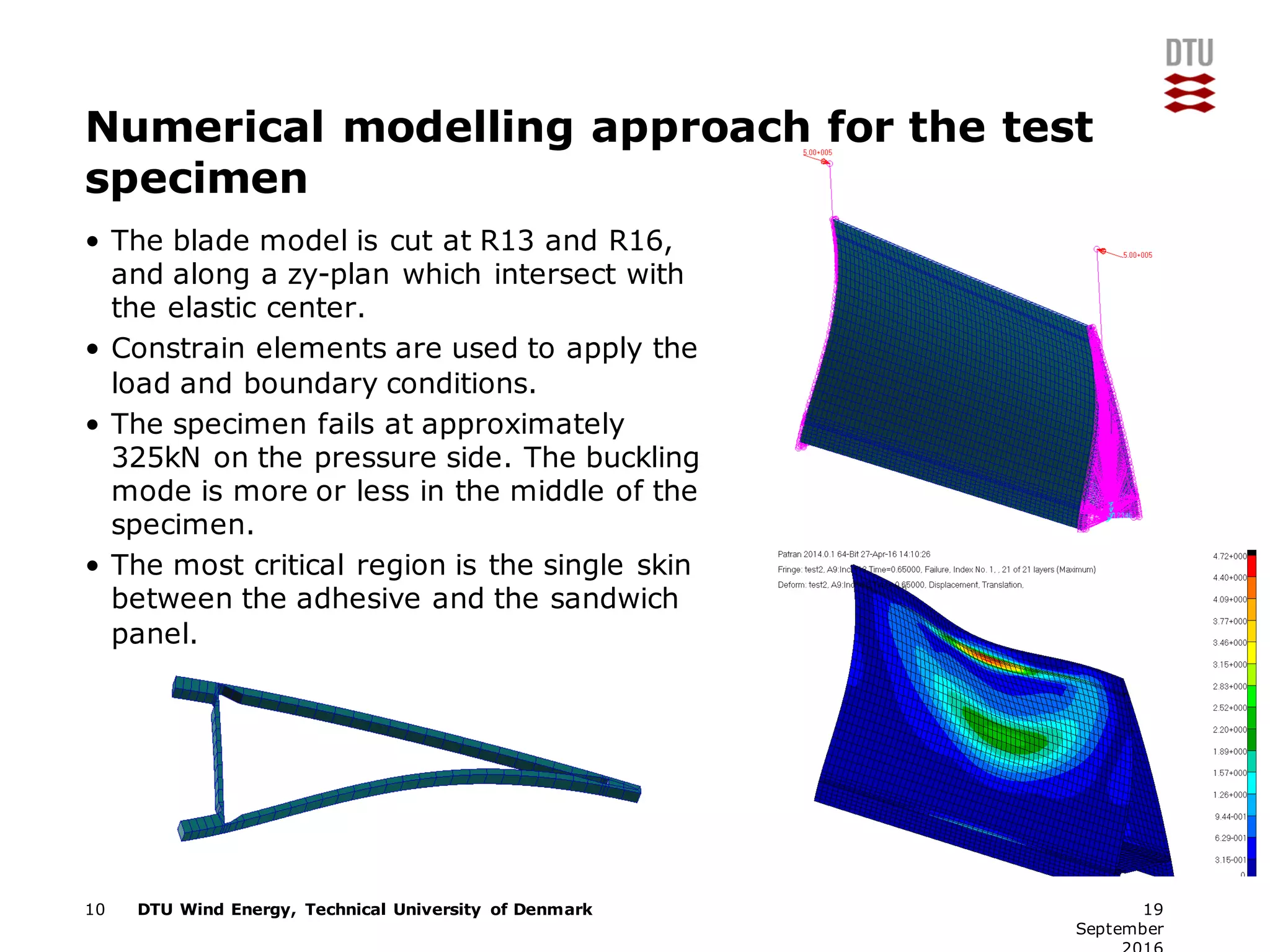

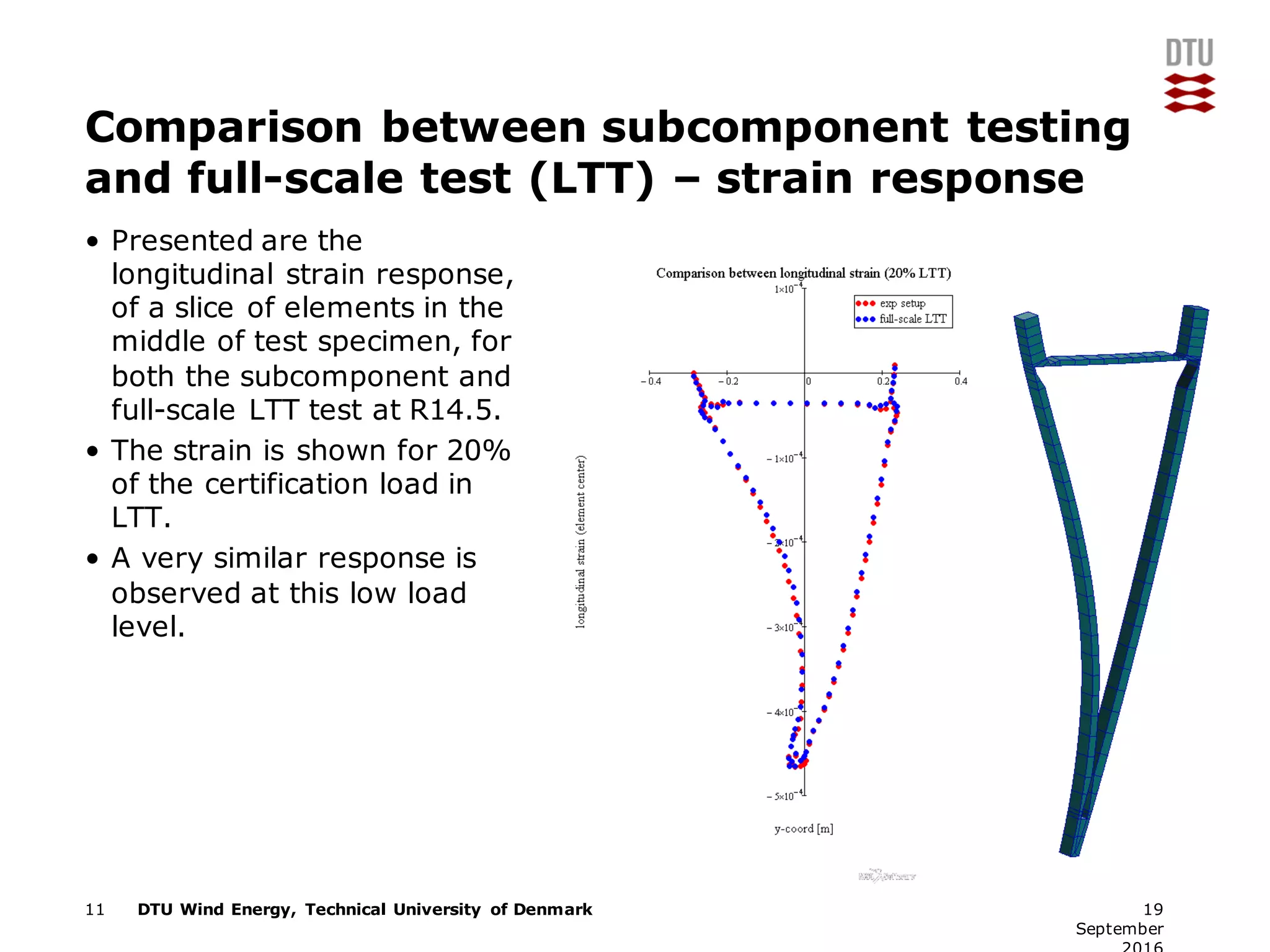

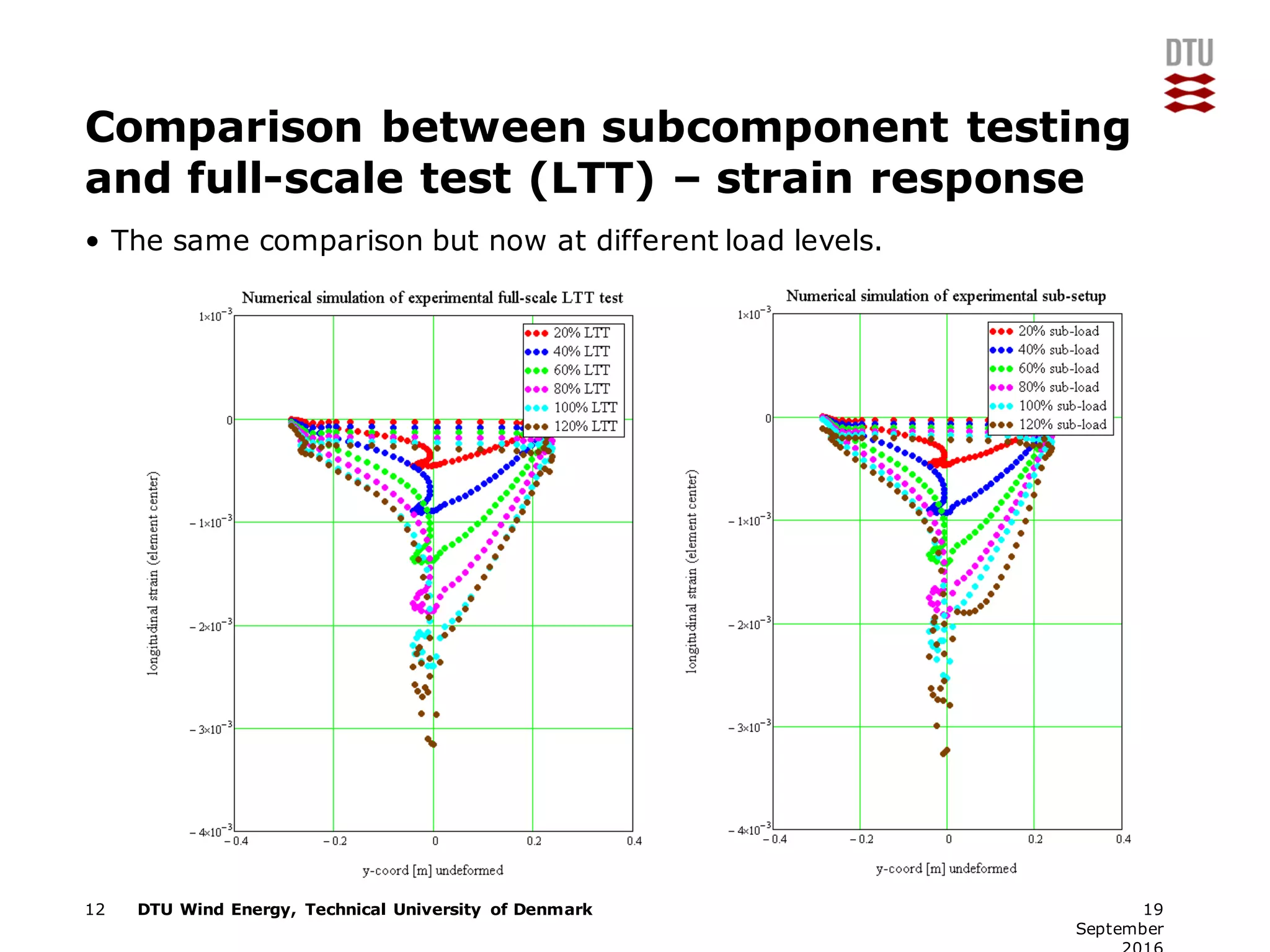

