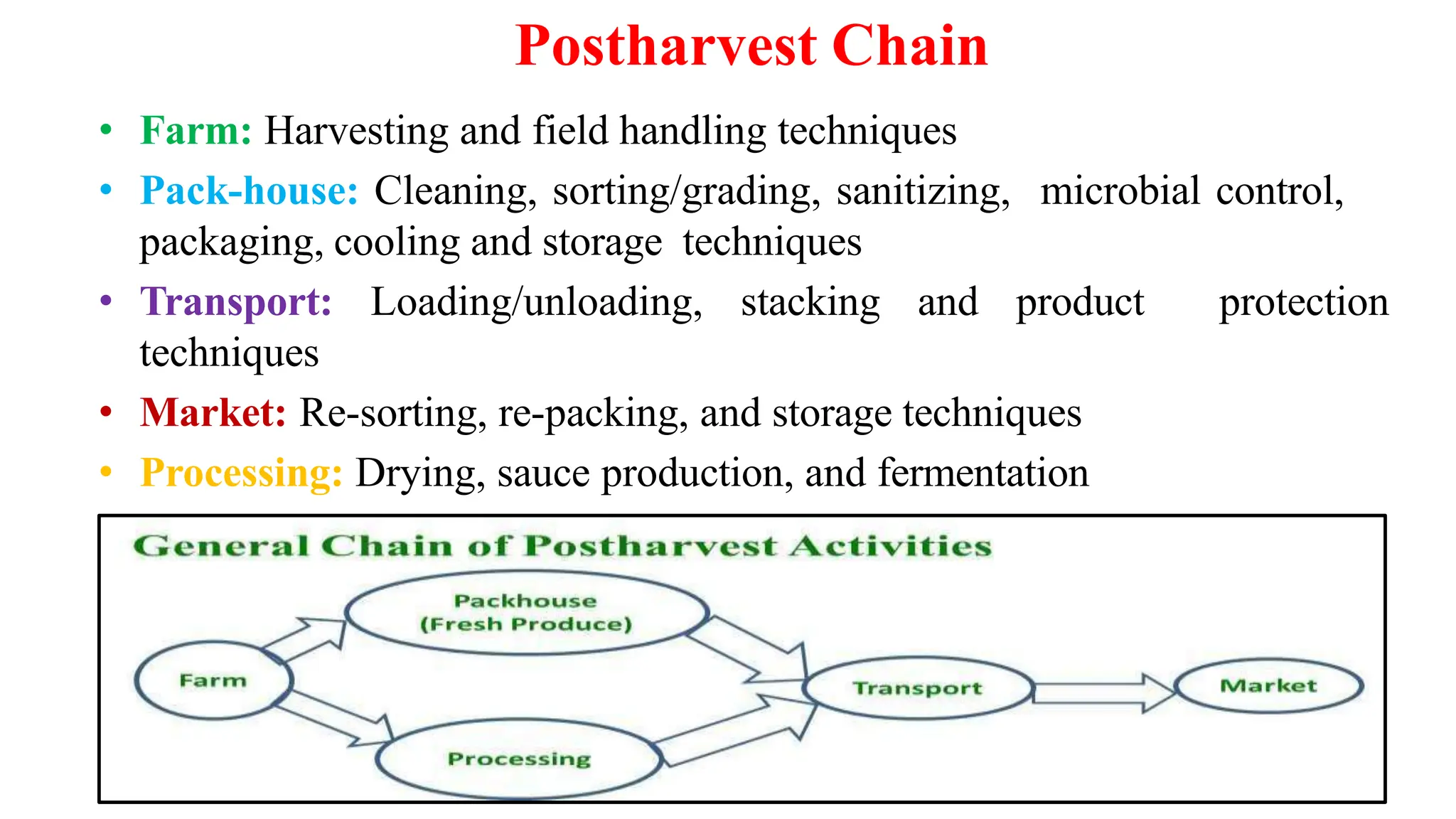

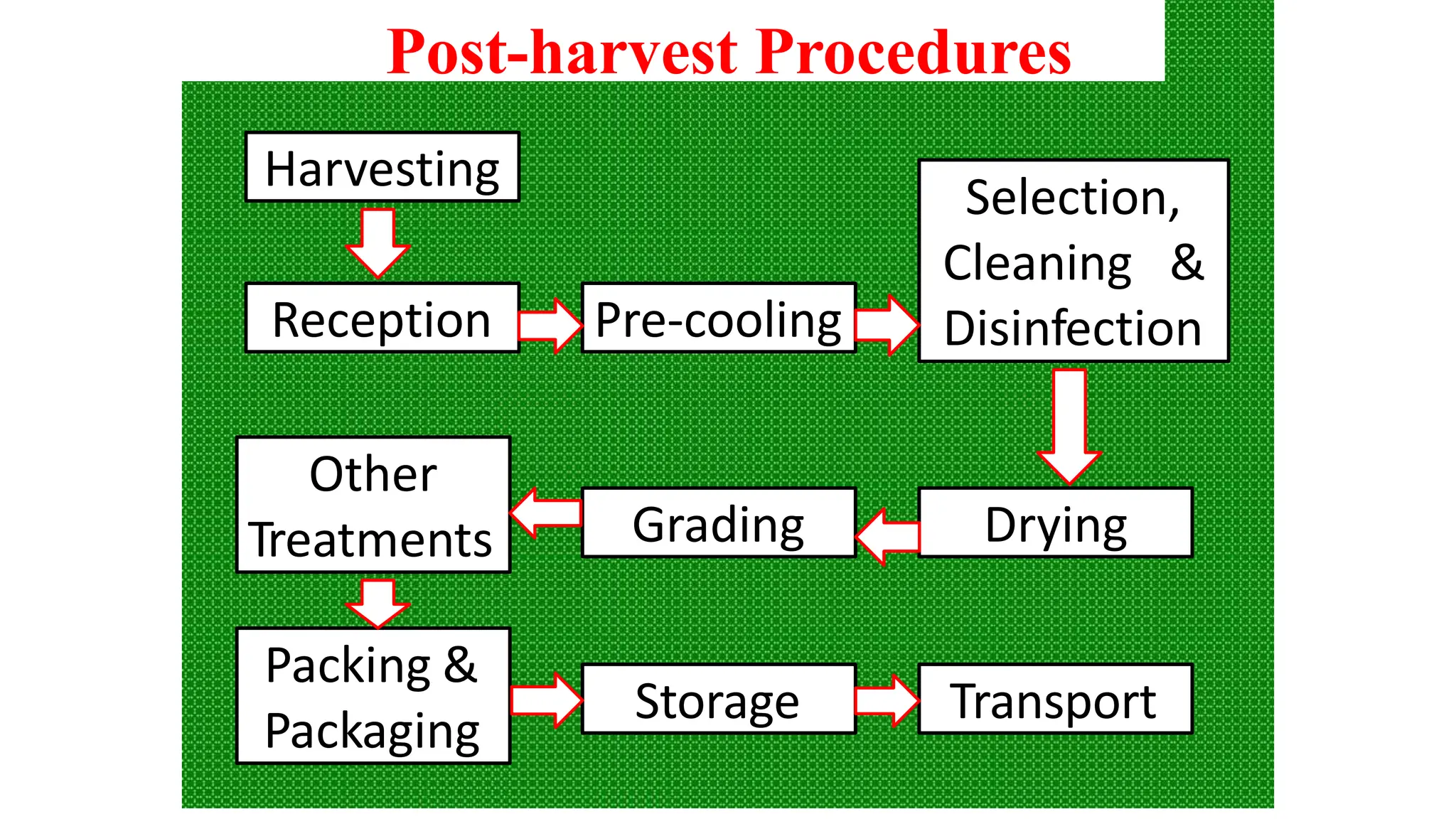

