1) Plastic analysis was performed using the lower-bound theorem and equilibrium method to determine the collapse load of a W30x99 beam with continuous lateral support.

2) The working load was first determined by calculating the yield moment My. Once yielding occurred, the plastic moment capacity Mp was used.

3) Equilibrium of internal and external moments was satisfied at the collapse mechanism to determine the ultimate load. The uniqueness theorem confirmed this was the collapse load.

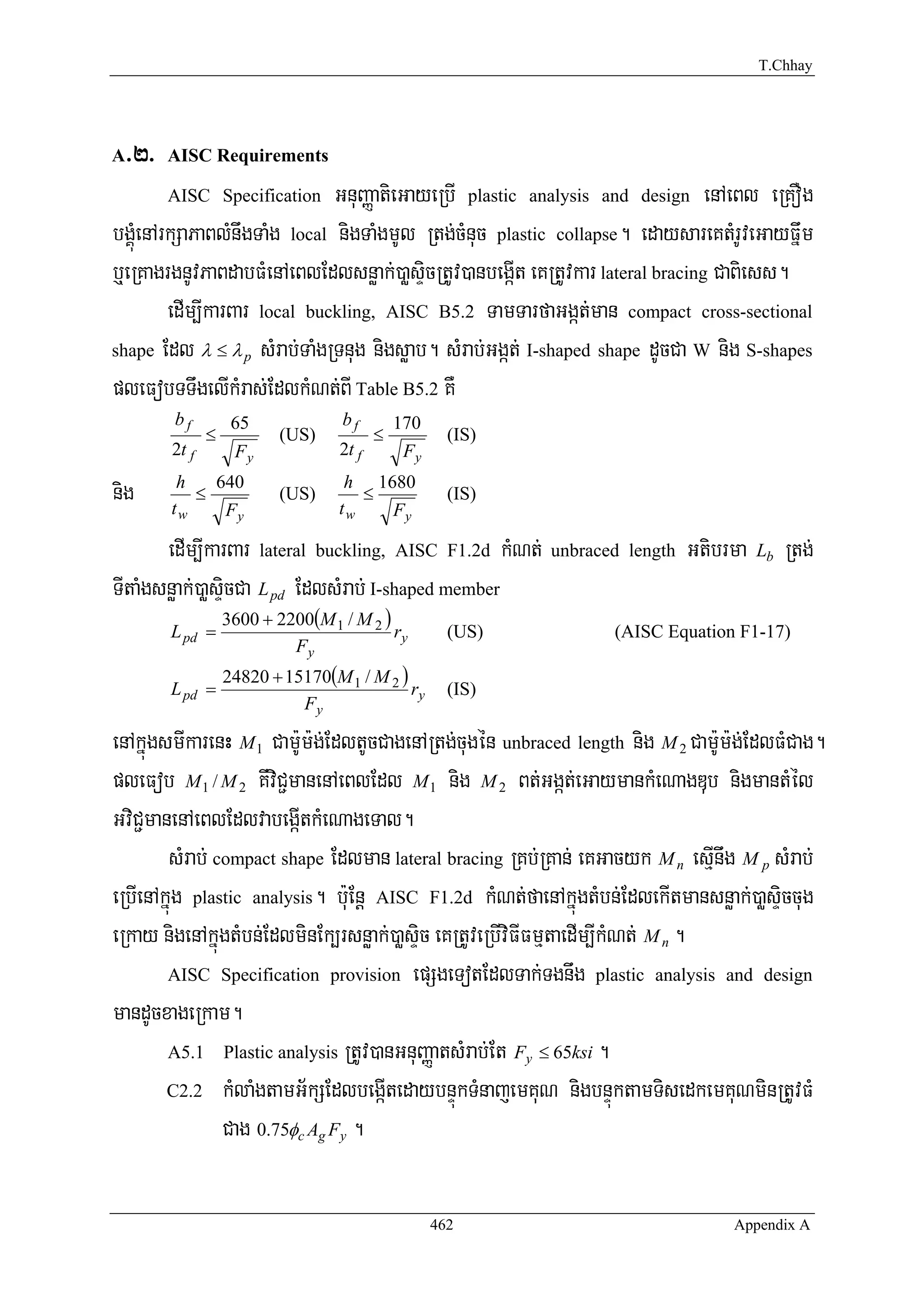

![T.Chhay

bnÞúkEdlRtUvKñaCa collapse load EdlRbsinebI mechanism bMeBjTaMg upper-boud

theorem nig lower-bound theorem vaCa mechanism EdlRtwmRtUv.

karviPaKEdlQrelI lower-bound theorem RtUv)aneKehAfa equilibrium method ehIyRtUv)an

bgðajenAkñúg]TahrN_ A>1.

]TahrN_ A>1³ rkbnÞúkcugeRkay (ultimate load) sMrab;FñwmEdlbgðajenAkñúgrUbTI A>4a eday

equilibrium method rbs; plastic analysis. snμt;eKeRbI continuous lateral support nig EdlRb

ePT A36 .

dMeNaHRsay³ Edk A36 muxkat; W 30 × 99 Ca comapact shape ehIyCamYynwg continuous lateral

support, tMrUvkar lateral bracing KWRKb;RKan; dUcenHeKGacTTYlyk plastic analysis.

