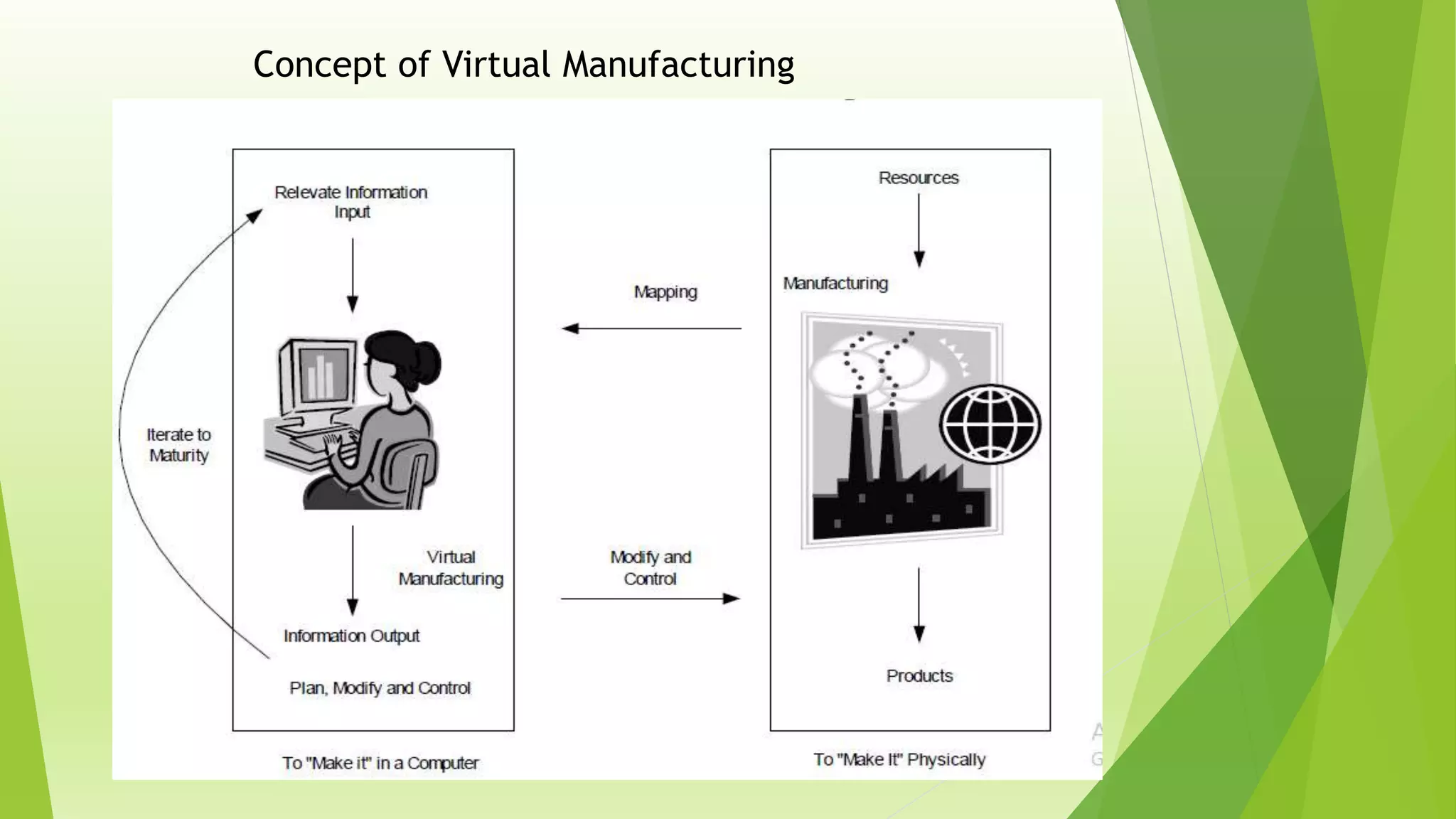

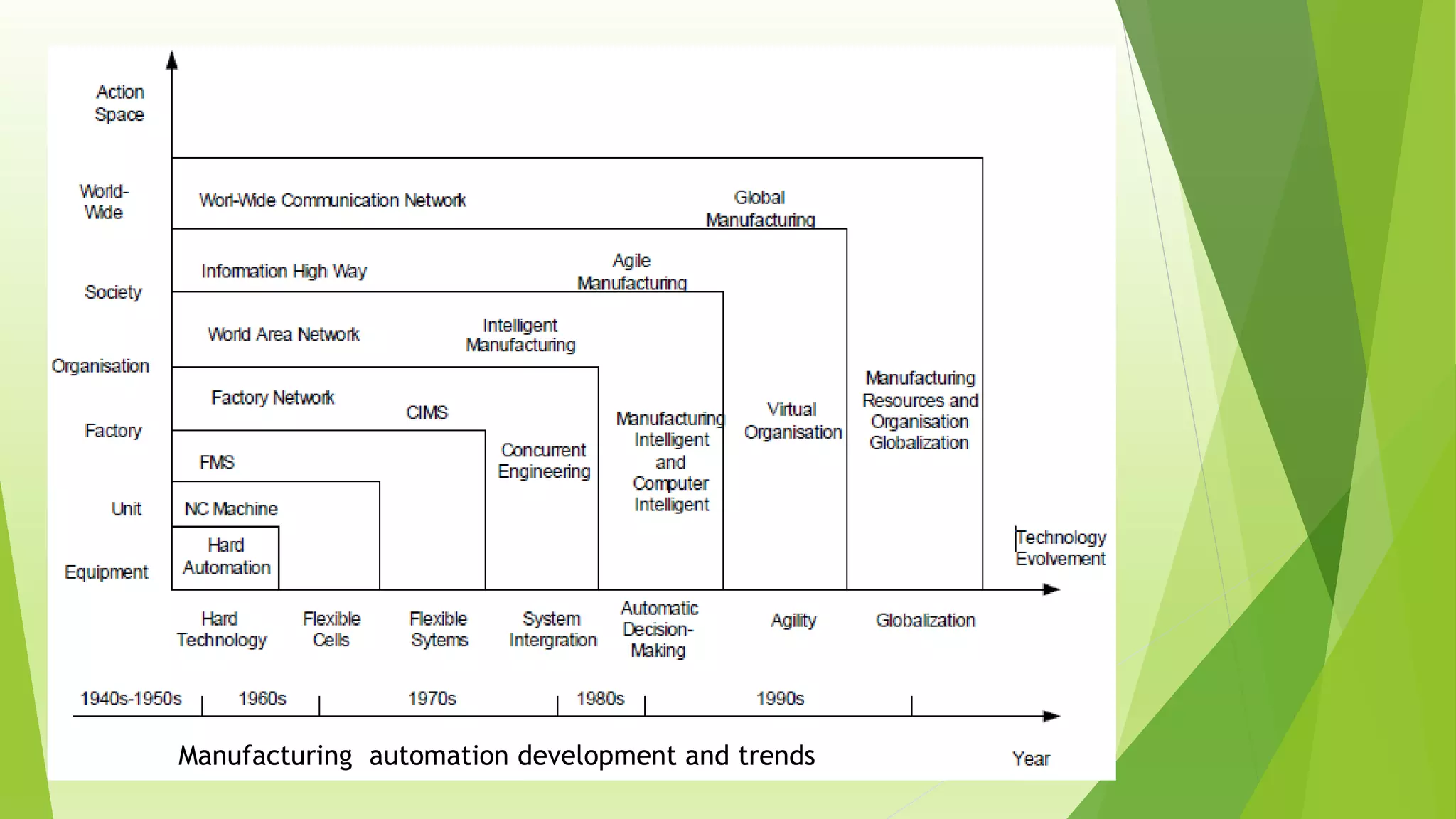

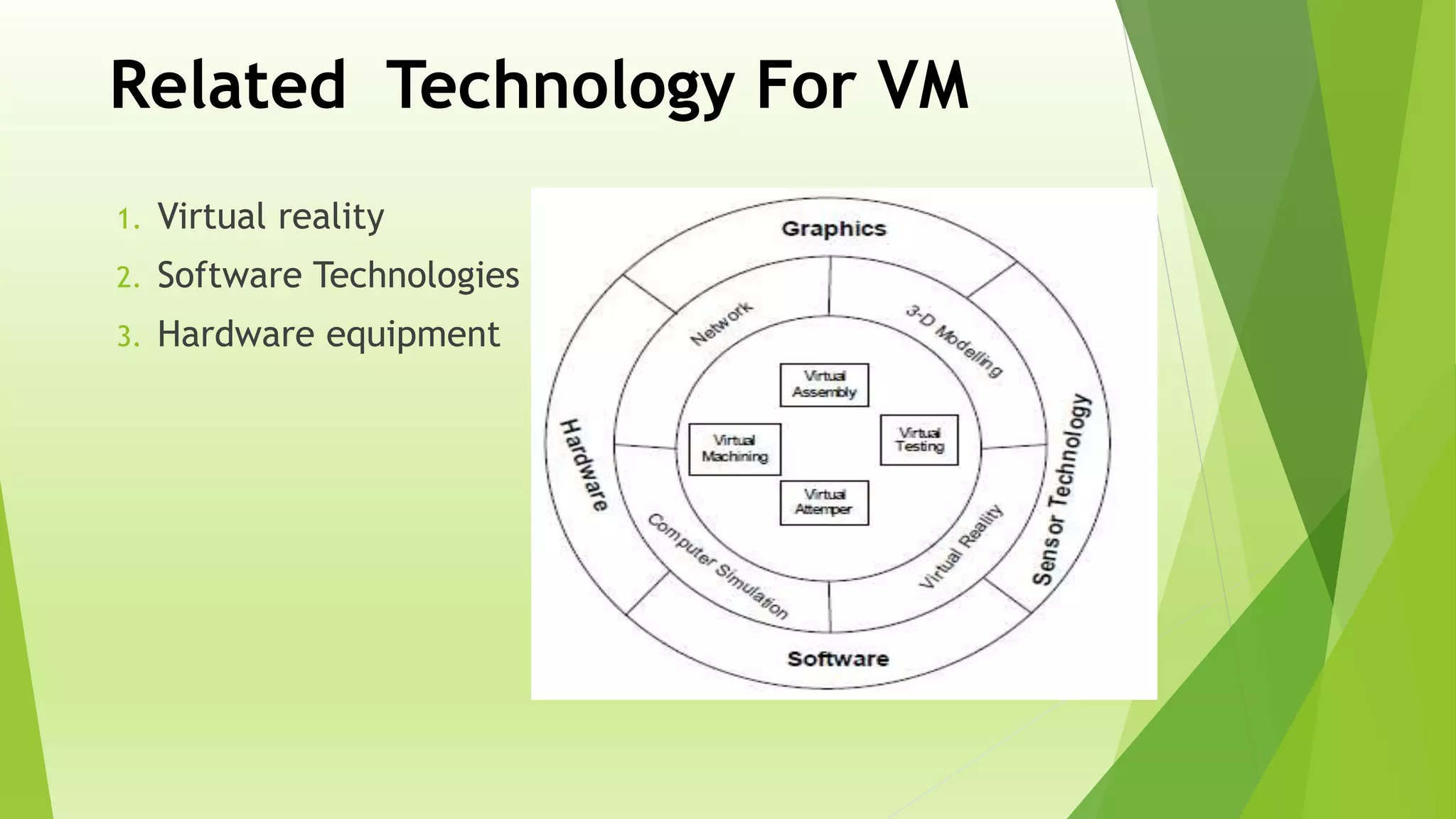

