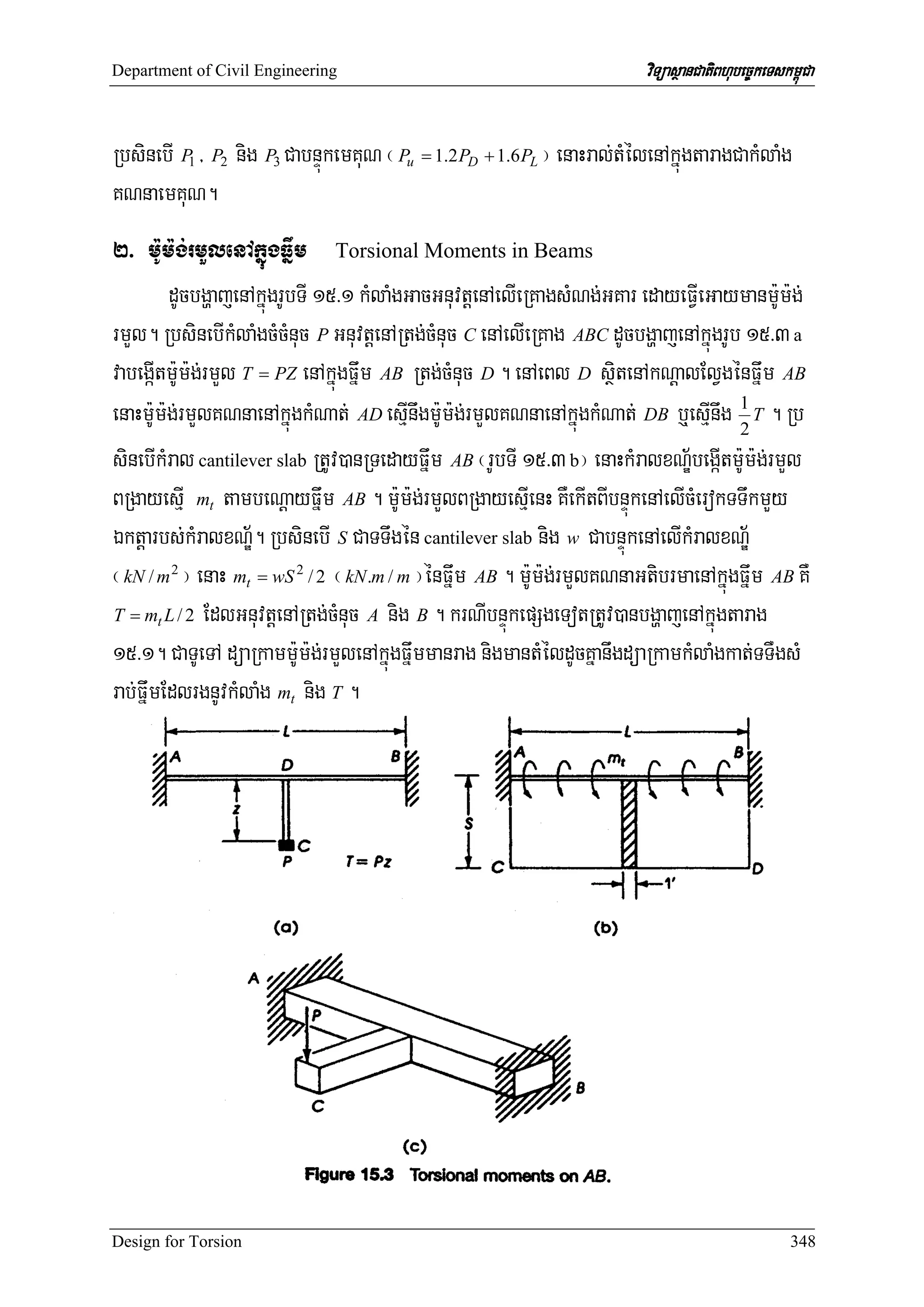

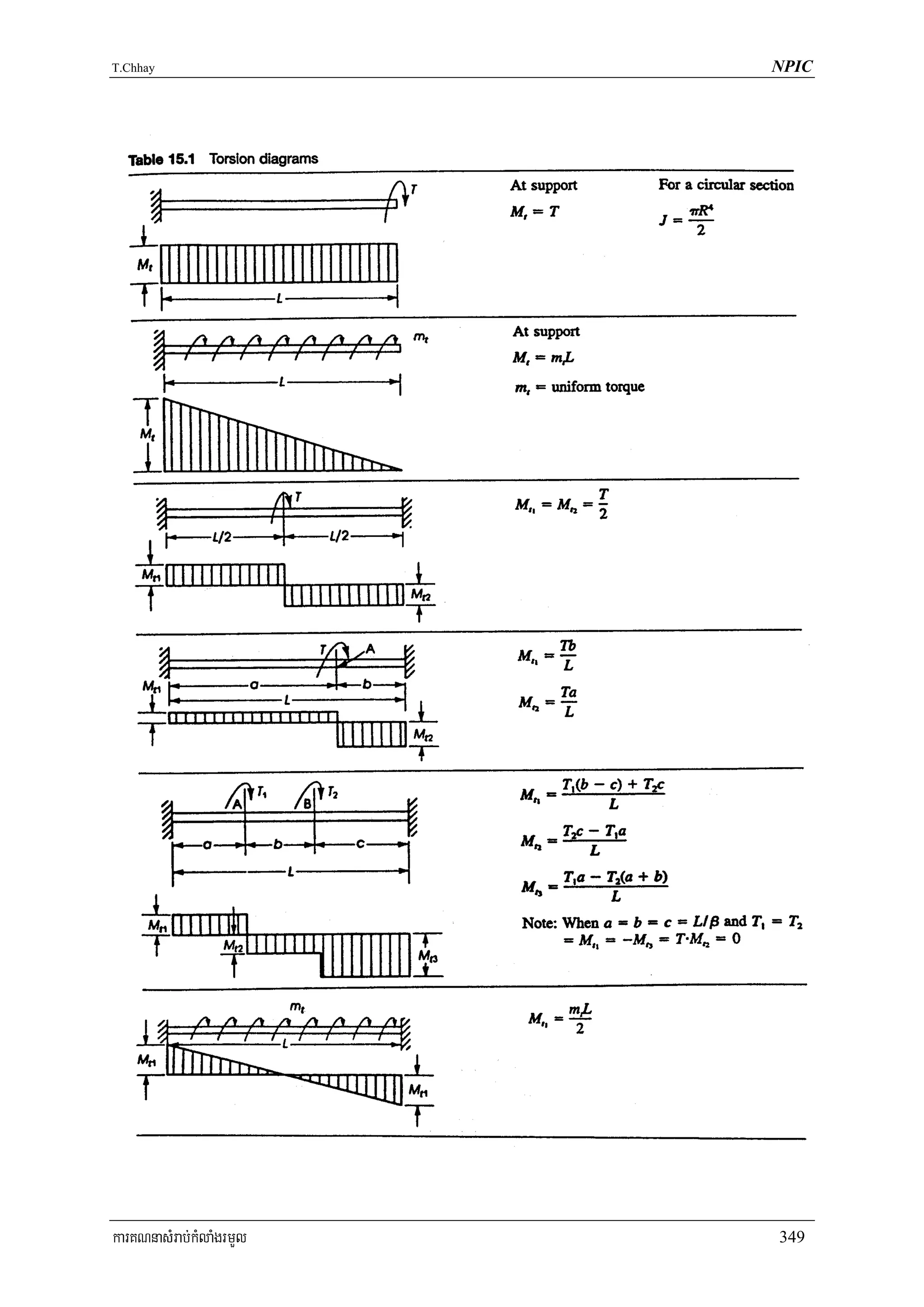

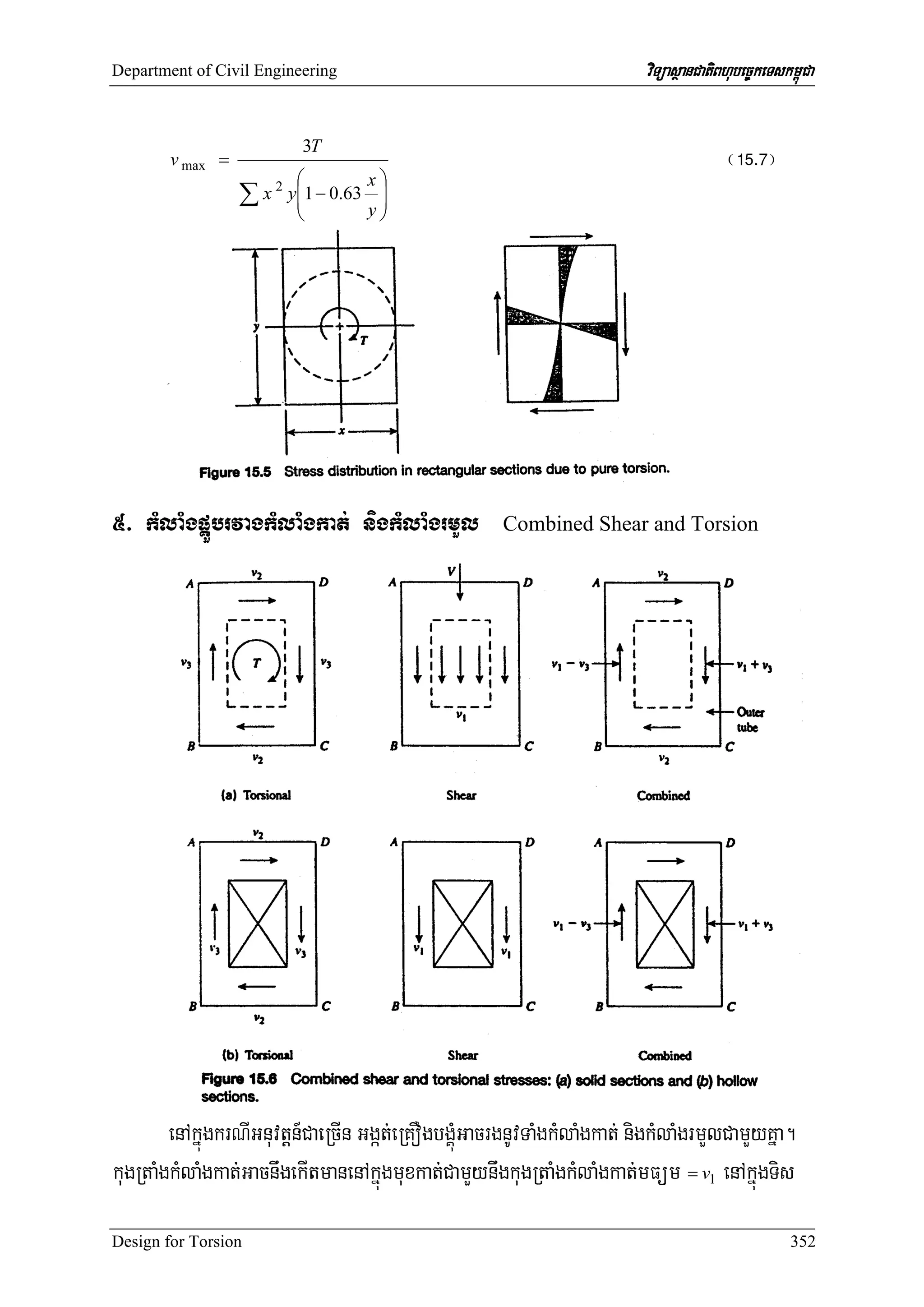

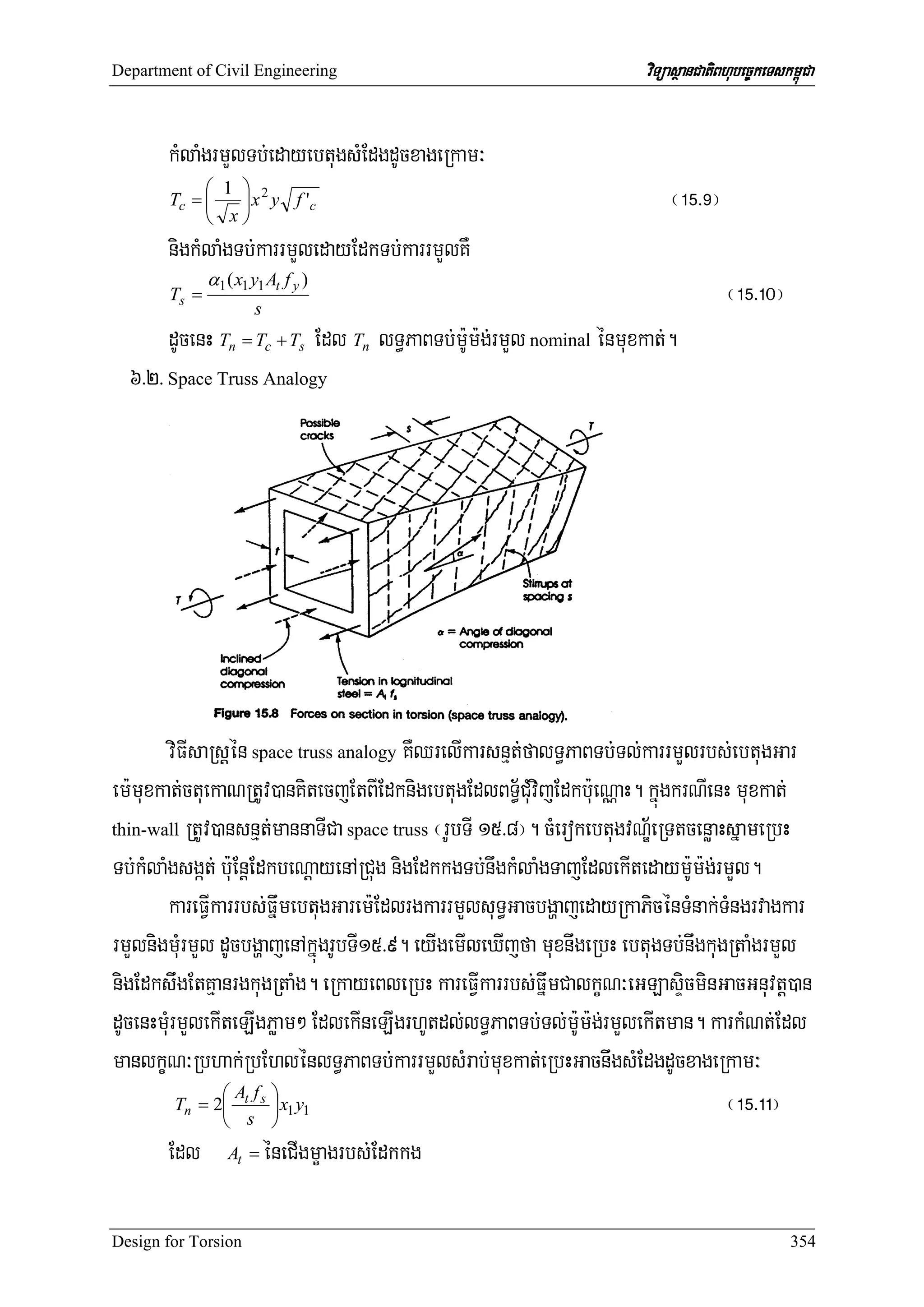

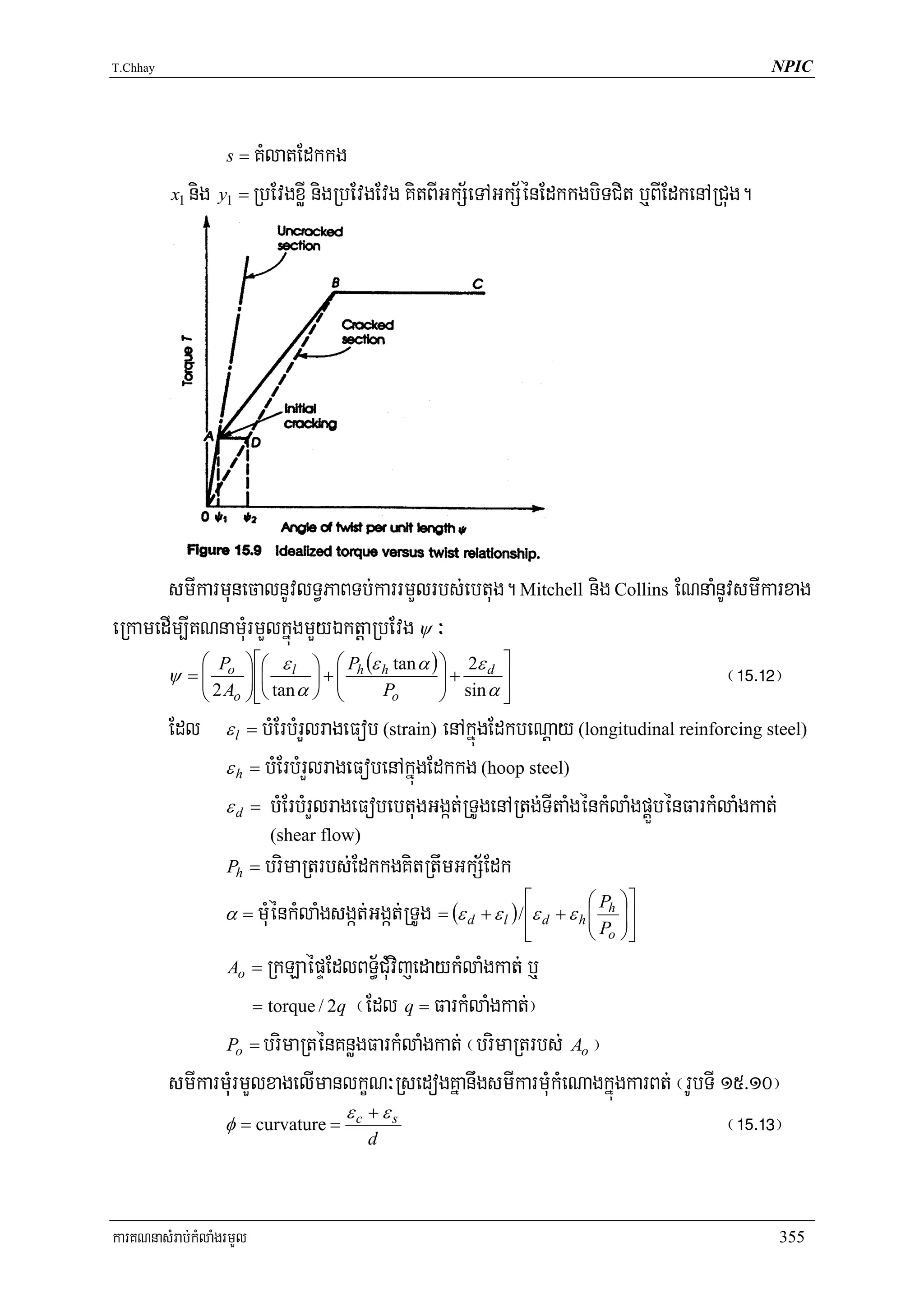

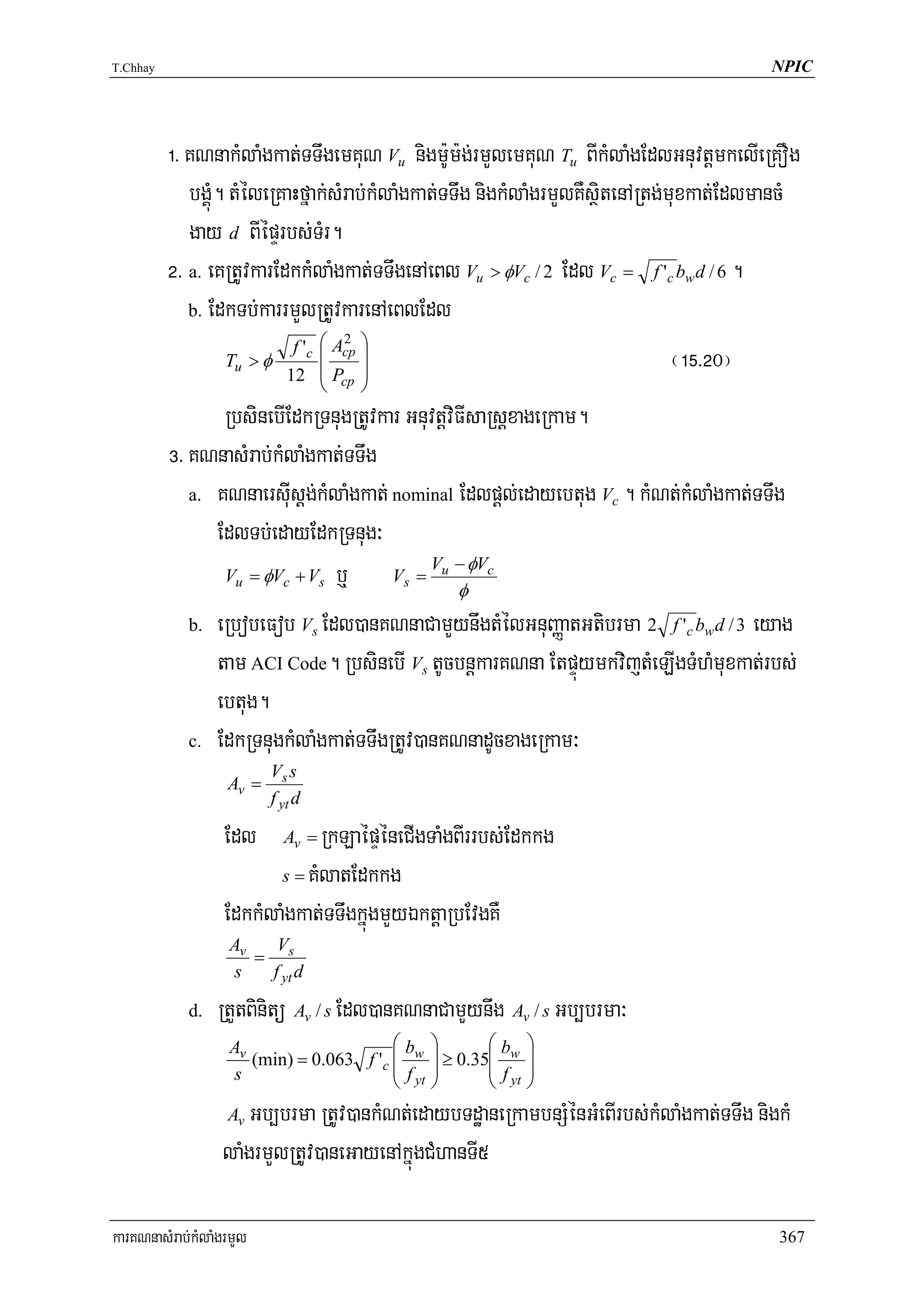

1. The document discusses torsional moments in beams. It introduces torsion and provides equations to calculate the torsional moment (T) in beams.