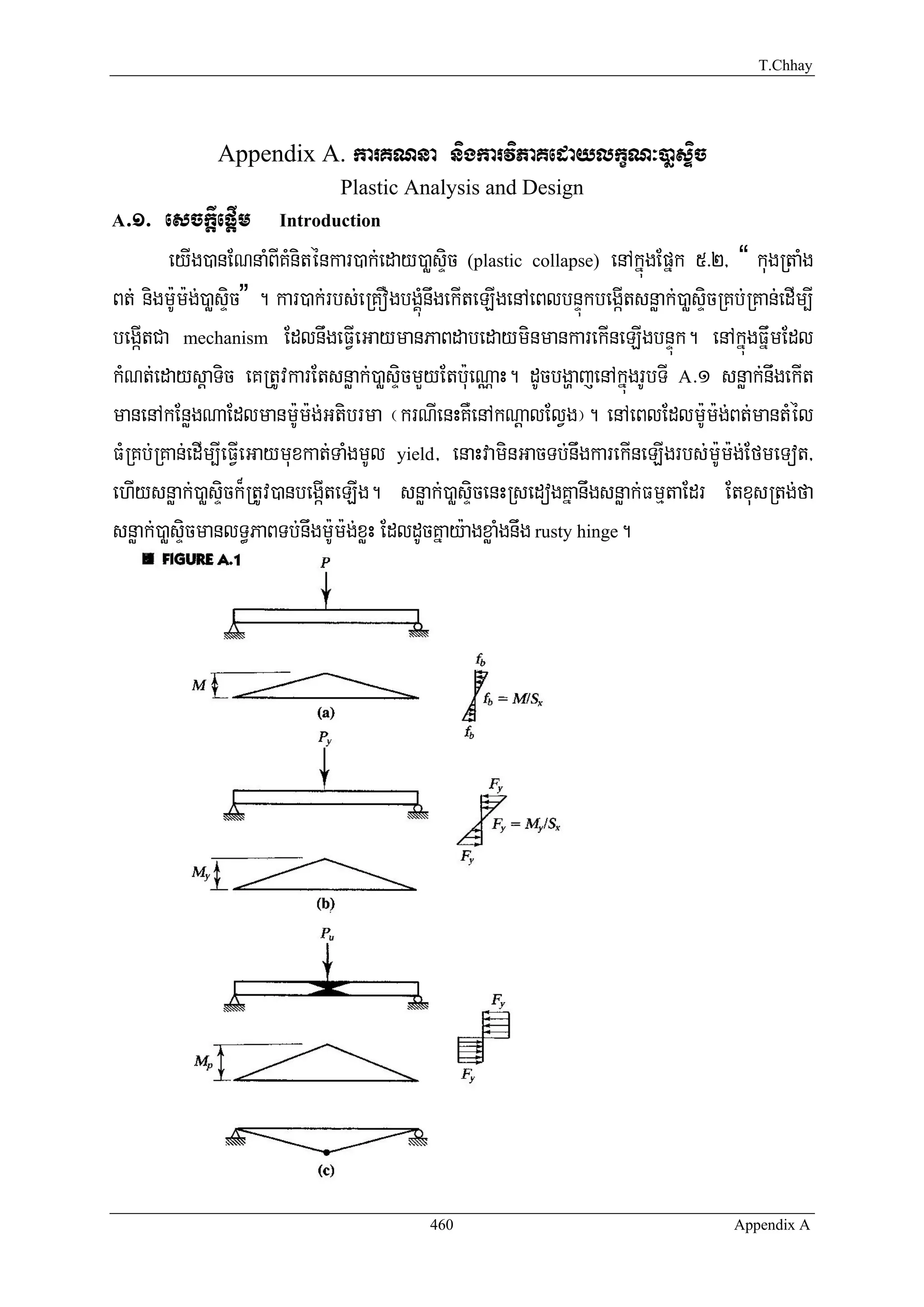

dMNak;karénkardak;bnÞúkelIFñwm BI working load eTAdl; collapse load

RtUv)anKUsbBa¢ak;enAkñúgrUbTI A>4a-d. enAeBl working load muneBl yielding ekIteLIgRKb;TIkEnøg

karEbgEckm:Um:g;Bt;RtUv)anbgðajenAkñúgrUbTI A>4a CamYynwgm:Um:g;GtibrmaEdlekItmanRtg;TMrbgáb;.

enAeBlEdlbnÞúkekIneLIgbnþicmþg² yielding cab;epþImekItmanRtg;TMr enAeBlEdlm:Um:g;Bt;eTAdl;

M y = Fy S x . enAeBlEdlbnÞúkekIneLIgkan;EtFM vanwgekItmansnøak;)aøsÞickñúgeBldMNalKñaenA

Rtg;cugnImYy² enAeBlEdl M p = Fy Z x . enARtg;kMrwténkardak;bnÞúkenH eRKOgbgÁúMenAmanesßrPaB

464 Appendix A](https://image.slidesharecdn.com/appendixaplasticanalysisanddesign-100715205010-phpapp02/75/Appendix-a-plastic-analysis-and-design-5-2048.jpg)

