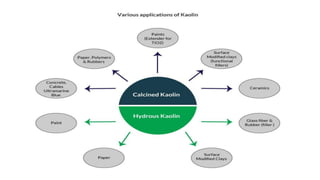

Kaolin is a non-metallic mineral composed mainly of kaolinite and other minerals. It is widely used in ceramics, paper, rubber, plastics and refractory industries due to its excellent processabilities. There are two main processes for processing kaolin ore - dry and wet processes. The dry process produces hard kaolin while the wet process produces soft kaolin.

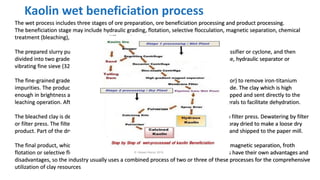

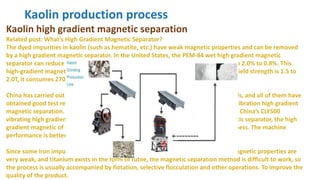

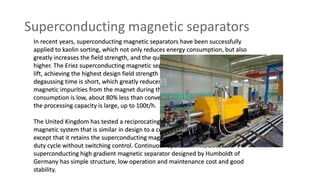

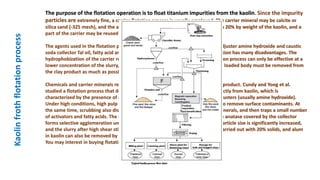

The wet process involves several stages including ore preparation, beneficiation to remove impurities using methods like magnetic separation, flotation or flocculation, and product processing. High gradient magnetic separation is commonly used to remove iron-titanium impurities. The beneficiated kaolin is then dewatered using processes like filtration or