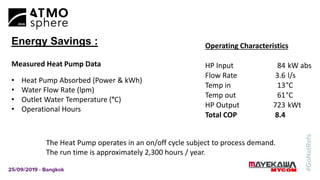

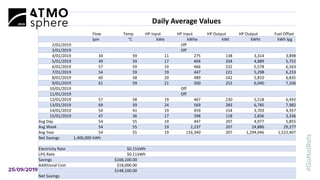

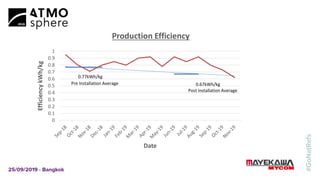

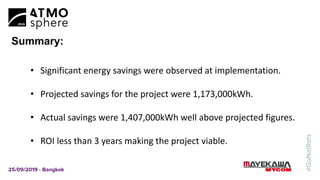

The document details a case study on the use of ammonia hot water heat pumps by Mayekawa Australia Pty Ltd, highlighting their advantages as natural refrigerants with zero ozone depletion and global warming potential. It outlines the energy savings achieved in a small goods production facility by utilizing waste heat, leading to significant reductions in energy consumption and costs. The implemented system demonstrated a return on investment (ROI) of less than three years, surpassing initial projected savings.

![Ammonia NH3

Refrigerant

ODP: Ozone Depletion Potential

GWP: Global Warming Potential ODP

GWP

[100yrs]

Safety

classification

Natural

Refrigerants

CO2 (R744) 0 1 A1

Ammonia (R717) 0 0 B2

Propane (R290) 0 3 A3

Iso-Butane

(R600a) 0 3 A3](https://image.slidesharecdn.com/5-1finalmillowmayekawaaustralia-190925124237/85/Ammonia-Hot-Water-Heat-Pump-Case-Study-5-320.jpg)

![Utilising Waste Heat :

THR = kWr + kW abs

1009.3kWr + 246.5kW abs

1.26 MW

MODEL : N220JL-V

REFRIGERANT : AMMONIA

RECOMMENDED PORT : M

BOOSTER : N

Vi : [-] 3.23

COMPRESSION RATIO : [-] 4.65

CAPACITY : [kW] 1009.3

ABSORBED POWER : [kW] 246.5

Typical IP Compressor @ Te/Tc -10°C / +35°C](https://image.slidesharecdn.com/5-1finalmillowmayekawaaustralia-190925124237/85/Ammonia-Hot-Water-Heat-Pump-Case-Study-6-320.jpg)

![Refrigeration Total Heat Rejection

SINGLE STAGE SCREW COMPRESSOR : 2019_ver.1

MODEL : N250VS*-M

REFRIGERANT : AMMONIA

RECOMMENDED PORT : L

Vi : [-] 2.98

COMPRESSION RATIO : [-] 4.65

CAPACITY : [kW] 1393.3

ABSORBED POWER : [kW] 330.6

SINGLE STAGE SCREW COMPRESSOR : 2019_ver.1

MODEL : N200VM*-M

REFRIGERANT : AMMONIA

RECOMMENDED PORT : L

Vi : [-] 3.23

COMPRESSION RATIO : [-] 4.65

CAPACITY : [kW] 824.9

ABSORBED POWER : [kW] 207.2

N200VMD

N250VSD

N160VLD LT = 334kW

Total: = 3,089kW

MT = 2,755kW](https://image.slidesharecdn.com/5-1finalmillowmayekawaaustralia-190925124237/85/Ammonia-Hot-Water-Heat-Pump-Case-Study-9-320.jpg)

![Heat Pump Design Data

REFRIGERANT AMMONIA

MODEL N6HK

BOOSTER N

CAPACITY [kW] 462.0

ABSORBED POWER [kW] 75.8

SPEED [min-1] 1450

LOAD [%] 100

CONDENSING TEMP. [degC] 70.0

EVAPORATIVE TEMP. [degC] 30.0

SUCTION SUPERHEAT [degC] 1.00

LIQUID SUBCOOLING [degC] 40.0

SUCTION PRES. [MPaA] 1.17

DISCHARGE PRES. [MPaA] 3.31

SWEPT VOLUME [m3/h] 193

DISCHARGE TEMP. [degC] 118

COP [-] 6.09

HEATING CAPACITY [kW] 532.0

COPh [-] 7.02

COPt [-] 13.1](https://image.slidesharecdn.com/5-1finalmillowmayekawaaustralia-190925124237/85/Ammonia-Hot-Water-Heat-Pump-Case-Study-10-320.jpg)