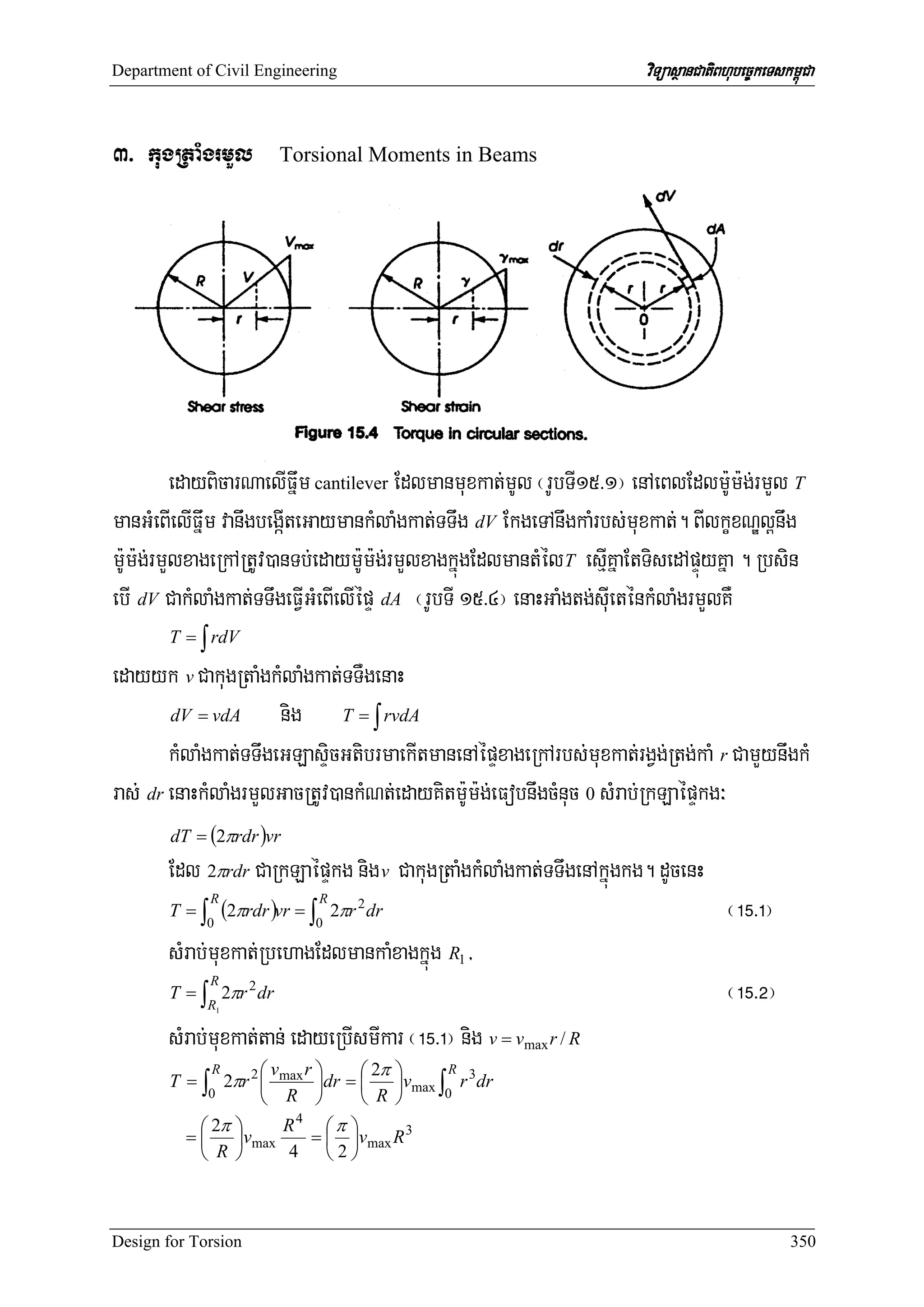

2. Formulas are given to calculate T based on the shear force (V) distribution in different beam sections like rectangular and circular. The maximum shear stress (vmax) is calculated from T.

3. For rectangular sections, a modification factor (α) is used to calculate vmax