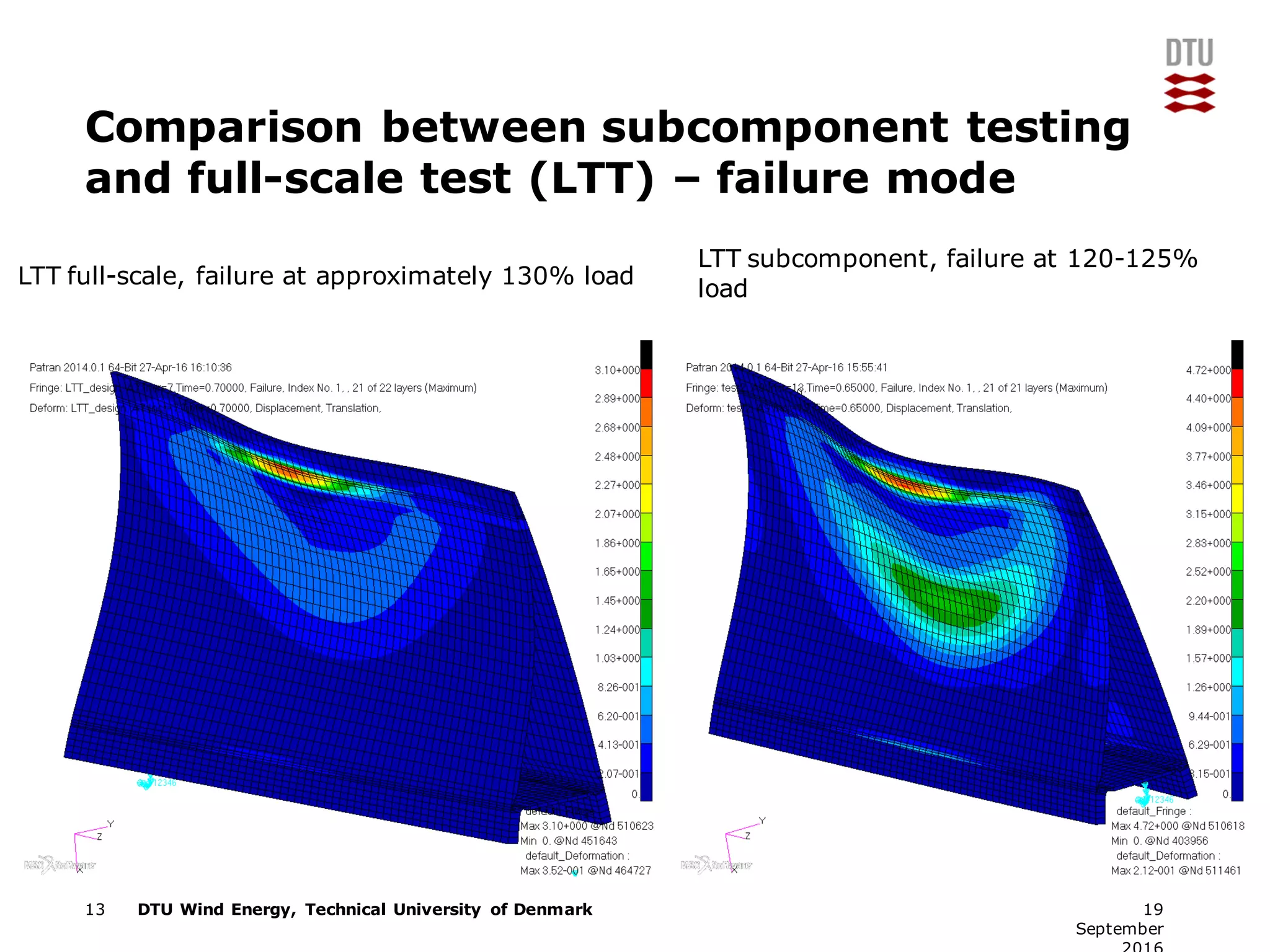

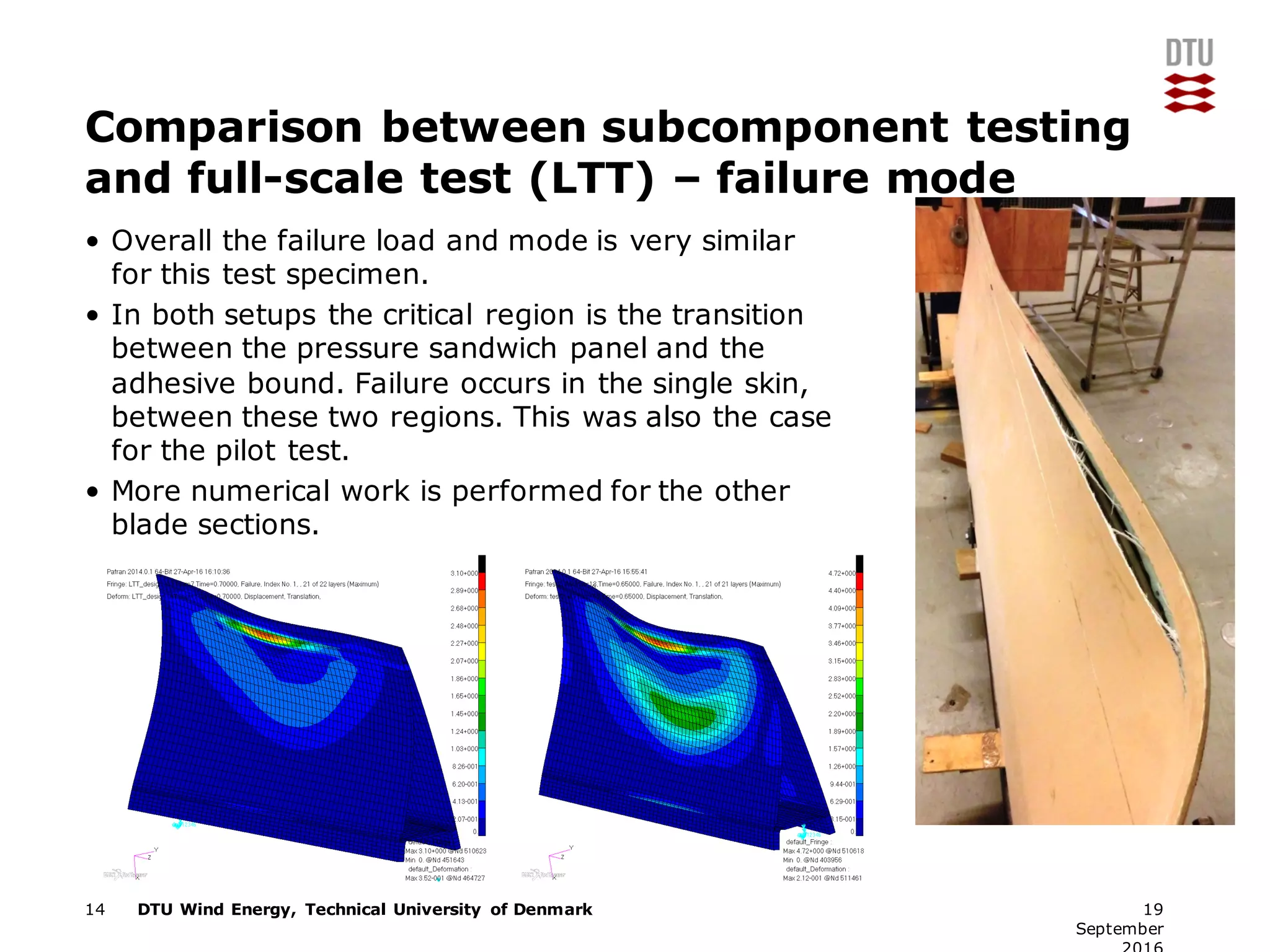

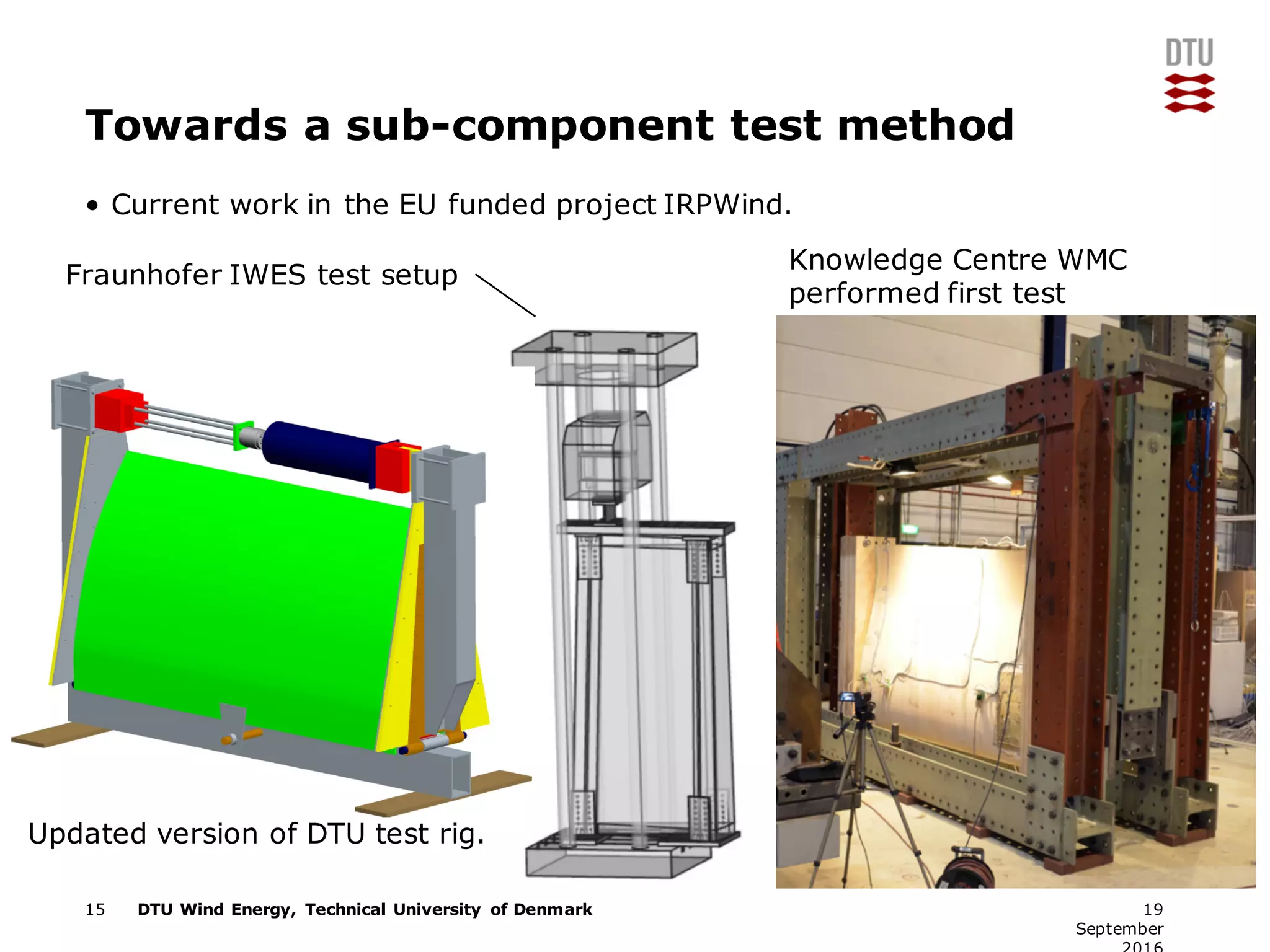

