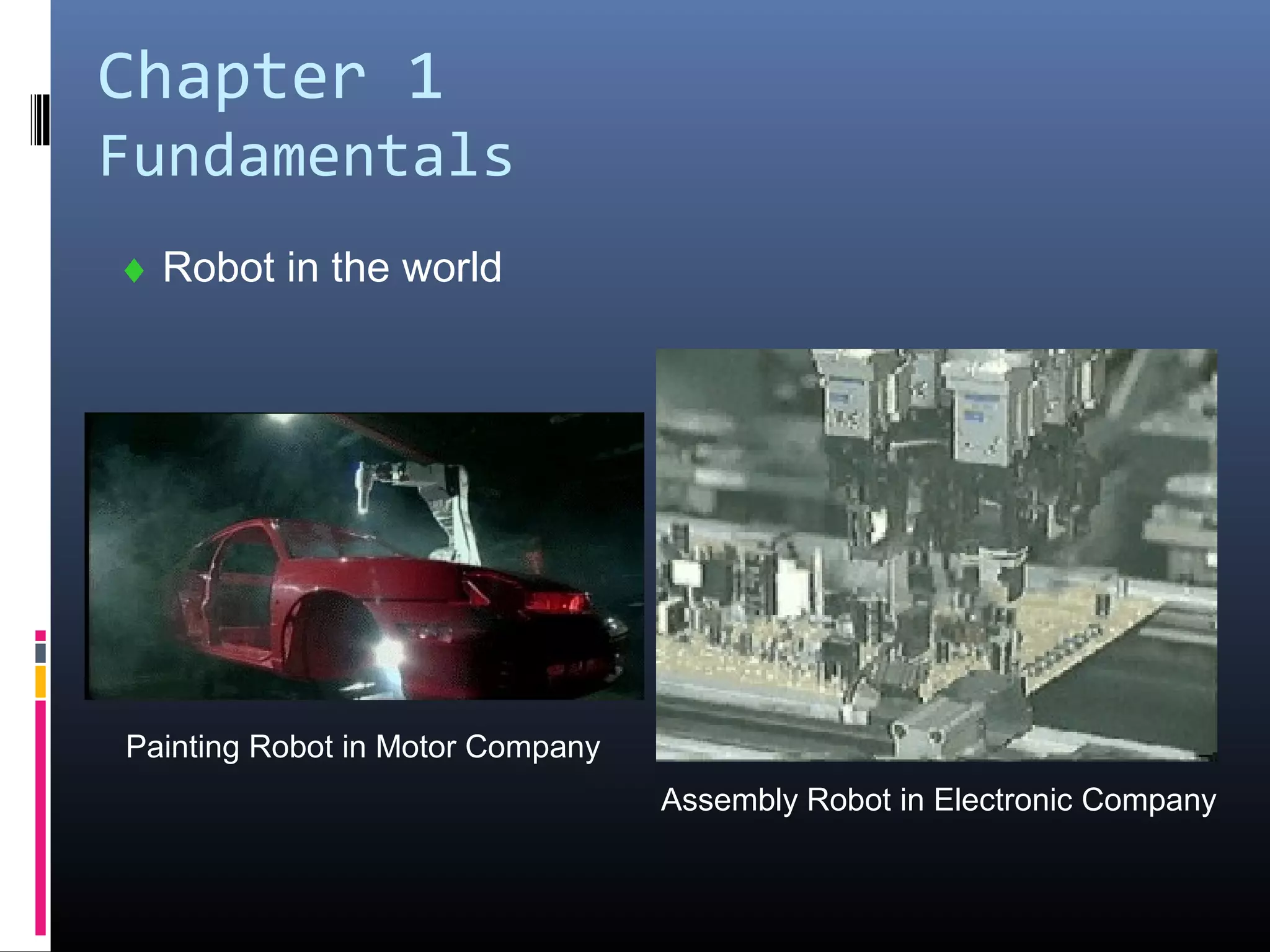

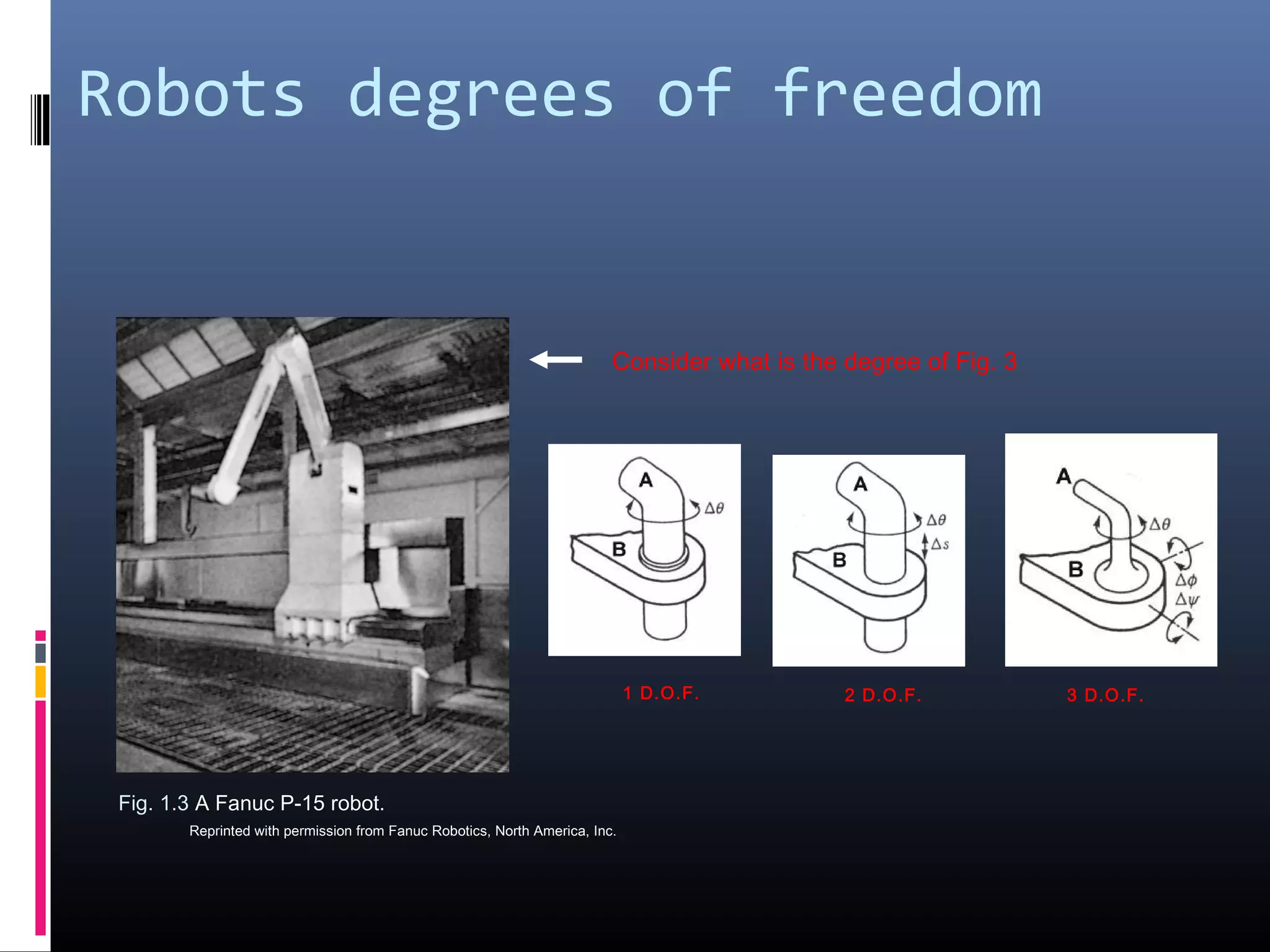

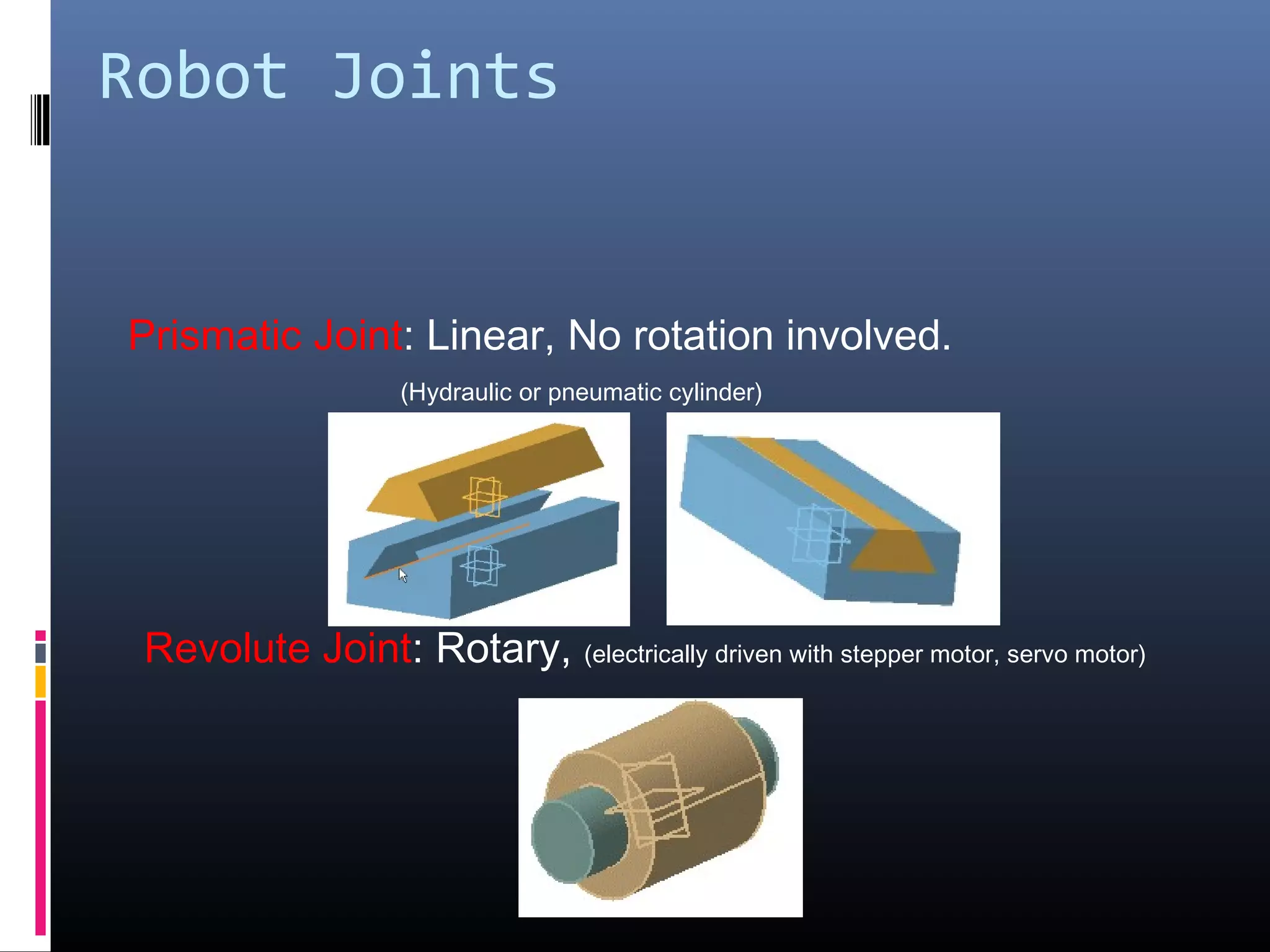