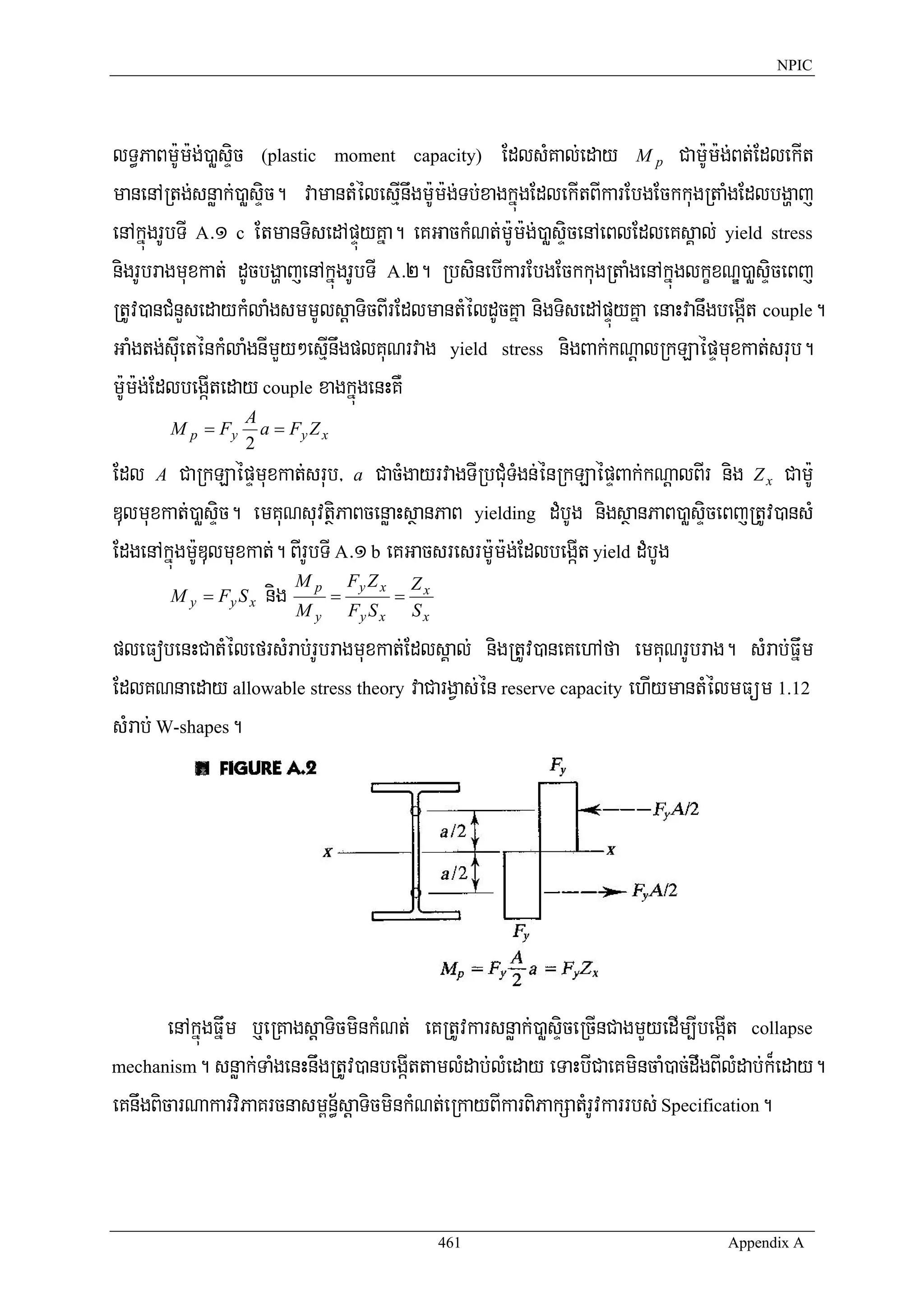

![NPIC

enAeLIy FñwmRtUv)anERbkøayeTACasþaTickMNt;edaykarekItmansnøak;)aøsÞicBIr. Mechanism nwgekIt

anEtenAeBlEdlekItmansnøak;)aøsÞicTIbI. vaGacekItmanenAeBlEdlm:Um:g;viC¢manGtibrmamantMél

M p . edayGaRs½ynwg uniqueness theorem/ bnÞúkEdlRtUvKñaCa collapse load BIeRBaHkarEbgEck

m:Um:g;KWsuvtßiPaB ehIyGacTTYlyk)anedaysþaTic.

enARKb;tMNak;kalénkardak;bnÞúk plbUkénéldac;xaténm:Um:g;viC¢man nigm:Um:g;GviC¢manGti-

brmaKW wL2 / 8 . enAeBl collapse, plbUkenHkøayeTACa

16M p

M p + M p = wu L2 b¤

1

wu =

8 L2

eKRtUvEteRbobeFobbnÞúkemKuNCamYynwgersIusþg;emKuN dUcenHeKeRcIneRbI φb M p Cag M p enAkñúg

smIkarBIxagedIm. b:uEnþedIm,IrkSanimitþsBaØaeGaymanlkçN³samBaØ eyIgeRbI M p enARKb;]TahrN_

TaMgGs;rhUtdl;CMhancugeRkayeTIbeyIgCMnYs φb M p eTAkñúgsmIkar. lT§plEdlRtwmRtUv

sMrab;]TahrN_enHKW

16φb M p

wu =

L2

sMrab; W 30 × 99

36(312 )

M p = Fy Z x = = 936 ft − kips

12

ehIy φb M p = 0.9(936) = 842.4 ft − kips

eKk¾GacTTYltMélrbs; φb M p edaypÞal;BI Load Factor Design Selection Table enAkñúg Part 4 of

the Manual.