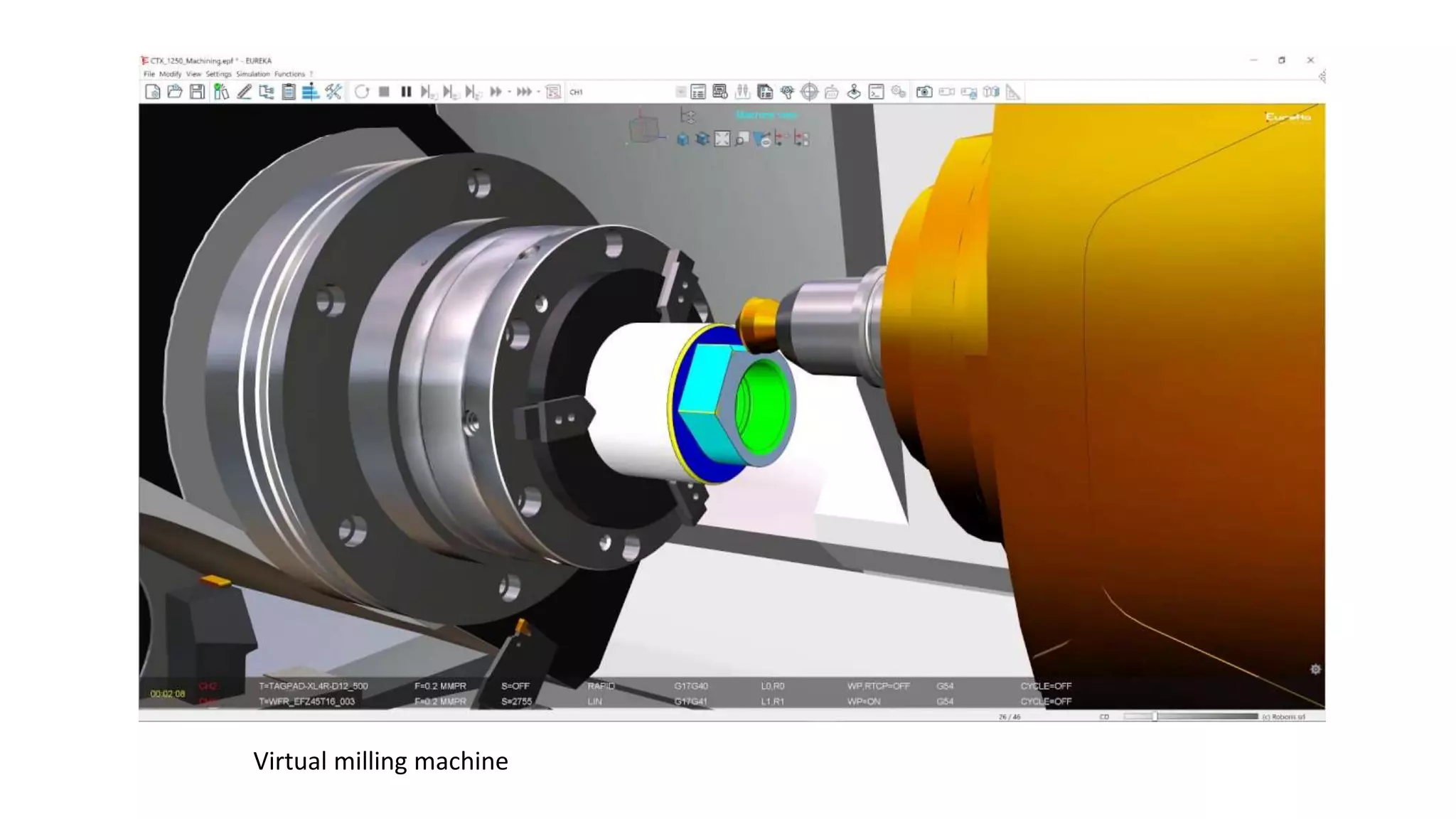

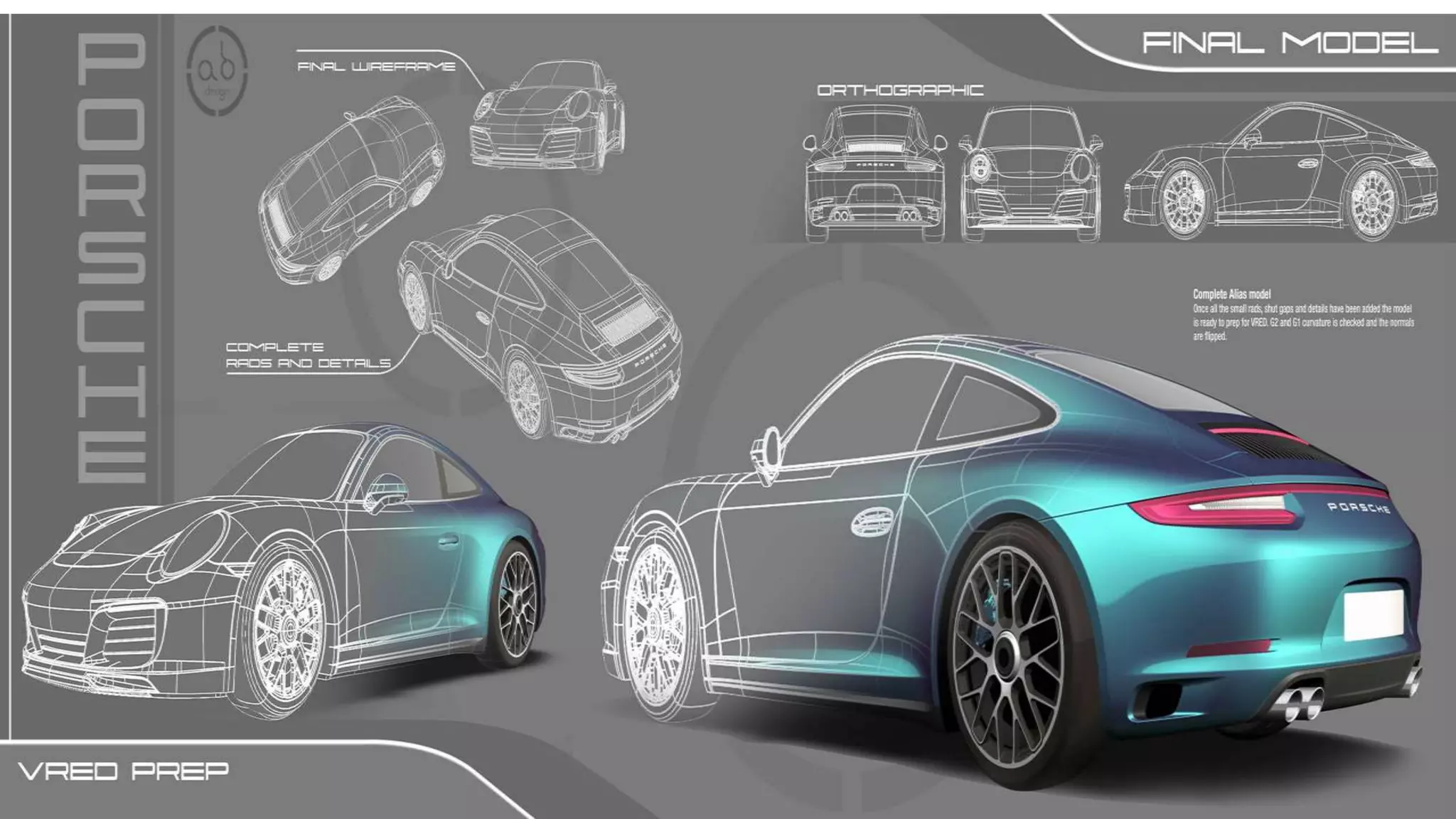

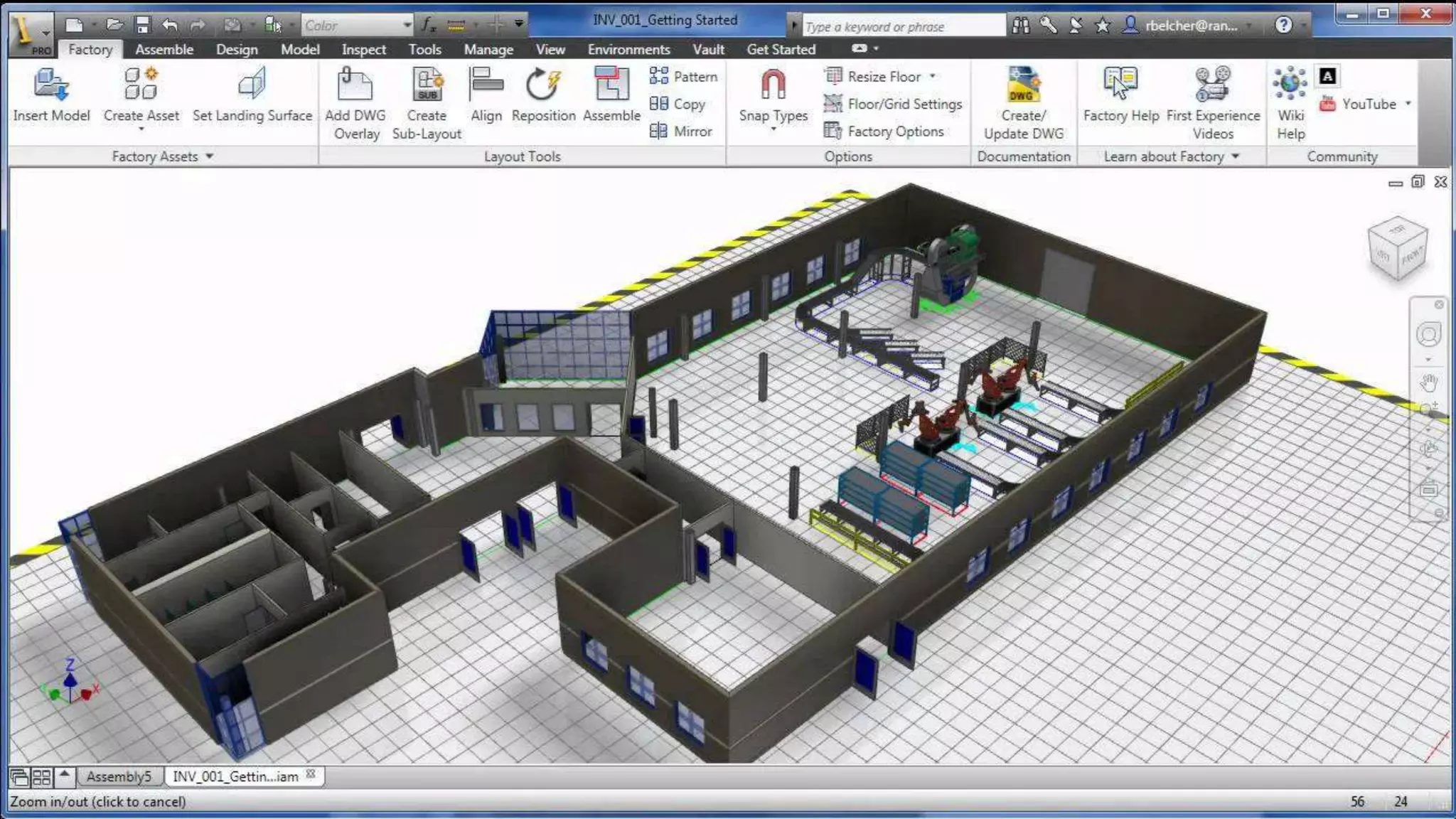

