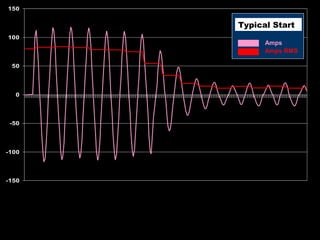

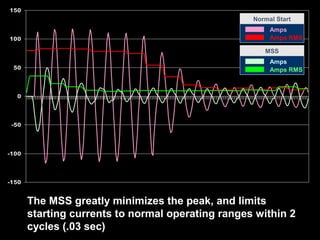

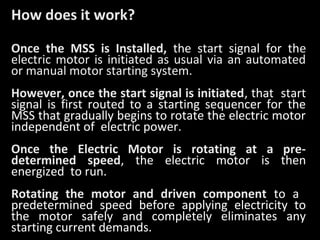

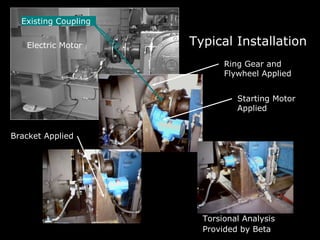

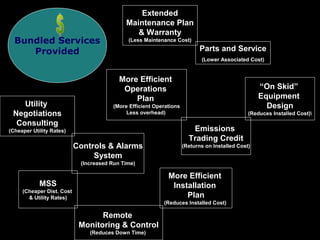

The Manning Starter System (MSS) is a new electric motor starting system that reduces the instantaneous current draw during motor starting to no more than the motor's rated operating current. This is a significant improvement over traditional starting methods, which can require startup currents that are 6-8 times higher than normal operating levels. The MSS achieves this by gradually rotating the motor via an applied starting motor before energizing the motor with electricity. This eliminates high starting currents and provides cost savings over conventional starting systems through lower equipment, installation, and operating costs as well as reduced electricity bills.