Design for Manufacture and Assembly Datum Systems Guide

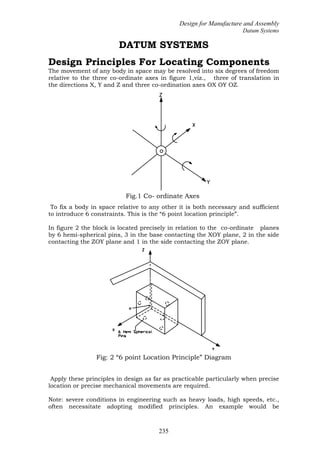

- 1. Design for Manufacture and Assembly Datum Systems 235 DATUM SYSTEMS Design Principles For Locating Components The movement of any body in space may be resolved into six degrees of freedom relative to the three co-ordinate axes in figure 1,viz., three of translation in the directions X, Y and Z and three co-ordination axes OX OY OZ. Fig.1 Co- ordinate Axes To fix a body in space relative to any other it is both necessary and sufficient to introduce 6 constraints. This is the “6 point location principle”. In figure 2 the block is located precisely in relation to the co-ordinate planes by 6 hemi-spherical pins, 3 in the base contacting the XOY plane, 2 in the side contacting the ZOY plane and 1 in the side contacting the ZOY plane. Fig: 2 “6 point Location Principle” Diagram Apply these principles in design as far as practicable particularly when precise location or precise mechanical movements are required. Note: severe conditions in engineering such as heavy loads, high speeds, etc., often necessitate adopting modified principles. An example would be

- 2. Design for Manufacture and Assembly Datum Systems 236 substitution of limited areas of contact for the point contact in figure 2 such as is often adopted in jig and fixture design. the point contact in figure 2 such as is often adopted in jig and fixture design. Fig- 3. Datum Spigot and Recess Assembly When locating one component relative to any other in an assembly, design so as to confine the need for positional accuracy to the minimum number of features, consider datum systems. Function of Datum Systems To align certain features on two components in accurate geometric relation when assembled. In the flange coupling, figure 3, a spigot B and recess A have been introduced in the design so as to align the respective shafts on assembly. To locate mating components accurately to finite assembly facilitates assembly. In figure 3 the datum spigot and recess also facilitates assembly of the securing bolts. To set as a convenient base from which to dimension other features. see surfaces A and D is figure 4

- 3. Design for Manufacture and Assembly Datum Systems 237 Fig: 4 Datum Based Dimensioning Common Datum Systems Group of two or three datum planes Function The system using two co-ordinate planes controls the relative movement of two components in 5 degrees of freedom, while that using three co-ordinate planes controls them in all 6 degrees of freedom. Geometric analysis Geometry involved is flatness and squareness of the planes. Location accuracy This is limited by the tolerances for flatness and squareness. The common is where one plane, usually in largest , is the principal datum, and in others are referred to this for squareness. see figure 5 where X is the principal datum. yy x z Fig: 5 Locational Accuracy of Principal Datum(X) Tolerances Assign flatness tolerances to each principal datum, and squareness tolerances to the other datums relative to the principal. X Z

- 4. Design for Manufacture and Assembly Datum Systems 238 Note: sometimes it may be necessary to assign special requirements to the flatness tolerance such as “surface must not be convex”, the latter to ensure no rock when assembled. Grouped datum plane and spigot assembling with Grouped datum plane and recess. Fig: 6 . Positional Datum Groups Function This system controls the movement of one component relative to the other in 5 degrees of freedom. The 6th degree not controlled by the system is rotation about OZ. The two planes control 3 degrees of freedom. Viz., translation in the Z direction, and rotation about OX and OY; the spigot and recess control 2 degrees of freedom, viz., translation in the X and Y directions. This system is used as a datum group for position, concentricity or symmetry. Geometric analysis The planes are the principal datums with zero position tolerance. The spigot and recess are the datums with zero position and squareness tolerances all on MMC, relative to the principal datums. Design the spigot short in length since a long spigot introduces redundancy by restraining rotational freedom about OX and OY,which is the function of the planes. Location accuracy This is limited only by the fit C between the spigot and recess and the flatness