16(842.4 )

cemøIy³ w u =

(30)2

= 15.0kips / ft

]TahrN_ A>2³RbsinebIFñwmenAkñúg]TahrN_ A>1 minman continuous lateral support cUrkMNt;TItaMg

EdlRtUvBRgwg.

dMeNaHRsay³ snøak;)aøsÞicenAxagcugekIteLIgkñúgeBldMNalKña ehIymuneBlsnøak;enAkNþalElVg

ekIteLIg. dUcenHeKKYrEtRtYtBinitü unbraced length GtibrmaedayeFobeTAnwgcug ¬snøak;cugeRkay

EdlekIteLIgmintMrUvkar bracing sMrab; plastic analysis eT¦.

465 Appendix A](https://image.slidesharecdn.com/appendixaplasticanalysisanddesign-100715205010-phpapp02/75/Appendix-a-plastic-analysis-and-design-6-2048.jpg)

![T.Chhay

edayeFobnwgsnøak;enAcugxageqVg snμt;facMnucBRgwgKWenAkNþalElVg. kñúgkrNIenH M 1 =

M 2 = M p dUcenHFñwmmankMeNagDub ¬m:Um:g;TaMgBIrmansBaØadUcKña¦ dUcenH M 1 / M 2 = +1 BI AISC

Equation F1-17, unbraced length GtibrmaKW

3600 + 2200(M 1 / M 2 ) 3600 + 2200(1.0)

L pd = ry = (2.10) = 338.3in. = 28.2 ft

Fy 36

cMNaMfa FñwmenHesÞIrEtRKb;RKan;edayminRtUvkar lateral bracing.

CamYynwg lateral mYyTl;enAkNþalElVg

L p = 15 ft < 28.2 ft (OK)

Unbraced length EdlRtUvBicarNarYmKWrYbbBa©ÚlTaMgsnøak;enAkNþalElVg. vaminmantMbn;Edlmin

enACab;nwgsnøak;)aøsÞiceT dUcenHvaminRtUvkarkarKNna design strength eT.

cemøIy³ eRbI lateral brace mYyenAkNþalElVg.

Mechanism method KWQrelI upper-bound theoremnigRtUvakrGegátRKb; collapse

mechanism EdlGacekItman. Collapse mechanism NaEdlRtUvkarbnÞúktUcCageKnwglub eyIy

bnÞúkEdlRtUvKñaCa collapse laod. eKRtUvGnuvtþeKalkarN_rbs; virtual work sMrab;viPaK

mechanism nImYy². Mechanism snμt;RtUvrgnUv virtual displacement RsbeTAtamclnaEdl

GacekItmanrbs; mechanism ehIyeKeGaykmμnþxageRkA nigkmμnþxagkñúgesμIKña. bnÞab;mkeKGacrk

TMnak;TMngrvagbnÞúk niglT§PaBTb;m:Um:g;)aøsÞic M p . bec©keTsenHRtUv)anbgðajenAkñúg]TahrN_

A>3 nig A>4.

