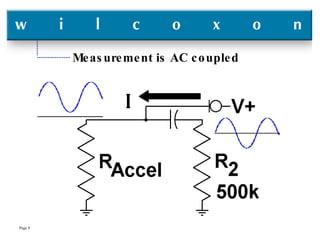

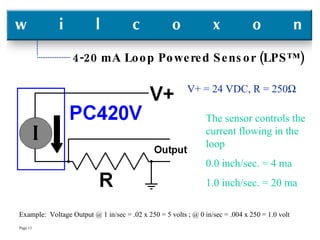

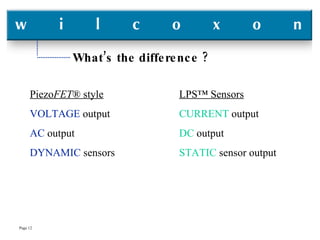

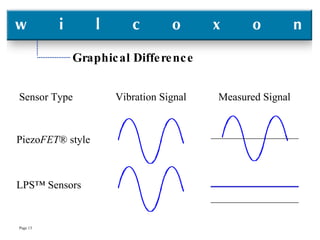

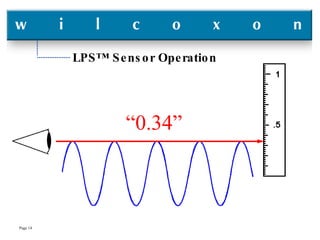

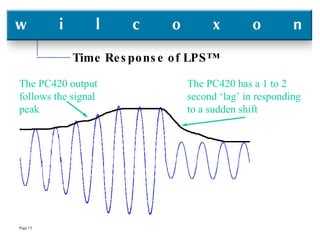

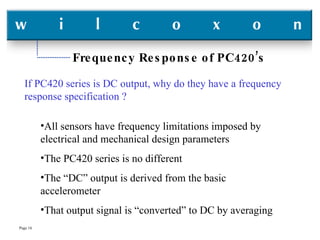

This document compares two types of sensors: dynamic sensors and loop powered sensors (LPSTM). Dynamic sensors use a constant current supply and have a voltage output and AC output. They are typically used by maintenance teams. LPSTM sensors use the voltage from a DCS/PLC system, have a current output and DC output, and are usually purchased by instrumentation and electronics teams under production departments. LPSTM sensors allow for more frequent monitoring of machinery vibration than traditional predictive programs and provide value for critical equipment.