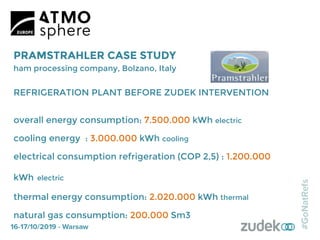

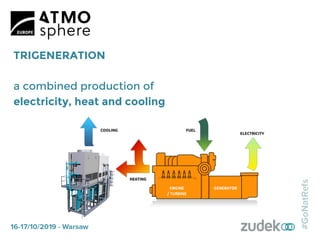

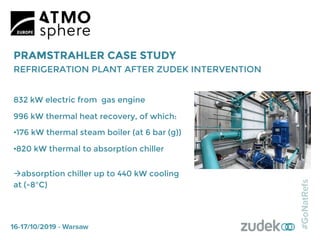

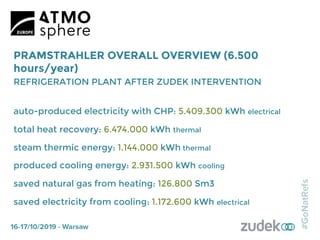

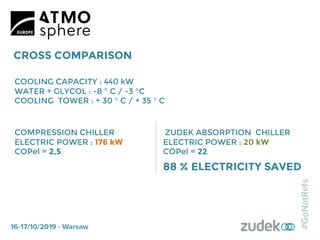

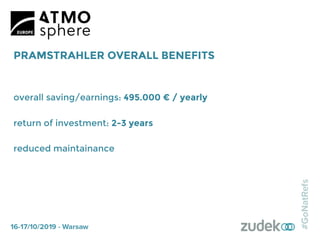

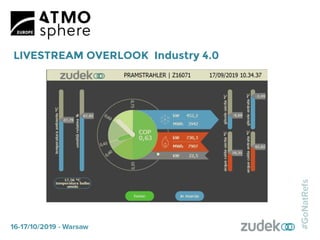

Zudek provides water-ammonia absorption chillers that use waste heat to produce cooling, reducing energy costs by up to 90%. A case study at a ham processing plant in Italy found that installing a Zudek chiller and gas engine-powered cogeneration system led to annual savings of 495,000 euros with a 2-3 year return on investment. The system produces electricity on-site, recovers waste heat to power the absorption chiller, and reduces the plant's cooling needs by 88% compared to the previous electric compression chiller with a COP of 2.5.