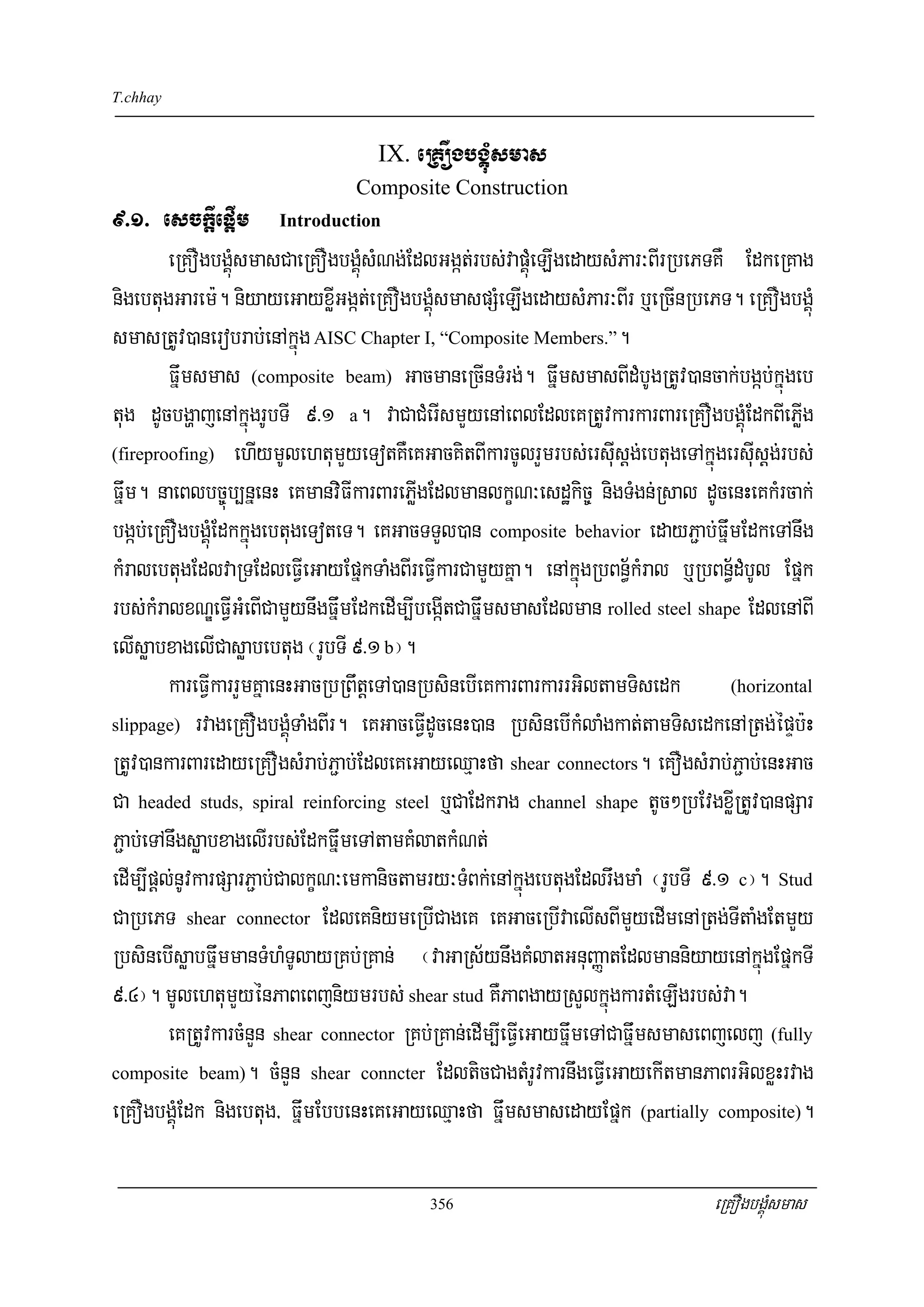

1) This document discusses composite construction, specifically composite beams. Composite beams are made of concrete cast on top of a steel beam, connecting the two materials and allowing them to act compositely.

2) Shear connectors like headed studs or channels are embedded in the concrete to connect the steel and concrete sections. This allows stresses and forces to be transferred between the two materials, making the beam behave compositely.

3) The elastic stresses in composite beams, including flexural and shear stresses, are analyzed based on the beam behaving as two different materials connected together. Formulas are provided to calculate the stresses based on the transformed area concept, where the steel and concrete sections are converted to an equivalent steel area

![T.chhay

]TahrN_ 9>1³ FñwmsmasmYypSMeLIgedayEdk A36 manrag W16 × 36 CamYynwgkMralebtugkMras;

5in. nigTTwg 87in. enABIxagelIFñwm. ersIusþg;rbs;ebtugKW f 'c = 4000 psi . kMNt;kugRtaMgGtibrma

enAkñúgEdk nigebtugEdlekItBIm:Um:g;Bt;viC¢man 160 ft − klips .

dMeNaHRsay³ Ec = w1.5

c f 'c = 1451.5 4 = 3495ksi

n=

E s 29000

Ec

=

3495

= 8 .3 yk n = 8

edaysarEtm:UDuleGLasÞicrbs;ebtugCatMélRbhak;RbEhl dUcenHeyIgGacyktMél n CatMélKt;

ehIyvanwgpþl;nUvPaBsuRkitRKb;RKan;. dUcenH

b 87

= = 10.88in.

n 8

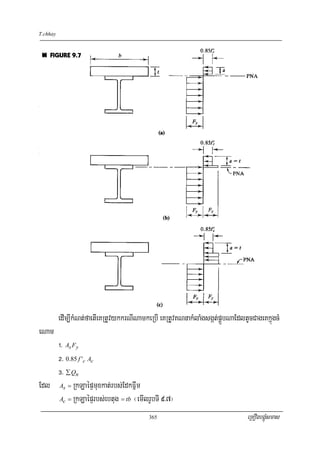

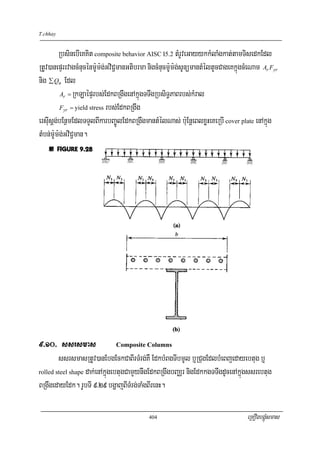

rUbTI 9>5 bgðajBI transformed section.

eKGackMNt;TItaMgrbs;G½kSNWtedayGnuvtþeKalkarN_m:Um:g;CamYynwgG½kSrbs;m:Um:g;enAEpñk

xagelIbMputrbs;kMral. karKNnaRtUv)ansegçbenAkñúgtarag 9>1 ehIycMgayBITItaMgx<s;bMputrbs;kM

raleTATIRbCMuTMgn;KW

∑ Ay 273.1

y= = = 4.202in.

∑ A 65.00

edayGnuvtþRTwsþIbTG½kSRsb nigedayerobCataragénkarKNnaenAkñúgtarag 9>2 eyIgTTYl)anm:Um:g;

niclPaBrbs; transformed section KW

I tr = 1526in.4

kugRtaMgenATItaMgx<s;bMputrbs;EdkKW

yt = y − t = 4.202 − 5.00 = −0.7980in.

Edl t CakMras;rbs;kMral

361 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-6-320.jpg)

![T.chhay

ersIiusþg;kMlaMgkat;srubrbs; shear connector

∑ Qn =

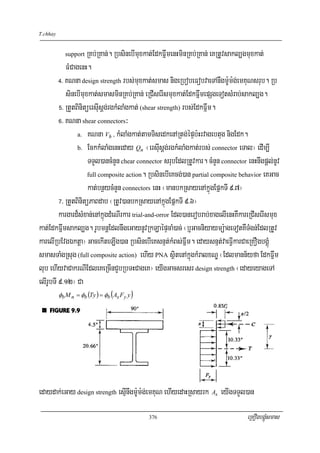

lT§PaBnImYy²bgðajBIkMlaMgkat;tamTisedkenARtg;épÞb:HrvagEdk nigebtug. enAeBlEdllT§PaBTI

mYylub eKeRbIEdkTaMgmUl ehIyeKGnuvtþkarEbgEcgkugRtaMgrbs;rUbTI 9>7 a. lT§PaBTIBIrRtUvKñanwg

ebtugEdllub ehIy PNA sßitenAkñúgEdk ¬rUbTI 9>7 b b¤ c¦. krNITIbIlubEtenAeBlEdleKeRbI

shear connector ticCagtMrUvkarsMrab; full composite behavior EdleFVIeGayekItman partial

composite behavior. eTaHbICa partial composite action GacekItmanCamYynwgkMralxNÐtan; b¤kM

ralxNÐEdlekItBI steel deck k¾eday k¾vaRtUv)anykmkniyayenAkñúgEpñkTI 9>7/ “Composite

Beams with Formed Steel Deck”.

