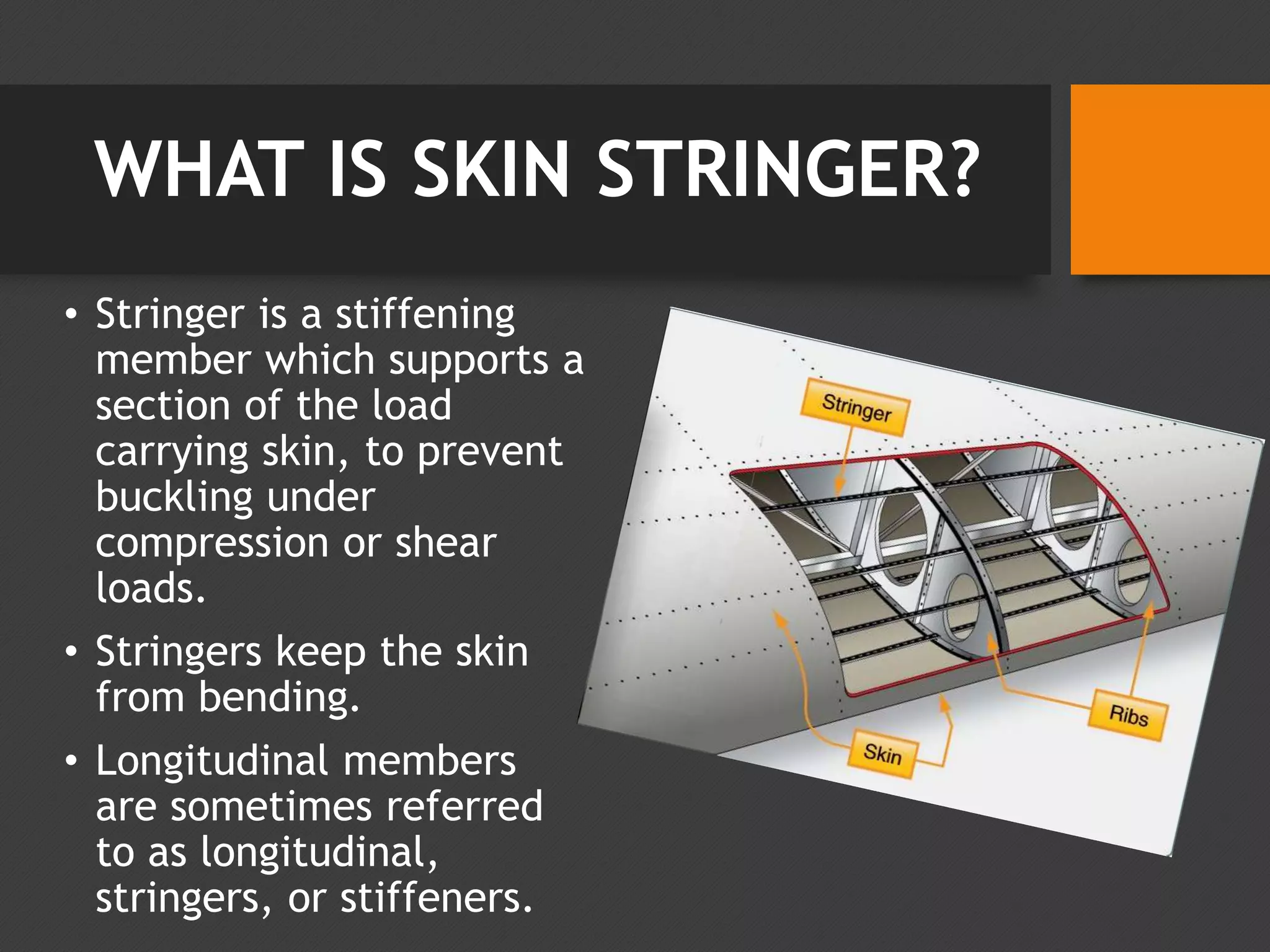

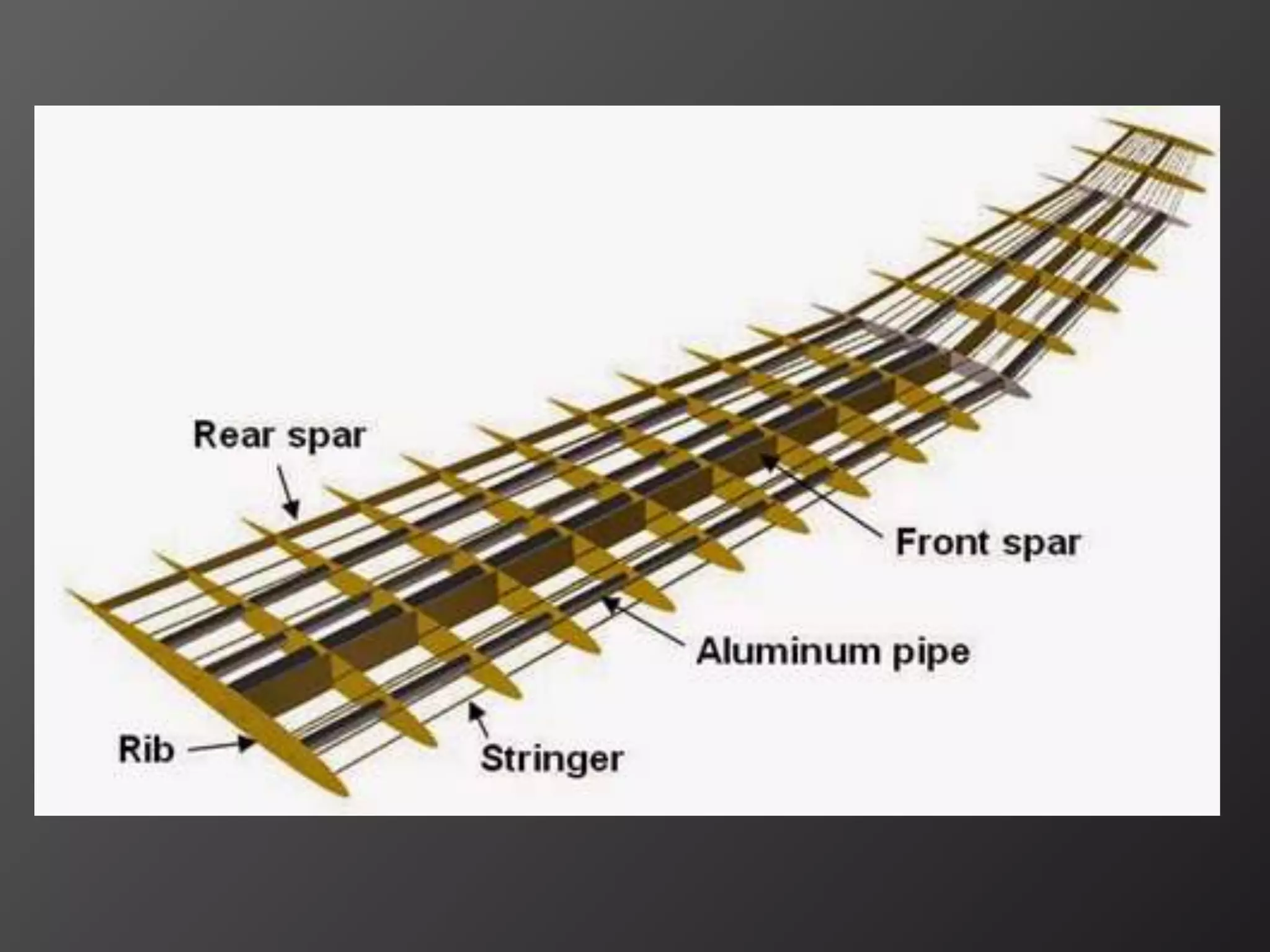

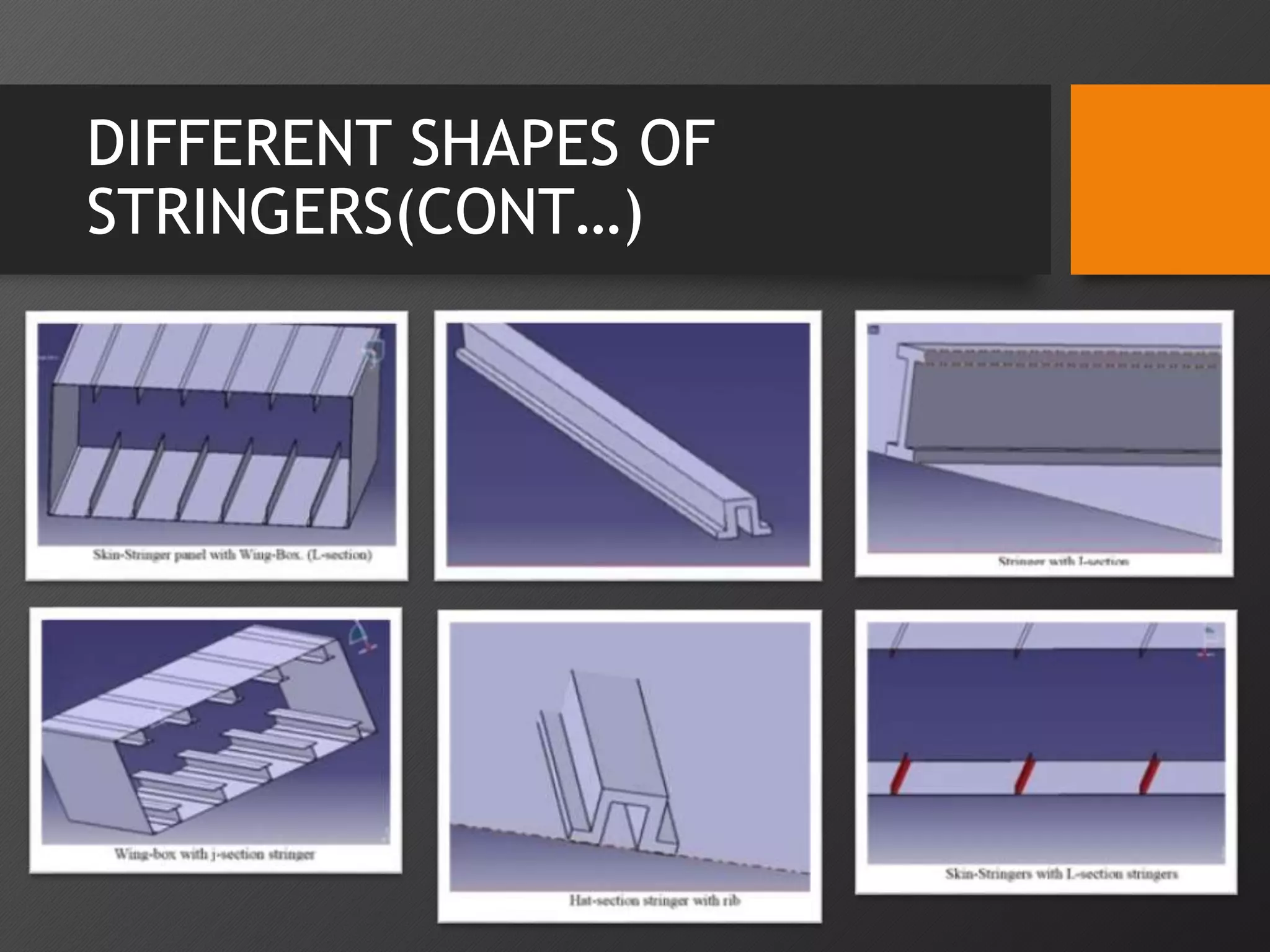

