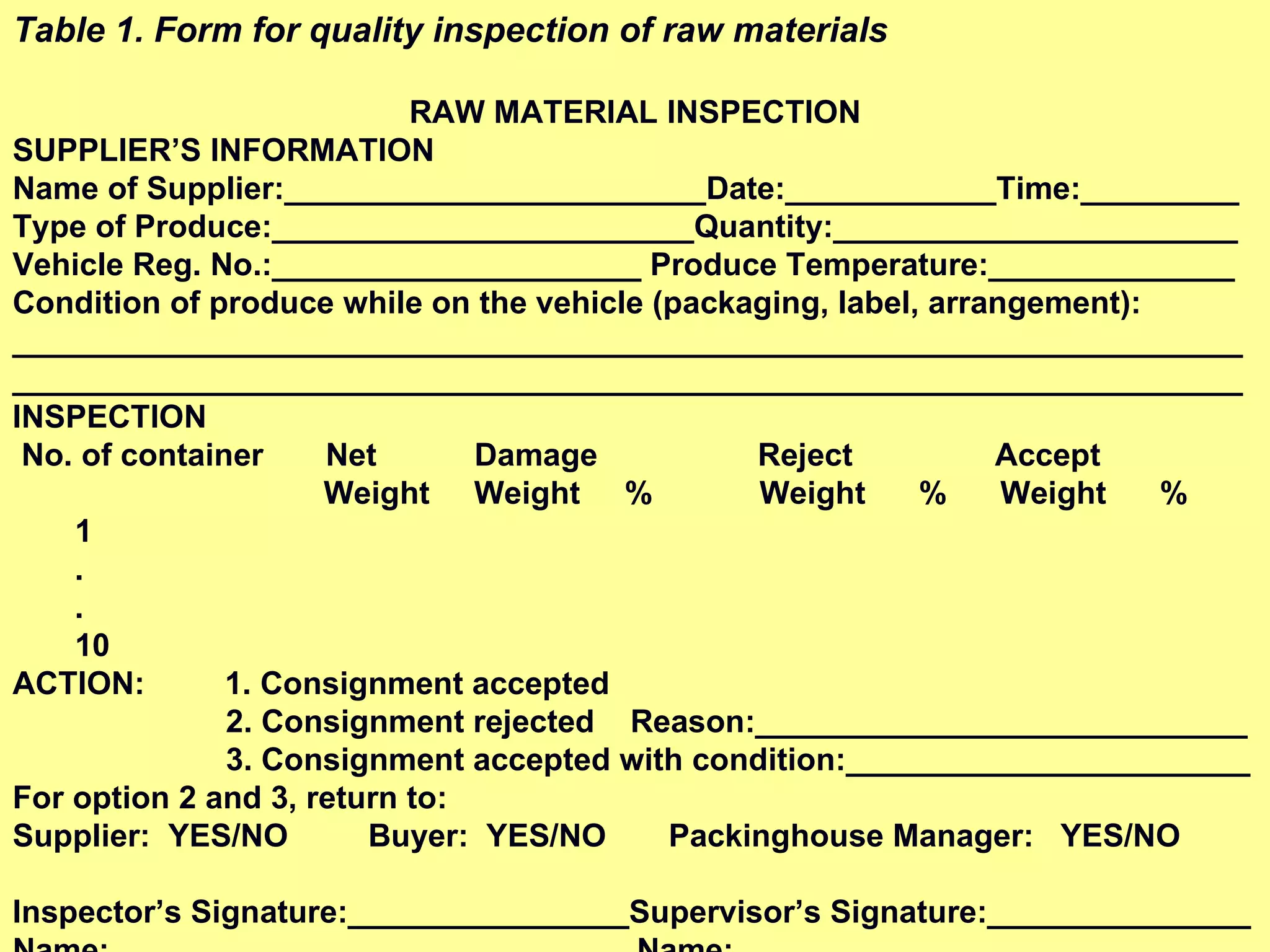

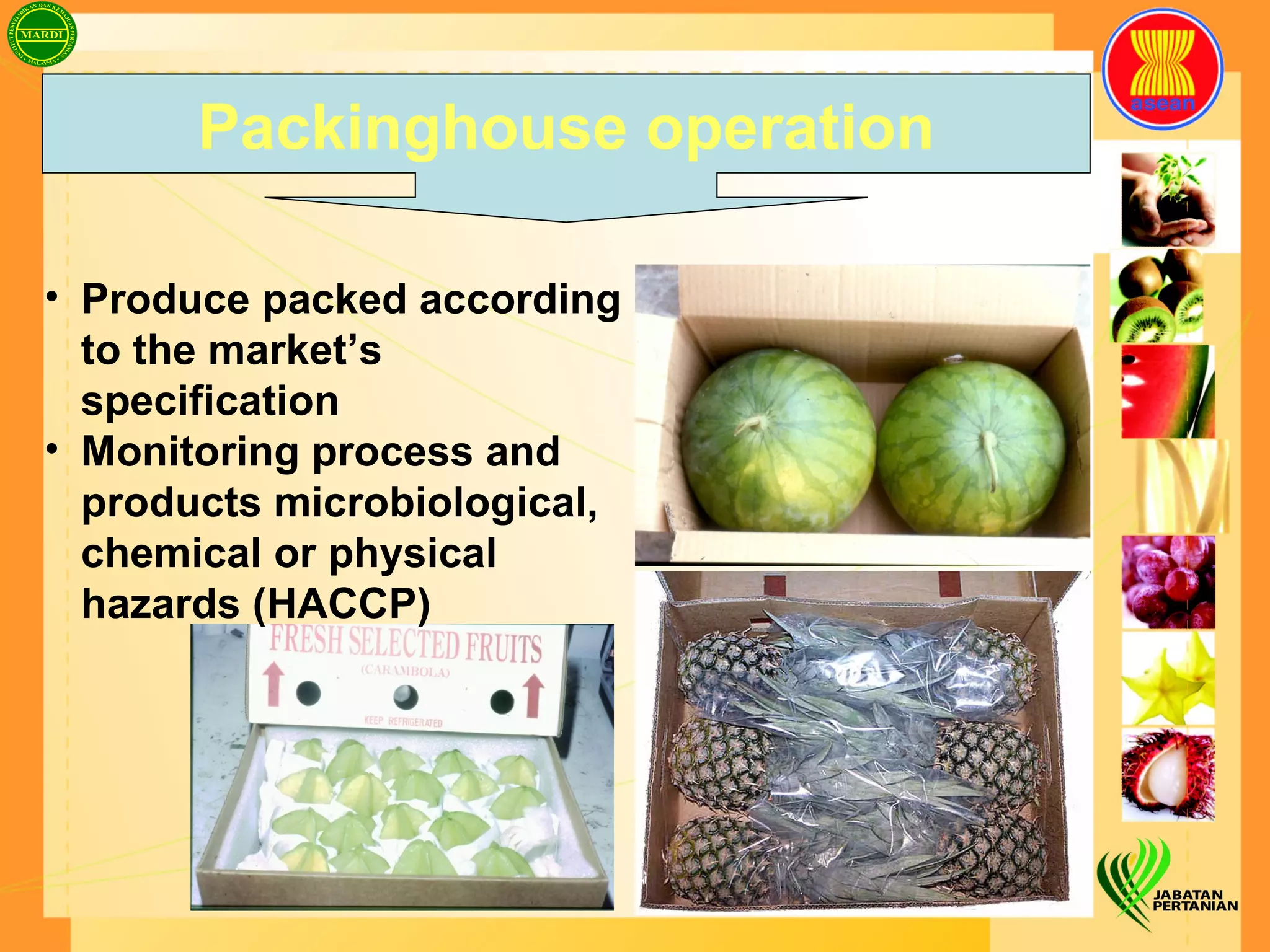

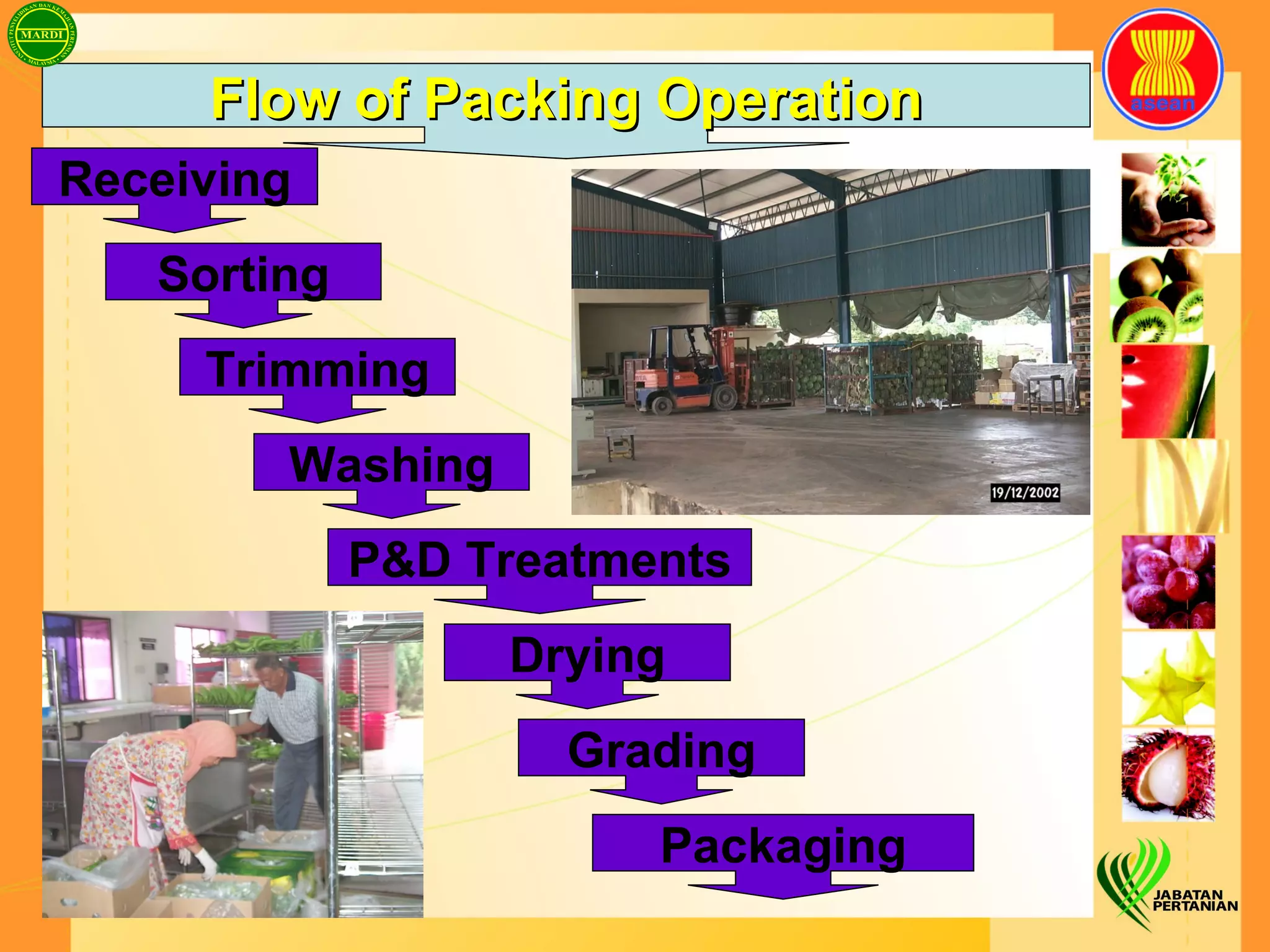