based on the ratio of y/x dimensions. For typical beam sections, α ranges from 0.2 to 0.3.

![T.Chhay NPIC

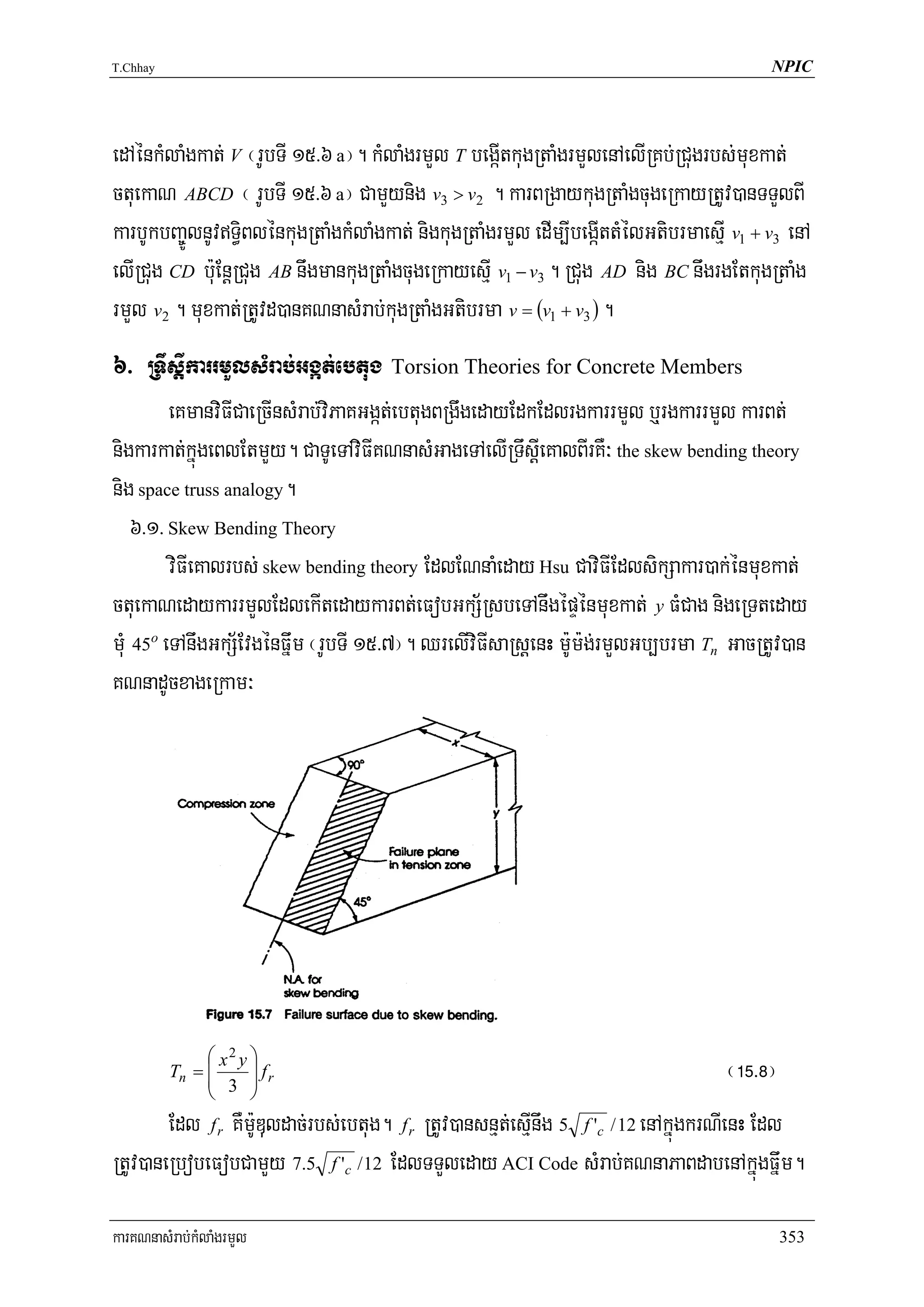

Ggát;eRKOgbgÁúMGacrgnUvEtkMlaMgrmYlsuT§ b¤enAkñúgkrNICaeRcIn vargCamYyKñakñúgeBlEtmYy

nUvkMlaMgkat;TTwg nigm:Um:g;Bt;. ]TahrN_TI15>1 bgðajBIkMlaMgepSg²EdlGacGnuvtþmkelImuxkat;

epSgKñaénFñwm cantilever.