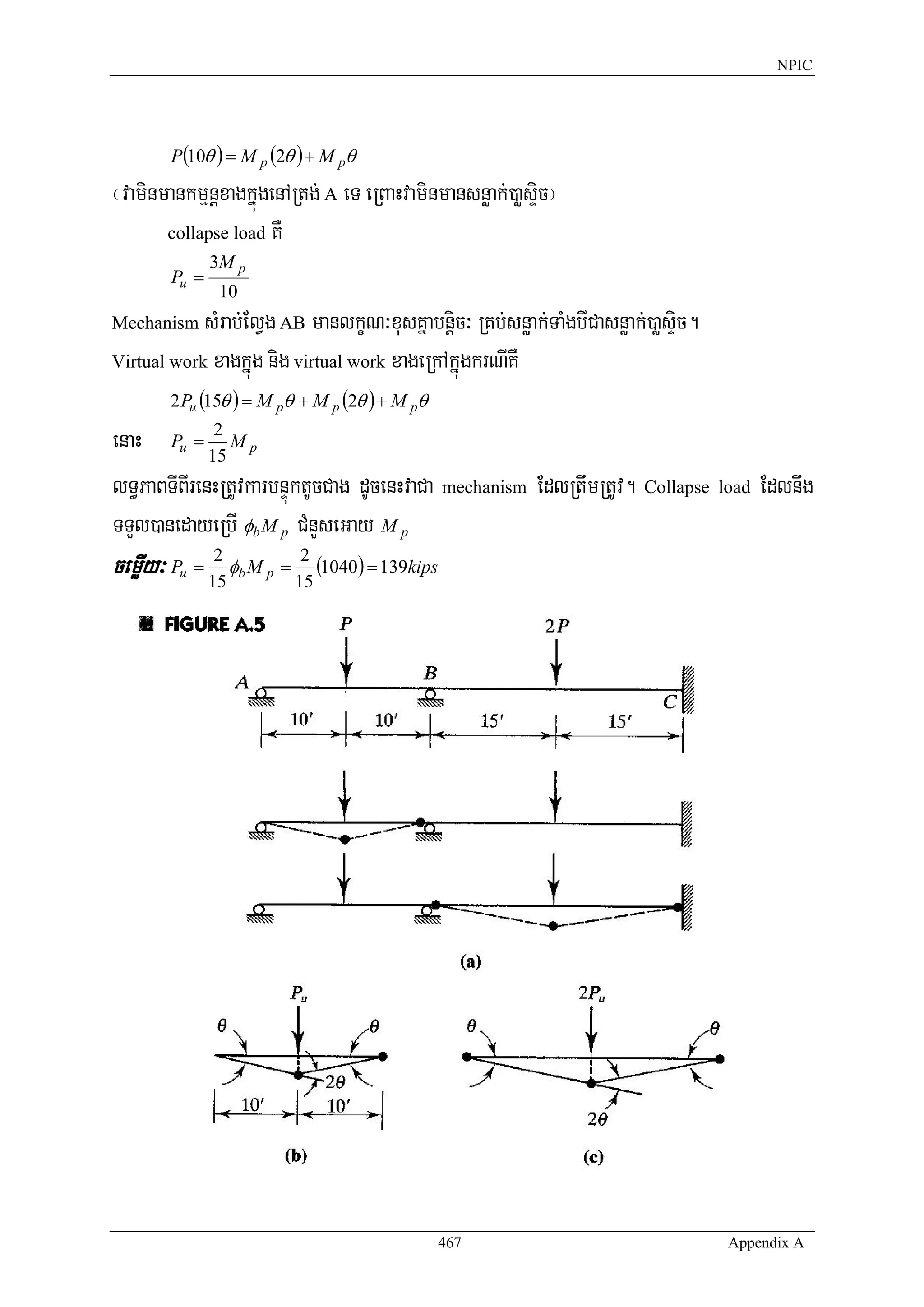

]TahrN_ A>3³ FñwmCab;EdlRtUv)anbgðajenAkñúgrUbTI A>5 man compact cross section Edlman

design strength φb M p = 1040 ft − kips . eRbI mechanism method edIm,Irk collapse load Pu .

snμt; continuous lateral support.

dMeNaHRsay³ eKman failure mechanism sMrab;FñwmenHBIry:ag. dUcEdlbgðajenAkñúgrUbTI A>5

vamanlkçN³RsedogKñaEdlkMNat;Ggát;nImYy²rgnUv rigid-body motion. edIm,IGegát mechanism

enAkñúgElVg AB dak; vitual rotation θ Rtg; A. karvilEdlRtUvKñaenARtg;snøak;)aøsÞicRtUv)anbgðaj

enAkñúgrUbTI A>5b ehIybMlas;TItamTisQrébnÞúkKW 10θ . BIeKalkarN_rbs; virtual work

kmμnþxageRkA = kmμnþxagkñúg

466 Appendix A](https://image.slidesharecdn.com/appendixaplasticanalysisanddesign-100715205010-phpapp02/75/Appendix-a-plastic-analysis-and-design-7-2048.jpg)