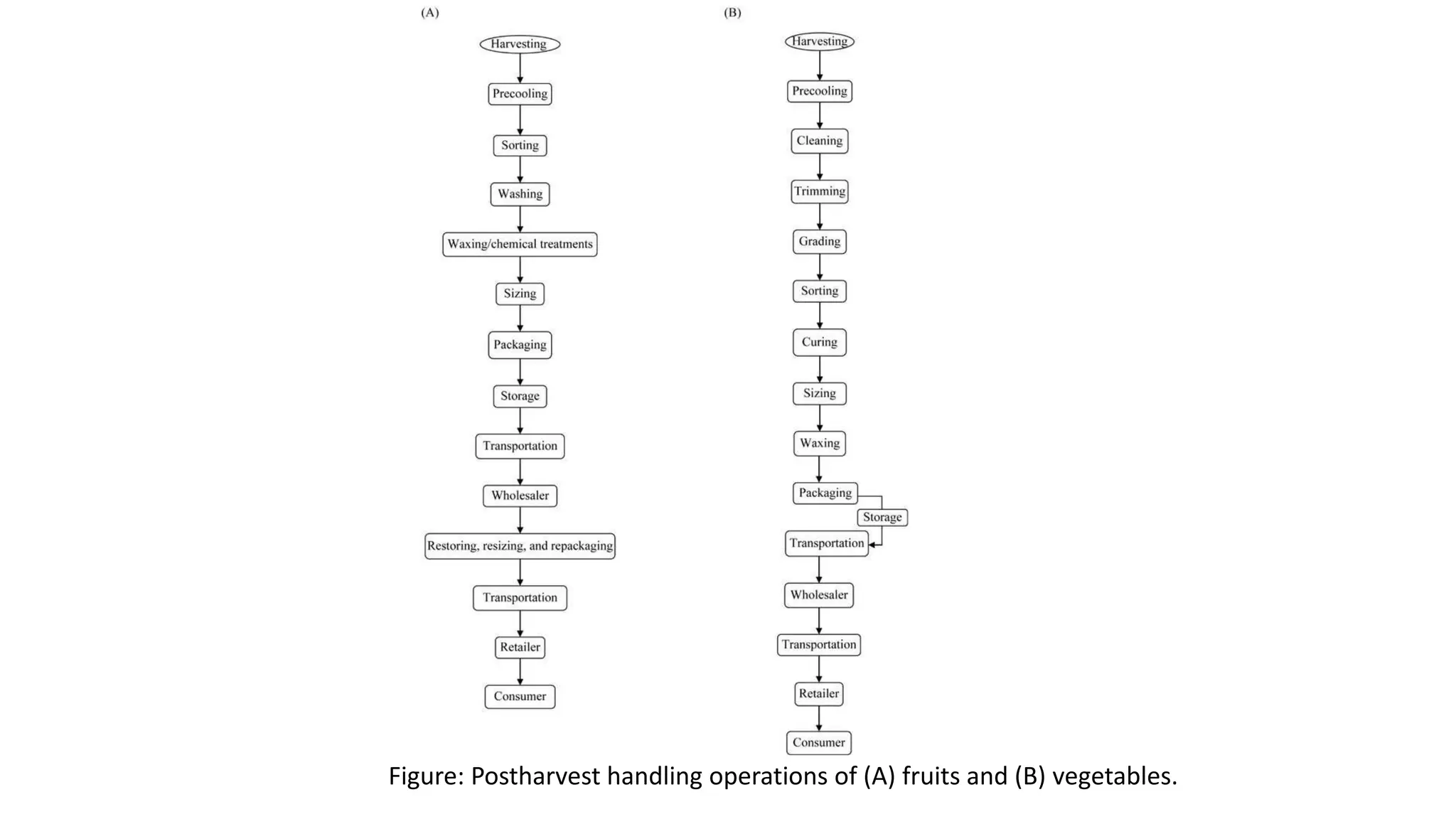

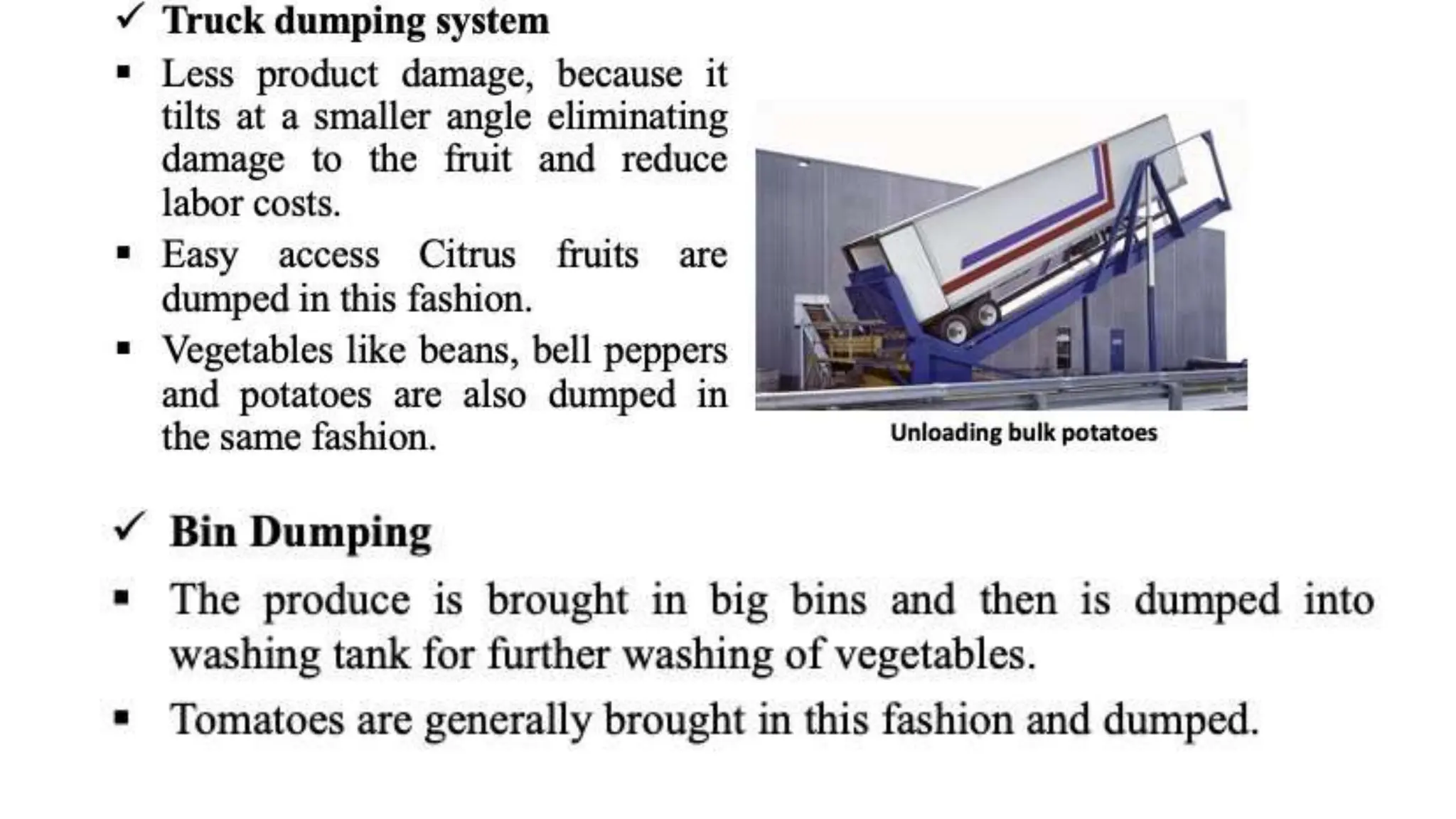

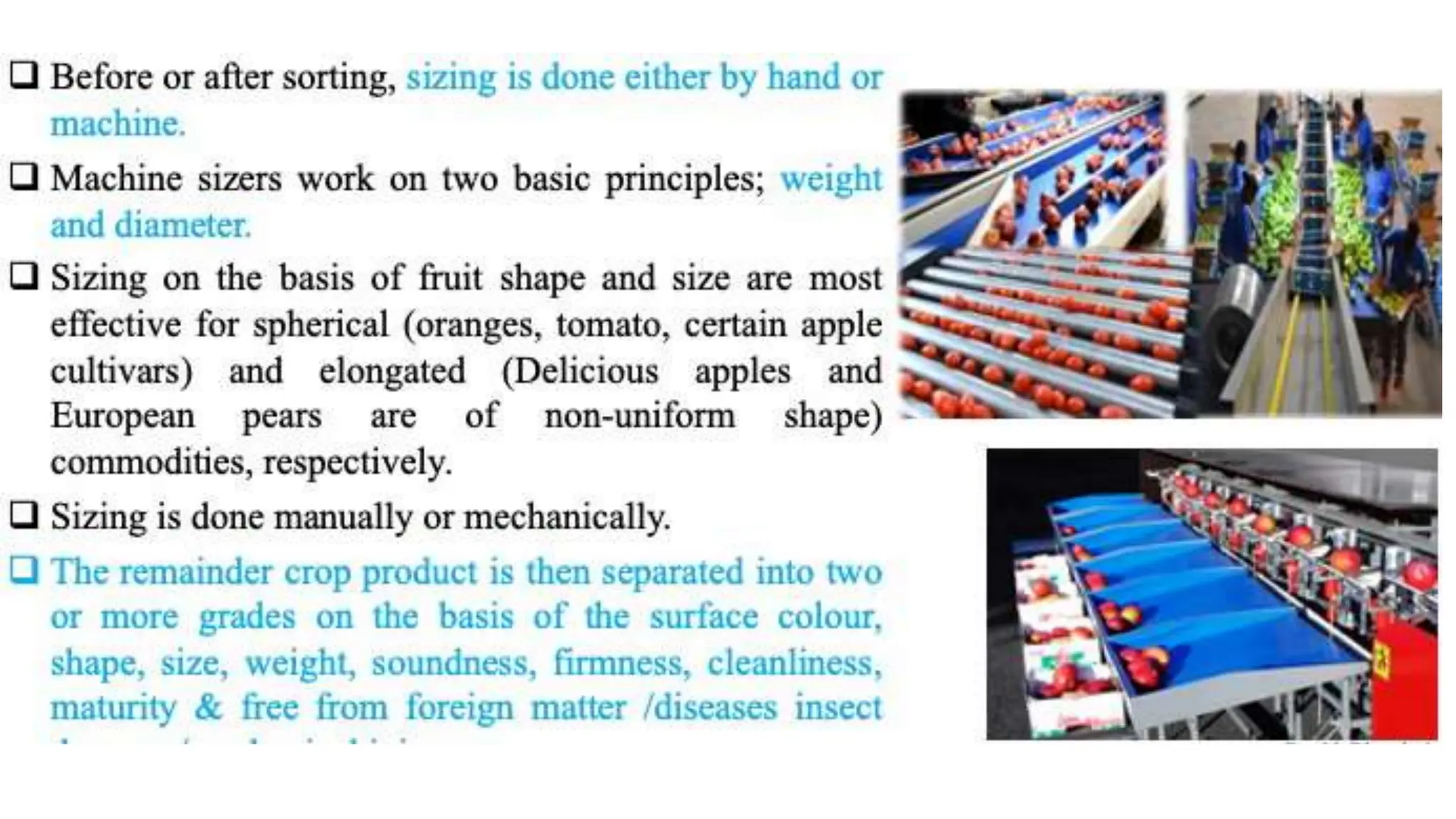

