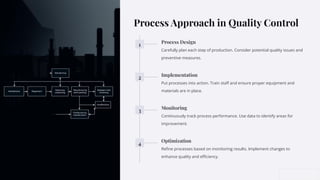

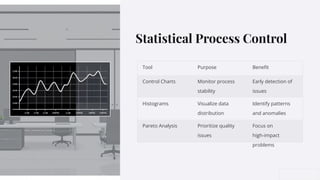

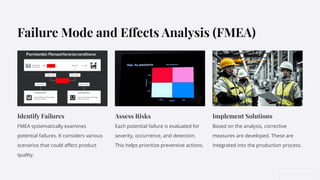

Quality control is essential for ensuring product excellence and customer satisfaction, involving systematic processes to meet specific standards through continuous monitoring and improvement. It focuses on identifying and preventing defects while fostering a customer-centric approach and teamwork across departments. Key tools include statistical process control and failure mode and effects analysis, which help identify and address quality issues effectively.