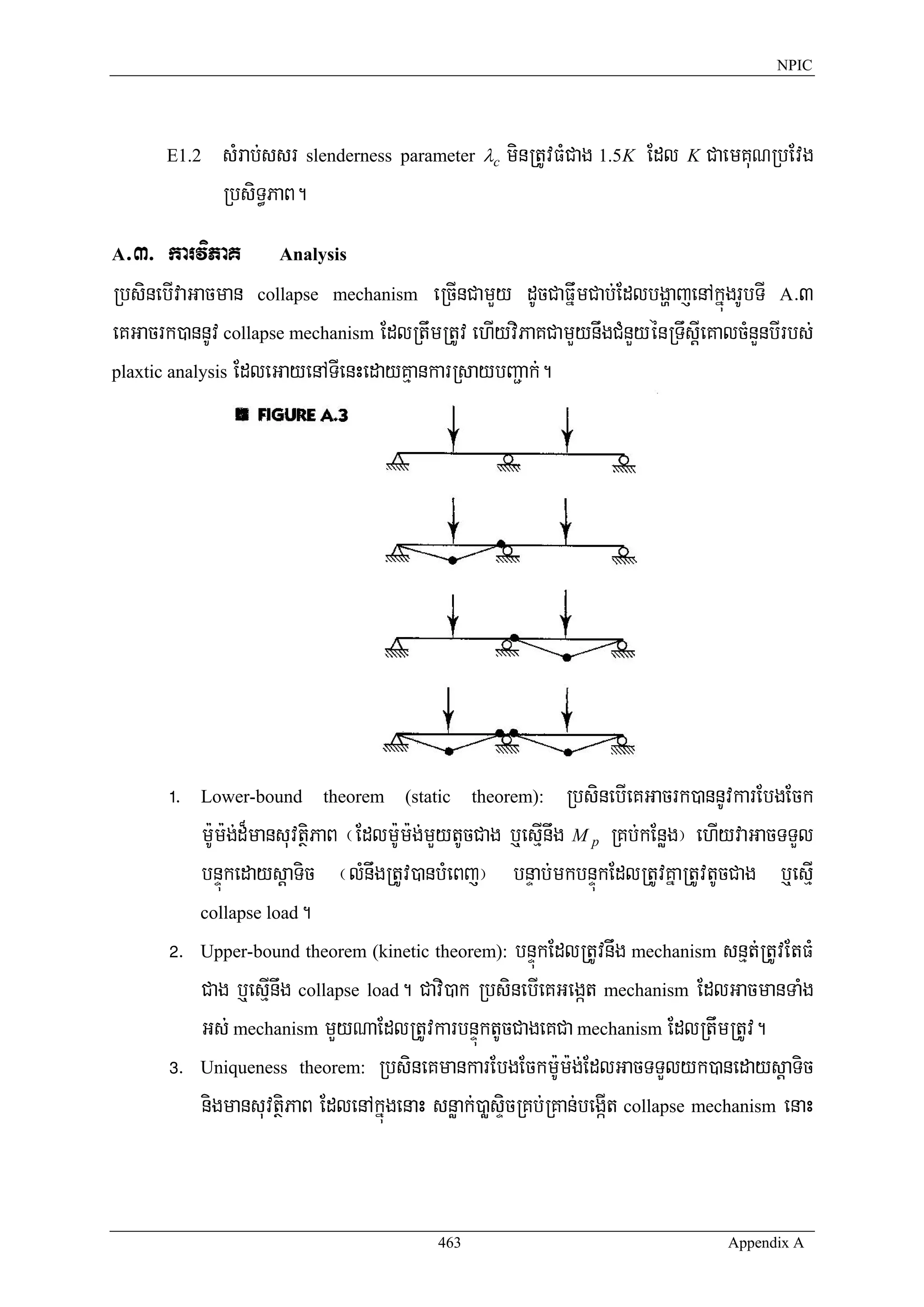

![T.Chhay

]TahrN_ A>4³ kMNt; collapse load P sMrab; rigid frame EdlbgðajenAkñúgrUbTI A>6. Ggát;

u

nImYy²rbs;eRKagKW W 21×147 Edlman Fy = 50ksi . snμt; lateral support Cab;.

dMeNaHRsay³ W 21×147 Ca compact shape sMrab; F y = 50ksi nigman lateral support Cab; dUc

enHvabMeBjlkçxNÐkñúgkareRbIR)as; plastic analysis.

dUcbgðajenAkñúgrUbTI A>6 eKman failure mode cMnYnbIsMrab;eRKagenH³ Fñwm mechanism enA

kñúgGgát; BC / sway mechanism nigmYyeTotCabnSMén mechanism BIrdMbUg. eyIgcab;epþImkarviPaK

mechanism nImYy²edaydak; virtual rotation θ enARtg;snøak;mYy ehIysresrsmIkarCaGnuKmn_

eTAnwgmMuenH.

468 Appendix A](https://image.slidesharecdn.com/appendixaplasticanalysisanddesign-100715205010-phpapp02/75/Appendix-a-plastic-analysis-and-design-9-2048.jpg)

![NPIC

Virtual displacement rbs;Fñwm mechanism RtUv)anbgðajenAkñúgrUbTI A>6 b. BIsmPaBén

kmμnþxageRkA nigkmμnþxagkñúg

⎛5 ⎞ ⎛2 ⎞

Pu (10θ ) = M pθ + M p ⎜ θ ⎟ + M p ⎜ θ ⎟

⎝3 ⎠ ⎝3 ⎠

EdleKeRbI M p CMnYseGay φb M p . edaHRsayrk Pu

Pu = 0.3333M p

RbsinebIeKminKit axial strain enAkñúgGgát; BC / sway mechanism nwgxUcRTg;RTaydUcbgðaj

enAkñúgrUbTI A>6 c CamYynwgbMlas;TItamTisedkdUcKñaRtg; B nig C . Cavi)ak muMrgVilénRKb;snøak;

TaMgGs;KWlkçN³RsedogKña³

Pu (15θ ) = M p (4θ ) b¤ Pu = 0.2667 M p

BIrUbTI A>6d/ eKalkarN_én virtual work sMrab; combined mechanism eGay

⎛5 ⎞ ⎛2 ⎞

Pu (15θ ) + Pu (10θ ) = M pθ + M p ⎜ θ ⎟ + M p ⎜ θ + θ ⎟ + M pθ

⎝3 ⎠ ⎝3 ⎠

Pu = 0.2133M p ¬lub¦

cemøIy³ Collapse load sMrab;eRKagKW Pu = 0.2133φb M p = 0.2133(1400) = 299kips

cMNaMfa vamancMnucdUcKñaxøHrvagviFIénkarviPaKTaMgBIr. eTaHbICa equilibrium method

minRtUvkarBicarNaRKb; mechanism k¾eday k¾vaRtUvkareGayeyIgdwgBI mechanism enAeBlEdlkar

EbgEcgm:Um:g;snμt;RsbeTAnwg mechanism mYy. viFITaMgBIrRtUvkarkarsnμt; failure mechanism b:uEnþ

enAkñúg equilibrium method eKRtUvRtYtBinitükarsnμt;nImYy²sMrab;suvtßiPaB nigkarEbgEckm:Um:g;Edl

GacTTYlyk)anedaysþaTic ehIyvaminRtUvkarkarGegátRKb; mechanism eT.