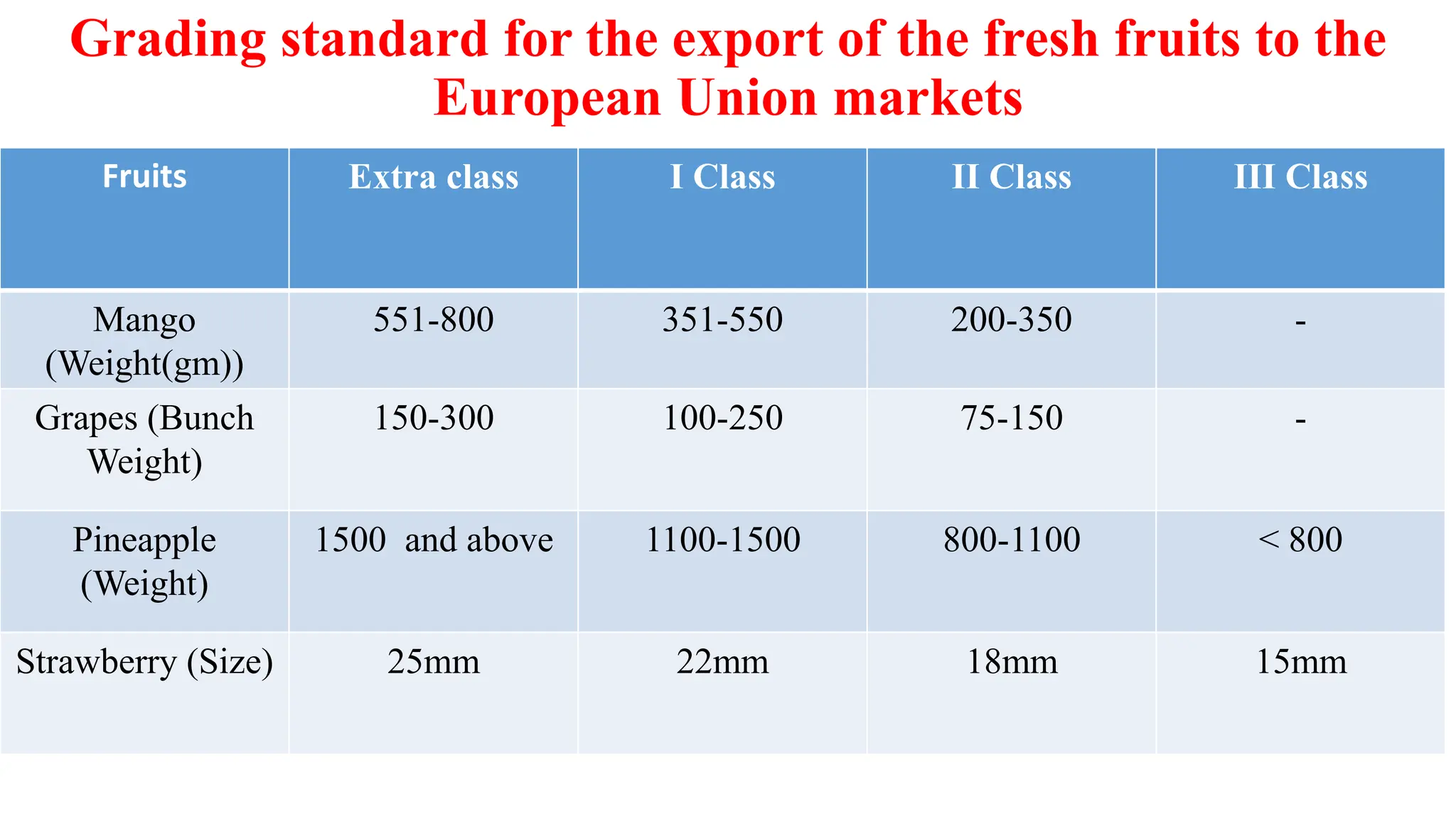

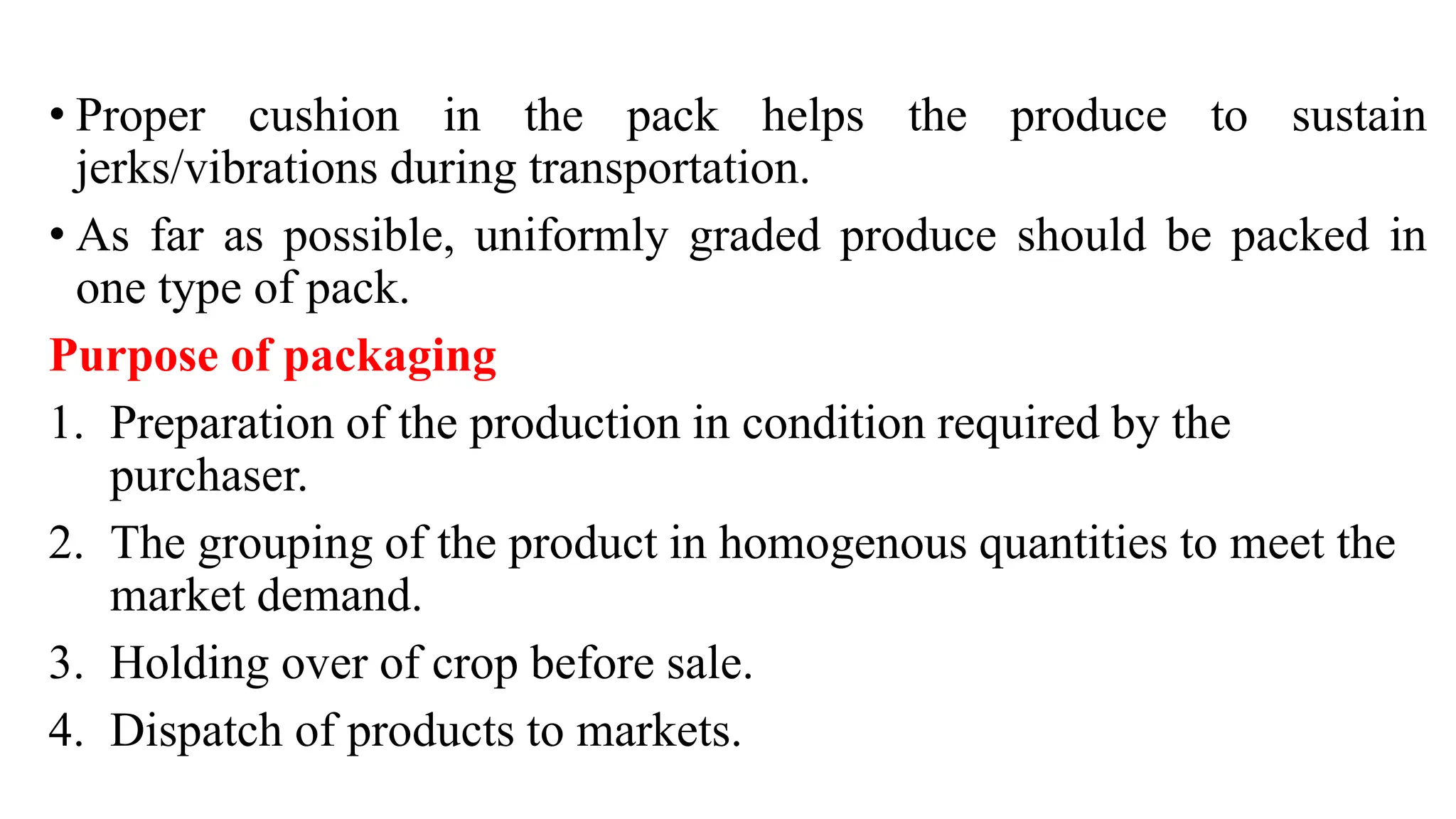

