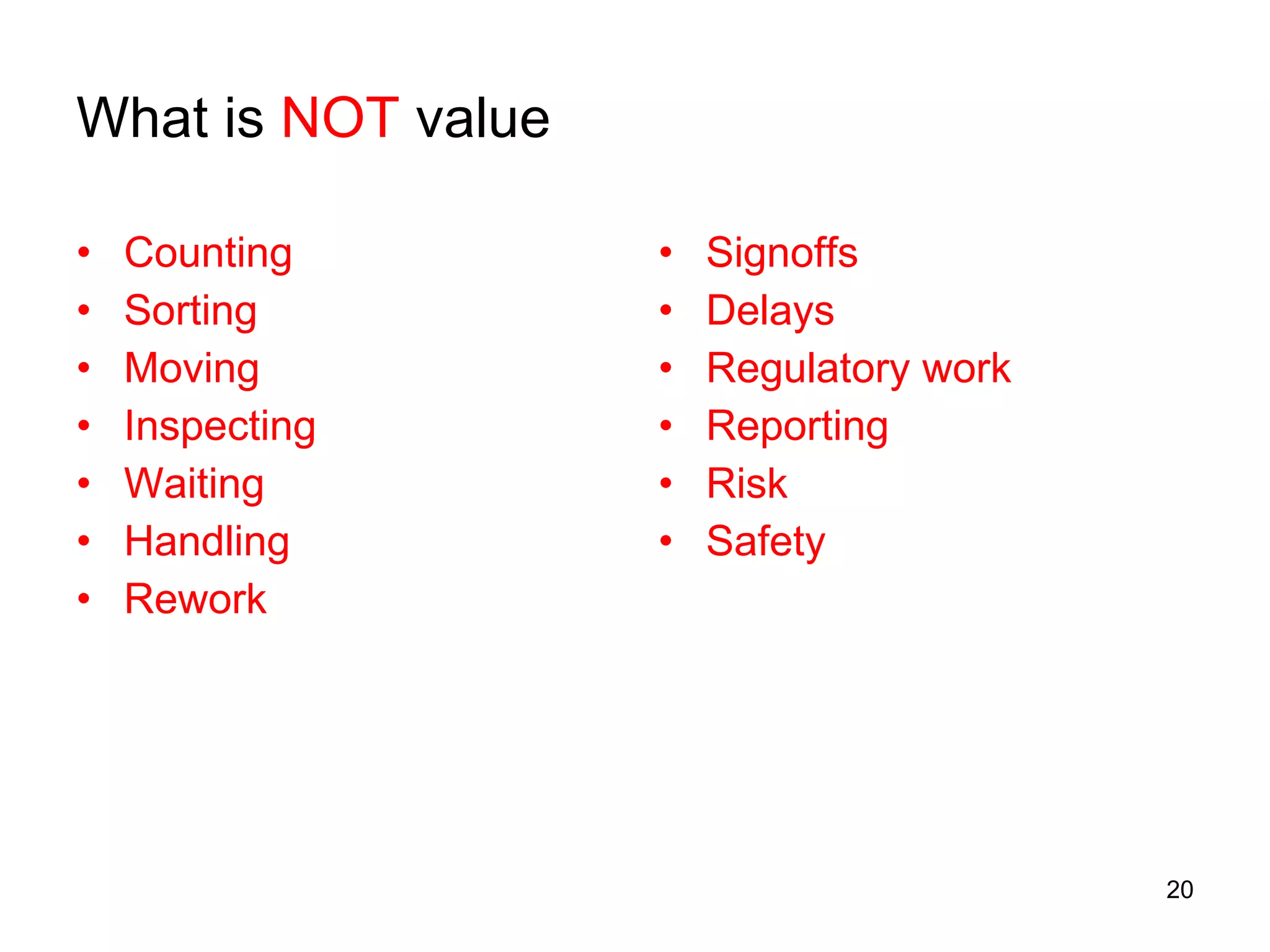

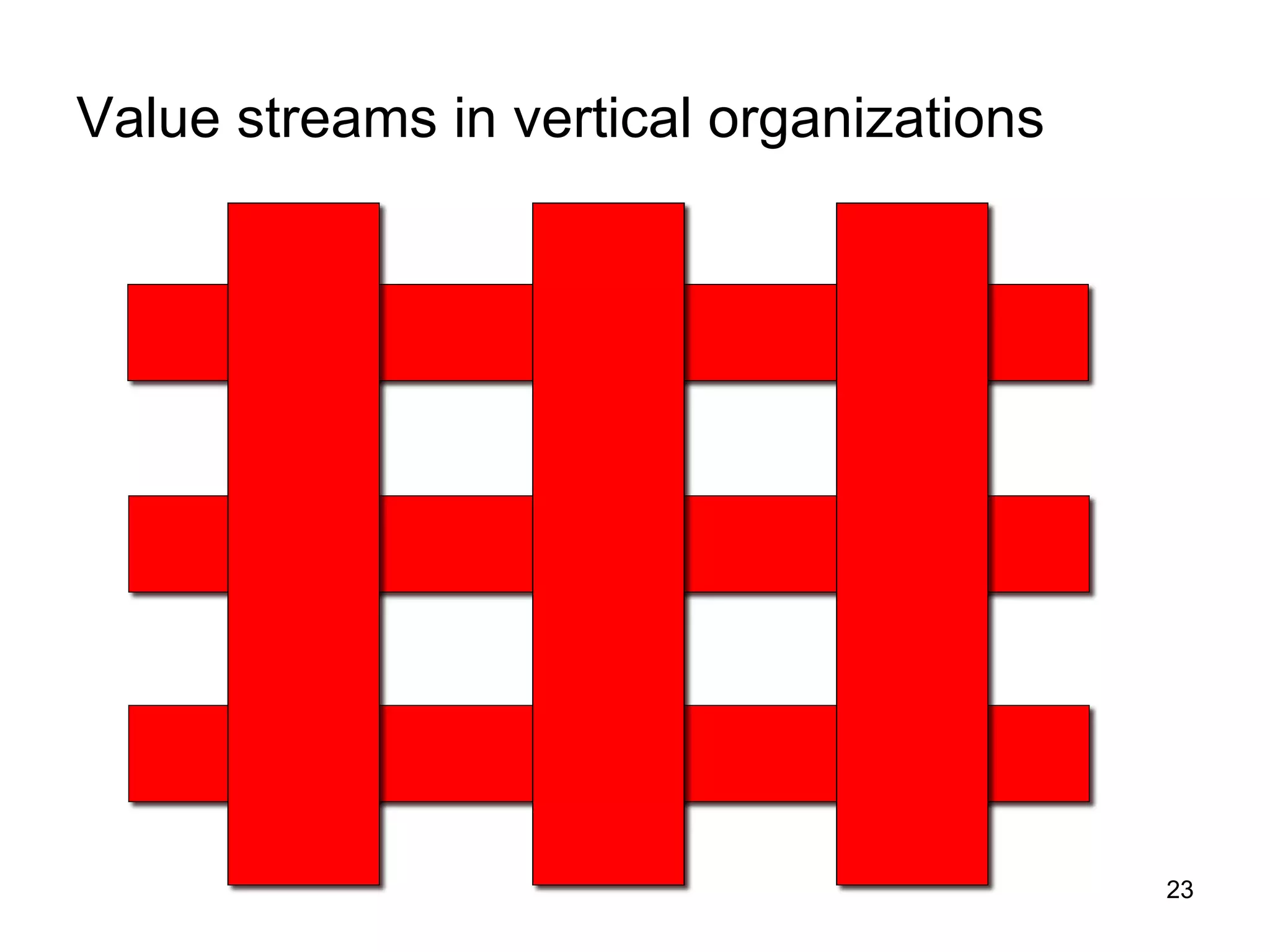

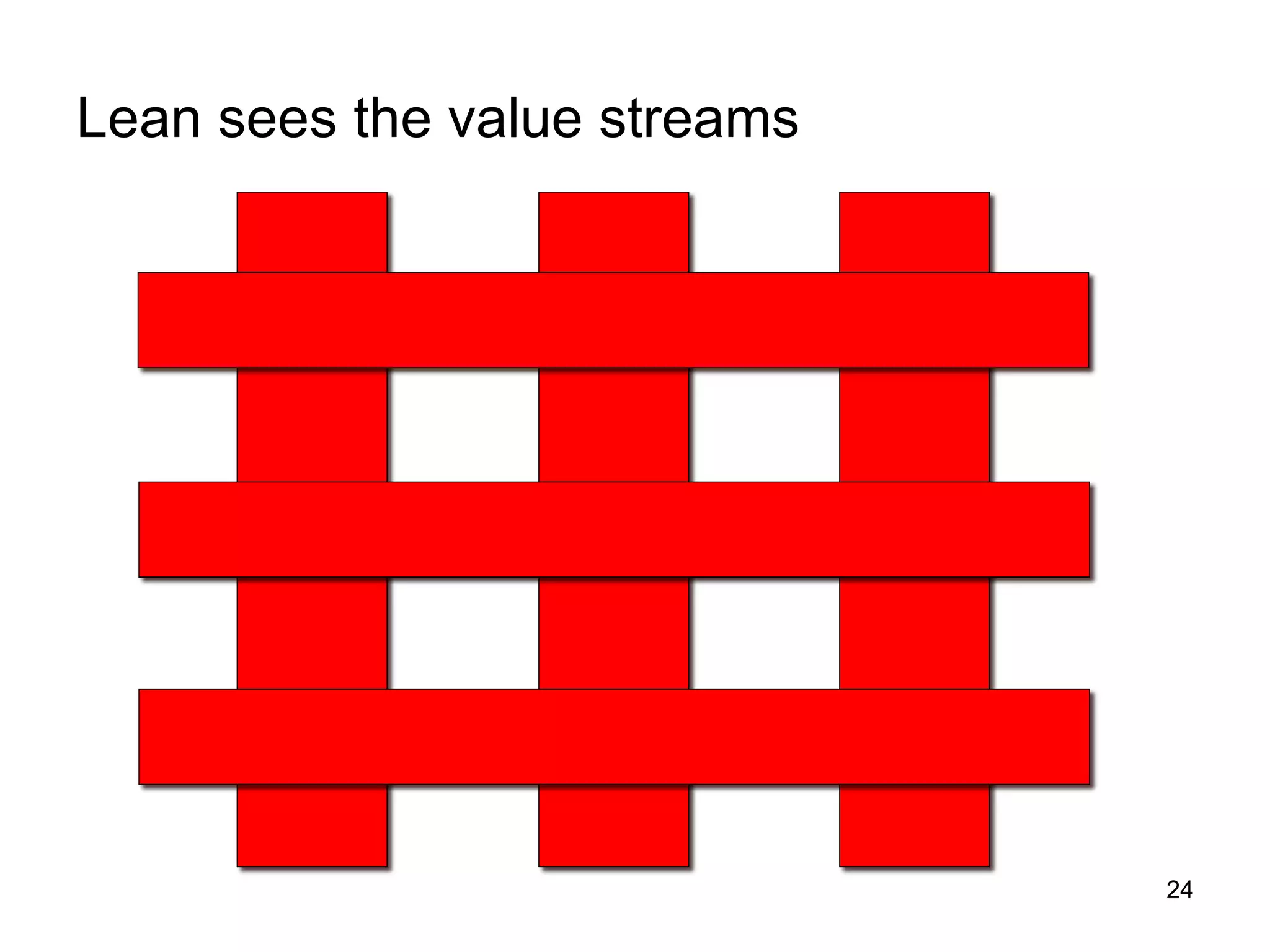