]TahrN_ 9>2³ KNna design strength rbs;Fñwmsmasrbs;]TahrN_ 9>1. snμt;faeKman shear

connector RKb;RKan;sMrab; full composite behavior.

dMeNaHRsay³ kMNt;kMlaMgsgát; C enAkñúgebtug ¬kMlaMgkat;tamTisedkenARtg;épÞb:Hrvagebtug

nigEdk¦. edaysarvaCa full composite action kMlaMgEdlmantMéltUcCagKW As Fy nig

0.85 f 'c Ac ³

As Fy = 10.6(36 ) = 381.6kips

0.85 f 'c Ac = 0.85(4)(5 × 87 ) = 1479kips

kMlaMgsgát;enAkñúgEdklub C = 381.6kips .

enHmann½yfaeKminRtUvkarkMras;TaMgmUlrbs;ebtugedIm,IbegáItkMlaMgsgát;EdlRtUvkareT. eKTTYl)an

karEbgEckkugRtaMgenAkñúgrUbTI 9>8.

eKk¾GacKNnakMlaMgsgát;rYmdUcxageRkam

C = 0.85 f 'c ab

366 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-11-320.jpg)

![T.chhay

enaHeyIg)an a = 0.85Cf ' b = 0.85(4.)(687) = 1.290in.

381

c

kMlaMg C nwgsßitenAelITIRbCMuTMgn;rbs;RkLaépÞrgkarsgát;enAkMBs; a / 2 BITItaMgx<s;bMput

rbs;kMralxNÐ. kMlaMgTajpÁÜb T ¬esμInwg C ¦ nwgsßitenATIRbCMuTMgn;rbs;RkLaépÞEdk. ékXñas;

rbs; couple RtUv)anbegáIteLIgeday C nig T KW

d a 15.86 1.290

y= +t − = +5− = 12.28in.

2 2 2 2

Nominal strength KWm:Um:g; couple b¤

M n = Cy = Ty = 381.6(12.28) = 4686in.kips = 390.5 ft − kips

ehIy design strength KW

φb M n = 0.85(390.5) = 332 ft − kips

cMeLIy³ design strength = 332 ft − kips

enAeBlEdlvaman full composite behavior ]TahrN_ 9>2 CaKMrUsMrab;lkçxNÐenH. karvi

PaKsMrab;krNI PNA EdlmanTItaMgsßitenAkñúgmuxkat;EdknwgRtUv)anrk enAeBlEdleKdwgfavaCa

partial composite action.

9>2> karsagsg;edaymankarTb; nigedayminmankarTb;

Shored Versus Unshored Construction

Tal;EtebtugrwgmaM nwgvaTTYl)annUv design strength rbs;va ¬y:agtic 75% énersIusþg;

sgát;enA 28 éf¶ f 'c ¦ enaHmanminmankareFVIkarCasmas (composite behavior) eT ehIyTMgn;rbs;kM

raldac;xatRtUv)anRTedaymeFüa)ayepSg². enAeBlEdlebtugrwgmaM vaGaceFVIkarCaeRKOgbgÁúM

smas ehIykMlaMgGnuvtþn_bnþbnÞab;RtUv)anTb;Tl;edayFñwmsmas. RbsinebIFñwmEdkRtUv)anRTeday

CnÞl;RKb;RKan;tambeNþayRbEvgrbs;vamunnwgebtugRtUv)ancak; TMgn;rbs;ebtugRss;nwgRtUvRTeday

CnÞl;beNþaHGasnñeRcInCagedayEdkFñwm. enAeBlEdlebtugrwgmaM CnÞl;beNþaHGasnñRtUv)anruHerI

ecj ehIyTMgn;rbs;kMralxNÐk¾dUcCabnÞúkbEnßmnwgRtUvRTedayFñwmsmas. b:uEnþRbsinebIeKmineRbI

CnÞl; rolled steel shape minRtwmEtRTTMgn;pÞal;rbs;vab:ueNÑaHeT b:uEnþvaRtUvRTTMgn;rbs;kMralxNÐ

nigBum<kñúgeBlebtugeFVIkarrwgmaM. enAeBlEdleKTTYl)an composite behavior bnÞúkbEnßm TaMg

367 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-12-320.jpg)

![T.chhay

bnÞúkefr nigbnÞúkGefrnwgRtUvRTedayFñwmsmas. eyIgnwgBicarNalkçxNÐxusKñaedaylMGitdUcxag

eRkam.

KμanCnÞl;³ muneBlebtugrwgmaM Unshored: Before Concrete cures

AISC I3.4 TamTarfa enAeBlEdleKmineRbICnÞl; EdkFñwmEtÉgdac;xatRtUvEtmanersIusþg;

RKb;edIm,I Tb;Tl;nwgbnÞúkGnuvtþn_TaMgGs;munnwgebtugTTYl)an 75% énersIusþg;rbs;va. ersIusþg;Tb;

karBt; (flexural strength) RtUv)anKNnaedayviFIFmμta edayQrelI Charpter F of the Specifica-

tion ¬CMBUk 5 enAkñúgesovePAenH¦. edayGaRs½yeTAelIkarKNnarbs;va Bum<sMrab;kMralebtugGac

pþl; b¤minGacpþl; lateral support sMrab;EdkFñwm. RbsinebIvaminpþl;Ca lateral support sMrab;EdkFñwm

eT eKRtUvyk unbraced length Lb mkKit ehIy lateral-torsional buckling GaclubelI flexural

strength. RbsinebIeKmineRbICnÞl;beNþaHGasnñeT EdkFñwmk¾GacRtUv)aneRbIedIm,ITb;Tl;nwgbnÞúksag

sg;bnÞab;bnSMEdr. edIm,IkarBarbnÞúkTaMgenH eKRtUvbEnßmbnÞúk 20lb / ft 2 = 1kN / m 2 (Hansell et al.,

1978).

KμanCnÞl;³ eRkayeBlebtugrwgmaM Unshored: After Concrete cures

eRkayeBleKTTYl)an composite behavior RKb;bnÞúkEdlGnuvtþCabnþbnÞab;TaMgGs;RtUv)an

RTedayFñwmsmas. b:uEnþ enAeBldac; RKb;bnÞúkTaMgGs;RtUv)anRTeday couple xagkñúg EdlRtUvKñanwg

karEbgEckkugRtaMgenAeBldac;. dUcenHmuxkat;smasRtUvEtmanersIusþg;RKb;RKan;edIm,IRTbnÞúkTaMgenH

EdlrYmbBa©ÚlTaMgbnÞúkEdlGnuvtþeTAelIFñwmEdkmunnwgebtugrwgmaM.

karsagsg;edayTl; Shored Construction

kñúgkarsagsg;edayeRbICnÞl; eKBicarNaEtFñwmsmas edaysareKminRtUvkareGayEdkFñwmRT

GVIepSgBIbnÞúkpÞal;rbs;vaeT.

ersIusþg;kMlaMgkat; Shear Strength

AISC I3.6 tMrUveGaykMlaMgkat;TaMgs;RtUvTb;Tl;edayRTnugrbs;EdkFñwm Edlpþl;eGayenA

kñúg Chapter F of the Specification.

]TahrN_ 9>3³ Edk W12 × 50 eFVIkarrYmKñaCamYynwgkMralxNÐebtugkMras; 4in. . TTwgkMralxNÐ

RbsiT§PaBKW 72in. . eKmineRbICnÞl; m:Um:g;Bt;EdlGnuvtþmkelIvamandUcteTA³ )anmkBITMgn;Fñwm

368 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-13-320.jpg)

![T.chhay

M beam = 13 ft − kips )anmkBITMgn;kMralxNÐ M slab = 77 ft − kips nigBIbnÞúkGefr

M L = 38 ft − kips . ¬enAkñúg]TahrN_enH eKminKitbnÞúksagsg;bEnßmeT¦. EdkEdleRbIKW A36

ehIy f 'c = 4000 psi . kMNt;faetI flexural rbs;FñwmenHRKb;RKan;b¤Gt;. snμt;favaCa full

composite action ehIyBum<pþl;Ca lateral suppoet dl;muxkat;EdkmuneBlebtugrwgmaM.

dMeNaHRsay³ muneBlebtugrwgmaM vamanEtbnÞúkGefrb:ueNÑaH ¬minmanbnÞúksagsg;enAkñúg]TahrN_

enHeT¦. dUcenHbnSMbnÞúk A4-1 lub ehIym:Um:g;emKuNKW

M u = 1.4(M D ) = 1.4(13 + 77 ) = 126 ft − kips

BI beam design chart enAkñúg Part 4 of the Manual sMrab;Edk A36

φb M n = 195 ft − kips > 126 ft − kips (OK)

eRkayeBlebtugrwgmaM FñwmsmasRtUvTb;Tl;nUvm:Um:g;emKuN

M u = 1.2M D + 1.6M L = 1.2(13 + 77 ) + 1.6(38) = 168.8 ft − kips

kMlaMgsgát; C CatMéltUcCageKén

As F y = 14.7(36 ) = 529.2kips

b¤ 0.85 f 'c Ac = 0.85(4)(4 × 72) = 979.2kips

PNA KWsßitenAkñúgebtug ehIy C = 529.2kips . BIrUbTI 9>8 kMBs;rbs;bøúgkugRtaMgsgát;KW

C 529.2

a= = = 2.162in.

