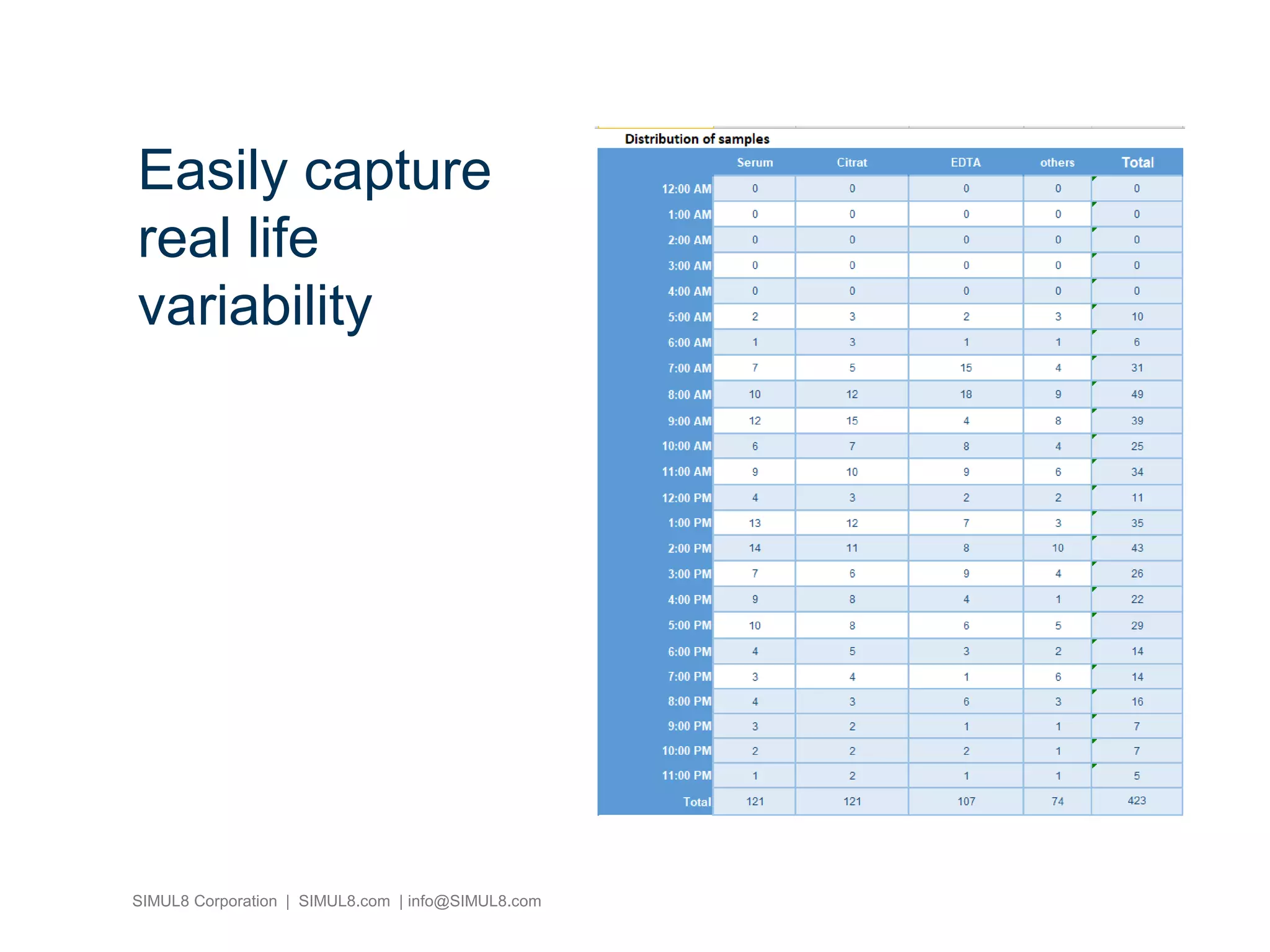

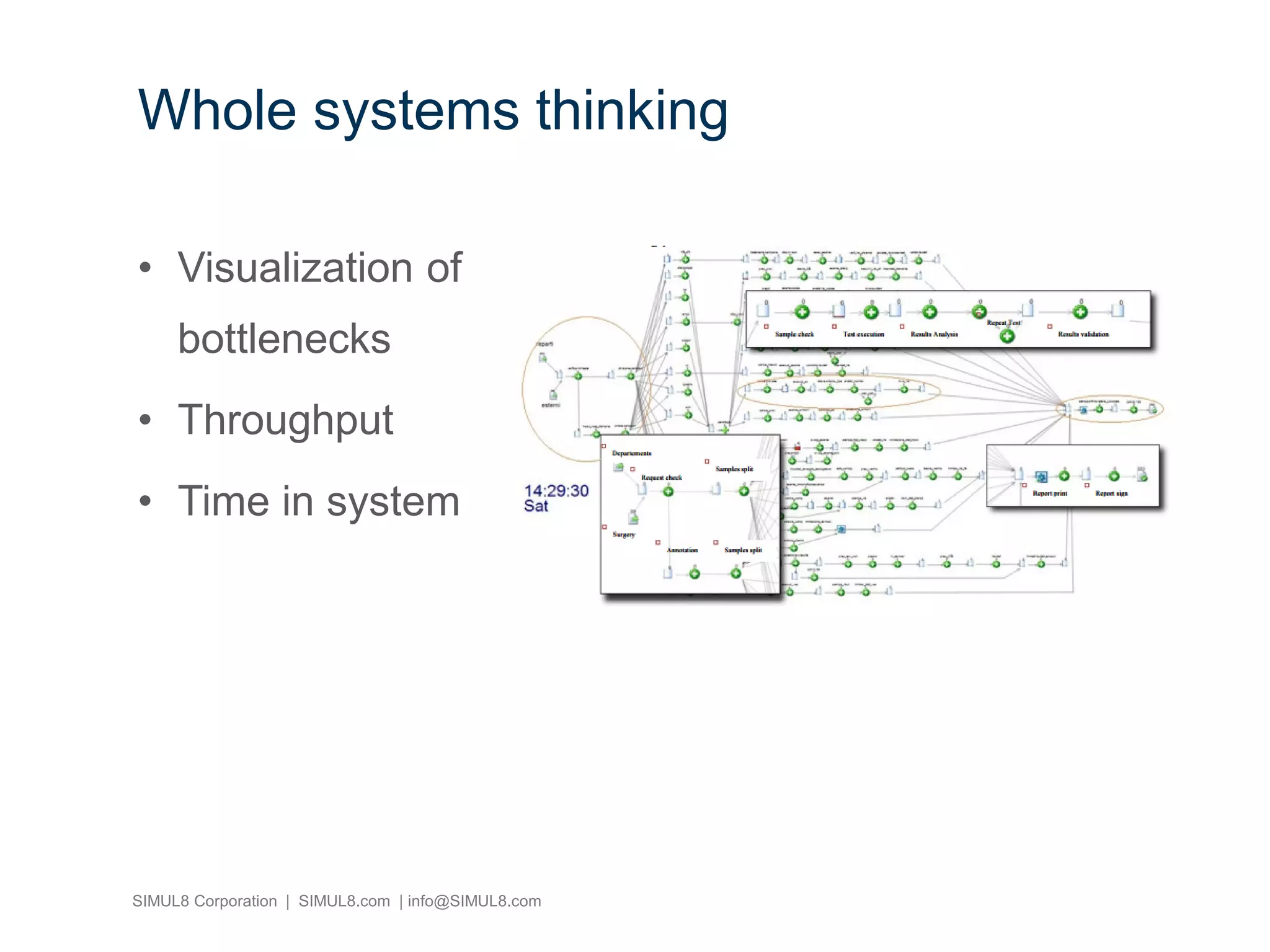

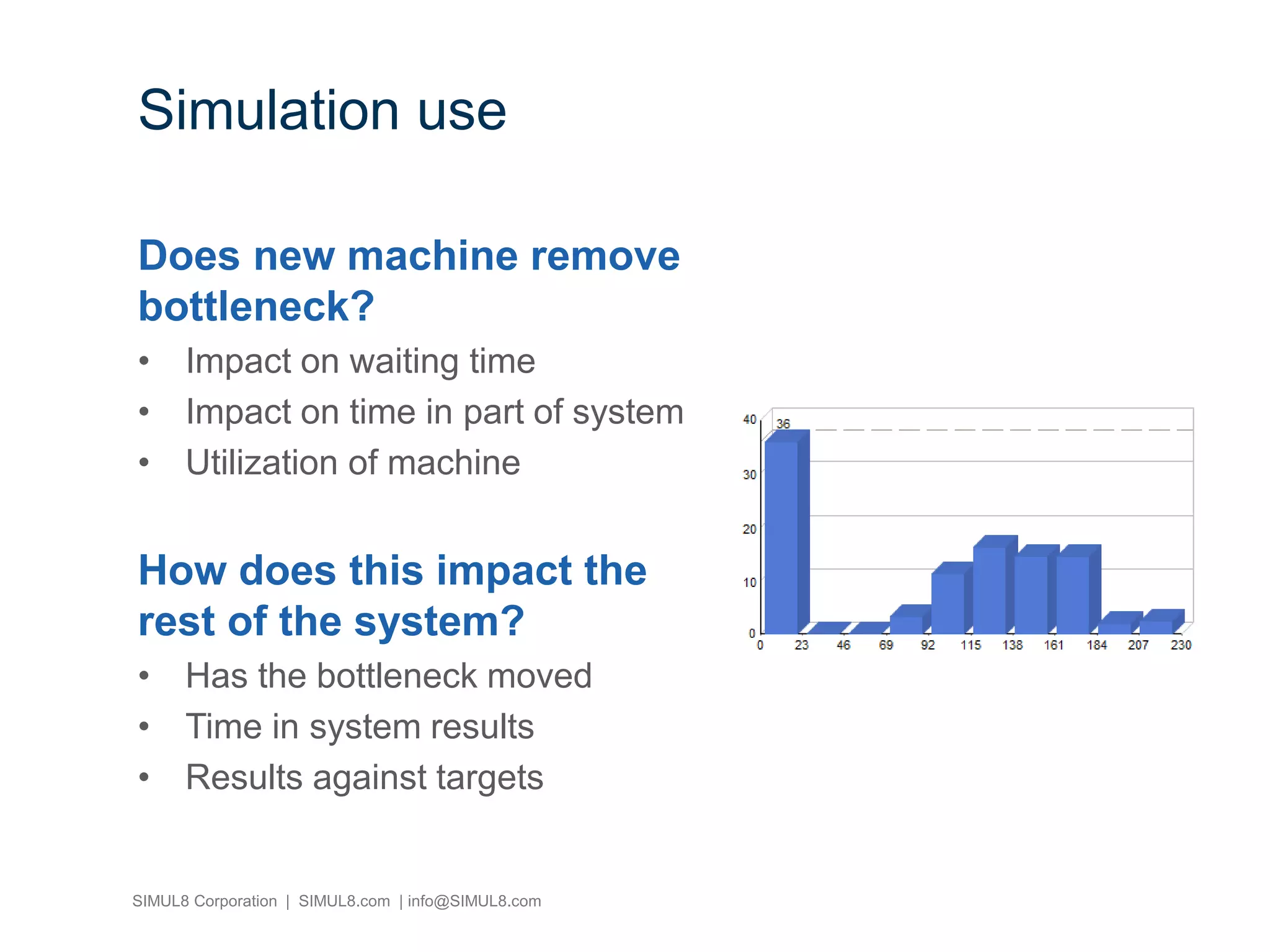