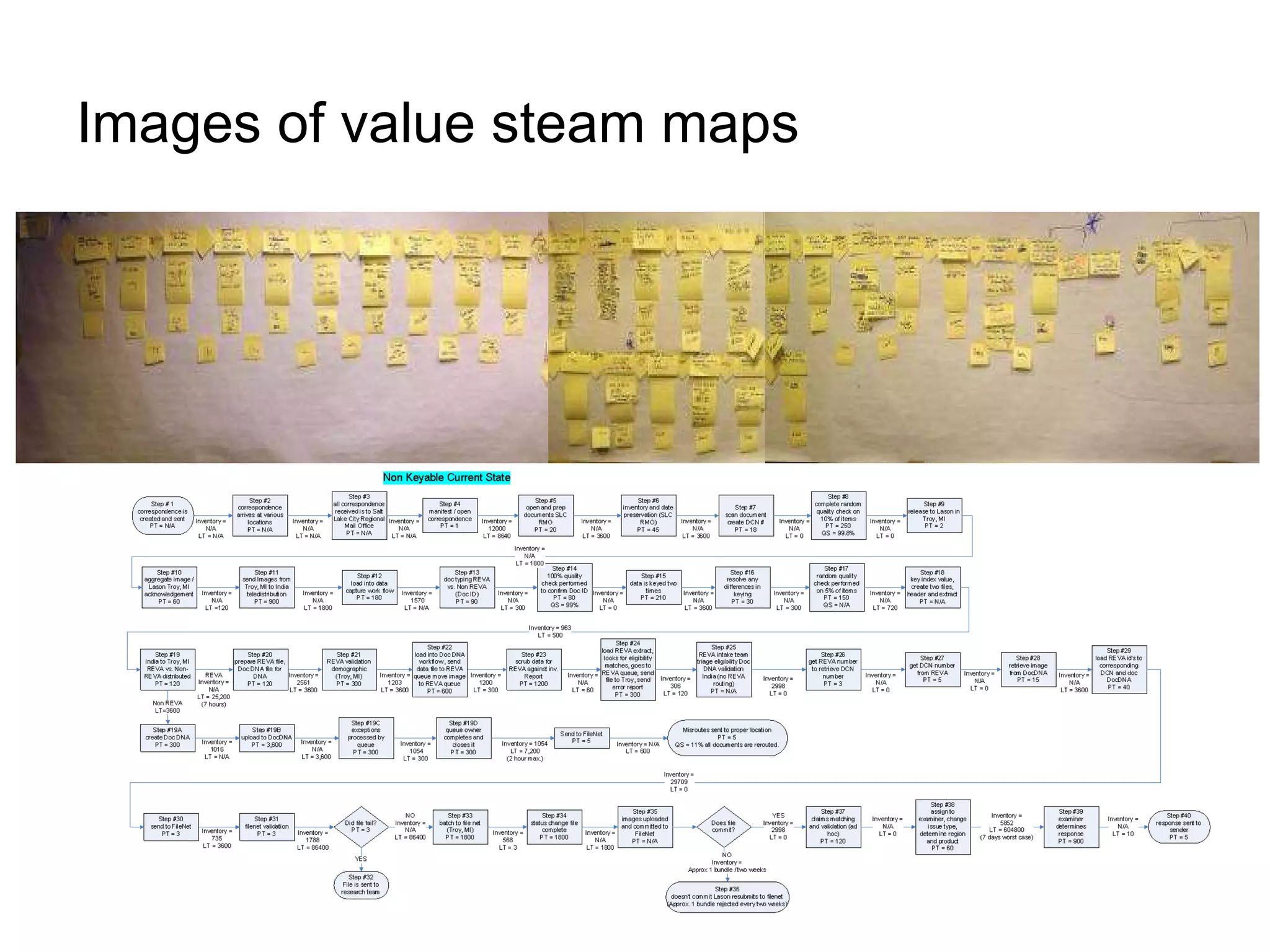

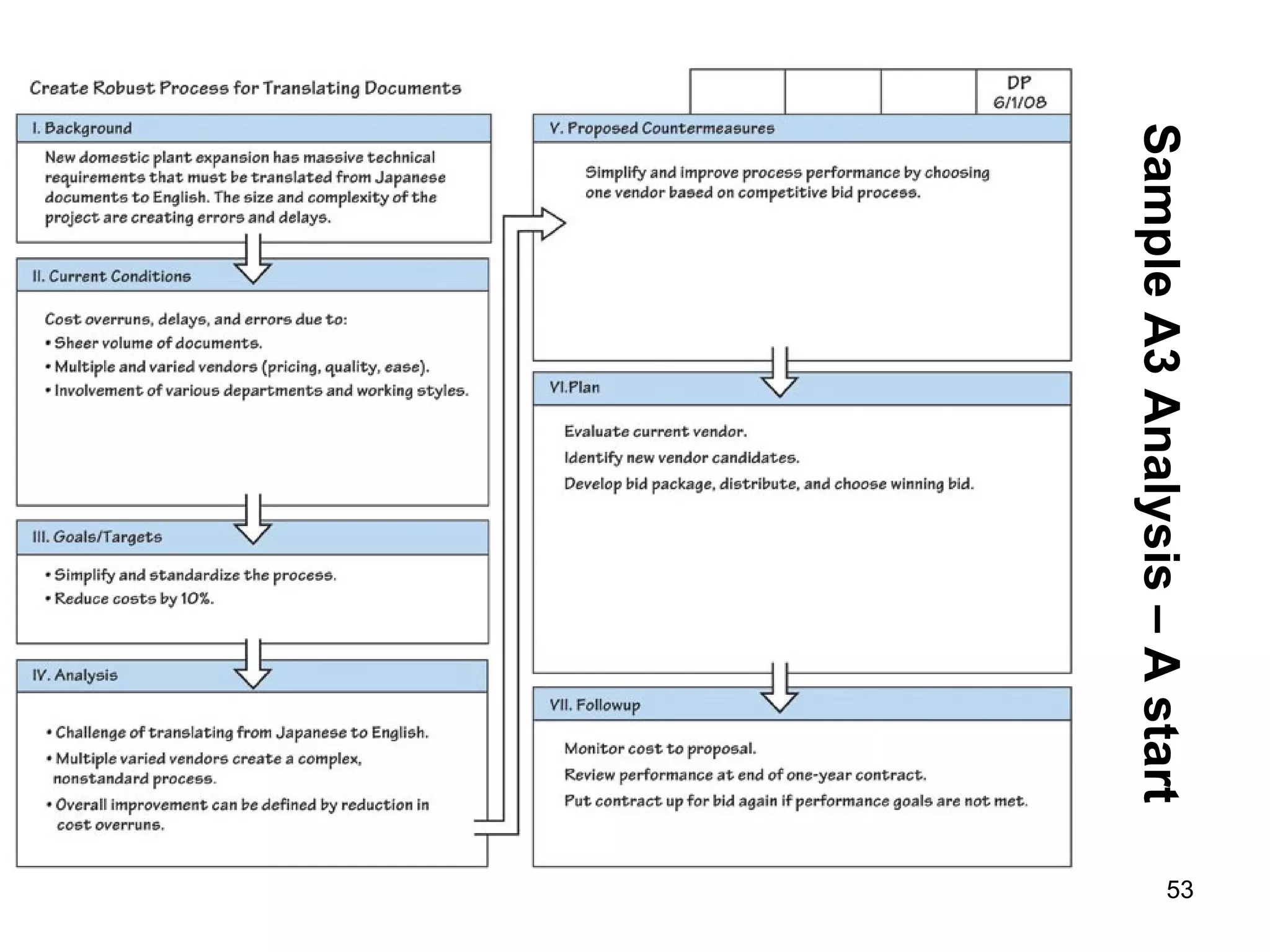

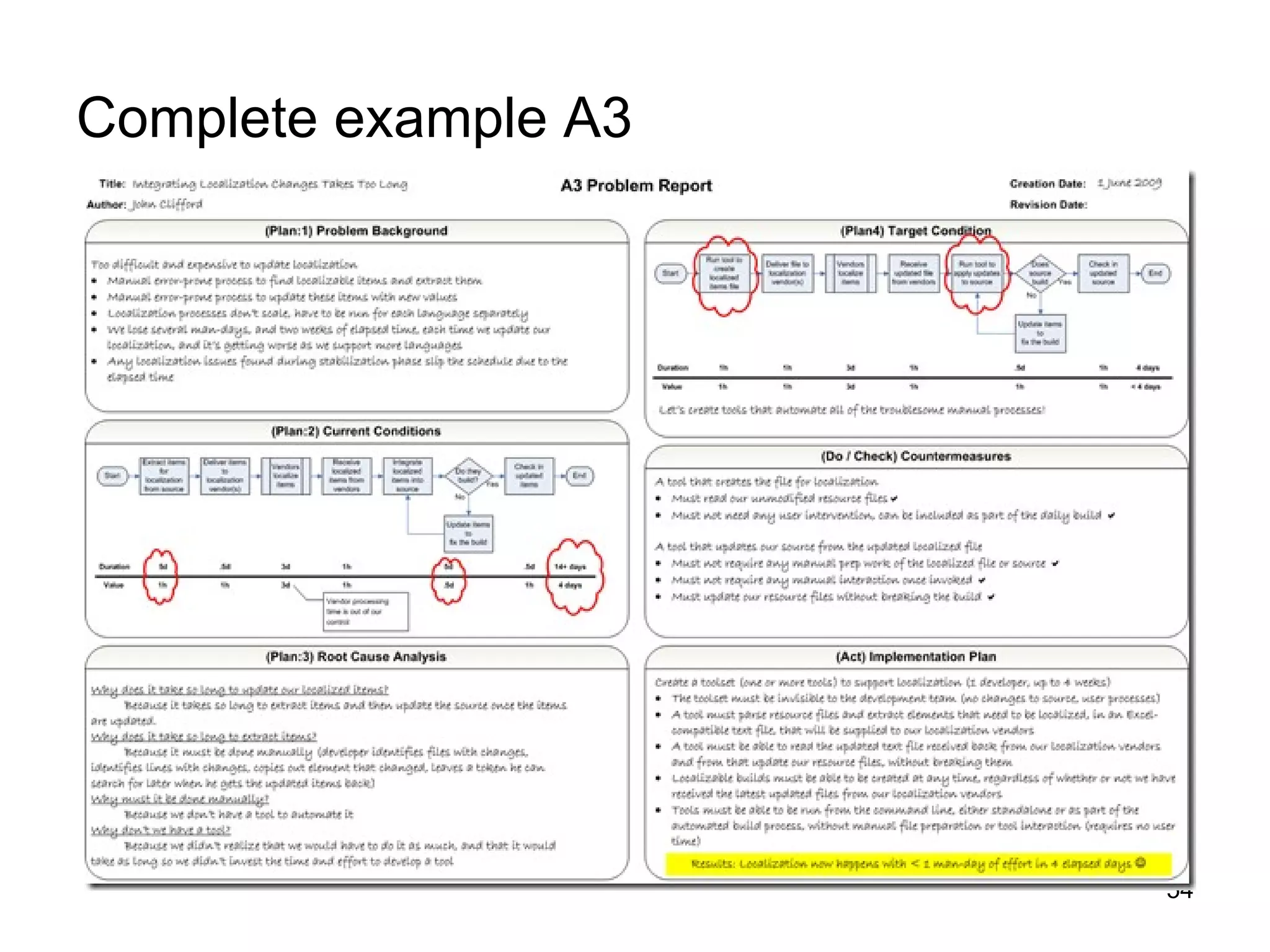

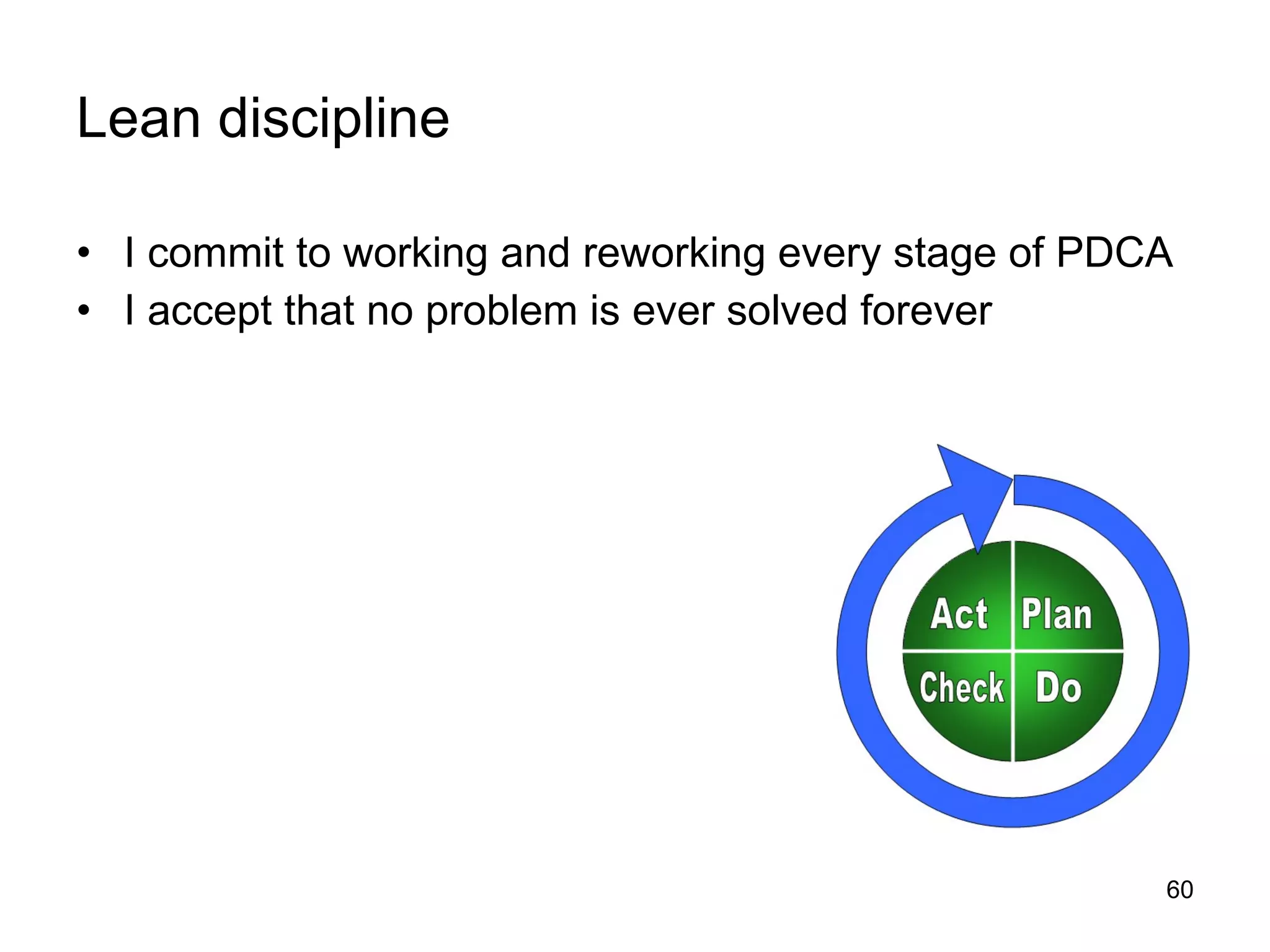

The document provides an overview of key Lean concepts and methods. It defines Lean as a business philosophy focused on reducing waste and increasing value. The core of Lean is eliminating non-value adding activities to improve efficiency. Key Lean techniques discussed include gemba walks, kaizen events, value stream mapping, A3 analysis, and 5S. Building a Lean culture requires continuous improvement and problem solving discipline.

![Want More? Ask me anytime… [email_address] [email_address]](https://image.slidesharecdn.com/leanideasandmethodsheath072111-13120651618427-phpapp02-110730173939-phpapp02/75/Lean-Ideas-And-Methods-Heath-07-21-11-67-2048.jpg)