- 5. Design for Manufacture and Assembly Datum Systems 239 DIA 1 Group No .001 DIA Magnitude Geometry Tols MMC No of Features 1B (a) Feature Letter POSN &SQ Type Datum Features A Y -0.304 25.4B O A of the planes. _ Take as criterion C=C±k where C is the mean fit and k is the permissible variation. Basic size Choose this from data sheets as appropriate. Fit, Design sizes and Tolerances The fit between spigot and recess should be chosen to suit the location accuracy required. Confine the choice to the fits given in data sheets. Do not specify flatness tolerances for the planes unless unusually precise location is required. Drawing practice Show the spigot and plane as one geometric group, and the recess and plane as another. See figure 7 and use tabular method (a) in general; Method (b) may be used if there is only one positional groups Geometric Groups and Tolerances

- 6. Design for Manufacture and Assembly Datum Systems 240 (b) Fig: 7 (a) Tabular Method (b) sketch for Using one positional Groups Example, figure 6 Design requirements Location accuracy to be for translation 0.0254mm Basic size for recess and spigot 25.4mm from data sheet Fit 1.01H8h8 from data sheet giving Recess: 25.4+0.0305 And spigot: 25.4-0.0305 Location accuracy is 0.0305± 0.0305 This is close enough to the design requirement to be satisfactory. Grouped Datum Plane , Spigot and Hole assembling with Grouped Datum Plane, Recess and Pin. See figure 8. Function This system controls the relative movements of two components in all 6 degrees of freedom, but rotation about OZ less precisely than the others. This system is used mainly as a datum group for positional features. Geometric analysis The planes are principal datums with zero position tolerances. The spigot and recess are datums with zero position and squareness tolerances on MMC relative to the principal datums.

- 7. Design for Manufacture and Assembly Datum Systems 241 Fig:8 Spigot & Hole with Recess & Pin Assembly (Grouped The hole and pin are datums having position and squareness tolerances MMC relative to the datum spigot and plane and the datum spigot and plane and the datum recess and plane Design spigot short in length for the same reason as in 3.22 above. Location accuracy Translational movement in the X, Y and Z directions is limited by the fit C between the spigot and recess and by the flatness of the planes. Take as before the criterion. _ C=C±k Rotation about OX and OY is limited by the flatness of the planes, about OZ by the fit between the spigot and recess and the hole and pin. The clearance between the latter including provision for the position tolerances for the position tolerances for the hole and pin. Take as criterion the mean angular play.ie, at minimum material conditions with no positional errors present.

- 8. Design for Manufacture and Assembly Datum Systems 242 Geometric Groups and Tolerances. 1 Group No 0.1 dia O dia Magnitude Geometry Tols MMC No of Features 1B C 1 Feature Letter POSN &SQ POSN &SQ Type Datum Feature A Fig: 9 (a) 9(b) Examples.-Grouped Datum Planes with spigot and Hole Assembly Basic Sizes Choose from data sheets as appropriate. Fits, design Sizes and Tolerances The fit between the spigot and recess should be chosen to suit the location accuracy required. Confine your choice to the fits shown in data sheets 4,5 and 6 for Hole basis; Hole Basis is preferred. Do not specify flatness tolerances for the planes unless unusually location is X Y22.0T.P A 25.000 5.000 DIA C +.075 Datum Face A POSN & SQ TOL O dia MMCdia B +0.003 POSN & SQ TOL 0.1 dia MMC Datums Spigot B MMC & Face A. 5.000 DIA +.075 22.0T. Y C X +0.003 25.000 dia B A

- 9. Design for Manufacture and Assembly Datum Systems 243 required. The fit between the hole and pin must satisfy the location accuracy required and also provide sufficient C min to allow for position tolerances. Confine your choice of fit to those given for positional fits in data sheets; the shaft basis will be applicable here. Drawing practice Show the plane, spigot and hole as one geometric group, with the plane as principal datum for the group. See figure 9(a). Similarly the plane would be shown as principal datum for the recess and the pin in the other component. The tabular method (a) in figure 9 is preferred in general; method (b) may be used if there is only one positional group other than the datum group. Example. Fig:10.Spigot & Hole with Recess & Pin Assembly (Grouped Datum Planes) Design requirements: Location accuracy to be For translation 0.03 0.03mm For rotational 40 minutes of arc Basic size, For recess and spigot 25.0mm For pin and hole 5.0mm