0.85 f 'c b 0.85(4)(72)

édXñas;m:Um:g;KW

d a 12.19 2.162

y= +t − = +4− = 9.014in.

2 2 2 2

design moment KW

φb M n = φb C y = 0.85(529.2 )(9.014 ) = 4055in.kips = 338 ft − kips > 168.8 ft − kips (OK)

cemøIy³ FñwmmanersIusþg;Bt; (flexural strength) RKb;RKan; .

Cak;Esþg karsagsg;edayeRBICnÞl;manRbsiT§PaBCagkarsagsg;EdlmineRbICnÞl; edaysar

KmineRbImuxkat;EdkedIm,IRTGVIepSgeRkABIbnÞúkxøÜnva. kñúgsßanPaBxøH kareRbIR)as;CnÞl;GaceGayeKRbI

R)as;muxkat;FñwmEdktUcCag. b:uEnþ eRKOgbgÁúMsmasCaeRcInminmaneRbICnÞl;eT edaysartMélbEnßm

rbs;CnÞl; CaBiesséføBlkmμ cMNayGs;ticCagkarsnSMsMécelITMgn;Edk.

369 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-14-320.jpg)

![T.chhay

9>3> TTwgsøabRbsiT§PaB Effect Flange Width

Epñkrbs;kMralxNÐEdleFVIkarCaeRKOgbgÁúMsmasCamYynwgEdkFñwmCaGnuKmn_eTAnwgktþaCaeRcIn

EdlrYmmanRbEvgElVg nigKMlatFñwm. AISC I3.1 tMrUveGayTTwgRbsiT§PaBrbs;kMralxNÐenAelIEpñk

nImYy²rbs;G½kSFñwmKWtMélEdltUcCageKkñúgcMeNam³

!> mYyPaKR)aMbIénRbEvgElVg.

@> mYyPaKBIrénKMlatFñwmEdlKitBIG½kSeTAG½kS.

#> cMgayBIG½kSFñwmeTARCUgEKmrbs;kMral.

lkçxNÐTIbIRtUv)anGnuvtþcMeBaHEtFñwmxagb:ueNaÑaH dUcenHsMrab;Fñwmxagkñúg TTwgRbsiT§PaBTaMgmUlRtUv

mantMéltUcCageKénmYyPaKbYnénRbEvgElVg b¤KMlatrbs;FñwmEdlKitBIG½kSeTAG½kS ¬edaysnμt;fa

FñwmmanKMlatesμI¦.

]TahrN_ 9>4³ RbB½n§kMralEdlpSMeLIgedayEdkFñwm W 12 × 44 EdlmanKMlatBIKña 9 ft nigRTnUvkM

ralebtugGarem:kMras; 4.5in. . RbEvgElVgKW 30 ft . edaybEnßmBIelITMgn;rbs;kMral eKmanbnÞúk

CBa¢aMgxNÐ 20 psf nigbnÞúkGefr 125 psf . EdkCaRbePT A36 ehIyersIusþg;rbs;ebtugKW

f 'c = 4000 psi . cUreFVIkarGegátFñwmxagkñúgedayeKarBtam AISC Specificastion RbsinebIeKmineRbI

CnÞl;beNþaHGasnñ. snμt; full lateral support kñúgGMLúgeBlsagsg; ehIybnÞúksagsg;bEnßmKW

20 psf . eKpþl;nUv shear connector RKb;RKan;sMrab; full composite action.

dMeNaHRsay³ bnÞúkEdlGnuvtþmuneBlebtugrwgmaMrYmmanTMgn;rbs;kMralxNÐ

(4.5 / 12)(150) = 56.25 psf .¬eTaHbICa normal-weight concrete manTMgn; 145 psf / EtebtugGarem:

RtUv)ansnμt;famanTMgn; 150 psf ¦. sMrab;FñwmEdlmanKMlat 9 ft bnÞúkGefrKW

56.25 × 9t = 506lb / ft

+ TMgn;Fñwm = 44lb / ftt

550lb / ft

bnÞúksagsg;KW 20(9) = 180lb / ft EdlRtUv)anKitCabnÞúkGefr. bnÞúk nigm:Um:g;emKuNKW

wu = 1.2wD + 1.6wL = 1.2(550) + 1.6(180) = 948lb / ft

M u = (0.948)(30)2 = 106.6 ft − kips

1

8

370 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-15-320.jpg)

![T.chhay

TTYl)anTMhM stud FmμtaKW 1/ 2 × 2 / 5 / 8 × 2 12 / 3 / 4 × 3 / 7 / 8 × 3 12 nig 1× 4 ¬b:uEnþ eKk¾GaceRbI

stud EdlEvgCagenHEdr¦.

]TahrN_ 9>5³ KNna shear connectors sMrab;RbB½n§kMralenAkñúg]TahrN_ 9>4.

dMeNaHRsay³ segçbTinñn½yEdl)anTTYlBI]TahrN_ 9>4³

W 21× 44 / Edk A36

f 'c = 4000 psi

kMras;kMralxNÐ t = 4.5in.

RbEvgElVg = 30 ft

BI]TahrN_ 9>4 kMlaMgkat;tamTisedk Vh EdlRtUvKñanwg full composite action KW

Vh = C = 468kips

sakl,g stud 1/ 2 × 2 . Ggát;GnuBaØatGtibrmaKW

2.5t f = 2.5(0.450 ) = 1.125in. > 0.5in. (OK)

RkLaépÞmuxkat;rbs; shear connector mYyKW

π (0.5)2

Asc = = 0.1963in.2

4

RbsinebIeyIgsnμt;ebtugCaebtugTMgn;Fmμta (normal-weight concrete) m:UDuleGLasÞicrbs;ebtugKW

Ec = w1.5 f 'c = (145)1.5 4 = 3492ksi

c

BI AISC Equation I5-1 ersIusþg;rgkMlaMgkat;rbs; connector mYyKW

Qn = 0.5 Asc f 'c Ec ≤ Asc Fu

= 0.5(0.1963) 4(3492 ) = 11.60kips

Asc Fu = 0.1963(60) = 11.78kips > 11.60kips yk Qn = 11.60kips

ehIy KMlattambeNþayGb,brmaKW 6d = 6(0.5) = 3in.

KMlattamTTwgGb,brmaKW 4d = 4(0.5) = 2in.

KMlattambeNþayGtibrmaKW 8d = 8(4.5) = 36in.

cMnYn stud EdlRtUvkarenAcenøaHcugFñwm nigkNþalFñwmKW

V 468

N1 = h = = 40.3

Qn 11.60

374 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-19-320.jpg)

![T.chhay

φb As Fy y = M u nig As =

Mu

φb F y y

b¤ As =

Mu

φb Fy (d / 2 + t − a / 2)

¬(>#¦

eKk¾GacsresrsmIkar (># vaCaTMgn;CagkarsresrCaRkLaépÞ. edaysarRbEvg 1 ft manmaD

As / 144 ft 3 ehIyEdkeRKOgbgÁúMmanTMgn;maD 490lb / ft 3

w = s (490 ) = 3.4 As lb / ft ¬sMrab; As KitCa in.2 ¦

A

144

BIsmIkar (># dUcenHTMgn;Edl)a:n;sμankñúgmYy ft KW

w=

3.4 M u

φ F (d / 2 + t − a / 2)

lb / ft ¬(>$¦

b y

Edl M u KitCa in. − kips / Fy KitCa ksi / ehIy d / t nig a KitCa in. . eKGaceRbIsmIkar (># b¤

(>$ edIm,IeRCiserIsmuxkat;sakl,g. smIkarTaMgBIrTamTarnUvkMBs;Edlsnμt; nigkar)a:n;sμan a / 2 .

dUcenH CaTUeTAbøúkkugRtaMgmankMBs;tUcNas; kMritlMeGogkñúgkarKNna a / 2 nwgmanT§iBltictYcelI

tMélEdl)anKNna As . eKsnμt; a / 2 = 1.0 .