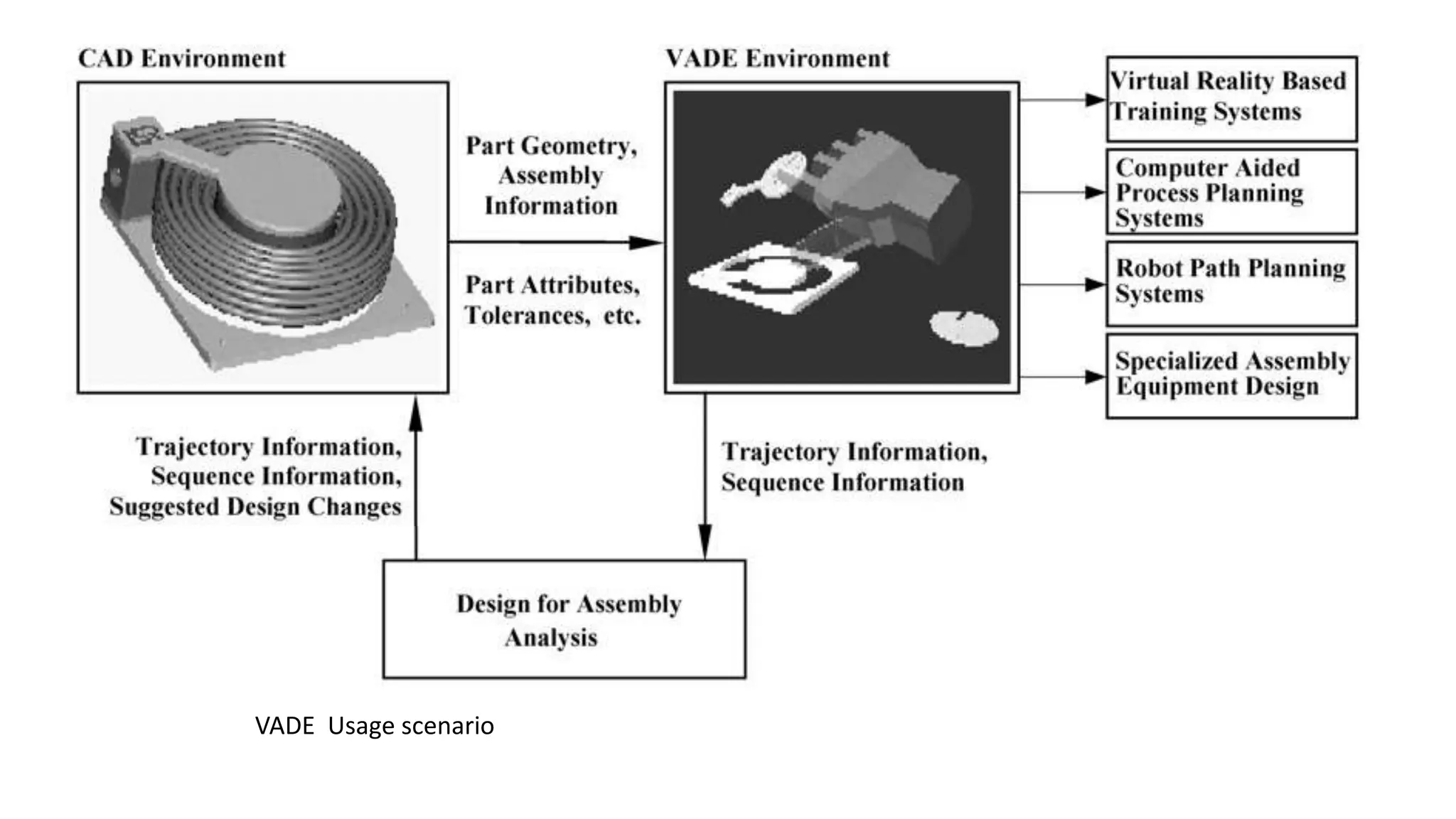

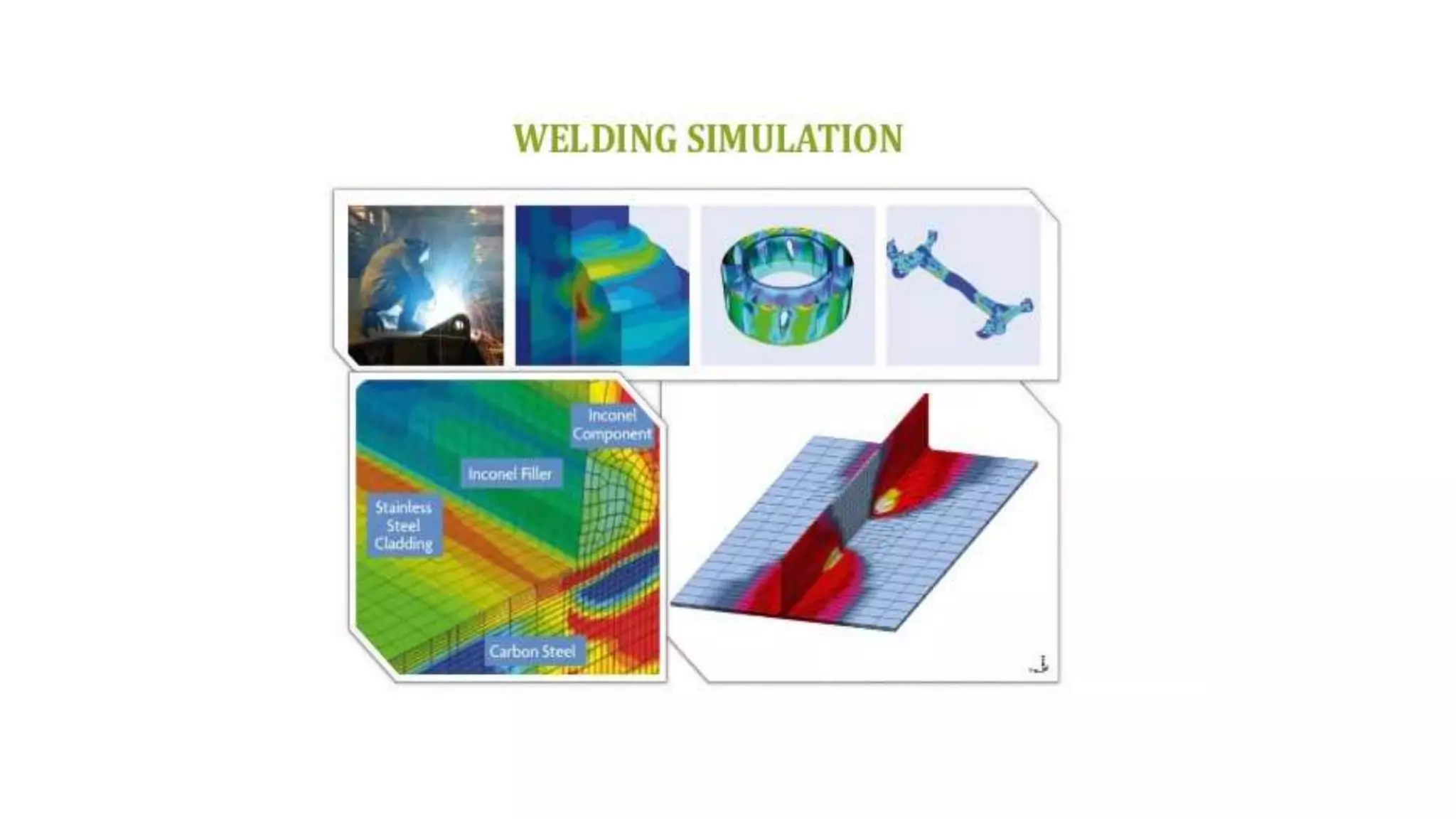

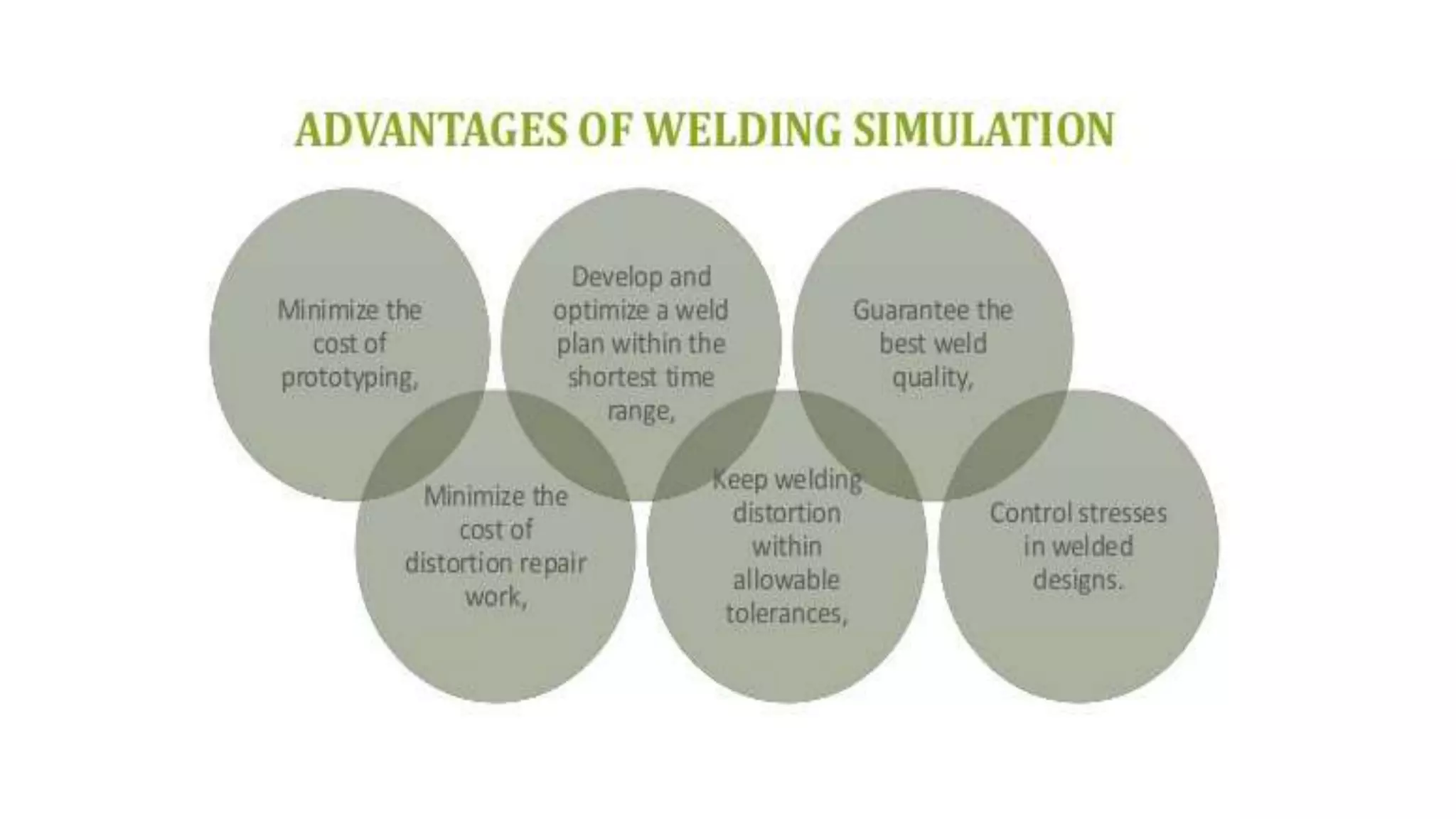

Virtual manufacturing is a new technology that uses computer simulation and virtual reality to model the real manufacturing process. It allows manufacturers to predict potential issues before production and evaluate products. Virtual manufacturing includes techniques like virtual design, machining, assembly, and testing. It provides benefits like reducing costs and errors. Example applications include Boeing using it for aircraft design and automakers using it for vehicle development. Virtual manufacturing systems map the real manufacturing system digitally to integrate information and simulate the physical processes.