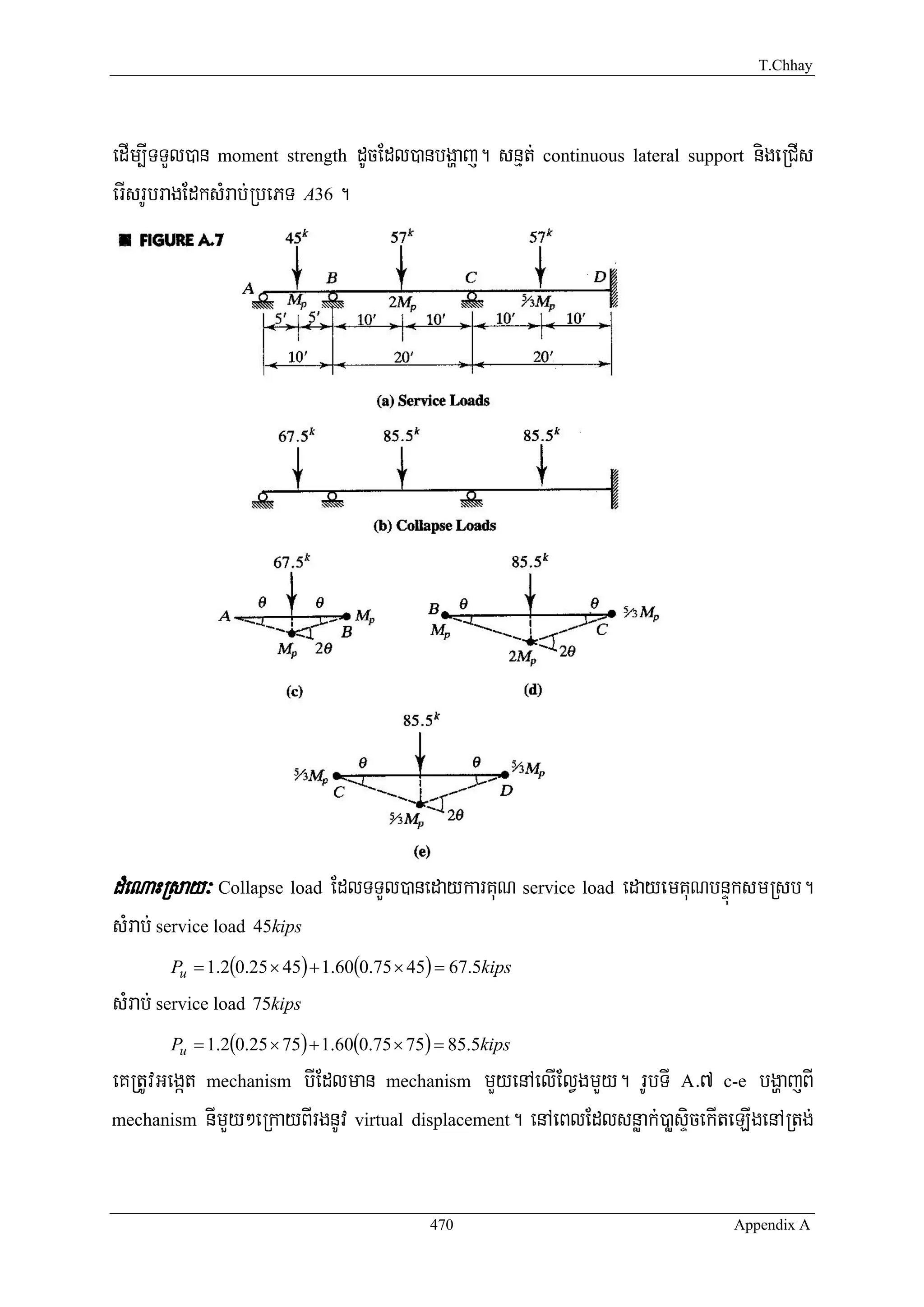

A >4> karKNnamuxkat; Design

dMeNIrkarénkarKNnaKWRsedogKñanwgkarviPaKEdr EtvaxusKñaRtg;faGBaØtiEdlRtUvrkCalT§

PaBm:Umg;)aøsÞicEdlRtUvkar M p . eKsÁal; collapse load EdlTTYl)anBIkarKuN service load nwgem

KuNbnÞúk.

]TahrN_ A>4³ FñwmCab;bIElVgdUcbgðajenAkñúgrUbTI A>7 RtUvRTnUv gravity service load. bnÞúknI-

mYy²pSMeLIgedaybnÞúkefr 25% nigbnÞúkGefr 75% . eKeRbI cover plate enAkñúgElVg BC nig CD

469 Appendix A](https://image.slidesharecdn.com/appendixaplasticanalysisanddesign-100715205010-phpapp02/75/Appendix-a-plastic-analysis-and-design-10-2048.jpg)