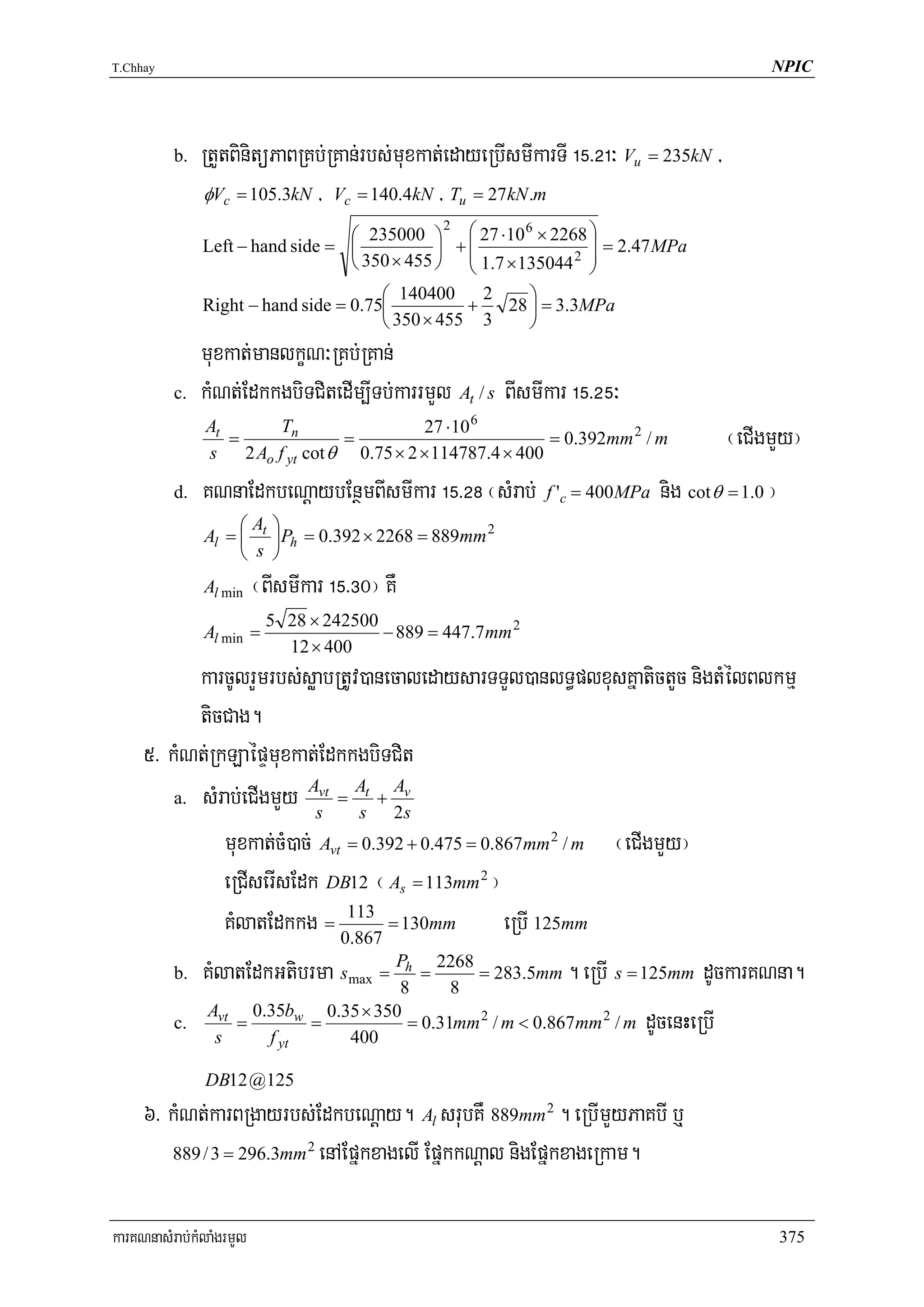

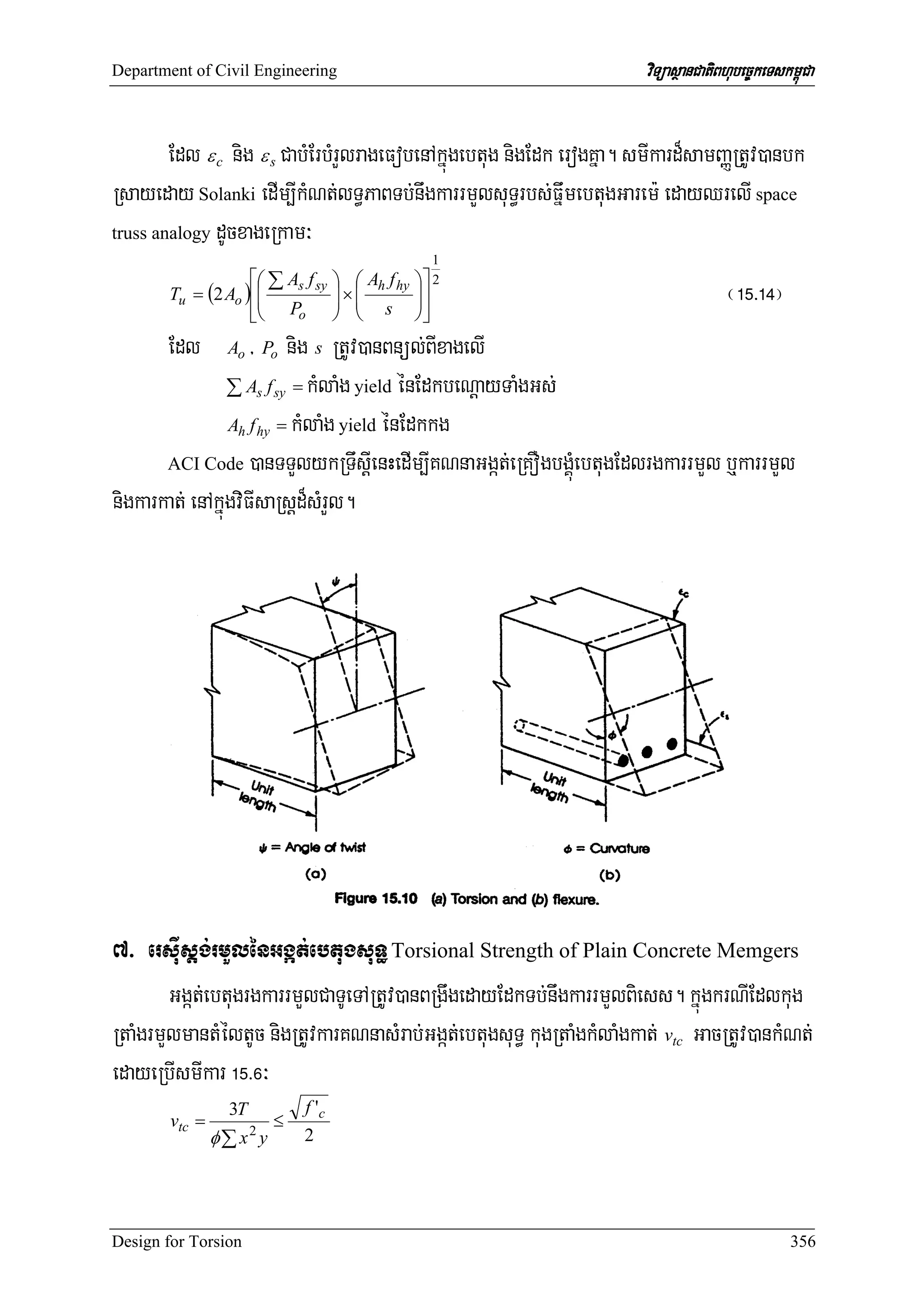

]TahrN_TI15>1³

KNnakMlaMgEdlmanGMeBIenAmuxkat; !/ @ nig # énFñwm cantilever EdlbgðajenAkñúgrUbTI 15>2. Fñwm

rgnUvkMlaMgbBaÄr P1 = 67kN / kMlaMgedk P2 = 53.5kN EdleFVIGMeBIenAcMnuc C nigbnÞúkedk

P3 = 89kN EdlGnuvtþenAcMnuc B nigEkgeTAnwgTisedArbs;kMlaMg P2 .

dMeNaHRsay³

yk N = kMlaMgEkg (normal force)/ V = kMlaMgkat; (shear force)/ M = m:Um:g;Bt; (bending

moment)/ T =m:Um:g;rmYl (torsional moment). kMlaMgTaMgGs;RtUv)anbgðajenAkñúgtaragxageRkam³

muxkat; N (kN ) M x (kN .m) M y (kN .m) V x (kN ) V y (kN ) T (kN .m)

! 0 − 180.9 144.45 53.5 67 0

@ − 53.5 ¬sgát;¦ 0 144.45 89 67 180.9

# − 53.5 ¬sgát;¦ 241.2 464.85 89 67 180.9

karKNnasMrab;kMlaMgrmYl 347](https://image.slidesharecdn.com/xvdesignfortorsion-100715083444-phpapp01/75/Xv-design-for-torsion-2-2048.jpg)

![Department of Civil Engineering viTüasßanCatiBhubec©keTskm<úCa

f 'c ⎛ Acp ⎞

2

Tu ≤ φ

12

⎜ ⎟=T

⎜ Pcp ⎟ a ¬!%>@0¦

⎝ ⎠

enAeBlEdl Tu FMCagtMélenAkñúgsmIkar !%>@0 Tu TaMgGs;RtUv)anTb;edayEdkkgbiTCit

nigEdkbeNþay. m:Um:g;rmYl Tu RtUv)anKNnaBImuxkat;EdlmanTItaMgRtg;cMgay d BIépÞénTMr nig

Tu = φTn Edl φ = 0.75 .

