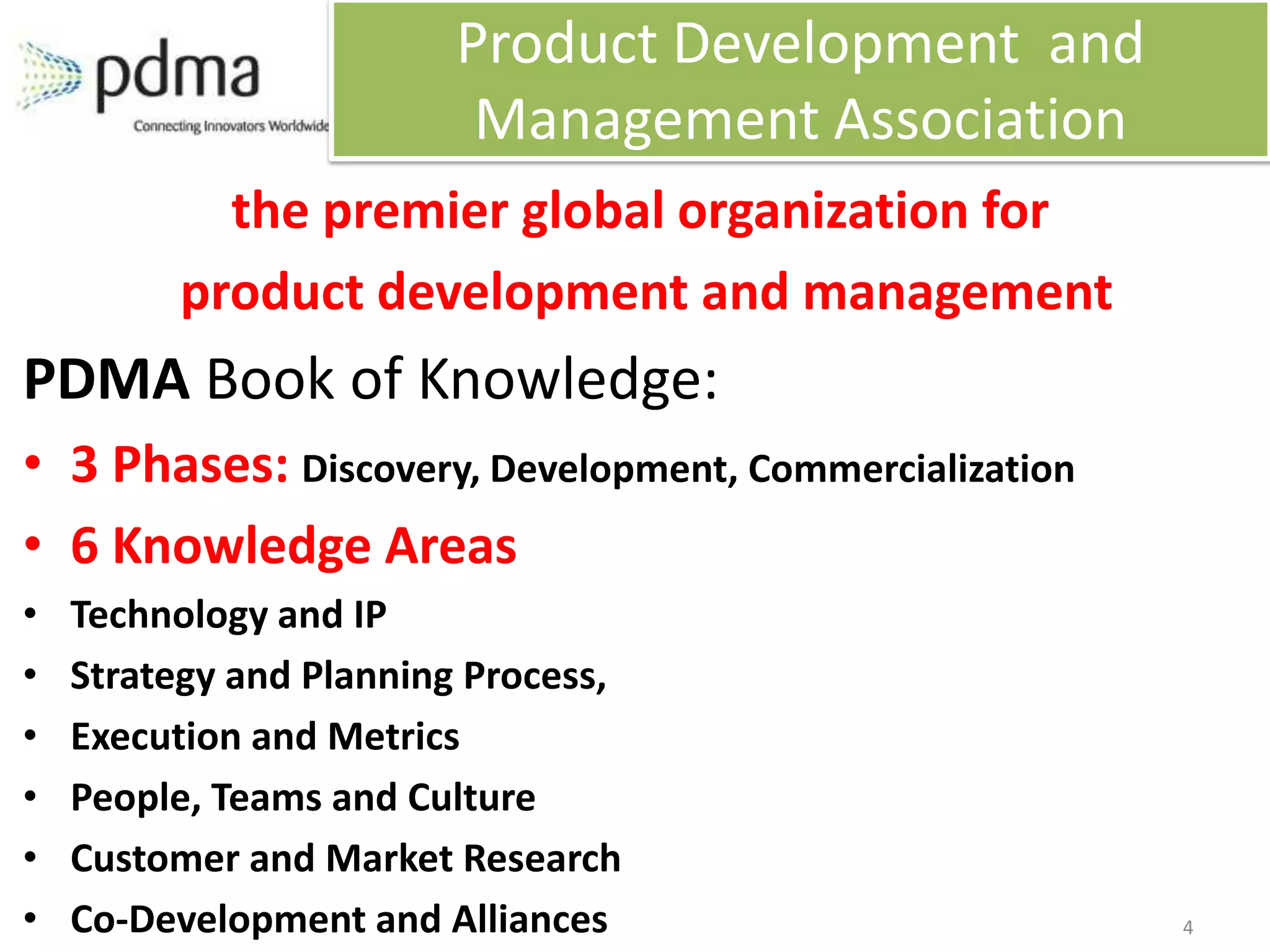

