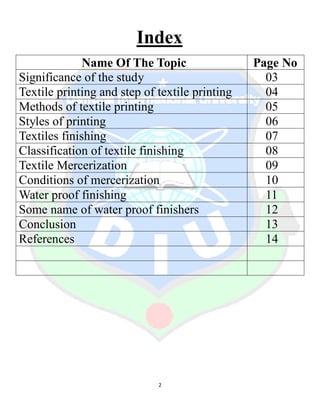

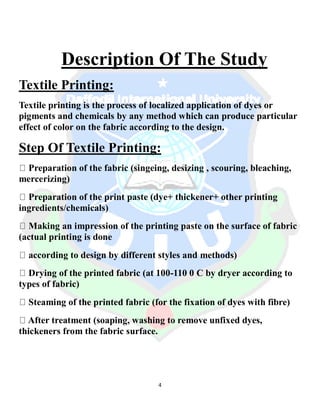

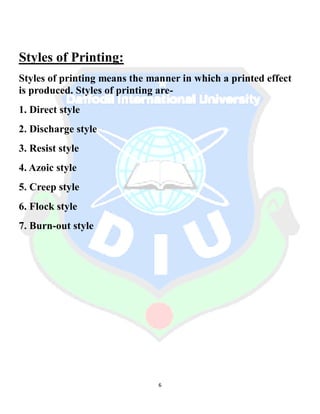

1. The document discusses textile printing and finishing processes, including the significance, steps of textile printing, methods of printing, styles of printing, textile finishing, classification of finishing, textile mercerization, conditions of mercerization, waterproof finishing, and important water repellent finishes.

2. Key topics covered include the preparation of fabric for printing, making the print paste, applying the print, drying and steaming the printed fabric, and different printing methods like screen, roller, and digital printing.

3. Textile finishing aims to make fabrics suitable for their end use by making them shrink proof, softer, stiffer, water repellent or crease resistant, and important finishes