RbsinebIeKeRbIsmIkar (>$ ehIyeKsnμt; nominal depth d enaHeKGaceFVIkareRCIserIsrUbrag

sakl,g)any:aggayRsYl. kareRbIsmIkarenHk¾pþl;nUvkarKNnaTMgn;FñwmedaypÞal;.

]TahrN_ 9>6³ RbEvgElVgrbs;RbB½n§kMralKW 30 ft ehIyKMlatFñwmKW 10 ft edayKitBIG½kSeTAG½kS.

eRCIserIs rolled steel shape nig shear connector EdlcaM)ac;edIm,ITTYl)ankareFVIkarCaeRKOgsmas

TaMgRsugCamYynwgkMralxNÐebtugGarem:kMras; 3.5in. . bnÞúkbEnßmEdlmanGMeBIelIkMralxNÐrYmman

bnÞúkCBa¢aMgxNÐ 10 psf nigbnÞúkGefr 55 psf . ersIusþg;ebtugKW f 'c = 4000 psi nigEdkEdleRbICa

RbePT A36 . snμt;faFñwmman full lateral support kñúgGMLúgeBlsagsg; ehIymanbnÞúksagsg;

20 psf .

dMeNaHRsay³ bnÞúkEdlRtUvRTmuneBlebtugrwgmaMKW

kMralxNг (3.5 /12)(150) = 43.75 psf

TMgn;kñúg 1 ft : 43.75(10) = 437.5lb / ft

bnÞúksagsg;³ 20(10) = 200lb / ft

¬TMgn;FñwmnwgRtUvKitenAeBleRkay¦

377 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-22-320.jpg)

![T.chhay

yk C = Vh = 276.5kips . kMBs;bøúkkugRtaMgsgát;enAkñúgkMralxNÐKw

C 276.5

a= = = 0.9036in.

0.85 f 'c b 0.85(4)(90)

ehIyédXñas;rbs; internal resisting couple KW

d a 15.69 0.9036

y= +t − = + 3.5 − = 10.89in.

2 2 2 2

design flexural strength KW

φb M n = φb (Cy ) = 0.85(276.5)(10.89) = 2550in.kips = 213 ft − kips > 174 ft − kips (OK)

RtYtBinitükMlaMgkat;

w L 1544(30 )

Vu = u = = 23.2kips

2 2

BI factored uniform load tables

φvVn = 76.3kips > 23.2kips (OK)

cemøIy³ eRbI W 16 × 26

eKRtUvkarm:UDuleGLasÞicrbs;ebtugedIm,IKNna shear connector. BI]TahrN_ 9>5/

Ec = 3492ksi sMrab;ebtugFmμtaCamYynwg f 'c = 4000 psi . sakl,g stud 1 / 2 × 2in.

¬ Asc = 0.1963in.2 ¦

Ggát;p©itGtibrma = 2.5t f = 2.5(0.345) = 0.8625in. > 0.5in. (OK)

BI AISC Equation I5-1/ ersIusþg;rgkMlaMgkat;rbs; connector mYyKW

Qn = 0.5 Asc f 'c Ec ≤ Asc Fu

= 0.5(0.1963) 4(3492 )

= 11.60kips

Asc Fu = 0.1963(60) = 11.78kips > 11.60kips

dUcenHyk Qn = 11.60kips

cMnYn stud EdlRtUvkarenAcenøaHcugFñwm nigkNþalElVgKW

V

N1 = h =

276.5

Qn 11.60

= 23.8 eRbI 24 sMrab;Bak;kNþalFñwm b¤Casrub 48

nig KMlattambeNþayGb,brmaKW 6d = 6(0.5) = 3in.

KMlattamTTwgGb,brmaKW 4d = 4(0.5) = 2in.

KMlattambeNþayGtibrmaKW 8t = 8(3.5) = 28in.

379 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-24-320.jpg)

![T.chhay

!> eRbI I s / m:Um:g;niclPaBrbs; rolled steel shape sMrab;PaBdabEdlekIteLIgedaysarbnÞúk

Gnuvtþn_muneBlebtugrwgmaM.

@> eRbI I tr / m:Um:g;niclPaBrbs; transfored section EdlKNnaCamYynwg b / n sMrab;PaBdab

EdlekIteLIgedaybnÞúkGefr nigsMrab;PaBdabdMbUg (initial deflection) EdlekIteday

bnÞúkefrEdlGnuvtþeRkayeBlebtugrwgmaM.

#> eRbI I tr EdlKNnaCamYynwg b / 2n sMrab; long-term deflection EdlekIteLIgedaysar

bnÞúkGefrEdlGnuvtþeRkayeBlebtugrwgmaM.

]TaheN_ 9>7³ KNnaPaBdabPøam² (immediate deflection) nig long-term deflection sMrab;Fñwm

enAkñúg]TahrN_ 9>4.

dMeNaHRsay³ segçbTinñn½yBI]TahrN_ 9>4³

W 21× 44 / Edk A36

kMras;kMralxNÐ t = 4.5in. ehIyTTwgRbsiT§PaBKW b = 90in.

f 'c = 4000 psi

bnÞúkGefrEdlGnuvtþmuneBlebtugrwgmaMKW wD = 550lb / ft ¬kMralxNÐbUknwgFñwm¦

bnÞúksagsg;KW wconst = 180lb / ft

bnÞúkGefrKW wL = 125(9) = 1125lb / ft

bnÞúkCBa¢aMgxNÐKW w part = 20(9) = 180lb / ft

PaBdabPøam²³

sMrab;FñwmbUknwgkMralxNÐ w = 550lb / ft

5wL4 5(0.55 / 12 )(30 × 12 )4

Δ1 = = = 0.41in.

384 EI s 384(29000)(843)

sMrab;bnÞúksagsg; w = 180lb / ft

5wL4 5(0.18 / 12 )(30 × 12 )4

Δ2 = = = 0.1342in.

384 EI s 384(29000 )(843)

PaBdabPøam²srubKW Δ1 + Δ 2 = 0.41 + 0.1342 = 0.544in.

381 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-26-320.jpg)

![T.chhay

PaBdabry³eBlxøIedaybEnßmbnÞúkGefr

Δ1 + Δ 3 + Δ 4 = 0.4100 + 0.0441 + 0.2755 = 0.730in.

PaBdabry³eBlEvgedayKμanbnÞúkGefr

Δ1 + Δ 5 = 0.4100 + 0.0504 = 0.460in.

PaBdabry³eBlEvgedaymanbnÞúkGefr

Δ1 + Δ 4 + Δ 5 = 0.4100 + 0.2755 + 0.0504 = 0.736in.

edaysarbnÞúkefrEdlGnuvtþeRkayeBlebtugrwgmaMmantMéltUc PaBdabEdl)anBI creep

mantMéltUcenAkñúg]TahrN_enH.

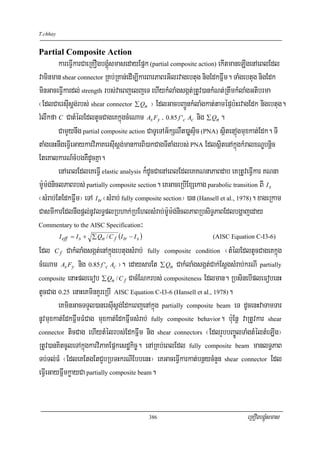

9>7> FñwmsmasCamYynwgkMralBum<Edk Composite Beams with Formed Steel Deck

kMralxNÐenAkñúgsMNg;eRKagEdkRtUv)anpÁúMeLIgkñúgTMrg;kMralEdkrnUt (ribbed steel deck)

EdlRtUv)anTukenAnwgkEnøgedIm,IeGayvakøayeTACaEpñkrbs;eRKOgbgÁúM. eTaHbICamankrNIelIkElgk¾

eday k¾rnUtrbs;bnÞHEdkRtUv)andak;eGayEkgnwgFñwmkMral ehIyRsbeTAnwgrtEdlRTFñwmenaH. rUbTI

9>16 bgðajBIrnUtEdlmanTisEkgnwgFñwm. eKtMeLIg shear stud enAelIFñwmsmasEdlmankMralrnUt

tamviFIdUcKñanwgkartMeLIg shear srud enAelIFñwmsmasEdlKμankMralrnUt. eKcat;TukfakarP¢ab;Kña

rvag deck eTAnwgFñwmEdkpþl;nUvTMrxag (lateral support) sMrab;FñwmEdkmuneBlebtugrwgmaM. kar

KNna nigkarviPaKFñwmsmasCamYynwg formed steel deck mansar³sMxan;dUcKñanwgkrNIFñwmsmas

CamYynwgkMralEdlmankMralesμIEdr EtxageRkamCakrNIelIkElgmYycMnYn³

!> eKminKitebtugenAkñúgrnUt ¬EdlenABIeRkamEpñkxagelIrbs; deck¦ enAeBlrnUtTaMgenaH

EkgnwgFñwm (AISC I3.5b). enAeBlrnUtRsbnwgFñwm ebtugenAkñúgrnUtenaHRtUv)anKitbBa©Úl

eTAkñúgkarkMNt;lkçN³muxkat; ehIyRtUv)anbBa©ÚleTAkñúgkarKNna Ac .

