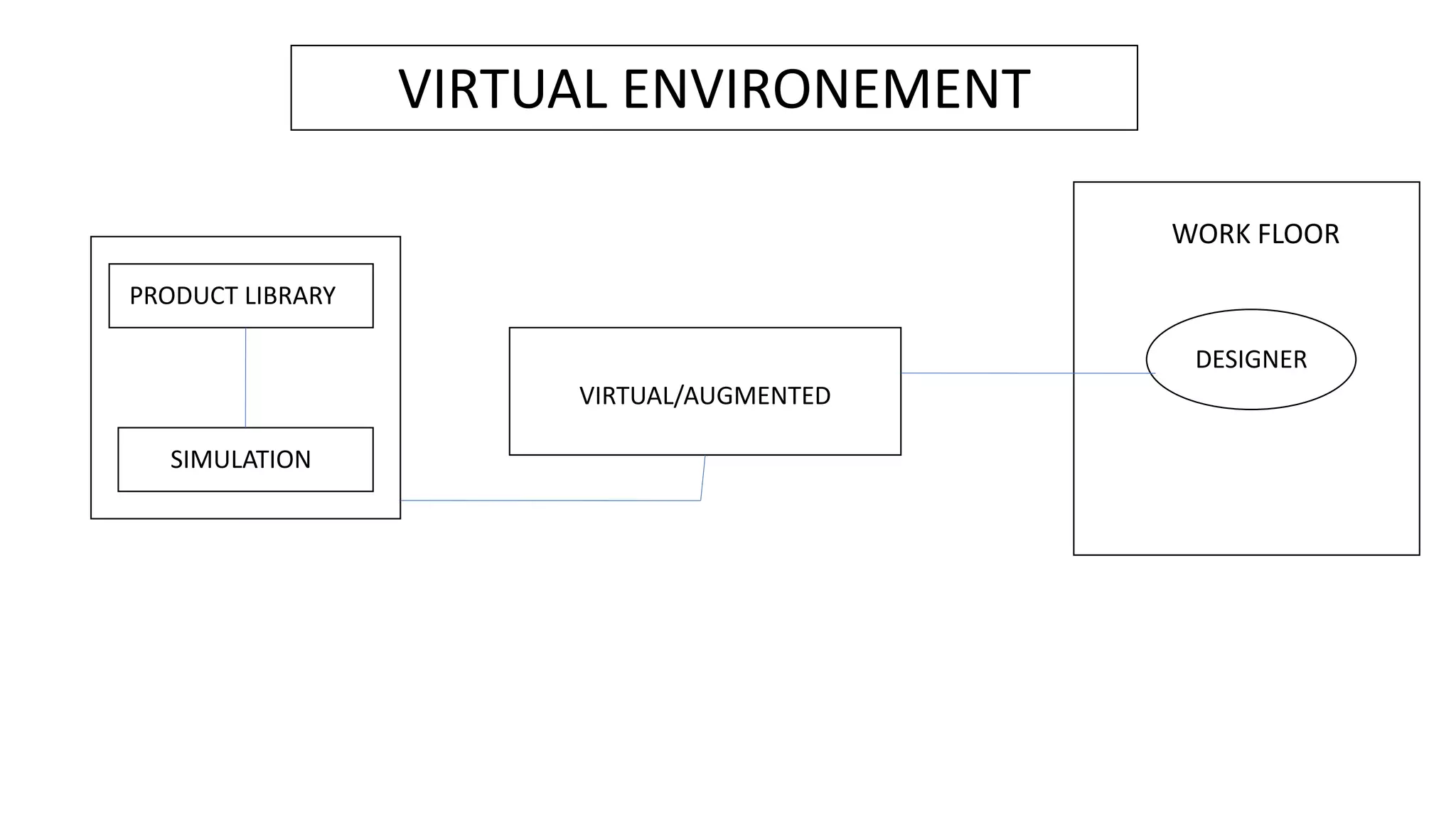

Virtual manufacturing is a computer-based system designed to model, simulate, and optimize factory operations and has evolved from testing machine tools to encompassing entire production processes. The advantages include reduced costs and enhanced precision, while drawbacks are the need for new equipment and a skilled workforce. Ultimately, it aims to bridge the gap between laboratory conditions and real-world manufacturing.