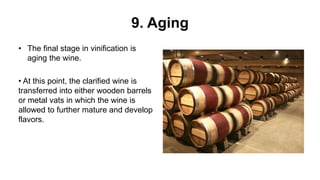

The document provides an overview of wine production, detailing the various steps involved from viticulture to bottling. Key processes include harvesting, fermentation, and aging, each influenced by factors such as climate and grape quality. It also outlines types of wines and the significance of yeast in transforming grape juice into alcoholic beverages.