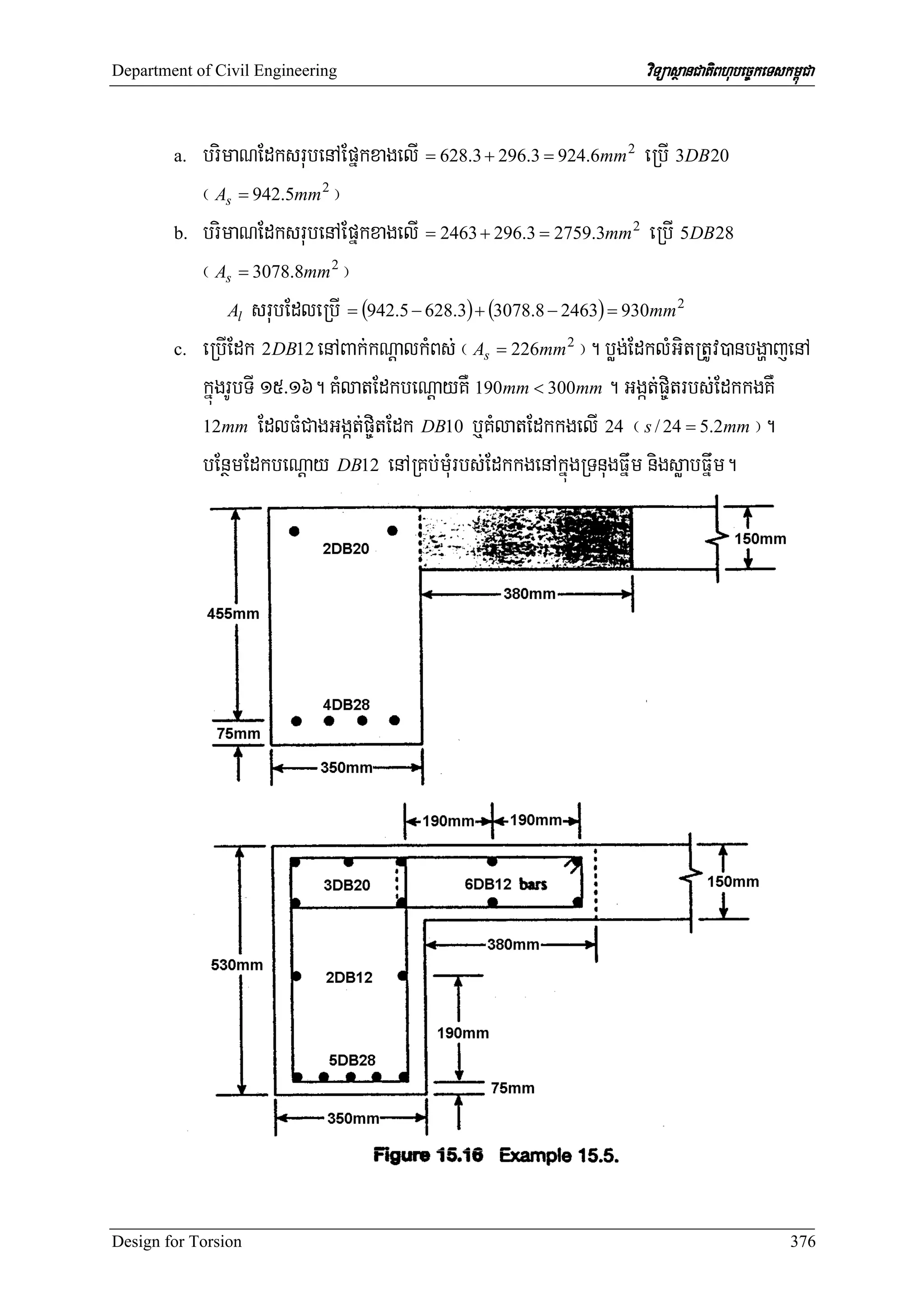

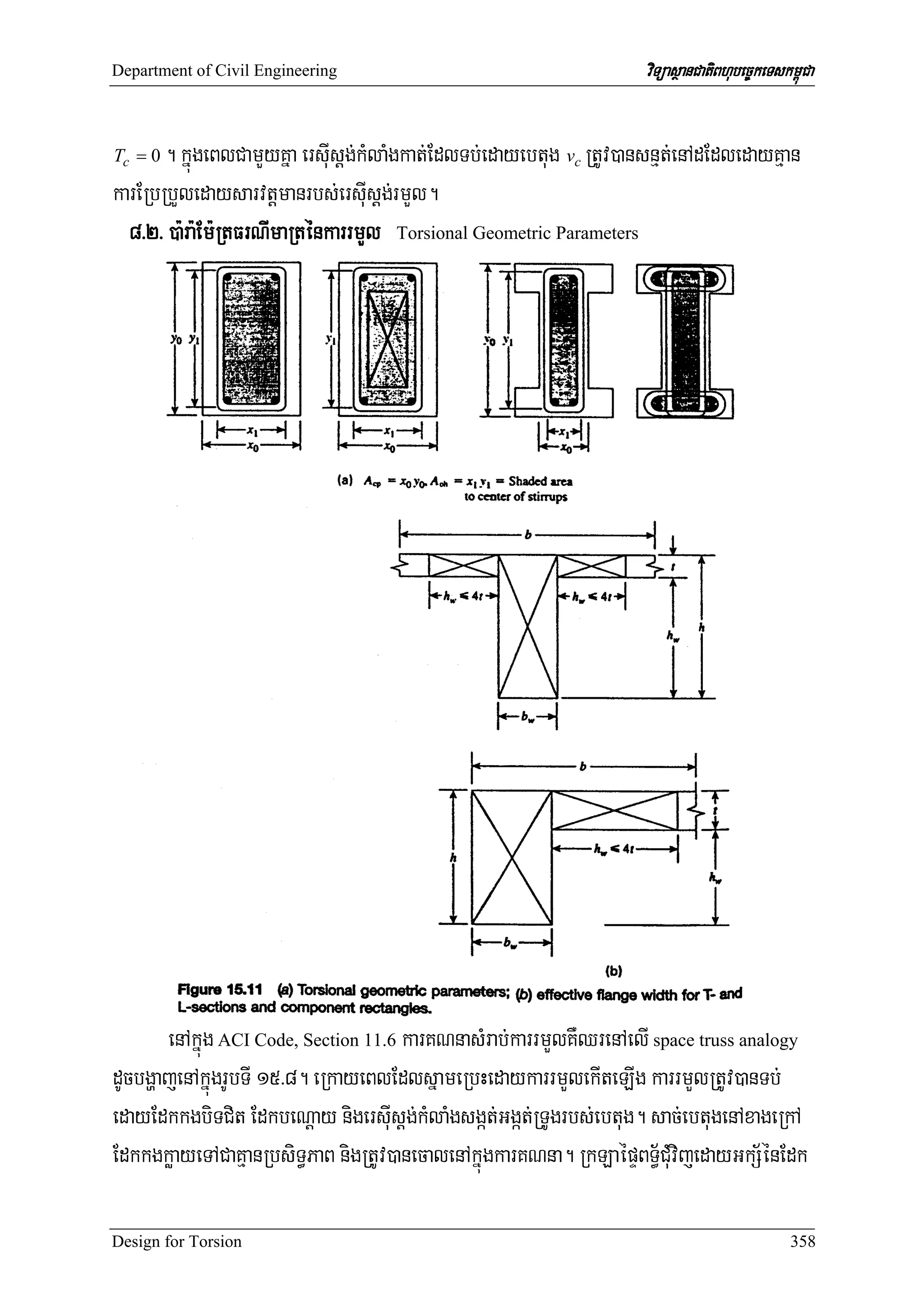

]TahrN_TI15>1³

sMrab;muxkat;bIEdlbgðajenAkñúgrUbTI 15>12 nigQrelIkarkMNt; ACI Code cUrkMNt;

a. m:Um:g;eFVIeGayeRbH φTcr

b. m:Um:g;rmYlemKuNGtibrma φTn EdlGacGnuvtþelImuxkat;nImYy²edaymineRbIEdkRTnugTb;kar

rmYl.

snμt; f 'c = 28MPa / f y = 400MPa / kMras;ebtugkarBarEdk 40mm nigeRbIEdkkg DB12 .

dMeNaHRsay³

1> muxkat; !

a. mU:m:g;eFVIeGayeRbH φTcr GacRtUv)anKNnaBIsmIkar !%>!(

f 'c ⎛ Acp ⎞

2

φTcr = φ ⎜ ⎟

3 ⎜ Pcp ⎟

⎝ ⎠

Design for Torsion 360](https://image.slidesharecdn.com/xvdesignfortorsion-100715083444-phpapp01/75/Xv-design-for-torsion-15-2048.jpg)