- 10. Design for Manufacture and Assembly Datum Systems 244 Both from data sheet Choose hole basis for both fits. Assign position tolerances as follows: For spigot 0 dia MMC For hole 0.15 dia MMC For recess 0 dia MMC For hole for pin 0.15 dia MMC For concentricity Of two dies of pins 0.04dia MMC Cmin for spigot and recess =0+0.10 =0 For hole and pin = 0.15+0.15+0.04+0.04 = 0.38 Provisional design sizes are as follows: Recess=25.0: spigot=25.0 Pin = 5.0-0.38: hole = 5.0 =4.62 Choose fits from data sheet as follows: Spigot and recess = 25.0 H8h9 Giving recess 25.000+0.033 And spigot 25.000-0.033 And hole and pin 5.0 H7h9 Giving hole 5.000+0.075 And pin 4.73-0.03 The location accuracy for translation =0.033+/-0.033 This is regarded as satisfactory. The maximum angular play =(5.075-4.700)+(25.033-24.963)*10800/n =69 minutes of arc. Criterion for location accuracy is therefore 35 minutes of arc approximately and hence is satisfactory. The position tolerances for the pin and the corresponding hole would be modified to suit the new Cmin 0.21let position tolerance For hole =0.1 dia MMC For pin =0.1 dia MMC For concentricity of two diameters of pin= 0.01dia MMC And let C=0.03 See figure 9 Grouped Datum Plane, Spigot and Tongue,

- 11. Design for Manufacture and Assembly Datum Systems 245 Assembling with Grouped Datum Plane, Recess and Gap. (Fig 11) Fig: 11. Spigot & Tongue Assembling with Recess and gap (Grouped Datum Planes) Function This system performs a similar function to 3.3 above, except that rotation about OZ can be more precisely controlled. Geometric Analysis For the planes, spigot and recess same remarks apply as in 3.32. The tongue and gap are also datum related to the other datums, but tolerances are assigned for symmetrically and squareness instead of for position and squareness. Location Accuracy In principle the same remarks apply as in 3.3. Basic sizes Choose from data sheets as appropriate Fits, Design sizes and Tolerances In principle the same remarks apply as in 3.3 above, except that the symmetry tolerance for the tongue relative to the spigot or for the gap relative to the

- 12. Design for Manufacture and Assembly Datum Systems 246 recess can be small, even zero on MMC.This requirement is much easier to attain with this design than with the corresponding position tolerances in section 3.3. Confine your choice of fit to those given in data sheets for hole basis; another data sheet for shaft basis; hole basis is preferred Drawing practice Show the plane, spigot and tongue as one geometric group with the plane as principal datum for the group see figure 9(a). Similarly the plane would be shown as the principal datum for the recess and pin other geometric group. The tabular method (a) in figure 9 is preferred in general; Method (b) may be used if there is only one positional group other than the datum group. . Fig 12(a) Fig 12 (b)

- 13. Design for Manufacture and Assembly Datum Systems 247 Grouped Datum Plane and Pins assembling with Grouped Datum Plane and Holes. See Figure 13 Fig 13 Grouped Datum Plane and Pins assembling with Grouped Datum Plane and Holes Function This system controls the relative movements of the two components in all 6 degrees of freedom and in principle relation as precise as translation. The two planes control 3 degrees of freedom viz. Translation in X and Y directions and rotation about OZ. Datum planes Datum pins O Datum plane X Y O Datum holes 1.2 TP Y Z 2 Holes 0.21500±0.0009 dia X Z