@> lT§PaBrbs; shear connector GacRtUv)ankat;bnßy

#> CaTUeTA eKminGacTTYl)an full composite behavior eT. mUlehtuKWfa KMlatrbs; shear

connector RtUv)ankMNt;edayKMlatrbs;rnUt ehIyeKminGaceRbIRKb;cMnYn connector Edl

RtUvkar. eTaHbICaeKGaceRbI partial composite design edayKμan formed steel deck k¾

eday k¾vaRtUv)anelIkykmkniyayenATIenH BIeRBaHPaKeRcInvaRtUvkar formed steel deck.

tamBitvaminEmnCaKuNvibtþieT EtvaCaCMerIsxagEpñkesdækic©.

384 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-29-320.jpg)

![T.chhay

tMrUvkarepSg² Miscellaneous Requirements

xageRkamCatMrUvkarEdl)anBI AISC Section I3.5 a nig b. GVIEdlnwgerobrab;xageRkamCa

tMrUvkarbEnßmBIelIGVIEdl)anerobrab;BIcxagedIm³

- kMBs;rnUtGtibrma hr = 3in. = 75mm

- TTwgmFümGb,brmarbs;rnUt wr = 2in. = 50mm b:uEnþtMélrbs; wr EdleRbIenAkñúgkar

KNnaminKYrFMCag clear width rbs;EpñkxagelIbMputrbs; deck eT.

- kMras;kMralGb,brmaenABIelIEpñkx<s;bMputrbs; deck = 2in. = 50mm .

- Ggát;p©it stud Gtibrma = 3 / 4in. . karTamTarsMrab; formed steel deck enHCakarbEnßmBI

elIGgát;p©itGtibrma 2.5t f .

- kMBs;Gb,brmarbs; stud BIelIEpñkx<s;bMputKW 1 1 2 in.

- KMlattambeNþayGtibrmarbs; shear stud = 36in. = 915mm

- eKRtUvP¢ab; deck eTAnwgsøabFñwmedayKMlatmineGayFMCag 18in = 460mm eday stud b¤

eday spot weld. kareFVIEbbenHedIm,IkarBar uplift.

TMgn; deck nigTMgn;kMral Slab and Deck Weight

edIm,IsMrYldl;karKNnaTMgn;kMral eyIgeRbIkMras;rbs;kMralTaMgmUledayvas;BI)atrbs; deck

eTAépÞxagelIrbs;kMralxNÐ. eTaHbICaviFIenH)a:n;sμanmaDebtugelIsk¾eday EtvamansuvtßiPaB. sMrab;

TMgn;maDebtugGarem: eyIgeRbITMgn;ebtugmaDsuT§bUkbEnßm 5 pcf = 80kg / m3 . CaTUeTA edaysarkM

ralxNÐenAelI formed steel deck CaebtugEdlBRgwgedayEdktic ¬eBlxøHeRbI welded wire mesh

CMnYseGaykareRbI reinforcing bar¦ karbEnßm 5 pcf = 80kg / m3 sMrab;EdkBRgwgGacmantMélFM b:uEnþ

deck manTMgn;cenøaHBI 2 psf = 9.6kg / m 2 eTA 3 psf = 14.5kg / m 2 .

eKGaceRbIvFImü:ageTot edayKitplbUkrvagkMras;kMralEdlenABIelI deck Edlx<s;CageK

CamYynwgBak;kNþalkMBs;rbs;rnUtCakMras;ebtugkñúgkarKNnaTMgn;rbs;kMral. kñúgkarGnuvtþ CaTUeTA

eKGacrkplbUkrvagTMgn;kMral nig deck enAkñúgtaragEdlpþl;eGayedayeragcRkplit deck.

]TahrN_ 9>8³ kMralxNÐRTedayFñwmEdleRbI formed steel deck EdlbgðajenAkñúgrUbTI 9>18 Ca

mYynwgkMralebtugGarem:EdlkMras;srubKW 4.75in. . rnUt deck EkgnwgFñwm. RbEvgElVgKW 30 ft

387 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-32-320.jpg)

![T.chhay

φb M p = 119 ft − kips > 107 ft − kips (OK)

eRkayeBlebtugrwgmaM bnÞúkemKuNsrubEdlRtUvRTedayFñwmsmas EdlRtUv)anEksMrYledaysarTMgn;

rbs;EdkFñwmKW

wu = 1.2(0.5 + 0.026 + 0.1) + 1.6(0.4) = 1.391kips / ft

ehIym:Um:g;emKuNKW

Mu =

1

(1.391)(30)2 = 156 ft − kips

8

TTwgkMralxNÐRbsiT§PaBrbs;muxkat;smasRtUvEtmantMéltUcCageKkñúgcMeNam

span 30(12)

4

=

4

= 90in. b¤ KMlatFñwm = 10(12) = 120in.

yk b = 90in. . sMrab; fully composite action kMlaMgsgát; C enAkñúgebtugKWCatMéltUcCageKkñúg

cMeNam

As Fy = 7.68(36 ) = 276.5kips

b¤ 0.85 f 'c Ac = 0.85(3)[90(4.75 − 1.5)] = 745.9kips

EdleKKitEtebtugenAelIEpñkx<s;bMputrbs; deck ¬dUcbgðajenAkñúgrUbTI 9>19¦ b:ueNÑaHsMrab;smIkarTI

BIrxagelI. CamYynwg C = 276.5kips kMBs;rbs;karBRgaykugRtaMgsgát;enAkñúgebtugKW

C 276.5

a= = = 1.205in.

0.85 f 'c b 0.85(3)(90)

édXñas;m:Um:g;rbs; internal resisting couple KW

d a 15.69 1.209

y= +t − = + 4.75 − = 11.99in.

2 2 2 2

ehIy design strength KW

0.85(276.5)(11.99)

φb M n = = 235 ft − kips > 156 ft − kips (OK)

12

RtYtBinitükMlaMgkat;

389 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-34-320.jpg)

![T.chhay

kMlaMgsuT§EdlRtUvepÞrenARtg;épÞb:HrvagEdk nigebtugKW

( )

T − C s = T − Pyf = As Fy − Pyf − Pyf = 276.5 − 2(68.31) = 139.9kips

EdlvatUcCagkMlaMgTajsuT§Cak;Esþg 210.4kips dUcenHsøabxagelIminRtUvkarrgkMlaMgsgát;eBj

kMras;søabrbs;vaeT. enHmann½yfa PNA sßitenAkñúgsøab. BIrUbTI 9>21 kMlaMgkat;tamTisedkEdl

RtUvepÞrKW

( )

T − C s = As Fy − b f t ' Fy − b f t ' Fy = Vh

276.5 − 2[5.5t ' (36)] = 210.4

edayKNnarkkMBs;énkMlaMgsgát;enAkñúgsøab eyIgTTYl)an

t ' = 0.1669in.

kMlaMgTajpÁÜbnwgeFVIGMeBIenAelITIRbCMuTMgn;rbs;RkLaépÞBIeRkam PNA. muneBleyIgKNna moment

strength eKRtUvkMNt;TItaMgTIRbCMuTMgn;sin. karKNnacMgayBITItaMgx<s;bMputrbs;EdkFñwm y RtUv)an

segçbenAkñúgtarag 9>6.

tarag 9>6

eRKOgbgÁúM A y Ay

W 16 × 36 7.68 15.69 / 2 = 7845 60.25

søab − 0.1669(5.50 ) = − 0.918 0.1669 / 2 = 0.0834 − 0.08

srub 6.762 60.17

∑ Ay 60.17

y= = = 8.898in.

∑ A 6.762

392 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-37-320.jpg)

![T.chhay

!> eRCIserIs ∑ Qn . enHCakarkMNt;rbs; Manual sMrab;kMlaMgsgát; C EdlCatMéltUcCag

eKén As Fy / 0.85 f 'c Ac nigersIusþg;rbs; shear connector srub ¬EdleyIgehAfa

∑ Qn ¦.