![Department of Civil Engineering viTüasßanCatiBhubec©keTskm<úCa

a. snμt;søabRtUv)andak;EdkkgbiTCit RbEcgRbsiT§PaBesμInwg

hw = 370mm < 4 ×150 = 600mm

Acp = 350 × 520 + 370 ×150 = 237500mm 2

Pcp = 2(b + h) = 2(350 + 370 + 520) = 2480mm

28 ⎛ 237500 2 ⎞

⎜ ⎟ = 30kN .m

φTcr = 0.75

3 ⎜ 2480 ⎟

⎝ ⎠

cMNaM³ RbsinebIsøabRtUv)anecal enaH

Acp = 350 × 520 = 182000mm 2

Pcp = 2(350 + 520) = 1740mm

φTcr = 25.2kN .m

b. φTn GnuBaØat φTn = φTcr = 30 = 7.5kN.m

4 4

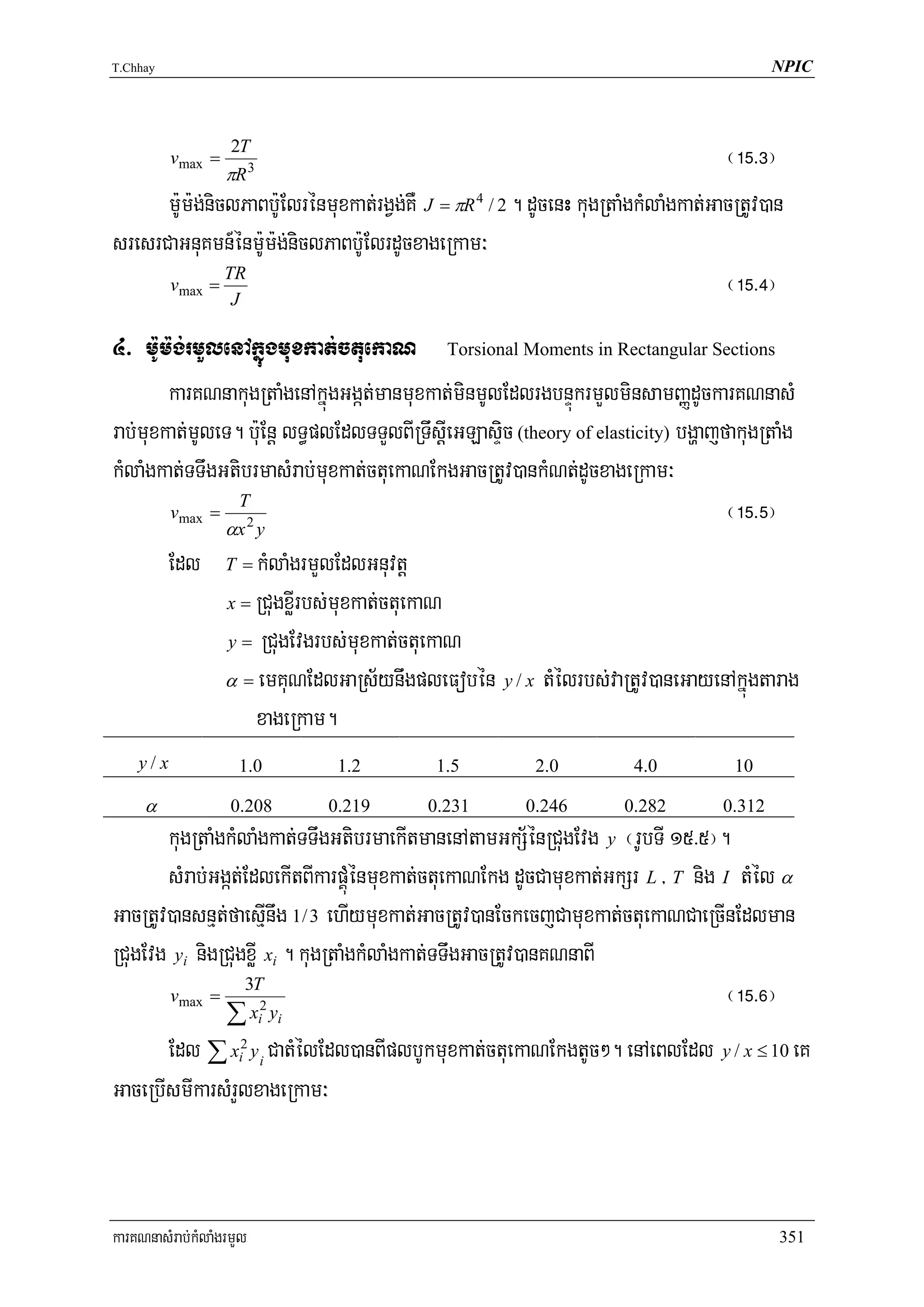

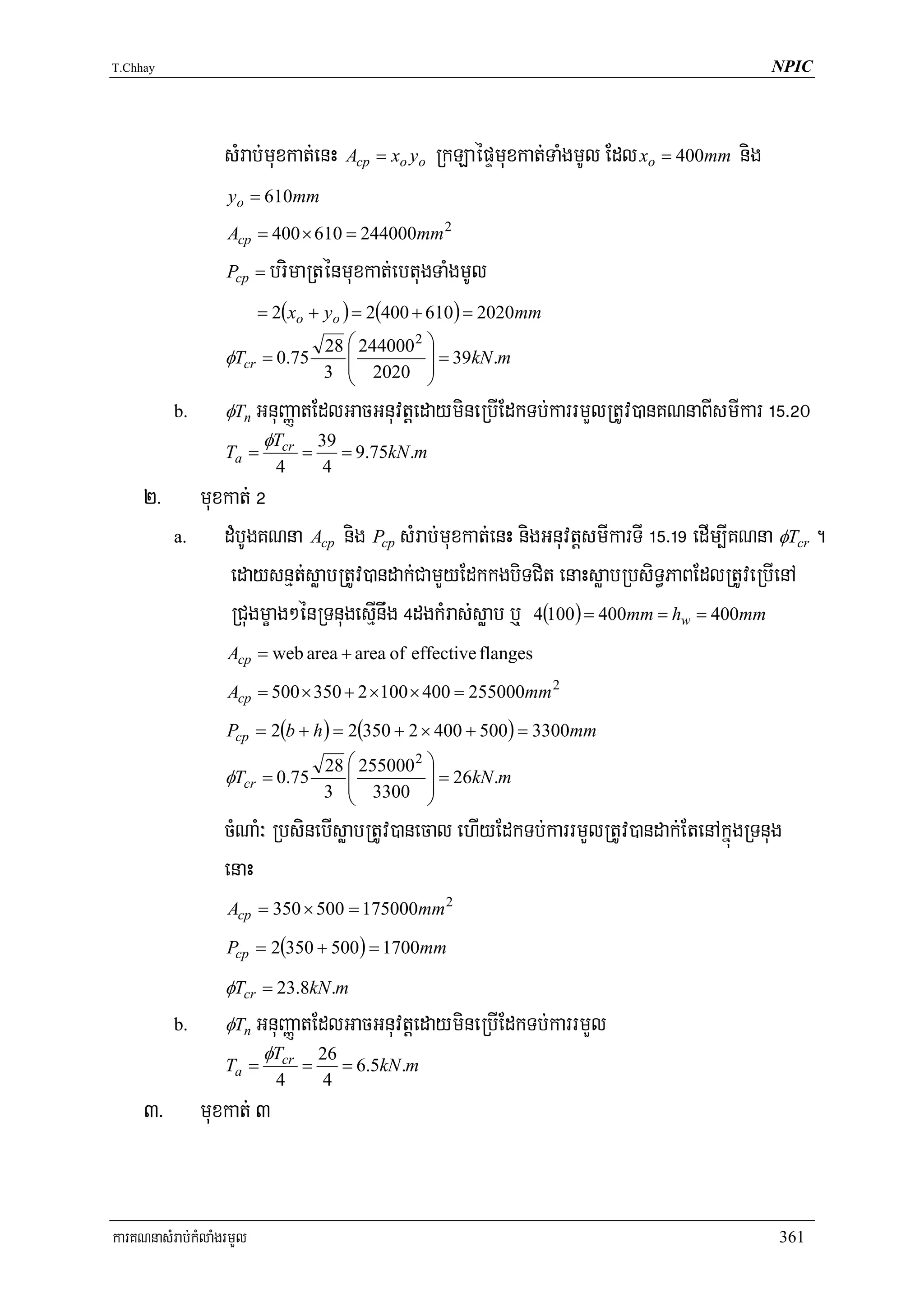

8>4> m:Um:g;rmYllMnwg nwgm:Um:g;rmYlRtUvKña Equilibrium Torsion and Compatibility Torsion

kñúgkarviPaKeRKOgbgÁáúMGgát;ebtug kMlaMgepSg²EdlGnuvtþrYmman kMlaMgEkg (normal force)/

m:Um:g;Bt; (bending moment)/ kMlaMgkat; (shear force) nigm:Um:g;rmYl Edl)anBnül;enAkñúg]TahrN_

TI 15>1. karKNnaGgát;ebtugGarem:KWQrelIkar)ak;rbs;Ggát;GMeBIrbs;bnÞúkemKuN. sMrab;Ggát;sþa

TicminkMNt; (statically indeterminate member) karEbgEckm:Um:g;mþgeTot (redistribution of

moments) ekItmanmuneBl)ak; dUcenHm:Um:g;KNnaGacnwgRtUv)ankat;bnßy b:uEnþ sMrab;Ggát;sþaTickM

Nt; (statically determinate member) dUcCaFñwmsamBaØ (simple beam) b¤Fñwm cantilever Kμankar

EbgEckm:Um:g;mþgeTotekIteLIgeT.

enAkñúgkarKNnaGgát;Edlrgm:Um:g;rmYl eKmanBIrkrNIEdlGacGnuvtþbnÞab;BIkareRbH.

!> krNIm:Um:g;rmYllMnwg (equilibrium torsion case) ekItmanenAeBlm:Um:g;rmYlEdlRtUvkar

sMrab;eRKOgbgÁúMsßitkñúgsßanPaBlMnwg ehIy Tu minGacRtUv)ankat;bnßyedaykarEbg

EckeLIgvijrbs;m:Um:g;eT dUckrNIFñwmTMrsamBaØ. kñúgkrNIenHEdkTb;rmYlRtUv)andak;

edIm,ITb;RKb; Tu . rUbTI 15>13 FñwmEdlenAEKmRTkMralxNн cantilever EdlKμankar

EbgEckm:Um:g;mþgeTotekItman.

@> krNIm:Um:g;rmYlRtUvKña (compatibility torsion case) ekItmanenAeBlm:Um:g;rmYl Tu Gac

RtUv)ankat;bnßyedaykarEbgEckkMlaMgkñúgmþgeTotbnÞab;BIeRbH enAeBlEdlPaBRtUvKña

Design for Torsion 362](https://image.slidesharecdn.com/xvdesignfortorsion-100715083444-phpapp01/75/Xv-design-for-torsion-17-2048.jpg)

![T.Chhay NPIC

énkMhUcRTg;RTay (compatibility of deformation) RtUv)anrkSa enAkñúgGgát;eRKOgbgÁúM.

rUbTI 15>14 bgðajBI]TahrN_sMrab;krNIenH EdlFñwmTTwgBIrmanGMeBIelIFñwmEKmbegáIt

m:Um:g;rmYl. mMurmYlFMekItman enAeBlsñameRbHedaykarrmYlelcecj Edlpþl;nUvkar

bgEckbnÞúkd¾FMenAkñúgeRKOgbgÁúM. vanwgeTAdl;m:Um:g;rmYlEdleFVIeGayeRbH Tcr eRkamGM

eBIénbnSM karBt; karkat; nigkarrmYl enAeBlEdlkugRtaMgem (principle stress) mantM

élRbEhl f 'c / 3 . enAeBlEdl Tu > Tcr m:Um:g;rmYlesμInwg Tcr ¬smIkar !%>!(¦

EdlGacsnμt;ekItmanenARtg;muxkat;eRKaHfñak;enACitépÞénTMr.