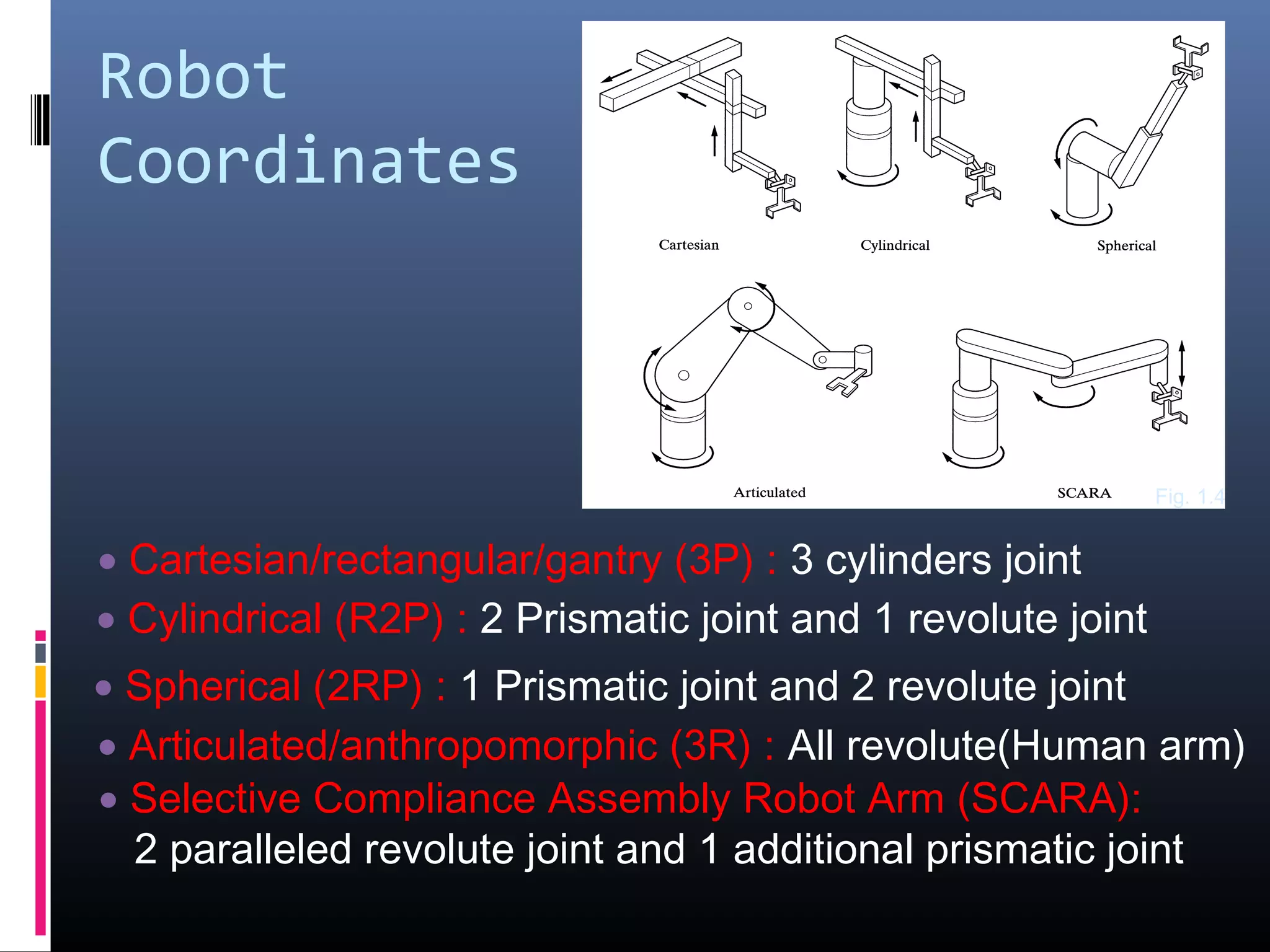

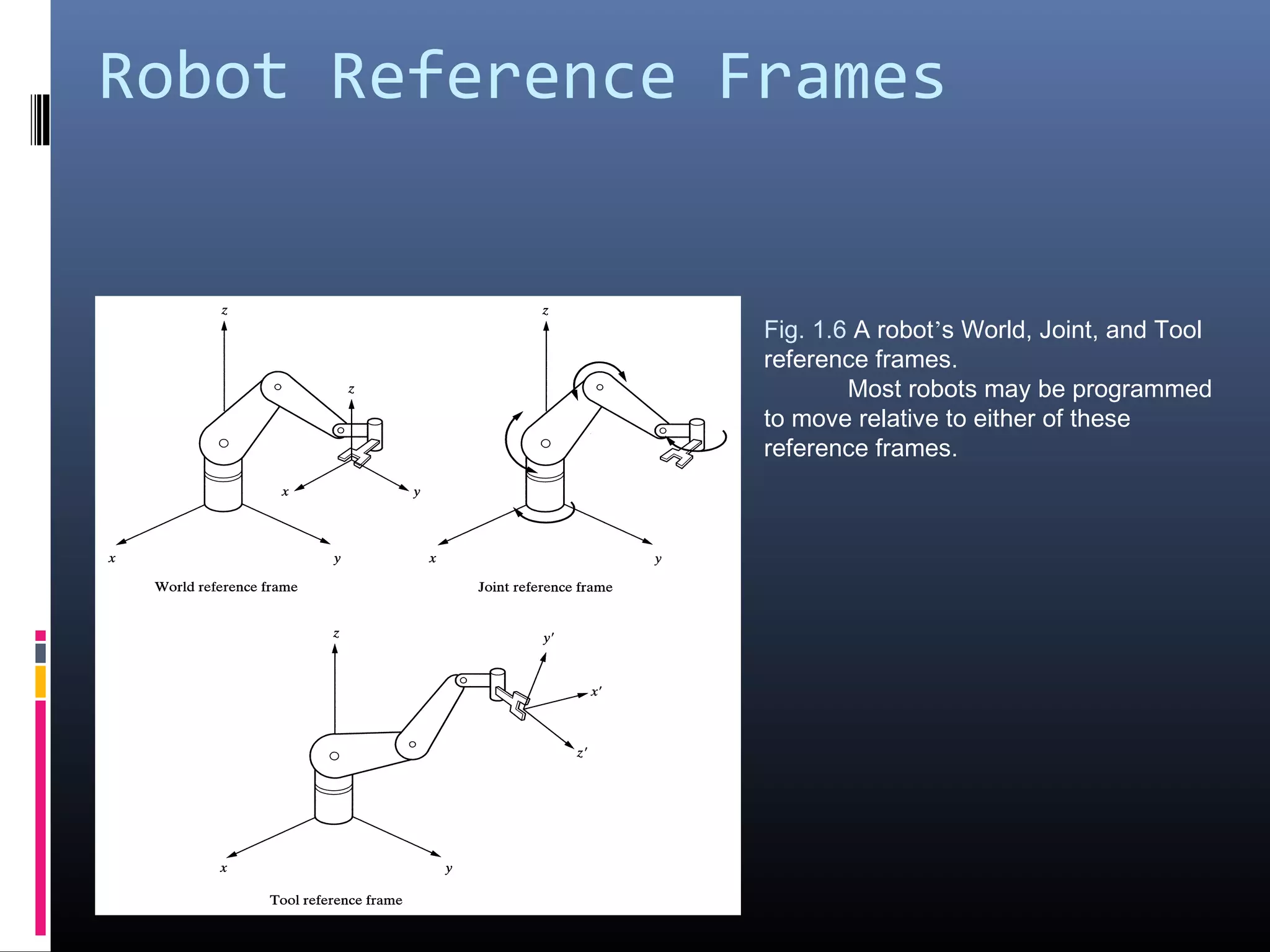