@> eRCIserIs Y 2 cMgayBITItaMgx<s;bMputrbs;EdkFñwmeTAkMlaMgsgát;pÁÜbenAkñúgebtugEdl

KNnaCa

a

Y2 = t −

2

TMhMenHRtUv)anbgðajenAkñúgrUbTI 9>26.

#> Gan φM n RbsinebIcaM)ac;eKRtUveFVI interpolation

sMrab;karKNna eKGacbBa©Úl φM n EdlTamTareTAkñúgtarag ehIyeKGacGaceRCIserIsEdk

Fñwm nig ∑ Qn . eKGacRtUvkartMél Y 2 dUcenHeKRtUvsnμt;kMBs;rbs;karBRgaykugRtaMgsgát;rbs;

ebtug ehIyeKGaceFVIkarKNnaeLIgvijeRkayeBlEktMrUv. Manual eGaynUvsmIkarsMrab;)a:n;sμan

TMgn;Fñwm EtRbsinebIeKeRbItarag eKminRtUvkarsmIkarenaHeT.

taragk¾eGaypgEdrnUvtMél φb M p EdlGacRtUvkarsMrab;RtYtBinitüFñwmEdlKμanCnÞl;kñúg

GMLúgeBlebtugrwgmaM ehIy Y1 CacMgayBITItaMgx<s;bMputrbs;EdkFñwmeTA PNA.

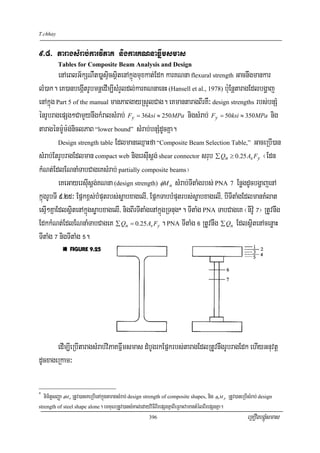

]TahrN_ 9>9³ KNna design strength rbs;FñwmsmasenAkñúg]TahrN_ 9>1 nig 9>2 edayeRbI

taragenAkñúg Part 5 of the Manual.

dMeNaHRsay³ BI]TahrN_ 9>1 FñwmsmaspSMeLIgedayEdk W 16 × 36 CamYynwgkMralxNÐEdlman

kMras; t = 5in. nigTTwgRbsiT§PaB b = 87in. . ersIusþg;sgát;enA @* éf¶rbs;ebtugKW f 'c = 4000 psi .

kMlaMgsgát;enAkñúgebtugCatMéltUcCageKén

As Fy = 10.6(36) = 381.6kips

397 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-42-320.jpg)

![T.chhay

b¤ 0.85 f 'c Ac = 0.85(4 )(5 × 87 ) = 1487kips

yk C = 381.6kips . kMBs;rbs;bøúkkugRtaMgsgát;

C 381.6

a= = = 1.290in.

0.85 f 'c b 0.85(4)(87 )

cMgayBITItaMgx<s;bMputrbs;EdkeTAkMlaMgsgát; C KW

a 1.290

Y2 = t − = 5− = 4.36in.

2 2

bBa©ÚleTAkñúgtaragCamYynwg ∑ Qn = 382kips nig Y 2 = 4.36 . edayeFVI interpolation eyIg

TTYl)an

φM n = 332 ft − kips

edayepÞógpÞat;CamYynwglT§plenAkñúg]TahrN_ 9>2 eyIgeXIjfavamantMéldUcKña. karKNnatam

rUbmnþ nigedayeRbItaragTTYl)anlT§plRsedogKña enAeBlEdl PNA sßitenAkñúgmuxkat;EdkFñwm.

cemøIy³ Design strength = 332 ft − kips

taragsMrab;m:Um:g;niclPaB lower bound EdlsMKal;eday I LB pþl;nUvkar)a:n;sμanm:Um:g;nicl

PaBrbs;muxkat;bMElgmanlkçN³suvtßiPaBsMrab;FñwmdUcKñaEdlmanenAkñúg design strength table.

karsnμt;d¾cMbgkñúgkareFVItaragenHKWfamanEtRkLaépÞebtugEdlTb;Tl;nwgm:Um:g;eTEdlmanRbsiT§PaB

kñúgkarKNnam:Um:g;niclPaB. kMlaMgenAkñúgebtugKW C = ∑ Qn nig RkLaépÞénmuxkat;bMElgEdlRtUv

KñaKW

∑ Qn ∑ Qn

Ac = =

stress in transformed area Fy

edIm,ICakarsMrYlteTAeTotkñúgkarKNna eKecalm:Um:g;niclPaBrbs;ebtugeFobnwgG½kSTIRbCMuTMgn;.

edIm,IbgðajBIviFIsaRsþenH eKnwgyktMélmYyenAkñúgtaragmkbMEbkenAkñúg]TahrN_ 9>10.

]TahrN_ 9>10³ karKNnapþl;nUvlT§plCa W 16 × 31 CamYynwg ∑ Q n = 241kips ¬TItaMg PNA

3¦ Y 2 = 4in. nig Fy = 36ksi . KNnam:Um:g;niclPaB lower bound.

dMeNaHRsay³ RkLaépÞebtugEdlRtUv)aneRbIKW

∑ Qn 241

Ac = = = 6.694in.2

Fy 36

398 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-43-320.jpg)

![T.chhay

muxkat;bMElgEdlRtUvKñaRtUv)anbgðajenAkñúgrUbTI 9>27 ehIykarKNnaRtUv)ansegçbenAkñúgtarag

9>9. kMNt;TItaMgTIRbCMuTMgn; Kitm:Um:g;eFobG½kSenA)atrbs;muxkat;Edk.

tarag 9>9

eRKOgbgÁúM A y Ay I d I + Ad 2

ebtug 6.694 19.88 133.1 - 6.88 316.9

W 16 × 31 9.12 7.94 72.4 375 5.06 608.5

srub 15.81 205.5 925.4in.4

∑ Ay 205.5

y= = = 13.00in.

∑ A 15.81

m:Um:g;niclPaBBItaragm:Um:g;niclPaB lower bound KW I LB = 925in.4 edayepÞógpÞat;CmYynwg

lT§plEdl)anKNna.

cemøIy³ I LB = 925in.4

]TahrN_ 9>11³ eFVIkarKNna]TahrN_ 9>8 eLIgvijCamYynwgCMnYyrbs;taragenAkñúg Part 5 of the

Manual .

dMeNaHRsay³ !> KNnaFñwm

BI]TahrN_ 9>8 M u = 153 ft − kips ¬edayminKitbBa©ÚlTMgn;Fñwm¦.

edaysnμt;fa a = 2in. eyIgTTYl)an

a 2

Y2 = t − = 4.75 − = 3.75in.

2 2

399 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-44-320.jpg)

![T.chhay

BI Composite Beam Selection Table, ral;karbnSMénEdkFñwm/ ∑ Qn nig Y 2 Edlpþl;nUv

design strength FMCag 153 ft − kips KWCaFñwmsakl,gEdlGacTTYlyk)an. lT§PaBBIrnwgRtUv)an

segçbenAkñúgtarag 9>10.

tarag 9>10

φM n (ft-kips)

rUbrag TItaMg PNA ∑ Qn (kips)

¬edayeFVI interpolation¦

W 16 × 26 7 69.1 160

W 14 × 22 3 159 159

Edk W 14 × 22 CarUbragEdlRsalCag b:uEnþedaysar ∑ Qn FMCag vanwgRtUvkar shear

connector eRcInCag ¬GaceRcInCagBIrdg¦. sMrab;mUlehtuenH sakl,g W 16 × 26 . KNna Y 2

eLIgvij³

C ∑ Qn 69.1

a= = = = 0.3011in.

0.85 f 'c b 0.85 f 'c b 0.85(3)(90 )

a 0.3011

Y 2 = t − = 4.75 − = 4.60in.

2 2

¬Edl b = 90in. KW)anmkBI]TarhN_ 9>8¦

φM n = 164.4 ft − kips

BI]TahrN_ 9>8/ M u = 156 ft − kips CamYynwgkarKitbBa©ÚlTMgn;Fñwm . vanwgtUcCag design

strength 164.4 ft − kips dUcenHkareRCIserIsenHGacTTYlyk)an. dUcKñaBI]TahrN_ 9>8 TaMg

flexural strength kñúgeBlsagsg; nig shear strength KWRKb;RKan;sMrab; W 16 × 26 .

cemøIy³ !> eRbI W 16 × 26 .

