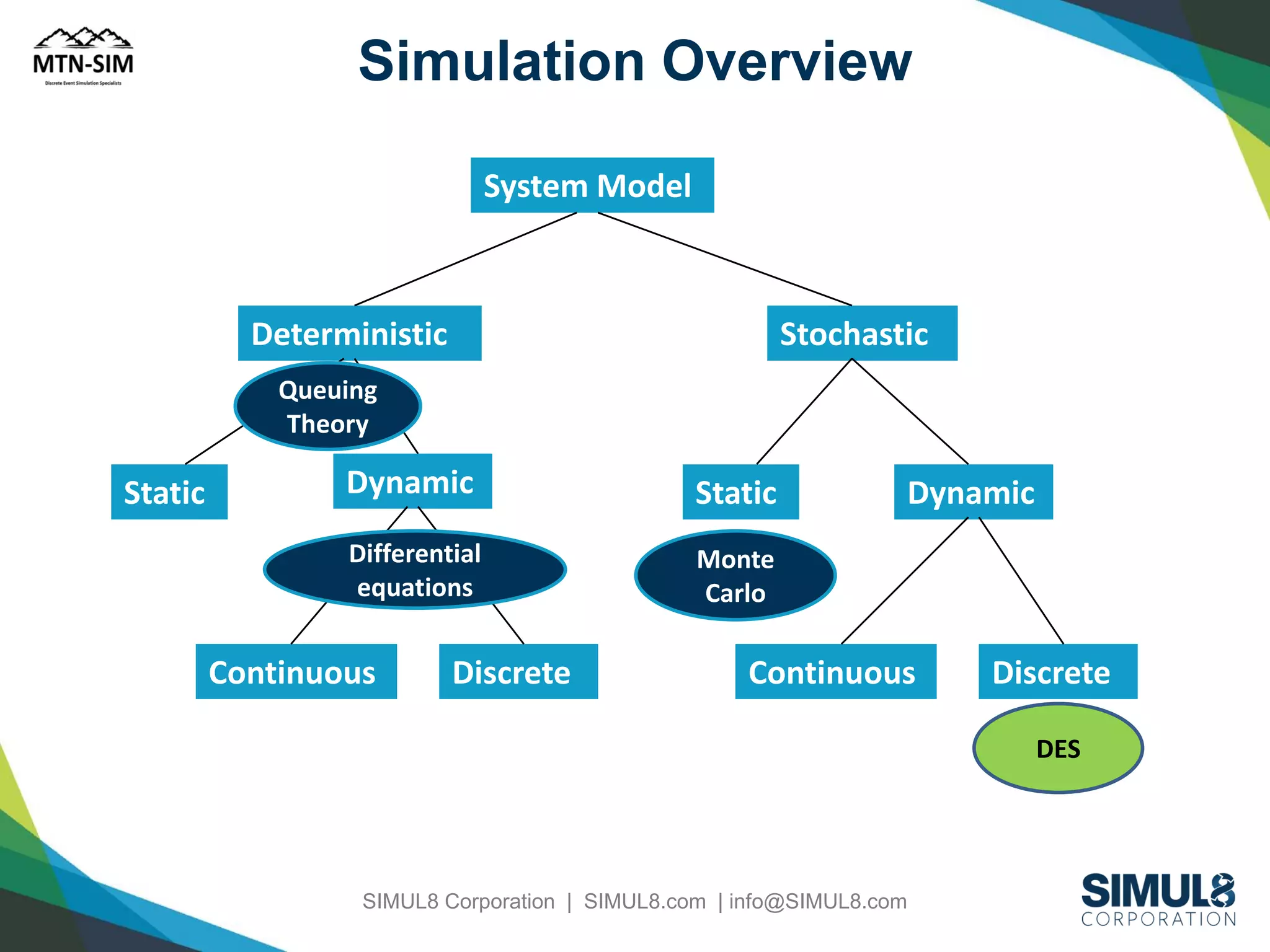

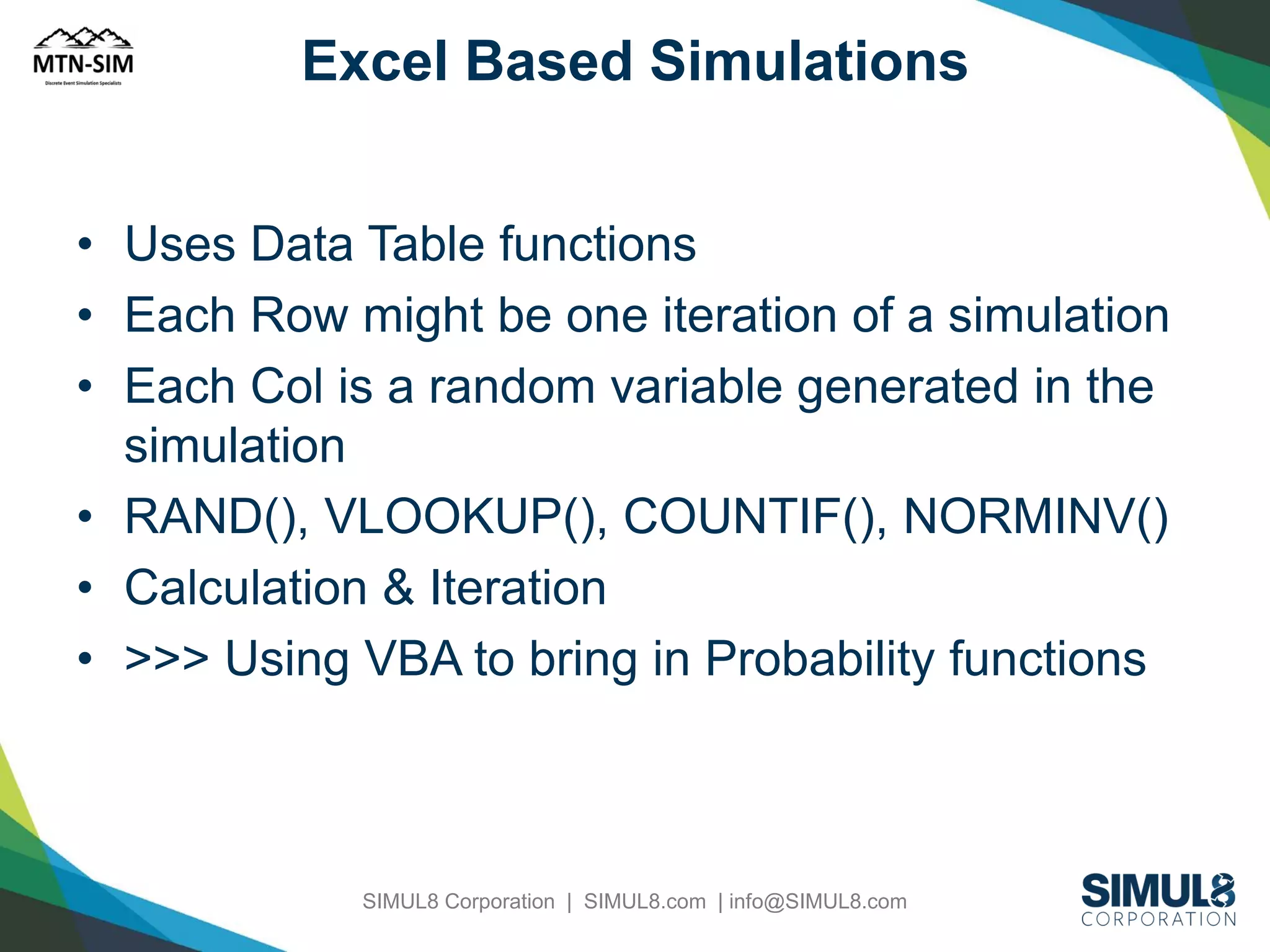

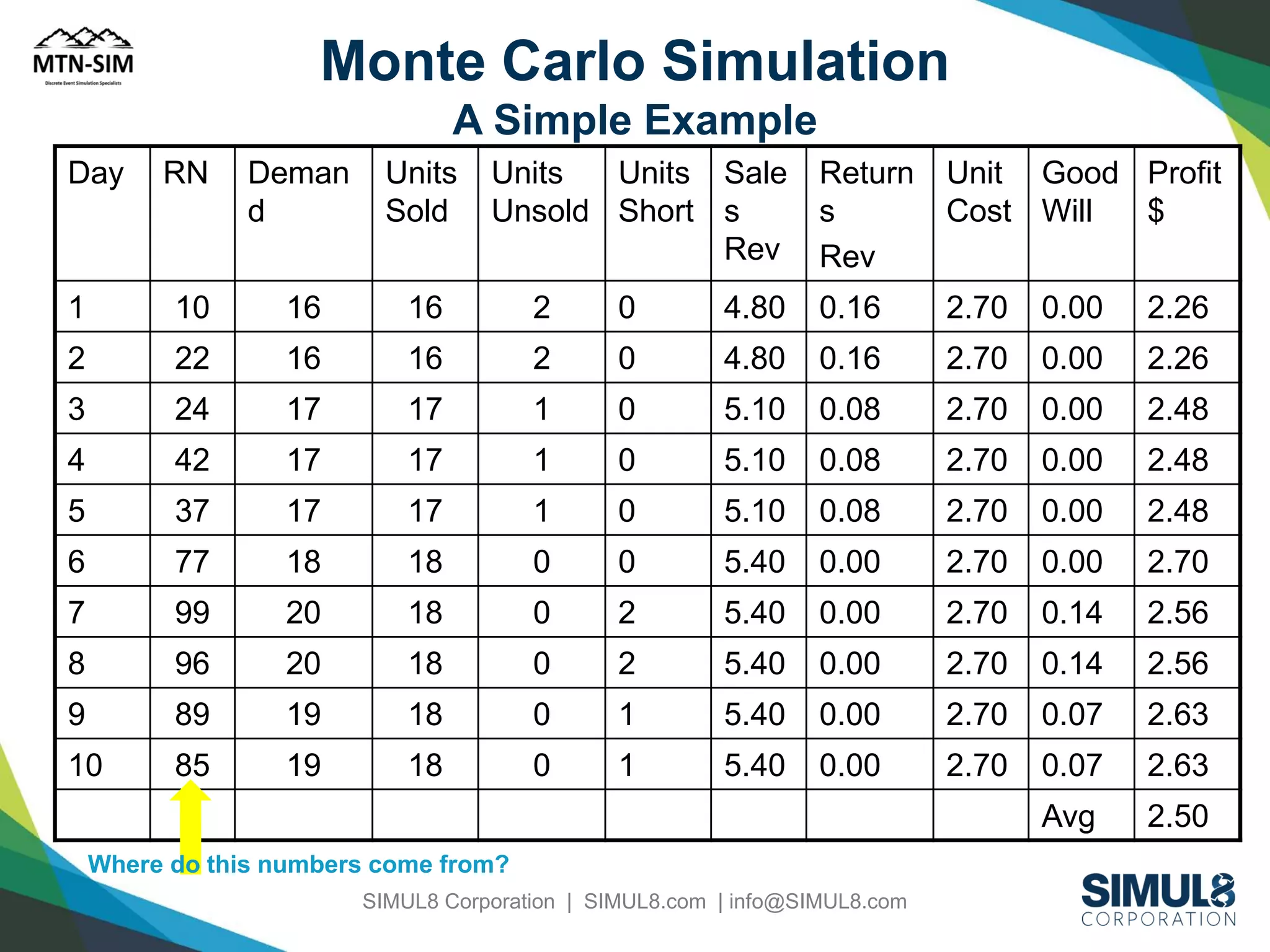

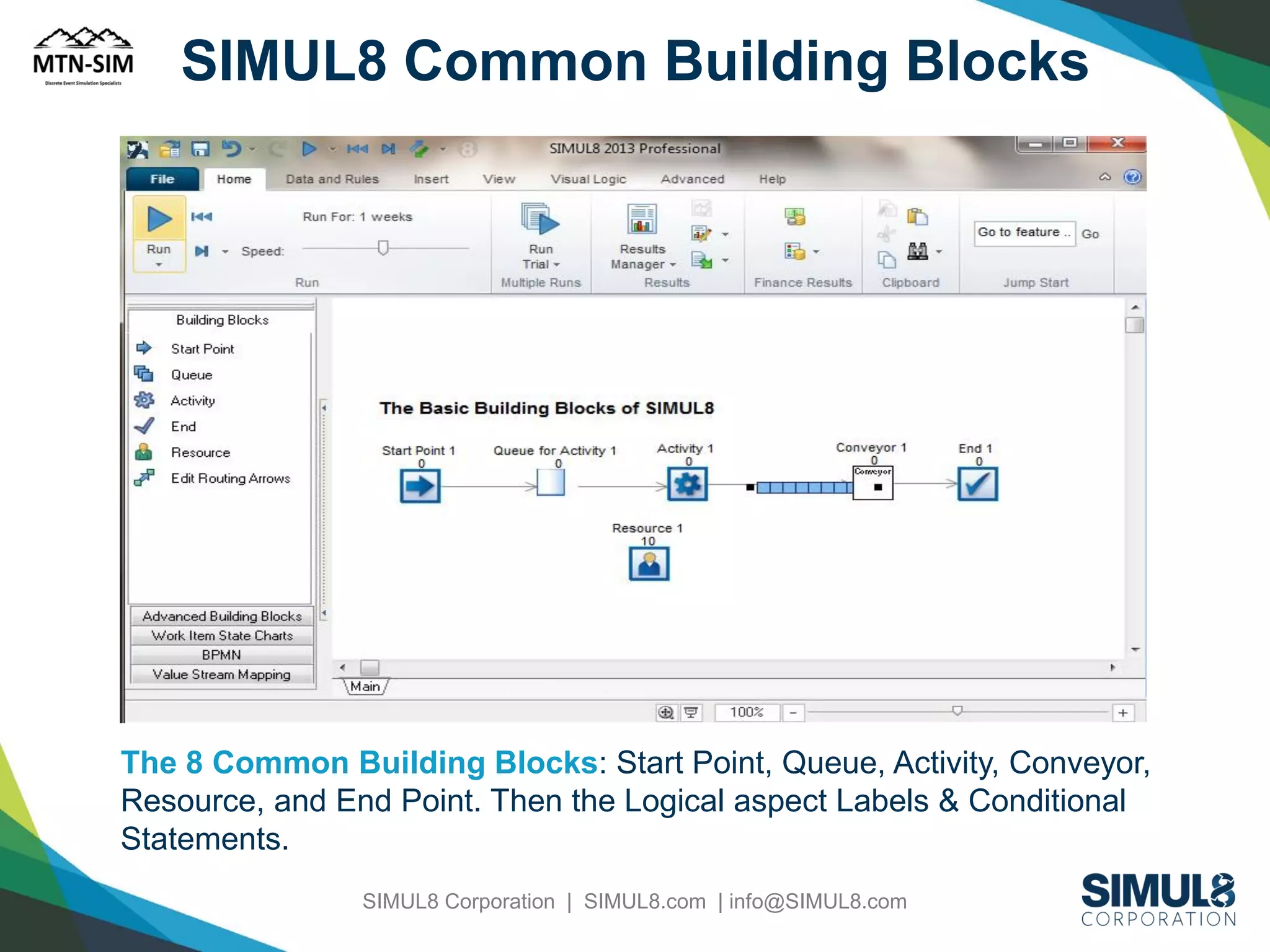

The document presents an overview of using simulation in manufacturing to address common issues and optimize processes. It discusses various types of simulation methods, including mathematical modeling, Monte Carlo simulation, and discrete event simulation, along with their applications for system design, operational procedures, and performance evaluation. Additionally, it highlights the benefits of simulation, such as improved realism, user involvement, and easier communication of results to decision-makers.