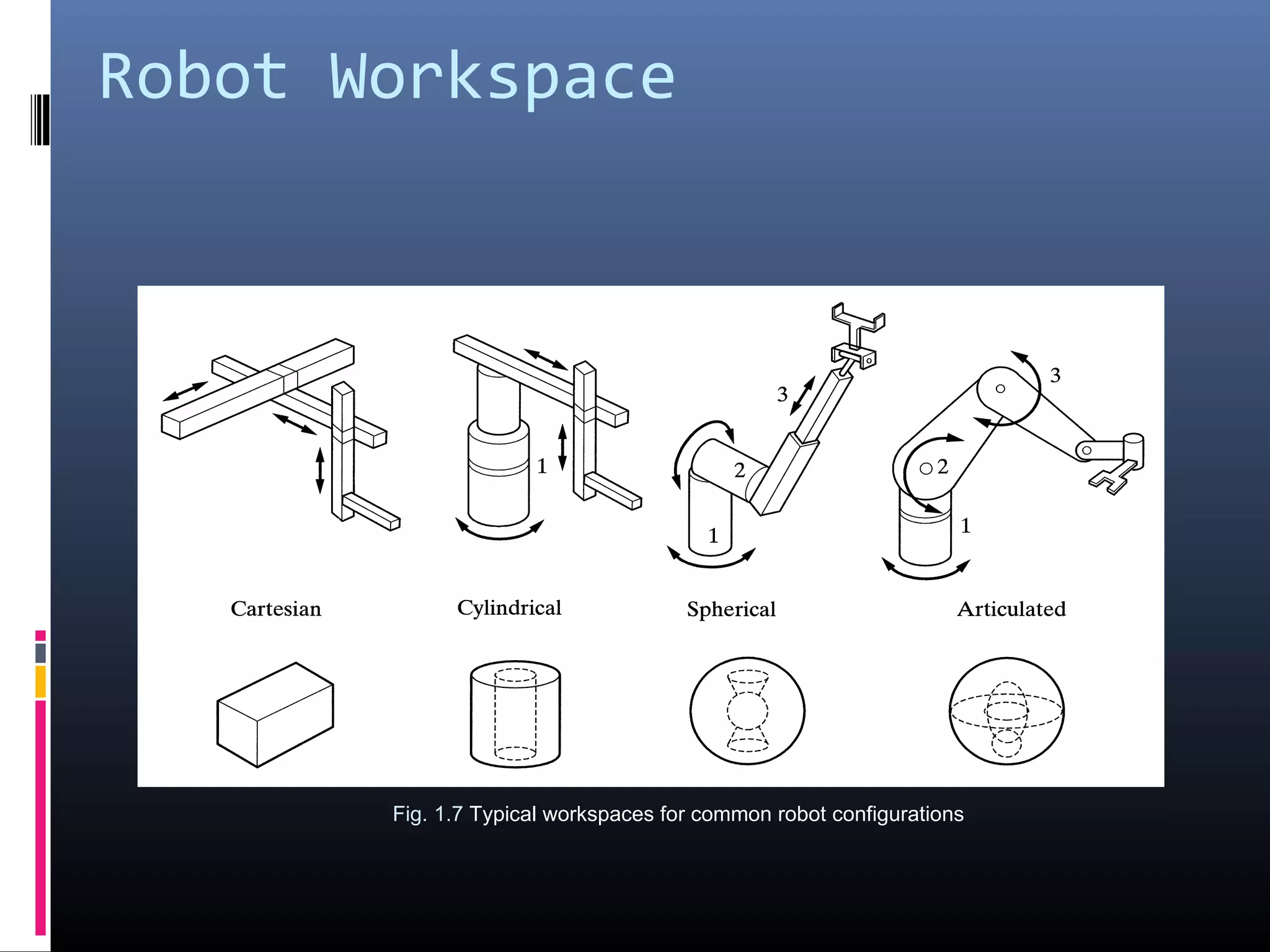

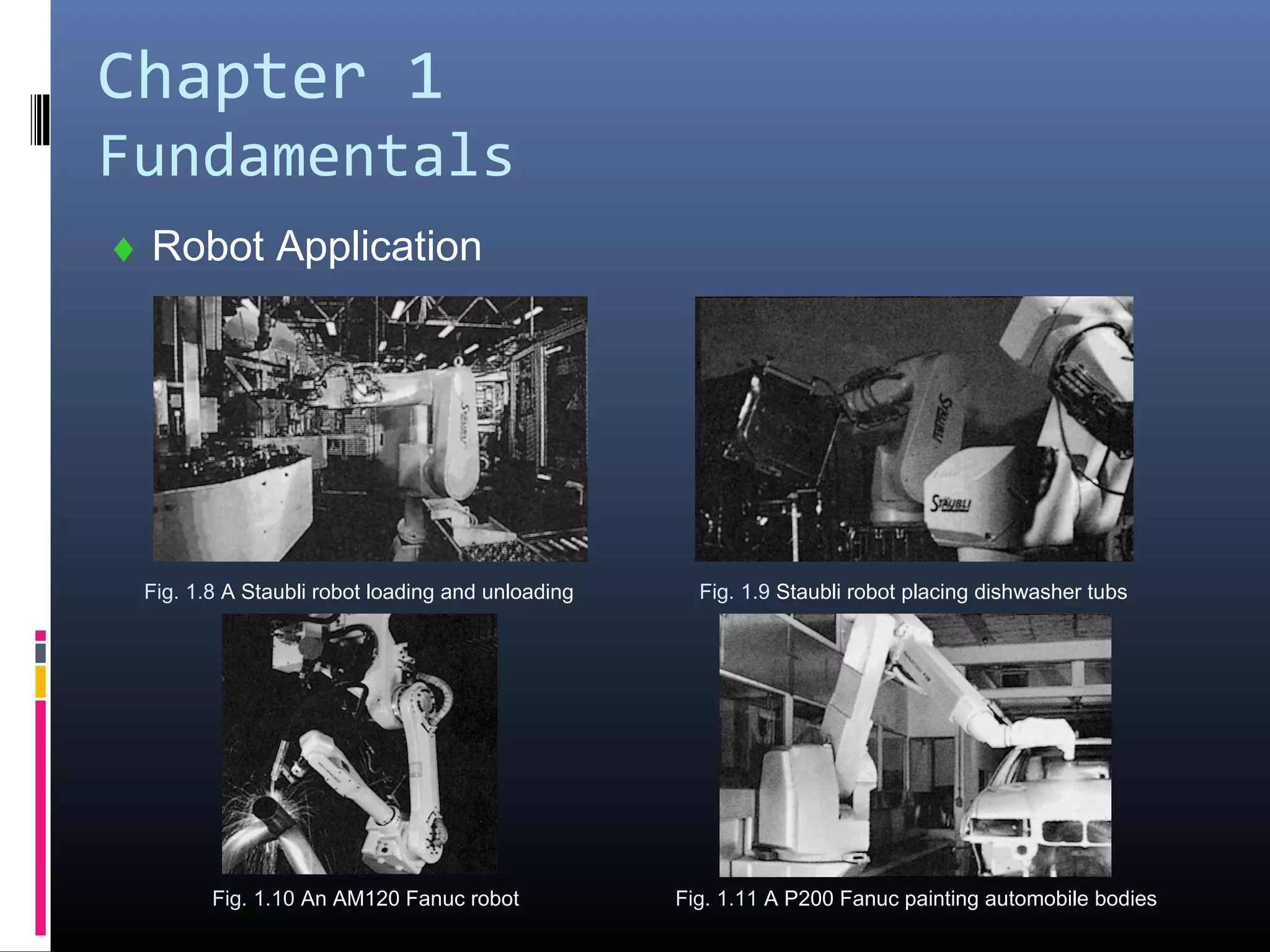

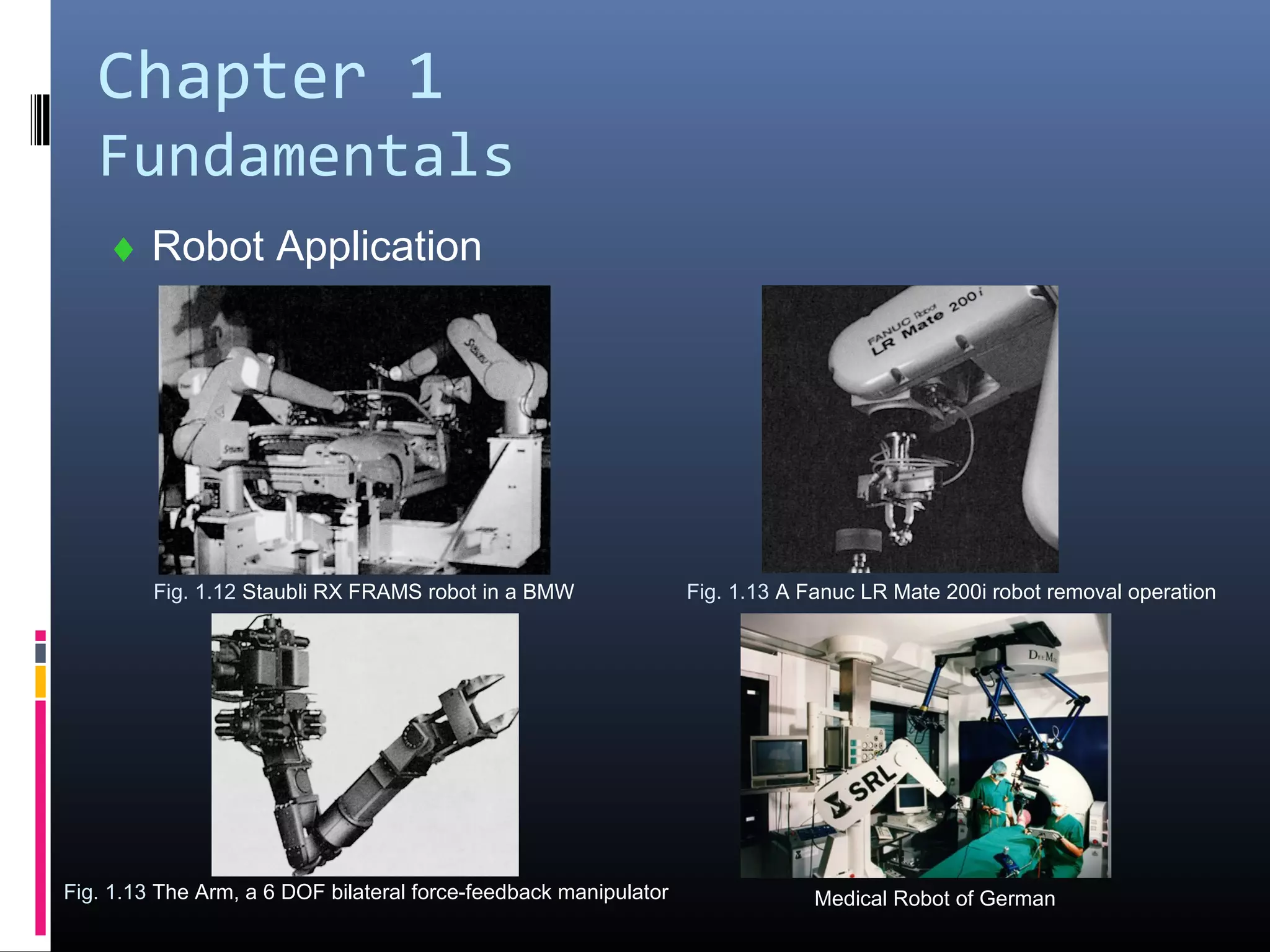

This document provides an introduction to robotics, including definitions of robots, classifications of robots, the typical parts of a robot like manipulators and end effectors, robot programming modes, languages, applications, and examples of industrial robots used for tasks like assembly, painting, loading/unloading, and medical procedures. Key topics covered include the history of robot development, degrees of freedom in robot motion, reference frames for robot positioning, and characteristics of industrial robots like payload capacity and precision.