- 14. Design for Manufacture and Assembly Datum Systems 248 Fig :14 Tabular method. Plane as datum for pins Geometric Analysis The planes are principal datums with zero position tolerances. The pins and holes are datums with position and squareness tolerances on MMC related to their respective principal datums. Location Accuracy Translation in the Z direction and rotation about OX and OY is limited by the flatness of the datum planes. Translation in the X and Y directions and rotation about OZ is limited by the fit between the holes and pins the clearance between the later including provision for the position tolerances for the holes and pins. Take as criterion the mean angular play calculated as half the maximum angular play ie at minimum material conditions with no positional errors present. Magnitude 2 Holes 0.21500±0.0009 dia 1.2 TP No of Features Letter Group No B 1 2 POSN &SQ .001 DIA Geometric Groups & Tolerances Feature Geometry Tols MMC Type 2.9 TP A 1.2 TP 2 Holes 0.21500±0.0009 dia A Datum Feature 2.9 TP A

- 15. Design for Manufacture and Assembly Datum Systems 249 Basic Sizes Choose from data sheets 2 or 3 as appropriate. Fits, Design Sizes and Tolerances Do not specify flatness tolerances for the planes unless unusually precise location is required. The fits between the holes and pins must satisfy the location accuracy required and also provide sufficient Cmin to allow for position tolerances . Assign the same position tolerances to each pin and to each hole. Confine your choice to the positional fits in data sheets 4 and the shaft basis may well be applicable here see data sheet 7. Drawing practice Show the plane and the two holes as one geometric group with the plane as datum for the group. see figure 14similarly the plane would be shown as datum for the pins in the other geometric group. The tabular method (a)in Figure 1.14is preferred in general method (b) may be used if there is only one positional group other than the datum group. Example, Figure 14 Design Requirement Location accuracy to be for rotation of 3 minutes of arc Basic size for pins and holes 6.35mm from data sheet2 Fit (on shaft basis)6.35 h8c9 from data sheet 7 giving pin 6.35 -- .0009 and hole 6.4262 + .0014 Cmin =.003 permitting .0015 dia MMC position tolerances for the pins and the holes. The maximum angular play =(.00531.5) x(10.800/π) =12 minutes of are approx. Criterion for location accuracy is 6 minutes of arc and this is too great in relation to the design requirement. Choose fit (on shaft basis) as 6.35 h8E8 from data sheet 7 giving pin 6.35 -- .0009 And hole 6.4262 + .0009 The maximum angular play =(.00281.5) x (10.800/π) =6.5 minutes of are approx. Criterion for location accuracy is thus 3.25 minutes of arc and in this case is regarded as satisfactory. Cmax = -.001 Position tolerances for strict interchangeability would be .005 dia but are considered to be too small. If we choose .001 dia MMC position tolerances for both the pins and the holes the virtual sizes of pin and hole become secured and then drilled and reamed for the insertion of dowels, which are normally a press fit.

- 16. Design for Manufacture and Assembly Datum Systems 250 If the cover Figure 1.13 were dealt within this way a suitable note would be inserted on the management drawing such as in figure 1.14. The t chosen here is 6.35h8s7. The holes B would then not ensure strict interchangeability between components but is an economical solution for small to medium Pin .251and Hole .250 Thus theoretically giving interference. However the metal interference will be only on one side of each pin and hole and will not be greater then .0005 Hence the fits and tolerances chosen are regarded as satisfactory. Use of Dowels This system is similar in design to the datum system of section 3.5 However the dowels generally play no part in the control during production. Usually the components are assembled together adjusted quantity production. Fig 15: Tabular method. Plane as datum for pins In the datum systems described in section 3 above the principal datum was invariably the plane or at surface and the spigot was made short in length to ensure that its function did not conflict with that of the planes. In same cases however such as in figure 15 the shaft may be used to align the component on assembly and is then made for the better to achieve this function. The shaft becomes the principal datum in the datum system and the surface Y is tolerenced for squareness in relation to Z as shown in figure 15. A shaft washer is inserted under the head so ads to provide for errors in squareness.. Magnitude 2 Holes 0.21500±0.0009 dia 1.2 TP No of Features Letter Group No B 1 2 POSN &SQ .001 DIA Geometric Groups & Tolerances Feature Geometry Tols MMC Type 2.9 TP A 1.2 TP 2 Holes 0.21500±0.0009 dia A Datum Feature 2.9 TP A