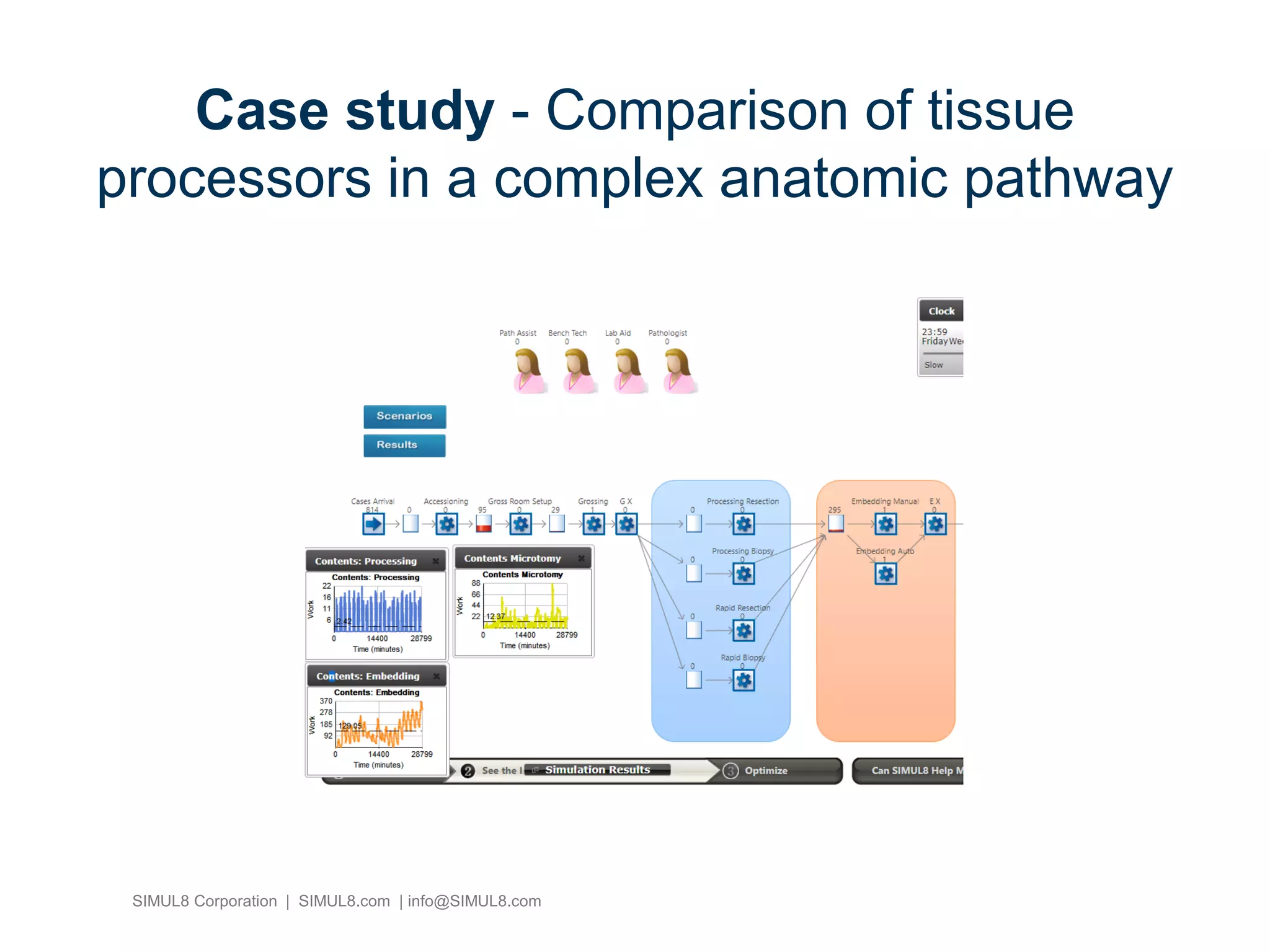

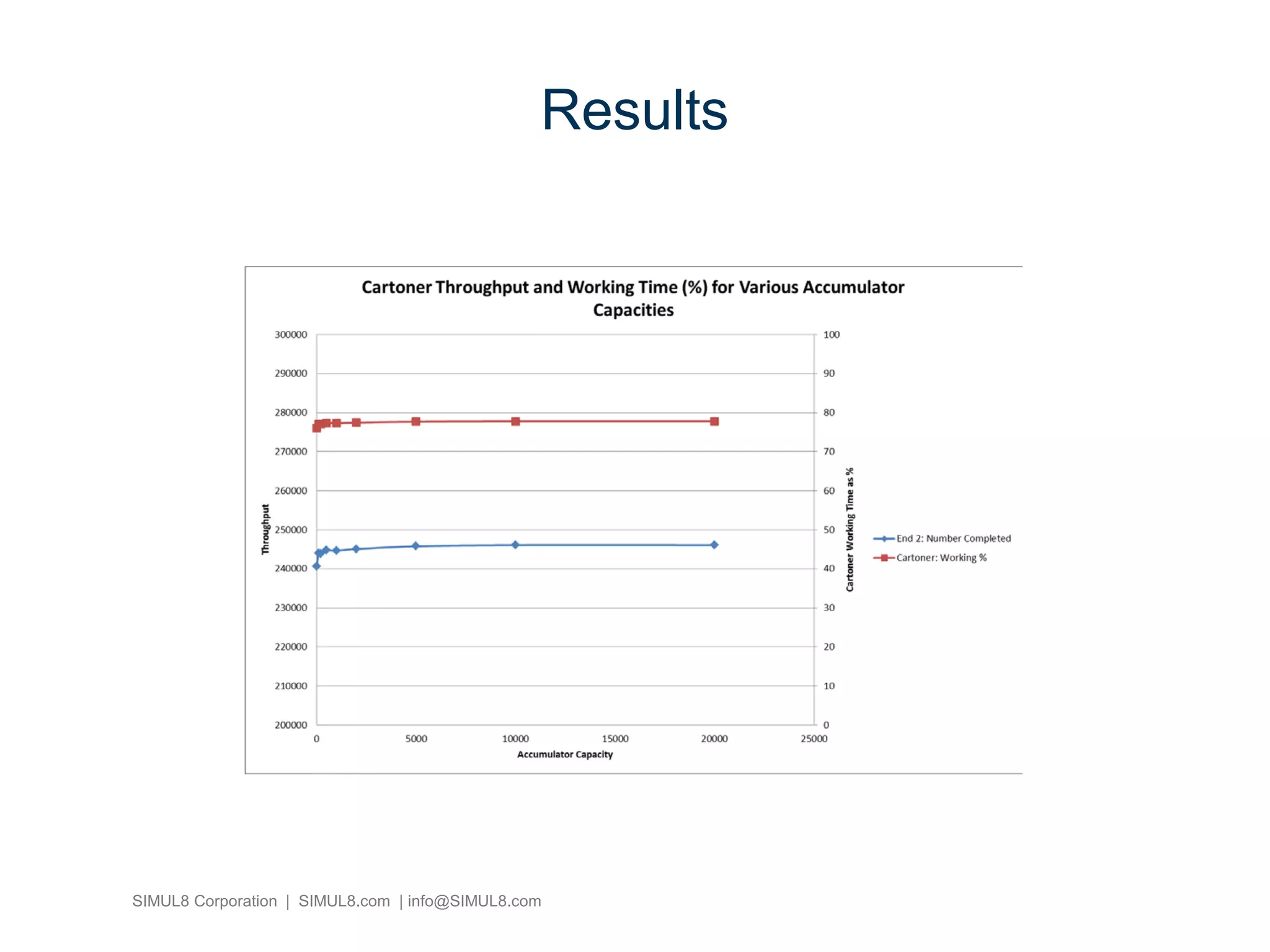

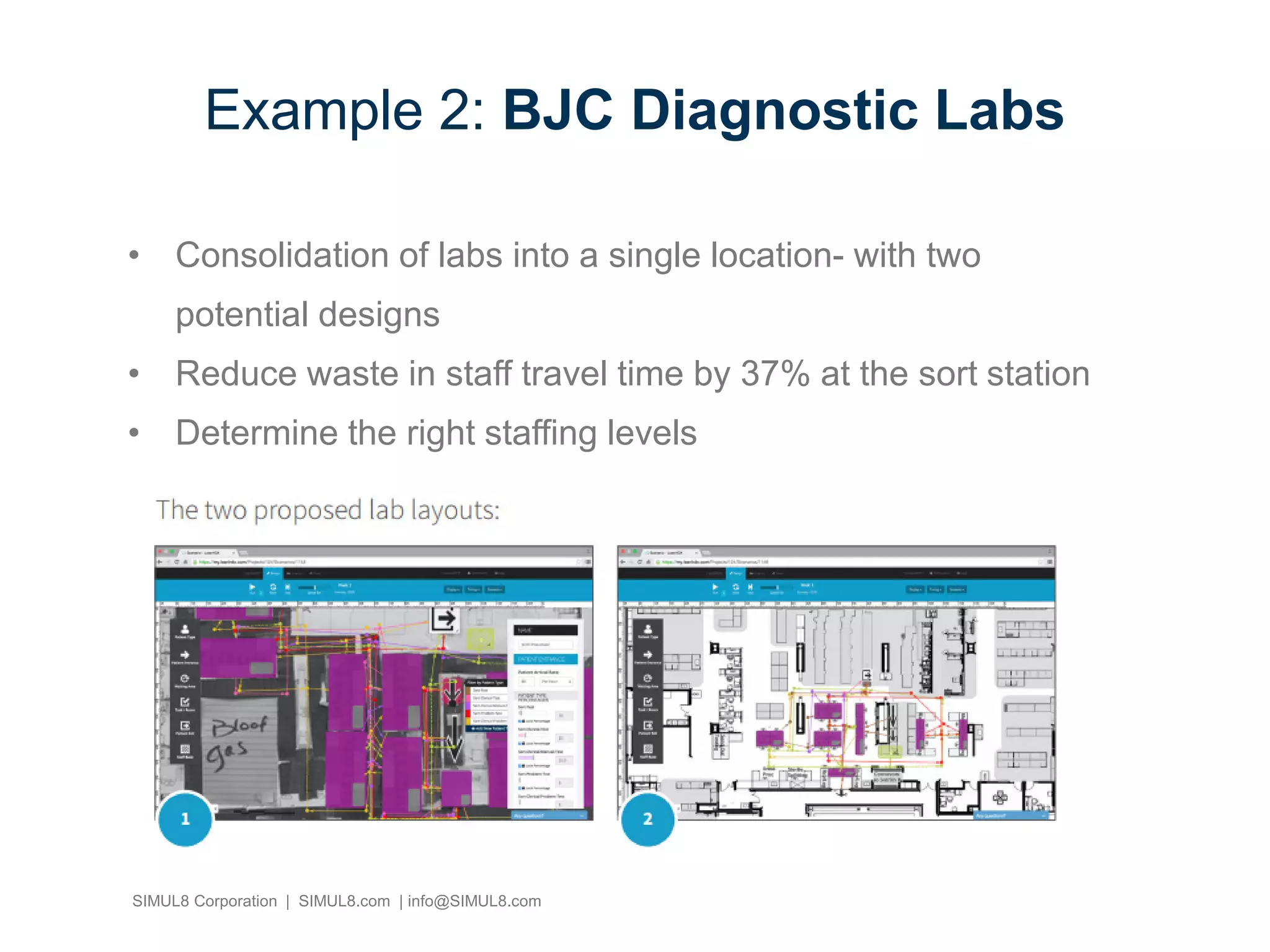