@> Shear connector

dMbUg sakl,g stud 3 / 4 × 3in. . cMnYnrbs; strud EdlRtUvkarKW

∑ Qn

N1 =

Qn

=

69.1

21.04

= 3 .3 yk 4 sMrab;Bak;kNþalFñwm dUcenHsrubKW 8 edIm

Stud 8 edImRtUvnwgKMlat

30(12)

= 45in.

8

400 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-45-320.jpg)

![T.chhay

KMlatenHFMCagKMlatGnuBaØatGtibrma 36in. dUcenHeKRtUveRbI stud eRcInCagenH. RbsinebI

eKdak; stud ral; 6 rnUtmþg KMlatnwgesμInwg 36 ehIycMnYn stud srubKW

30(12)

= 10, N1 = 5

36

kMlaMgkat;EdlRtUvKñaEdlRtUvepÞrKW

∑ Qn = 5(21.04) = 105.2kips

edIm,IgayRsYlkñúgkareRbItarag eyIgnwgyktMél ∑ Qn = 104kips enaH

104

a= = 0.4532in.

0.85(3)(90)

0.4532

Y 2 = 4.75 − = 4.523in.

2

BI Composit Beam Selection Table, design strength KW

φM n = 182 ft − kips > 156 ft − kips (OK)

cemøIy³ @> eRbI stud 3 / 4 × 3in. cMnYn 10 edIm edayKMlatesμI²Kña. edIm,IkarBar uplift eFVI spot weld

ral;KMlat 18in. ¬sßitenAcenøaH stud¦.

#> PaBdab

BI]TahrN_ 9>8 PaBdabrbs;EdkFñwmmuneBlTTYl)an composite behavior KW

Δ1 = 1.098in. ¬edayminKitbnÞúksagsg;¦

sMrab;PaBdabEdlekIteLIgeRkayeBlebtugrwgmaM eKGaceRbIm:Um:g;niclPaB lower bound

Edl)anBItarag. eRbI W 16 × 26 CamYynwg ∑ Qn = 104kips ¬PNA TItaMg ^¦ nig Y 2 = 4.523in.

I LB = 623in.4

vaminmankarEbgEckm:Um:g;niclPaBsMrab;karKNnaPaBdabbEnßmEdlekIteLIgedaysar

creep. b:uEnþ m:Um:g;niclPaB lower bound mantMéltUcCagm:Um:g;niclPaBmuxkat;bMElgCak;Esþg

ehIyT§iBlTaMgmUlKWnwgpþl;nUvPaBdabFMCagkar)a:n;sμan. RbsinebIbnÞúkefrry³eBlyUrtUc

eKGaceRbIm:Um:g;niclPaB lower bound.

w = wD + wL = 0.100 + 0.400 = 0.500kips / ft

ehIyPaBdabEdlRtUvKñaKW

5wL4 5(0.500 / 12 )(30 × 12 )4

Δ2 = = = 0.5044in.

384 EI LB 384(29000 )(623)

PaBdabsrubKW

401 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-46-320.jpg)

![T.chhay

Δ1 + Δ 2 = 1.098 + 0.5044 = 1.602in.

PaBdabGnuBaØatGtibrmaKW

L 30(12)

= = 1.500in. < 1.602in. (N.G.)

240 240

kñúgkarKNna Rtg;cMnucenH eyIgmanCMerIsBIr³ ¬!¦ KNnaPaBdabEdlmanPaBsuRkitCageday

eRbImuxkat;bMElg b¤¬@¦ eRCIserIskarbnSMrvagEdkFñwm nig shear connector CamYynwgm:Um:g;niclPaB

lower bound. edaysareKalbMNgrbs;]TahrN_enHcg;bgðajBIkareRbItarag eyIgnwgeRCIserIsCM

erIsTI @.

KNnam:Um:g;niclPaB lower bound EdlRtUvkar. PaNdabEdlekItBIkMralxNÐ nigTMgn;Fñwm

nwgminpøas;bþÚr dUcenHPaBdabGnuBaØatGtibrmaEdlekIteLIgedaysarbnÞúkEdlGnuvtþeRkayeBlebtug

rwgmaMKW

Δ 2 Gtibrma = 1.50 − Δ1 = 1.50 − 1.098 = 0.4020in.

5wL4

BI Δ 2 = 384EI

LB

I LB EdlRtUvkarKW

5wL4 5(0.500 / 12 )(30 × 12 )4

I LB ≥ = = 782in.4

384 EΔ 2 384(29000 )(0.4020 )

sMrab; W 16 × 26 CamYynwg PNA # nig Y 2 = 4.5in. / m:Um:g;niclPaB lower bound KW

I LB = 804in.4 . BI Composite Design Selection Table, sMrab; PNA # kMlaMgkat;tamTisedkKW

∑ Qn = 208kips

edIm,ITTYltMélRtwmRtUv Y 2 nig I LB dMbUgKNnaTItaMgrbs;kMlaMgsgát;enAkñúgebtug

∑ Qn 208

a= = = 0.9063in.

0.85 f 'c Ac 0.85(3)(90 )

a 0.9063

Y 2 = t − = 4.75 − = 4.30in.

2 2

BItaragm:Um:g;niclPaB lower bound edayeFVI interpolation

I LB = 788in.4 > 782in.4 (OK)

cMnYnrbs; shear connector EdlRtUvkarKW

∑ Qn

N1 =

Q

=

208

21.04

= 9 .9 yk 10 sMrab;Bak;kNþalFñwm b¤srub 20 edIm

n

402 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-47-320.jpg)

![T.chhay

edaysarKMlatrbs;rnUt deck, stud mYysMrab;ral;rnUt 3 sMrab;KMlat 18in. nwgpþl;nUv stud

20 edIm.

cemøIy³ #> edIm,IbMeBjtMrUvkarPaBdab begáIncMnYn stud BI 10 eTA 20 dak;mYyenAkñúgral;rnUt 3 .

]TahrN_ 9>11 bgðajplRbeyaCn_rbs;tarag. CaBiess composite Beam Selection

Table sMrYlkarKNna partially composite beam Edl PNA sßitenAkñúgmuxkat;EdkFñwm.

9>9> FñwmCab; Continuous Beams

sMrab;FñwmTMrsmBaØ cMnucénm:Um:g;sUnüenARtg;TMr. cMnYn connector EdlRtUvkarenAcenøaHTMr nig

cMnucEdlmanm:Um:g;GtibrmaKWcMnYnBak;kNþaléncMnYnsrubRtUvkar. sMrab;FñwmCab; cMnucrbt;k¾CacMnucén

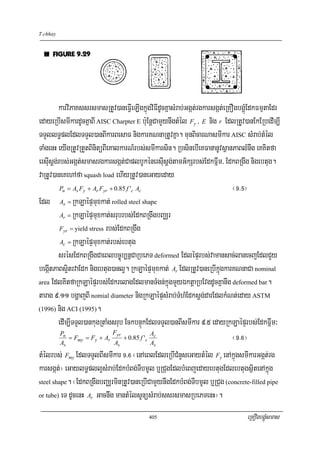

m:Um:g;sUnüEdr nigCaTUeTAeKRtUvkar connector 2N1 sMrab;ElVgnImYy². rUbTI 9>28 a bgðajBIRbePT

FñwmCab; nigtMbn;EdlRtUvkar shear connector. enAtMbn;m:Um:g;GviC¢man kMralebtugnwgrgkMlaMgTaj

dUcenHvanwgKμanRbsiT§PaB. enAkñúgtMbn;enH vanwgminman composite behavior EdleyIgRtUvBicarNa

enaHeT. RbePT composite behavior EtmYyKt;EdlGacmanKWenAcenøaHFñwmEdk nigEdkBRgwgtam

beNþayenAkñúgkMral. muxkat;FñwmsmasEdlRtUvKñaRtUv)anbgðajenAkñúgrUbTI 9>28 b. RbsinebIeK

eRbIKMnitenH eKRtUvpþl;nUvcMnYn shear connector RKb;RKan;edIm,ITTYlnUvdWeRkénPaBCab;rvagEdkFñwm

nigEdkBRgwg.

AISC Specification in Section I3.2 pþl;nUvCMerIsBIrsMrab;m:Um:g;GviC¢man.

!> edayQrEtelIersIusþg;rbs;EdkFñwmb:ueNÑaH.

@> edayrYmbBa©ÚlTaMgEdkBRgwgenAkñúgmuxkat;smasRtUvRbQmnwglkçxNÐxageRkam³

a. EdkFñwmRtUvEt compact nigman latereal support RKb;RKan;

b. eKRtUvEtdak; shear connector enAtMbn;mUm:g;GviC¢man ¬cenøaHcMnucm:Um:g;sUnü

:

nigcMnucm:Um:g;GviC¢manGtibrma¦

c. EdkBRgwgenAkñúgTTwgRbsiT§PaBRtUvEtmanRbEvgbgáb;RKb;RKan; ¬TMBk;¦

ersIusþg;rbs;muxkat;smasKYrEtQrelIkarBRgaykugRtaMg)aøsÞicCamYynwg φb = 0.85 .