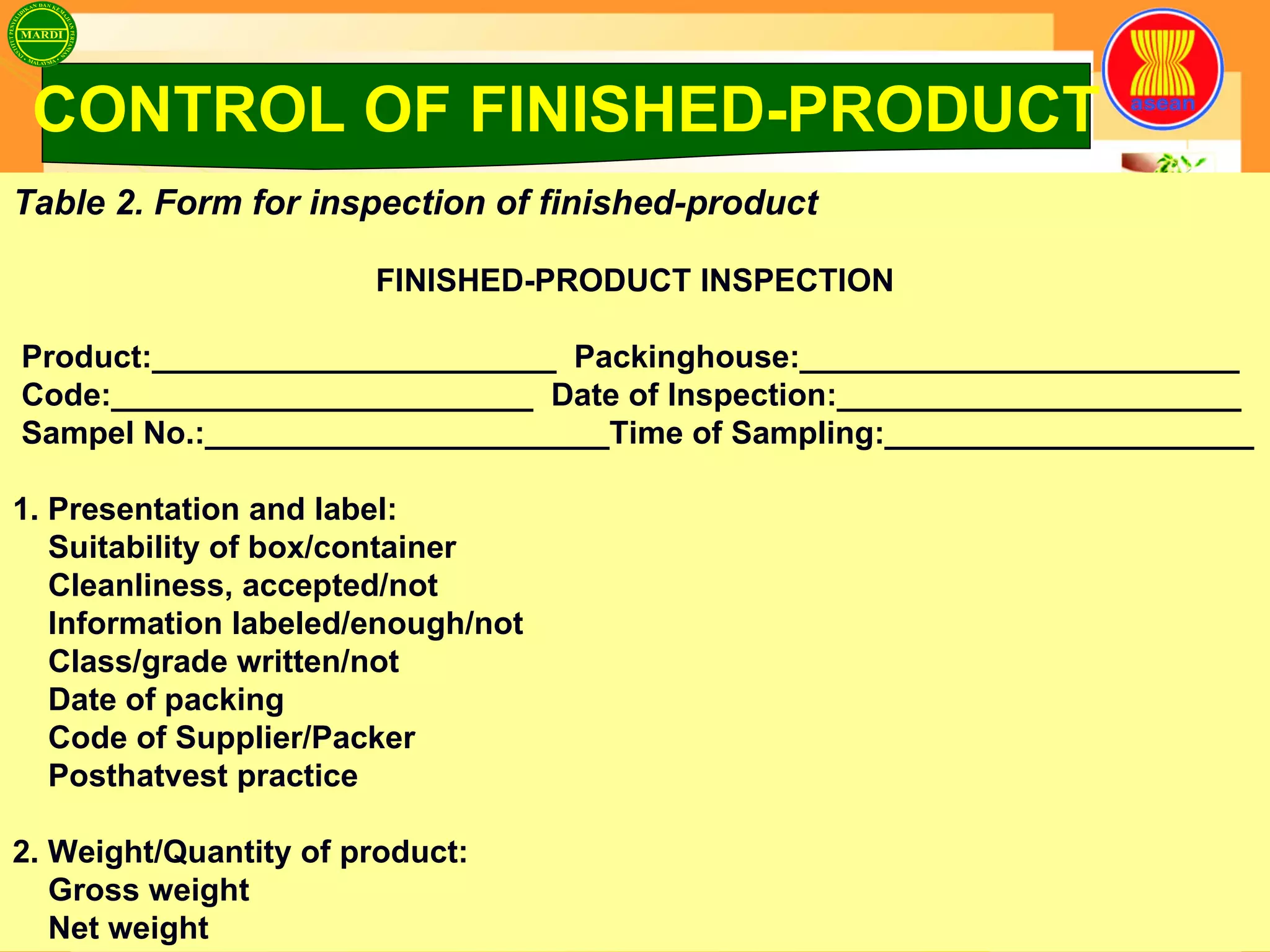

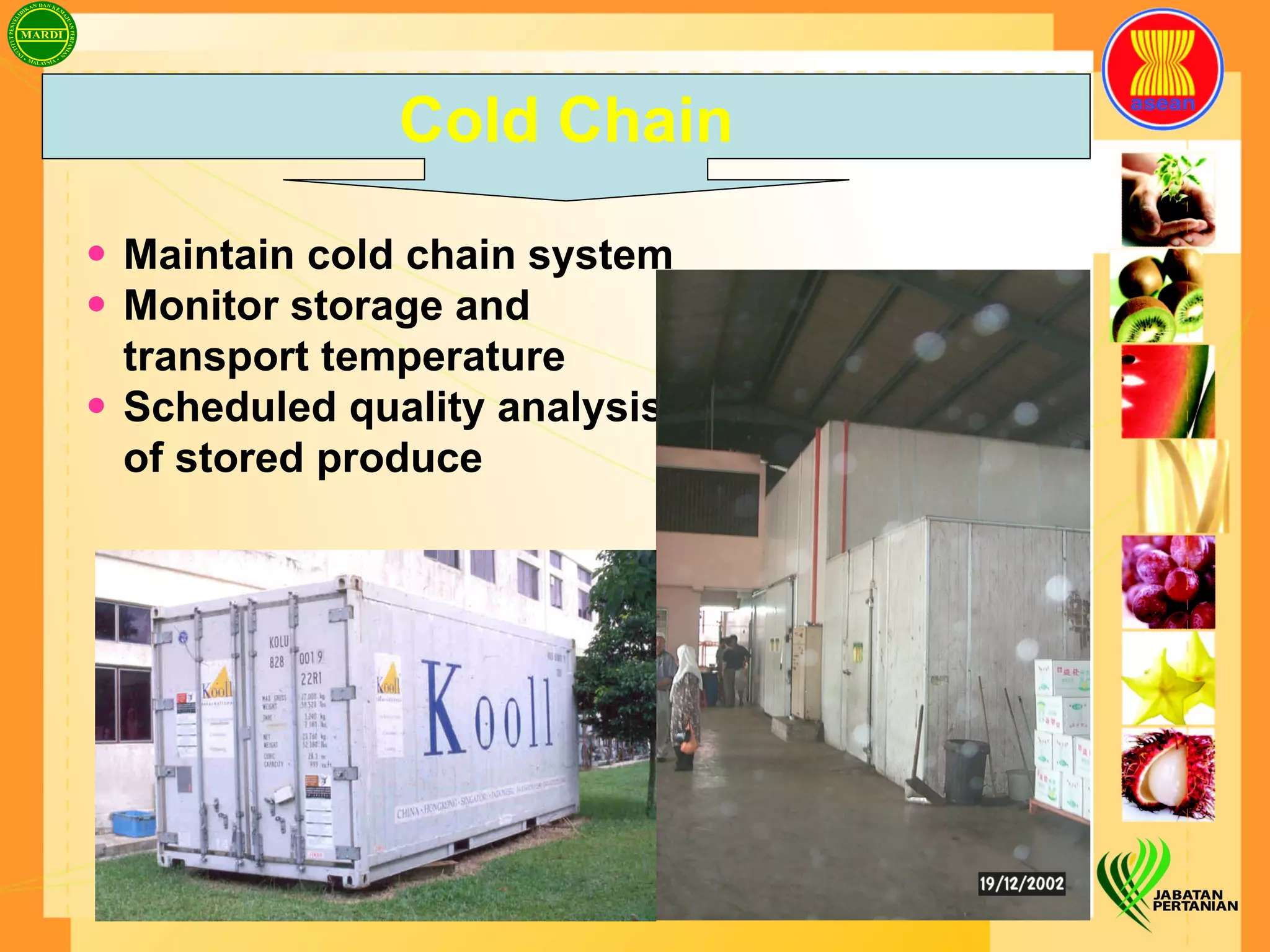

The document discusses Good Manufacturing Practices (GMP) for postharvest handling and minimal processing of fruits and vegetables. It outlines the key components of GMP, including control of the packinghouse, raw materials, operations, finished products, and traceability. Proper implementation of GMP helps ensure product quality and safety is maintained throughout postharvest handling and processing.