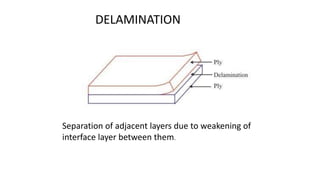

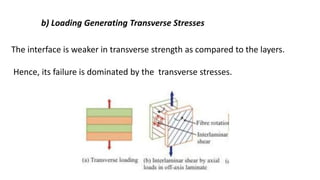

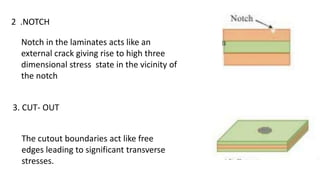

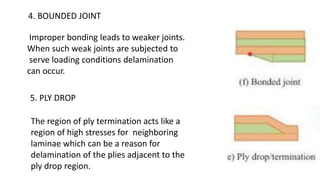

Delamination occurs due to the separation of adjacent layers in a composite material. It can be caused by manufacturing defects, stresses that act transverse to the layers, or laminate geometry issues like free edges, notches, cut-outs, poor bonding, or ply drops. Delamination reduces strength and stiffness, causes stress concentrations, and can lead to further growth and compressive failure of the laminate.