ACI Code kMNt;m:Um:g;rmYlKNnaesμInwgtMéltUcCageKén Tu Edl)anBIbnÞúkemKuN b¤ φTcr

BIsmIkar !%>!(.

8>5> karkMNt;énersIusþg;m:Um:g;rmYl Limitation of Tortional Moment Strength

ACI Code,Section 11.6.3 kMNt;TMhMmuxkat;edaysmIkarxageRkamBIr³

!> sMrab;muxkat;tan;

karKNnasMrab;kMlaMgrmYl 363](https://image.slidesharecdn.com/xvdesignfortorsion-100715083444-phpapp01/75/Xv-design-for-torsion-18-2048.jpg)

![T.Chhay NPIC

sMrab; θ = 45o nig f yt = 400MPa enaH Al = ( At / s )Ph ¬!%>@*¦

EdkbeNþayTb;karrmYlKYrmanGgát;p©ity:agticesμIKMlatEdkkgelI 24 b¤ s / 24 b:uEnþ

minRtUvtUcCag DB10 . EdkbeNþayRtUvdak;enAkñúgEdkkgbiTCitCamYyKMlatGtibrma

esμI 300mm . y:agehaceKRtUvdak;EdkmYyedImenARKb;mMurbs;Edkkg. CaTUeTAmYy

PaKbIén Edk Al RtUv)anbEnßmeTAelIEdkTaj mYyPaKbIenABak;kNþalkMBs;rbs; mux

kat; nigmYyPaKbIeTotenAEpñksgát;.

%> kMNt;RkLaépÞsrubénEdkkgbiTCitEdlbNþalBI Vu nig Tu .

Avt = ( Av + 2 At ) ≥

0.35bw s

f

¬!%>@(¦

yt

eRCIserIsEdkkgbiTCitsmrmüCamYyKMlat s EdlmantMéltUcCageKkñúgcMeNam 300mm

nig Ph / 8 .

EdkkgKYrRtUv)andak;enAcMgay (bt + d ) eRkaycMnucEdlRTwsþIRtUvkar Edl bt = TTwgén

muxkat;EdlTb;nwgkMlaMgrmYl.

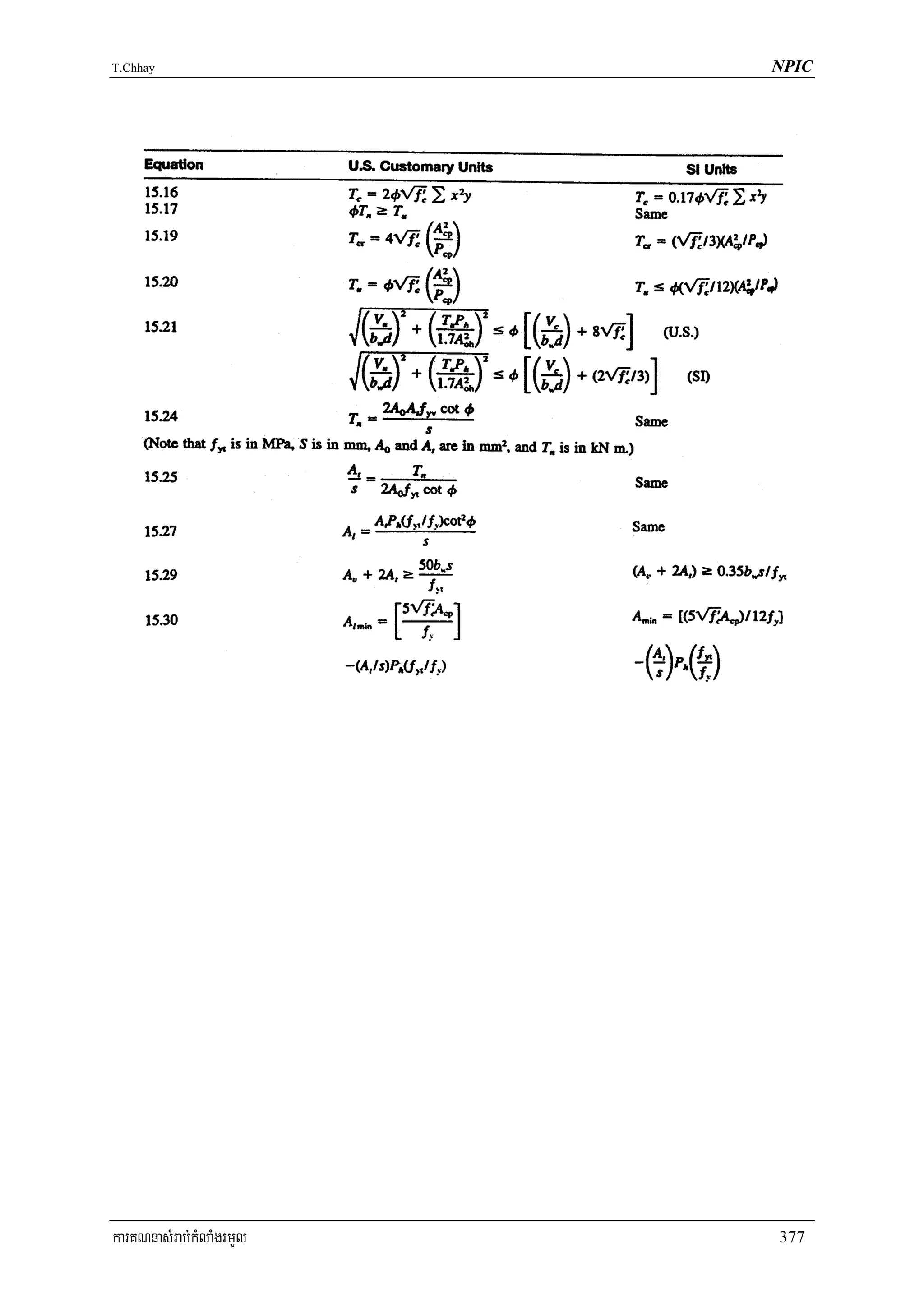

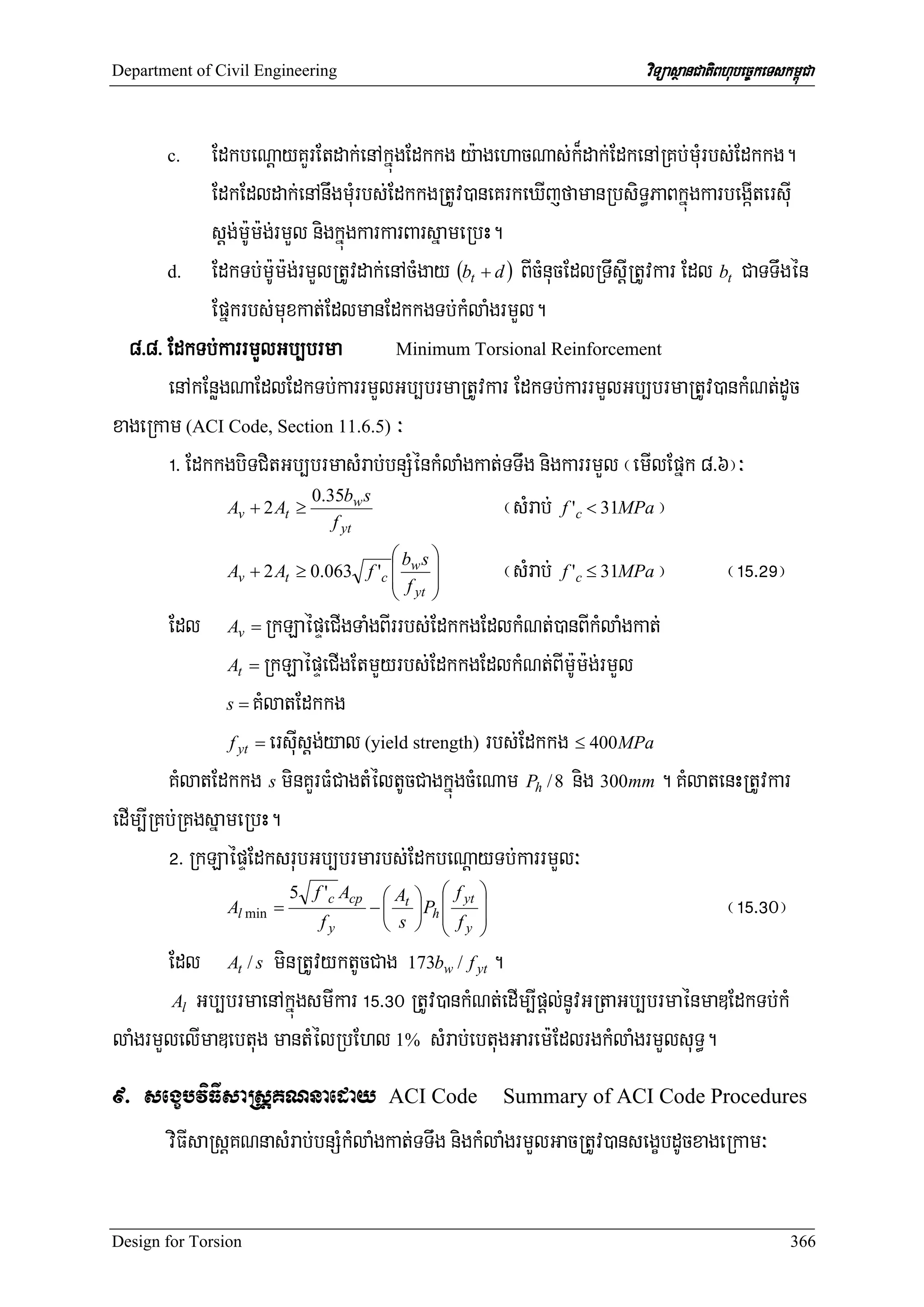

]TahrN_15>3³ (Equilibrium Torsion)

kMNt;brimaNEdkRTnugcaM)ac;sMrab;muxkat;ctuekaNEkgdUcbgðajenAkñúgrUbTI 15>15. muxkat;rgnUvkM

laMgkat;emKuN Vu = 213.5kN nigkMlaMgrmYllMnwg (equilibrium torsion) Tu = 41kN .m enATItaMg

EdlmancMgay d BIépÞénTMr. eKeGay f 'c = 28MPa nig f y = 400MPa .

karKNnasMrab;kMlaMgrmYl 369](https://image.slidesharecdn.com/xvdesignfortorsion-100715083444-phpapp01/75/Xv-design-for-torsion-24-2048.jpg)

![Department of Civil Engineering viTüasßanCatiBhubec©keTskm<úCa

5 28 (232000)

Al (min) = − (0.535)(1592) = 427mm 2

12 × 400

Al = 851.72mm 2 lb;

5> kMNt;RkLaépÞEdkkgsrub

a. sMrab;eCIgmYyrbs;Edkkg

Avt At Av

= +

s s 2s

EdkkgEdlcaM)ac; Avt = 0.535 + 0.25 = 0.785mm 2 / m ¬eCIgmYy¦

eRbIEdk DB12 RkLaépÞmuxkat;rbs;EdkkgsMrab;eCIgmYyKW 113mm 2

= 144mm yk 140mm

113

spacing of stirrups =

0.785

b. KMlatGtibrma s = h = = 199mm b¤ 300mm mYyNaEdltUcCag.