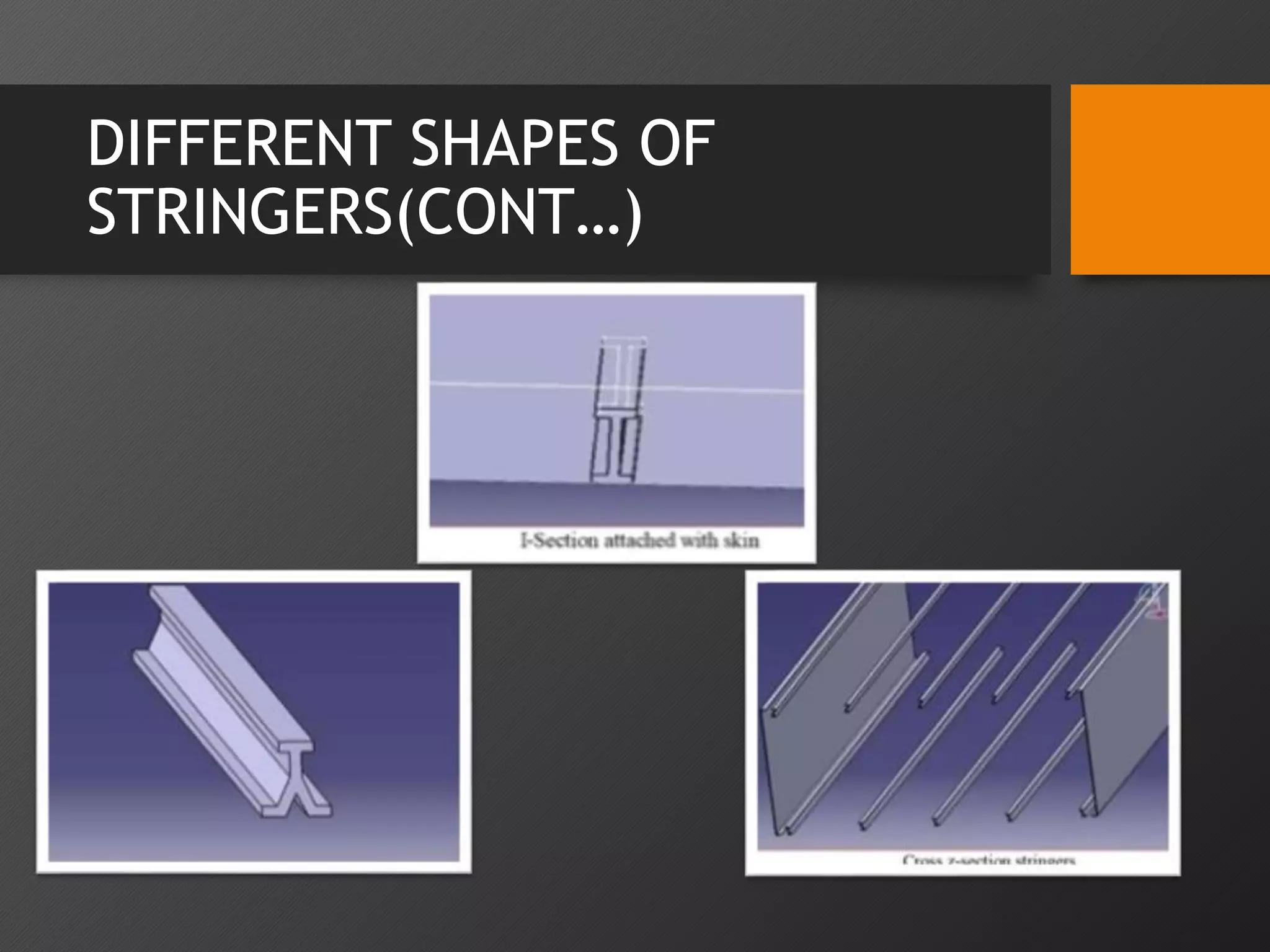

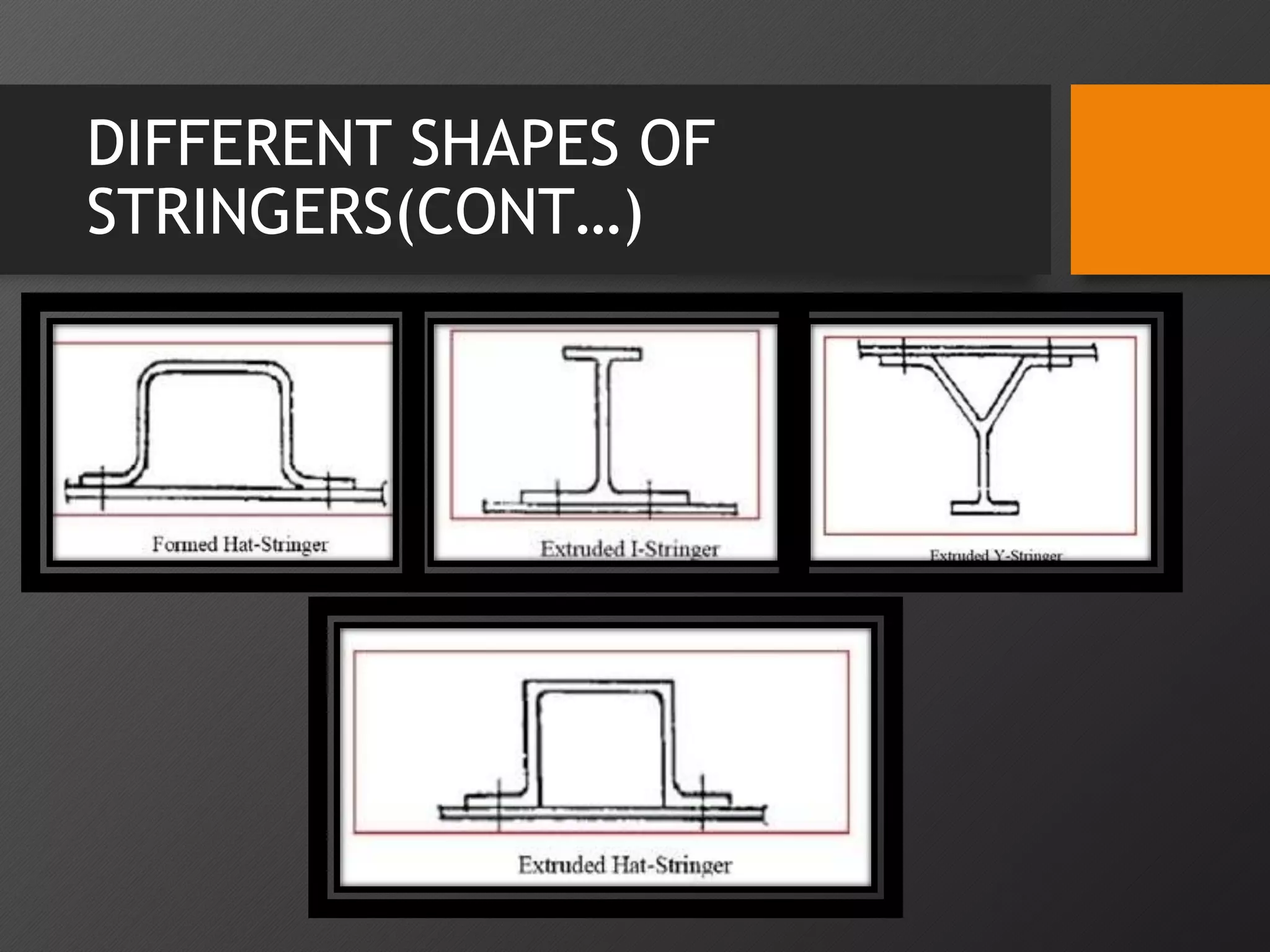

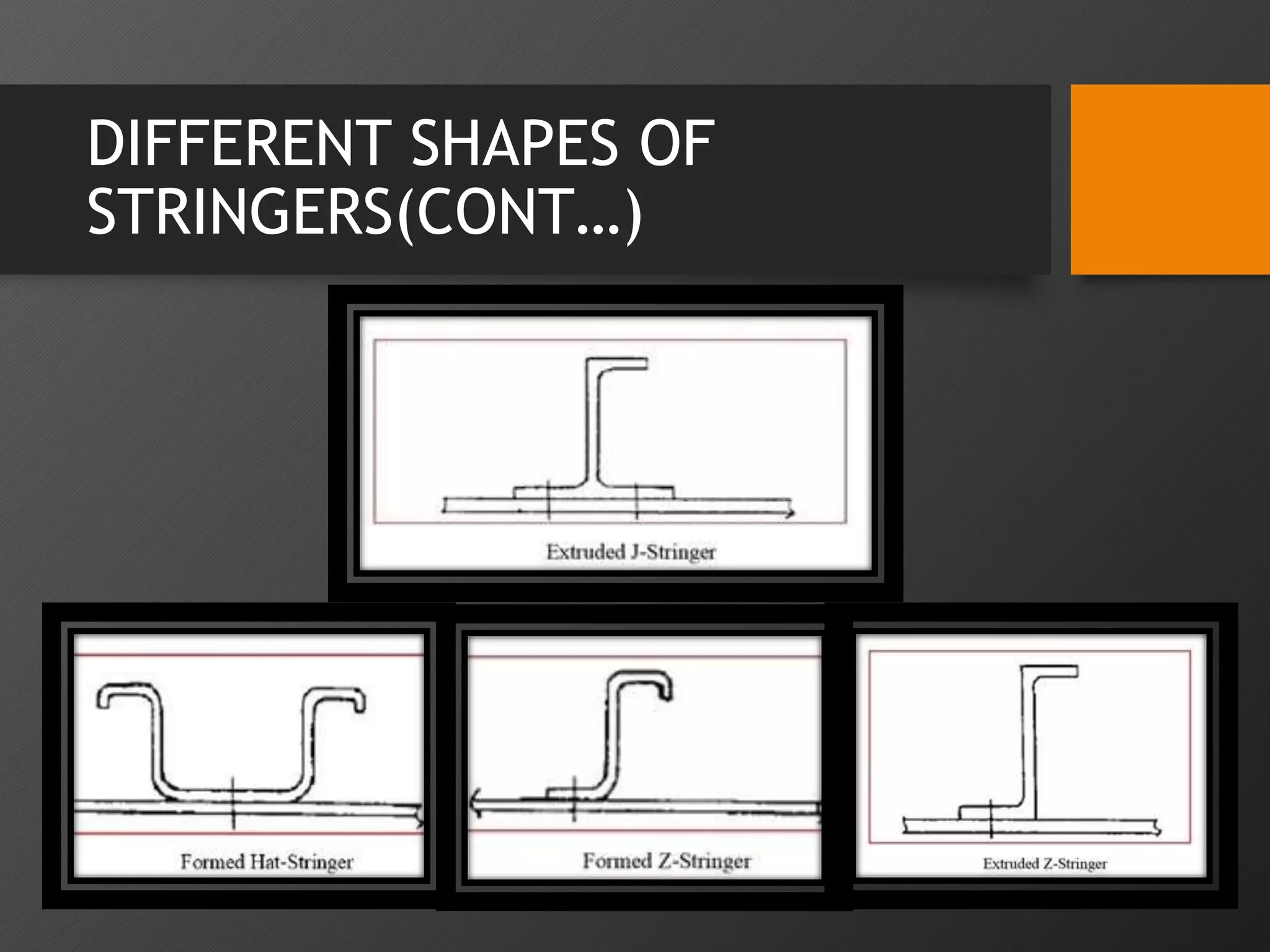

Stringers are longitudinal stiffening members that support aircraft skin and prevent buckling. They transfer loads between the skin and supporting structures like frames and ribs. Stringers are commonly made of aluminum alloy and come in different cross-sectional shapes. Current research is optimizing stringer design and implementing designs in CAD software to minimize weight while ensuring strength and stability. Future work could extend the design methodology to include multiple cracks, fasteners instead of adhesive, drag forces, and design of the full wing box.