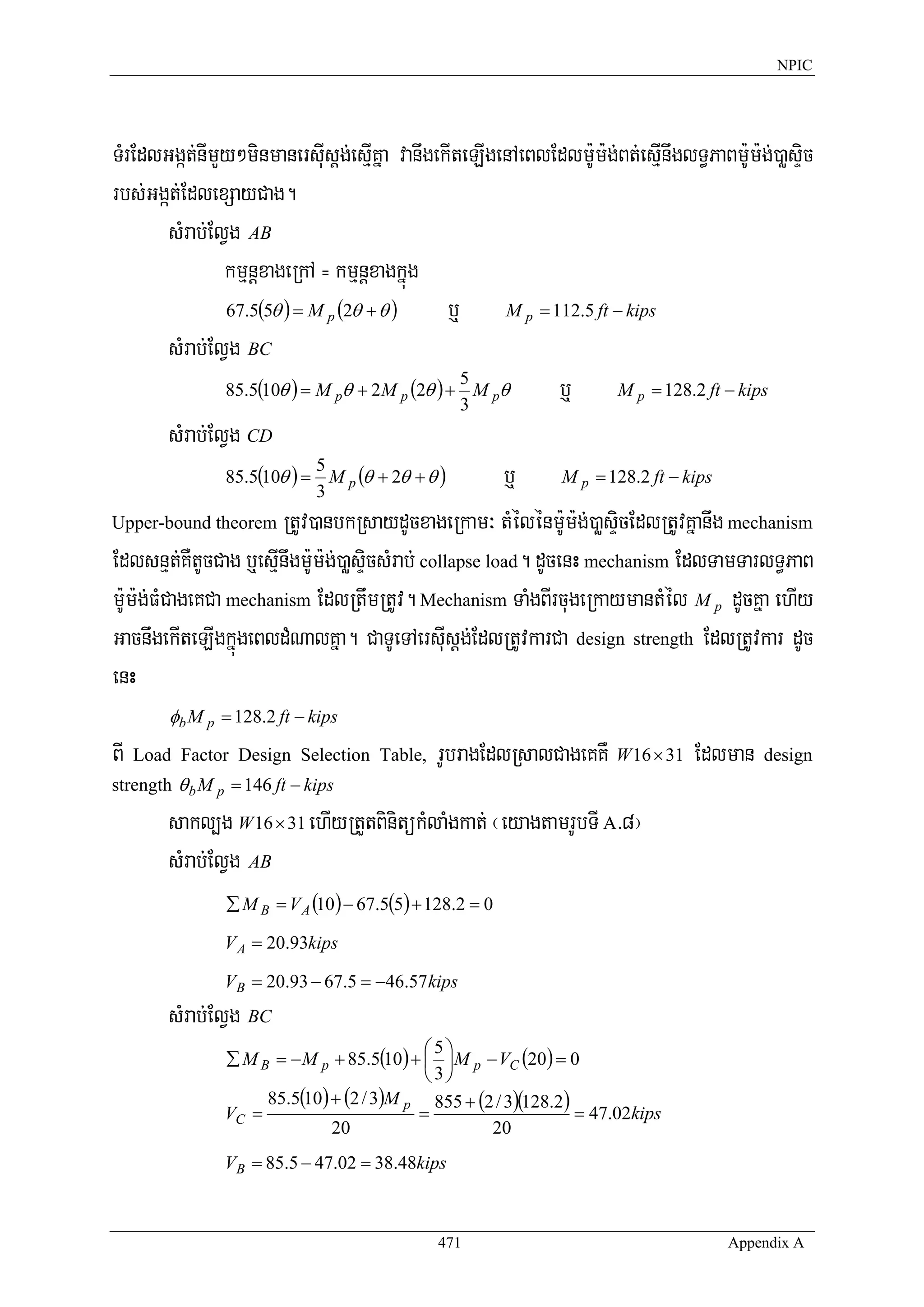

![T.Chhay

sMrab;ElVg CD

∑ M C = − M p + M p + 85.5(10) − VD (20) = 0

5 5

3 3

VD = 42.75kips = VC

dUcenH kMlaMgkat;TTwgGtibrma VC KW)anmkBIElVg BC b¤esμIKña 47.02kips .

BItaragbnÞúkBRgayesμIemKuNenAkñúg Part 4 of the Manual, shear design strength rbs;

W 16 × 31 KW

φvVn = 84.9kips > 47.02kips (OK)

cemøIy³ eRbI W 16 × 31 .

A >5> karsnñidæan Conclusion Remark

karviPaKén mechanism EdlrgbnÞúkBRgaybgðajBIPaBsμúKsμajbEnßmeTotEdlmin)anerob

rab;enATIenH. bBaðaCak;EsþgenAkñúg plastic analysis or design rYmbBa©ÚlnUvkardak;bnÞúkEbbenH

y:agCak;Esþg. elIsBIenH eKKYrGegátGnþrGMeBIénT§iBlrbs;kMlaMgtamG½kS nigm:Um:g;Bt;sMrab;Ggát;

EdlrgTaMgkMlaMgtamG½kS nigm:Um:g;Bt; dUcenA rigid frame enAkñúg]TahrN_ A>4 .

cMeBaHviFIviPaKEdlmanlkçN³TUeTAdUcCa equilibrium method manniyayy:aglMGitenAkñúg

the plastic methods of structural analysis (Neal, 1977). ehIyvamanrUbmnþEdlman

lkçN³sμúKsμajsMrab; mechanism method eTotpg. CamYynwgviFIenH EdleKsÁal;faCa method of

inequalities eKGackMNt; mechanism EdlRtwmRtUveday linear programming technique eday

pÞal;. eKGaceRbI plastic design FmμtasMrab;KNnaeRKOgbgÁúMPaKeRcIn b:uEnþCaTUeTA mechanism

method EdlbgðajenAkñúg]bsm<½n§enHKWRKb;RKan;ehIy.

472 Appendix A](https://image.slidesharecdn.com/appendixaplasticanalysisanddesign-100715205010-phpapp02/75/Appendix-a-plastic-analysis-and-design-13-2048.jpg)