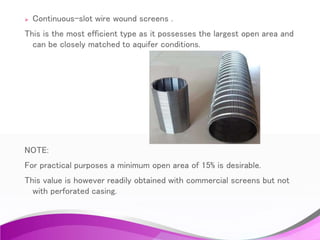

This document summarizes information about ground hydrology and well completion. It discusses the different types of wells, including shallow and deep wells. It also describes various well construction methods, such as digging, boring, and drilling. Additionally, it covers topics like well casing, cementing, gravel packing, and screen placement. Proper well completion is emphasized as being important for maximizing well yield and longevity.