P 1592

8 8

KMlatEdleRbIKW 140mm < 199mm

0.35bw 0.35 × 400

c. Avt / s Gb,brma = = = 0.35mm 2 / m < 0.785mm 2 / m

f yt 400

6> edIm,IrkkarBRgayEdkbeNþay cMNaMfa Al srub = 851.72mm 2 . eRbImYyPaKbIenAEpñkxag

elI b¤ 851.72 / 3 = 283.9mm 2 edIm,IbEnßmenAkñúgEdkrgkarsgát; A's . eRbImYyPaKbIdak;enA

EpñkxageRkam edIm,IbEnßmBIelIEdkrgkarTaj nigEdkmYyPaKbIeTotdak;enAkMBs;Bak;kNþal.

a. RkLaépÞEdksrubenAEpñkxagelIesμI 226 + 283.9 = 509.9mm 2 . eRbI 3DB16

¬ As = 603mm 2 ¦

b. RkLaépÞEdksrubenAEpñkxageRkamesμI 3078.8 + 283.9 = 3362.7 mm 2 . eRbI 3DB 28

nig 2DB32 enARCugmMu ¬ As srub = 3455.8mm 2 ¦

Al srubEdleRbI = (603 − 226 ) + (3455.8 − 3078.8) = 754mm 2

c. enAkMBs;Bak;kNþal eRbIEdk 2DB12 ¬ As = 226mm 2 ¦

bøg;srésEdklMGitRtUv)anbgðajenAkñúgrUbTI 15>15. KMlatEdkbeNþayesμInwg

230mm EdltUcCagKMlatEdkGtibrmaEdlRtUvkar 300mm 2 . Ggát;p©itEdkkg DB12 Edl

eRbIFMCagGgát;p©itGb,brma DB10 b¤KMlatEdkkgelI 24 ¬ s / 24 = 5.8mm ¦.

]TahrN_15>4³ (Compatibility Torsion)

edaHRsay]TahrN_TI 15>3 eLIgvij RbsinebIkMlaMgrmYlemKuNCa compatibility torsion.

dMeNaHRsay³

Design for Torsion 372](https://image.slidesharecdn.com/xvdesignfortorsion-100715083444-phpapp01/75/Xv-design-for-torsion-27-2048.jpg)

![T.Chhay NPIC

eyagtamdMeNaHRsaykñúg]TahrNITI 15>3

!> kMlaMgKNnaKW V u = 213.5kN nig compatibility torsion Tu = 41kN .m

@> CMhan (a) nig (b) dUcKñaenAkñúg]TahrN_TI 15>3. eKRtUvkarEdkRTnug.

#> CMhan (c) KWdUcKña.

$> KNnasMrab;kMlaMgrmYl³

edaysar compatibility torsion Tu = 41kN .m enaH Tu KNnaRtUvtUvCag 41kN .m b¤ φTcr

RtUv)aneGayenAkñúgsmIkar !%>!(

f 'c ⎛ Acp ⎞ 0.75 28 ⎛ 232000 2 ⎞ − 6

2

φTcr = φ ⎜ ⎟= ⎜ ⎟ ⋅10 = 38.7 kN .m

3 ⎜ Pcp ⎟ 3 ⎜ 1840 ⎟

⎝ ⎠ ⎝ ⎠

edaysarEt φTcr < Tu / eRbI Tu = 38.7kN .m . GnuvtþeLIgvijRKb;CMhanenAkñúg]TahrN_TI

15>3 edayeRbI Tu = 38.7kN .m edIm,IkMNt;famuxkat;RKb;RKan;.

At

s

= 0.5mm 2 / m ¬eCIgmYy¦

Al = 0.5 × 1592 = 796mm 2

eRbI Al = 852mm 2 > Al (min)

%> Avt caM)ac; = 025 + 0.5 = 0.75mm 2 / m ¬eCIgmYy¦

.

113

s= = 150.6mm

0.75

eRbI 150mm . eRCIserIsEdkbeNþay nigEdkkgdUckñúg]TahrN_TI 15>3.

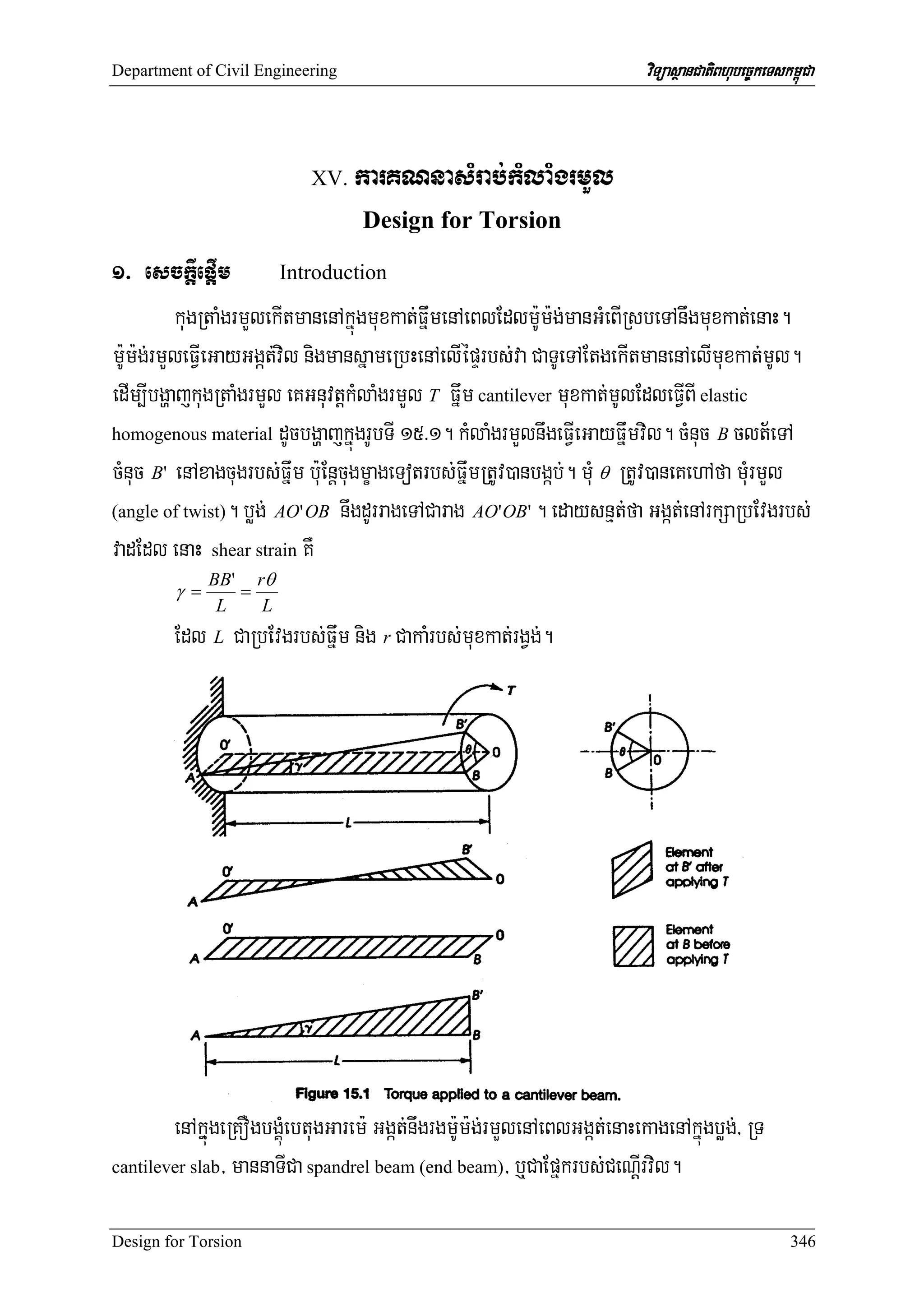

]TahrN_15>5³ (L-section with Equilibrium Torsion)

FñwmxagénRbBn§½kMralxNнrbs;GKardUcbgðajenAkñúgrUbTI 15>16. muxkat;enAcMgay d BIépÞénTMrrg

nUv Vu = 235kN nig equilibrium torque Tu = 27kN .m . KNnaEdkRTnugcaM)ac;edayeRbI

f 'c = 28MPa nig f y = 400MPa sMrab;RKb;EdkEdleRbIenAkñúgFñwm.

dMeNaHRsay³

1> kMlaMgKNnaKW Vu = 235kN nig Tu = 27kN .m

2> a. EdkTb;kMlaMgkat;RtUvkarenAeBl Vu > φVc / 2

φ f 'c 0.75 28

φVc = bw d = 350 × 455 ⋅10 − 3 = 105.3kN

6 6

φVc

Vu > = 52.65kN

2

karKNnasMrab;kMlaMgrmYl 373](https://image.slidesharecdn.com/xvdesignfortorsion-100715083444-phpapp01/75/Xv-design-for-torsion-28-2048.jpg)