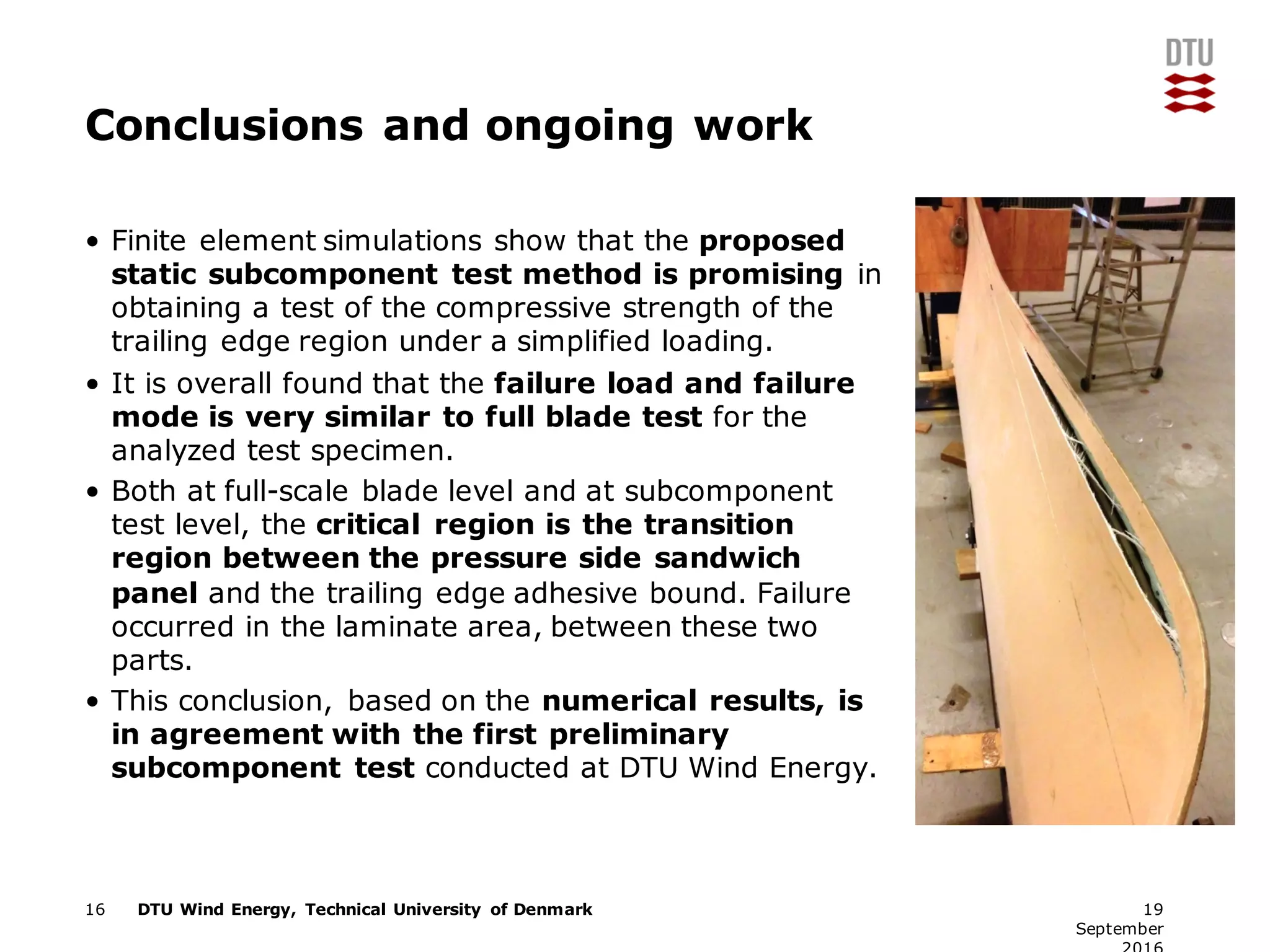

The document discusses developing a new subcomponent test method for the trailing edge region of wind turbine blades. Current blade certification involves full-scale blade testing, but a new standard allows for subcomponent testing. Finite element simulations show that a proposed static subcomponent test produces failure loads and modes similar to full-scale tests for the trailing edge region. Both testing methods show critical failure in the transition between the pressure-side sandwich panel and trailing edge adhesive bond. The subcomponent test is being developed as an industry certification standard to supplement full-scale blade testing.