403 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-48-320.jpg)

![T.chhay

@> Encased sections RtUvEteKarBtamlkçxNÐlMGitxageRkam³

a. eKRtUvEteRbITaMgEdlbBaÄr nigEdkkg. KMlatrbs;EdkkgminRtUvFMCagBIrPaKbI én

vimaRttUcCageKrbs;ebtug. RkLaépÞmuxkat;rbs;Edkem nigEdkkgminRtUvtUcCag

0.007in.2 / in. b¤ 0.18mm 2 / mm énKMlatEdk.

b. vaRtUvEtmankMras;ebtugkarBarEdky:agtic 1.5in. ≈ 38mm sMrab;Edkkg nigEdkbBaÄr.

c. EdkbBaÄrEdlRTbnÞúk (load-carrying longitudinal reinforcement) RtUvEtCab;enA

framed level. EdkbBaÄrsMrab;Tb;ebtugGacpþac;enARtg; framed level.

#> ersIusþg;rbs;ebtug f 'c RtUvEtsßitenAcenøaH 3ksi ≈ 21MPa nig 8ksi ≈ 55MPa sMrab;eb

tugTMgn;Fmμta ¬minmanlT§plBiesaFn_sMrab; f 'c FMCag 55MPa eT¦ nigy:agticbMput

4ksi ≈ 28MPa sMrab;ebtugTMgn;Rsal.

$> kñúgkarKNna Yield stress rbs;EdkeRKOgbgÁúM nigEdkBRgwgbBaÄrminRtUvFMCag 55ksi

≈ 380 MPa eT. karkMNt;RtUv)anTTYlBIkarBicarNa local stability. enAeBlEdlEdk

eRKOgbgÁúMhMuB½T§edayebtug vanwgminman local stability eT. ebtugnwgGachMuB½T§Edk)an

RKb;RKan;ebIvaminmankarpÞúHépÞebtug (spall). RbsinebIeKsnμt;eGayebtugman spall enA

eBlebtugman strain 0.0018 enaHkugRtaMgEdkRtUvKñaenAkñúgEdkKW

Fmax = ε max E = 0.0018(29000) = 52.2ksi

EdlRtUv)anKitCatMélkMNt;Rtwm 55ksi .

%> edIm,IkarBar local buckling enAkñúg pipes b¤ tubes EdlbMeBjedayebtug kMras;rbs;

pipes b¤ tubes minRtUvtUcCag

t = b Fy / 3E sMrab;muxkat;ctuekaNEdlmanTTwgxageRkA b

b¤ t = D Fy / 8E sMrab;muxkat;rgVg;EdlmanGgát;p©itxageRkA D

]TahrN_ 9>12³ Ggát;rgkarsgát;smasEdlman W 12 ×136 RtUv)andak;enAkñúgssrebtugEdlman

TMhM 20 × 22in. dUcbgðajenAkñúgrUbTI 9>30. eKeRbIEdk #10 bYnedImCaEdkbBaÄr nigEdk #3 CaEdk

kgEdlmanKMlat 13in. edayKitBIG½kSeTAG½kS. Edkman yield stress Fy = 50MPa ehIyeKeRbI

EdkBRgwgRbePT Grade 60. ersIusþg;rbs;ebtugKW f 'c = 5ksi . KNna design strength sMrab;RbEvg

RbsiT§PaB 16 ft sMrab;G½kSTaMgBIr.

408 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-53-320.jpg)

![T.chhay

cemøIy³ eKkMNt;tMélEksMrYl F nig E Edl)anBI AISC Equation I2-1 nig I2-2. tMélEdl

my m

RtUvkarsMrab;smIkarTaMgenHKW³

Fyr = 55ksi tMélEdlkMNt;eday AISC I2.1

Ar = 4(1.27 ) = 5.08in.2

Ac = net area rbs;ebtug = 20(22) − As − Ar = 440 − 39.9 − 5.08

= 395.0in.2

sMrab; f 'c = 5ksi

Ec = w1.5 f 'c = (145)1.5 5 = 3904ksi

c

BI AISC Equation I2-1, yield stress EdlEksMrYlKW

⎛A ⎞ ⎛A ⎞

Fmy = Fy + c1 Fyr ⎜ r ⎟ + c2 f 'c ⎜ c ⎟

⎜A ⎟ ⎜A ⎟

⎝ s⎠ ⎝ s⎠

⎛ 5.08 ⎞ ⎛ 395 ⎞

= 50 + 0.7(55)⎜ ⎟ + 0.6(5)⎜ ⎟ = 84.60ksi

⎝ 39.9 ⎠ ⎝ 39.9 ⎠

BI AISC Equation I2-2, m:UDuleGLasÞicEdlEksMrYlKW

⎛A ⎞

⎟ = 29000 + 0.2(3904)⎛

395 ⎞

E m = E + c3 E c ⎜ c

⎜A ⎟ ⎜ ⎟ = 36730ksi

⎝ s ⎠ ⎝ 39.9 ⎠

kaMniclPaBEdlRtUv)aneRbIenAkñúgsmIkarGgát;rgkarsgát;én AISC Cahpter E GacCa r sMrab;Edk

eRKOgbgÁúM b¤ 0.3b edayykmYyNaEdlmantMélFMCag. enAkñúg]TahrN_enH buckling nwgekIteLIg

eFobnwgG½kS y rbs;Ggát; dUcenH r sMrab;muxkat;KW ry = 3.16in . enAkñúgbøg; buckling

0.3b = 0.3(20 ) = 6in. ¬lub¦

dUcenH rm = 6in. . eKGacKNna design strength dUcKñasMrab;Ggát;rgkarsgát;FmμtaedayeRbI

tMélEksMrYl Fmy / Em nig rm CMnYseGay Fy / E nig r

409 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-54-320.jpg)

![T.chhay

KL Fmy 16(12 ) 84.60

λc = = = 0.4888 < 1.5

rmπ Em 6π 36730

Fcr = (0.658)λc Fmy = (0.658)(0.4888 ) (84.60 ) = 76.55ksi

2 2

nominal strength KW

Pn = As Fcr = 39.9(76.55) = 3054kips

ehIy design strength KW

φc Pn = 0.85(3054) = 2600kips

cemøIy³ design compressive strength KW 2600kips

taragsMrab;viPaK nigKNna Tables for Analysis and Design

mantaragEdlsMrYly:agxøaMgdl;karviPaK nigkarKNnassrsmas.

Part 5 of the Manual

taragTaMgenHmanlkçN³RsedogKñanwg column strength table enAkñúg Part 3 of the Manual. eK

eGay axial compressive design strength CaGnuKmn_eTAnwgRbEvgRbsiT§PaBsMrab; concrete-filled

pipes and tubes nigsMrab; encased W-shapes. sMrab; encased column Edkem nigEdkkgEdlbM

eBjtMrUvkar AISC RtUv)anrab;bBa©Úl. eKeGaytMél rmx / rmy sMrab;krNITaMgenaHEdl K x L ≠ K y L .

]TahrN_ 9>13³ Ggát;rgkarsgát;EdlmanRbEvg 18 ft RtUvRTnUvbnÞúkeFVIkar (service load) srub

1000kips EdlpSMeLIgedaycMENkesμIKñaénbnÞúkefr nigbnÞúkGefr. Ggát;enHmanTMr pinned enAcug

TaMgsgçag CamYynwgTMrbEnßmenAkMBs;Bak;kNþaltamG½kSexSay. eRbItaragenAkñúg Part 5 of the

Manual edIm,IeRCIserIsEdk W EdlmanrUbragkaerEdlbgáb;kñúgebtug (square encased W-shape)

CamYynwgRkLaépÞebtugEdltUcCageKEdlGaceFVIeTA)an. eRbIEdk A36 Edksrés grade 60 nig

f 'c = 3.5ksi .

dMeNaHRsay³ bnÞúktamG½kSemKuNKW

Pu = 1.2(500 ) + 1.6(500 ) = 1400kips

tamkarGegátelItaragbgðajfa sMrab; f 'c = 3.5ksi nigtMélén rmx / rmy ERbRbYlBI 1.0 eTA 1.22

EdltMélPaKeRcInesμInwg 1.0 . edaysar

410 eRKOgbgÁúMsmas](https://image.slidesharecdn.com/9-compositeconstruction-100715205005-phpapp02/85/9-composite-construction-55-320.jpg)