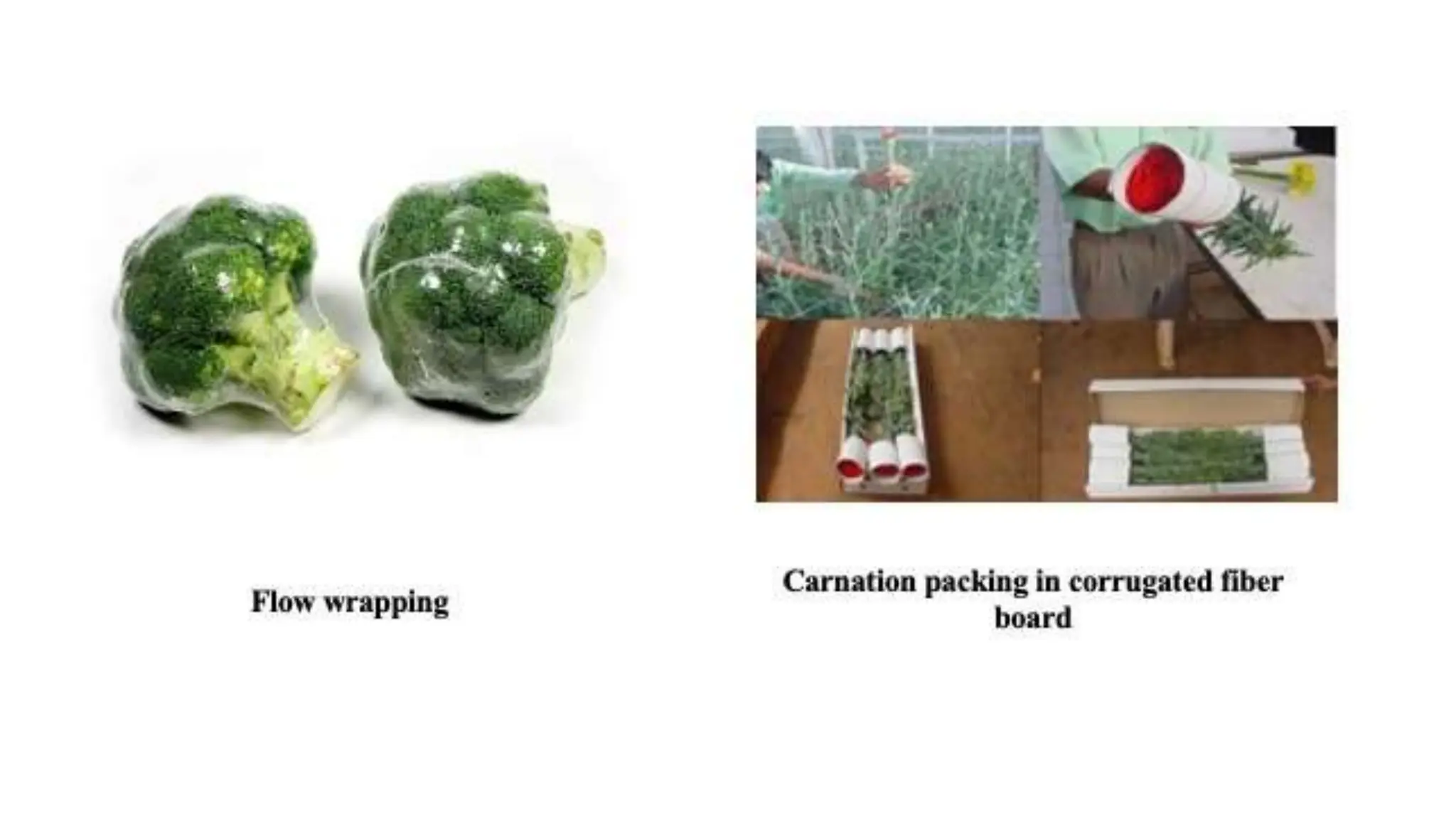

The document outlines postharvest handling processes for fruits and vegetables, detailing steps such as harvesting, cleaning, sorting, grading, packing, and storage. It emphasizes the importance of effective packing and packaging materials to protect produce, minimize damage, and meet market demands. Additionally, it describes various packaging options and practices used in countries like Bangladesh, Nepal, and Cambodia.