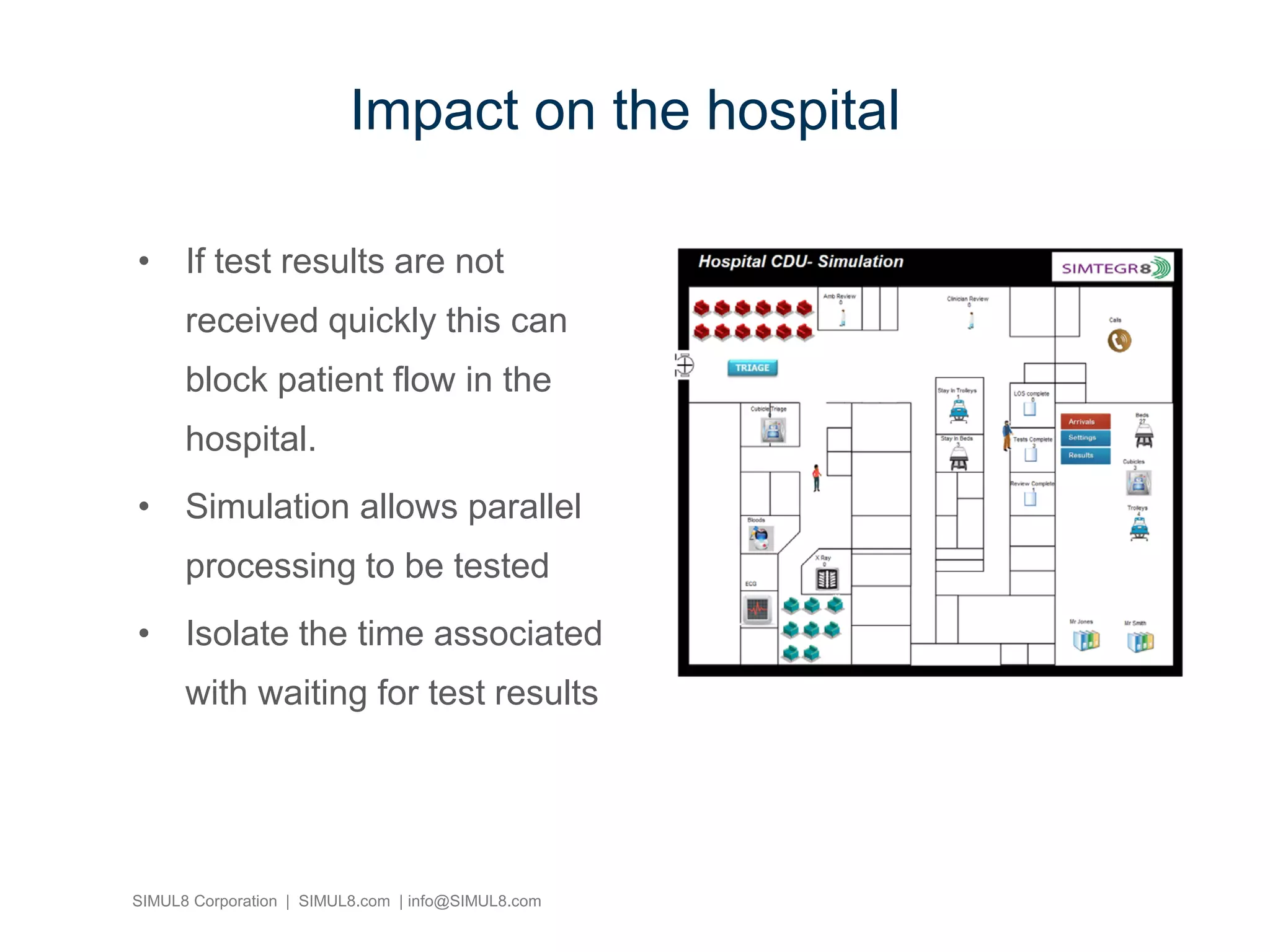

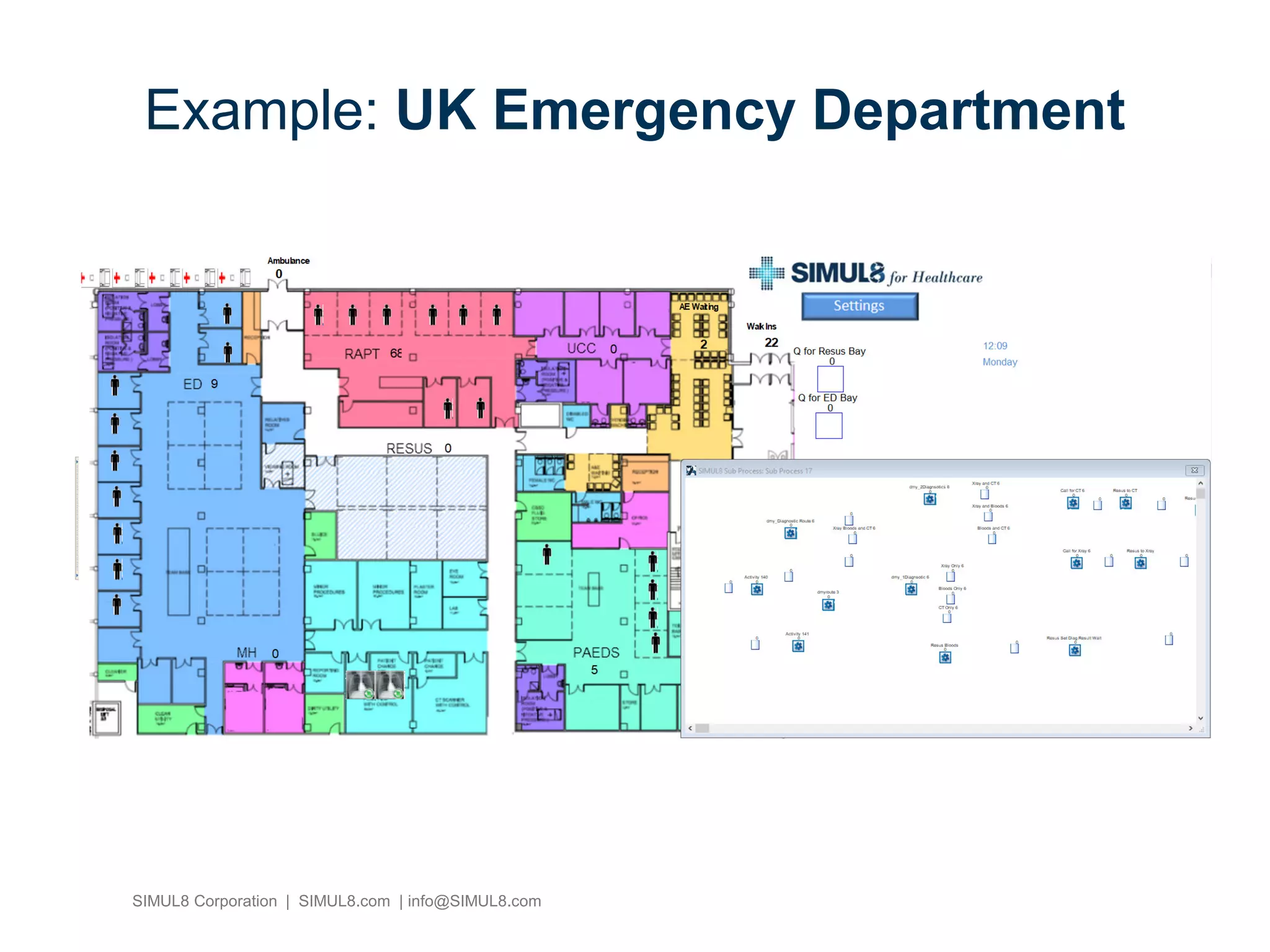

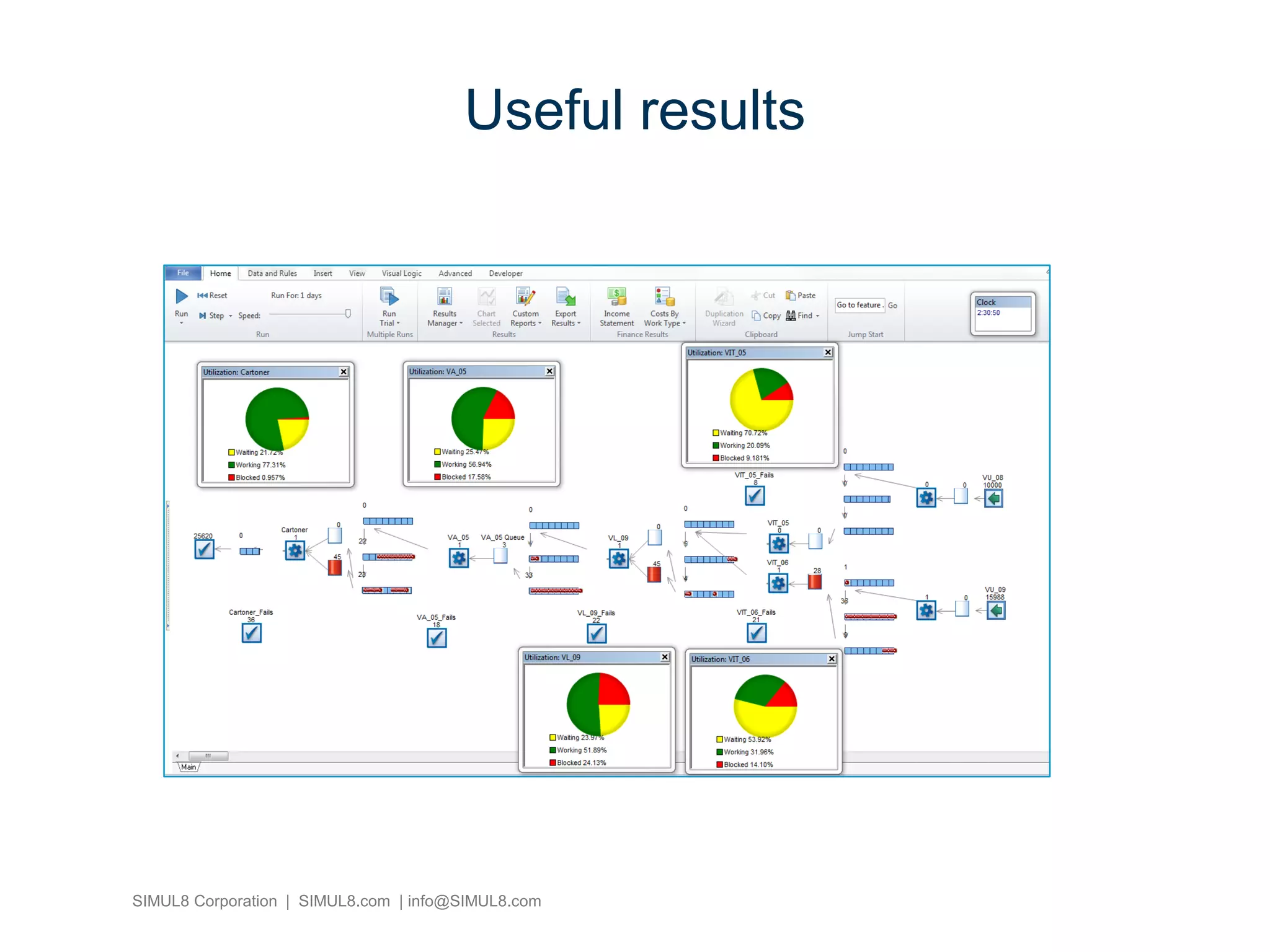

Tom Stephenson from SIMUL8 Corporation gives a presentation on improving laboratory flow with simulation. He discusses how simulation can be used to test improvements, assess the impact of new machinery, optimize layouts, and understand how systems will cope with demand changes. Common uses of simulation for laboratories include evaluating new equipment purchases, assessing total laboratory automation, and testing different layouts and demand scenarios. Case studies are presented on comparing tissue processors and simulating an automated laboratory and its impact on patient flow.