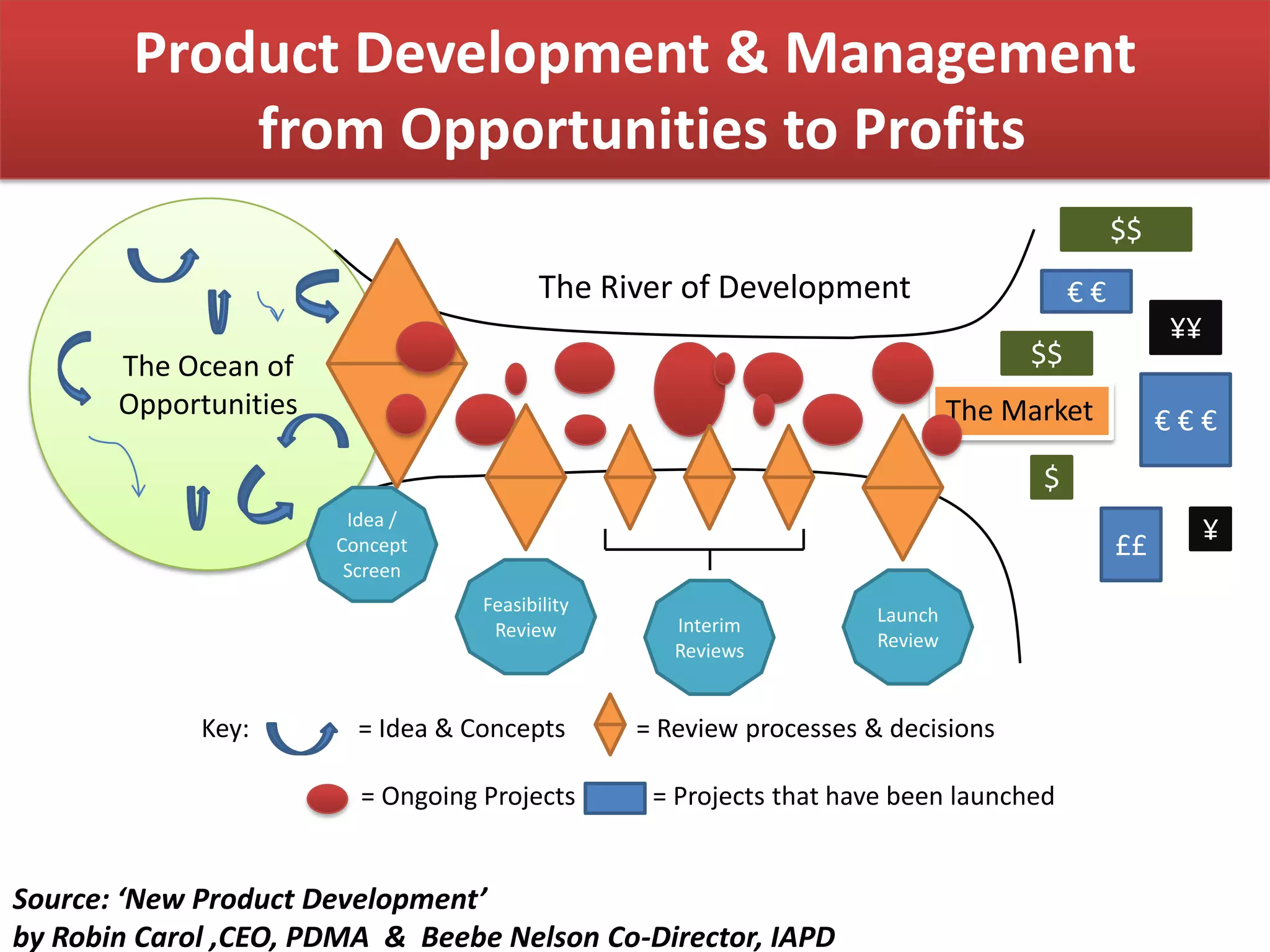

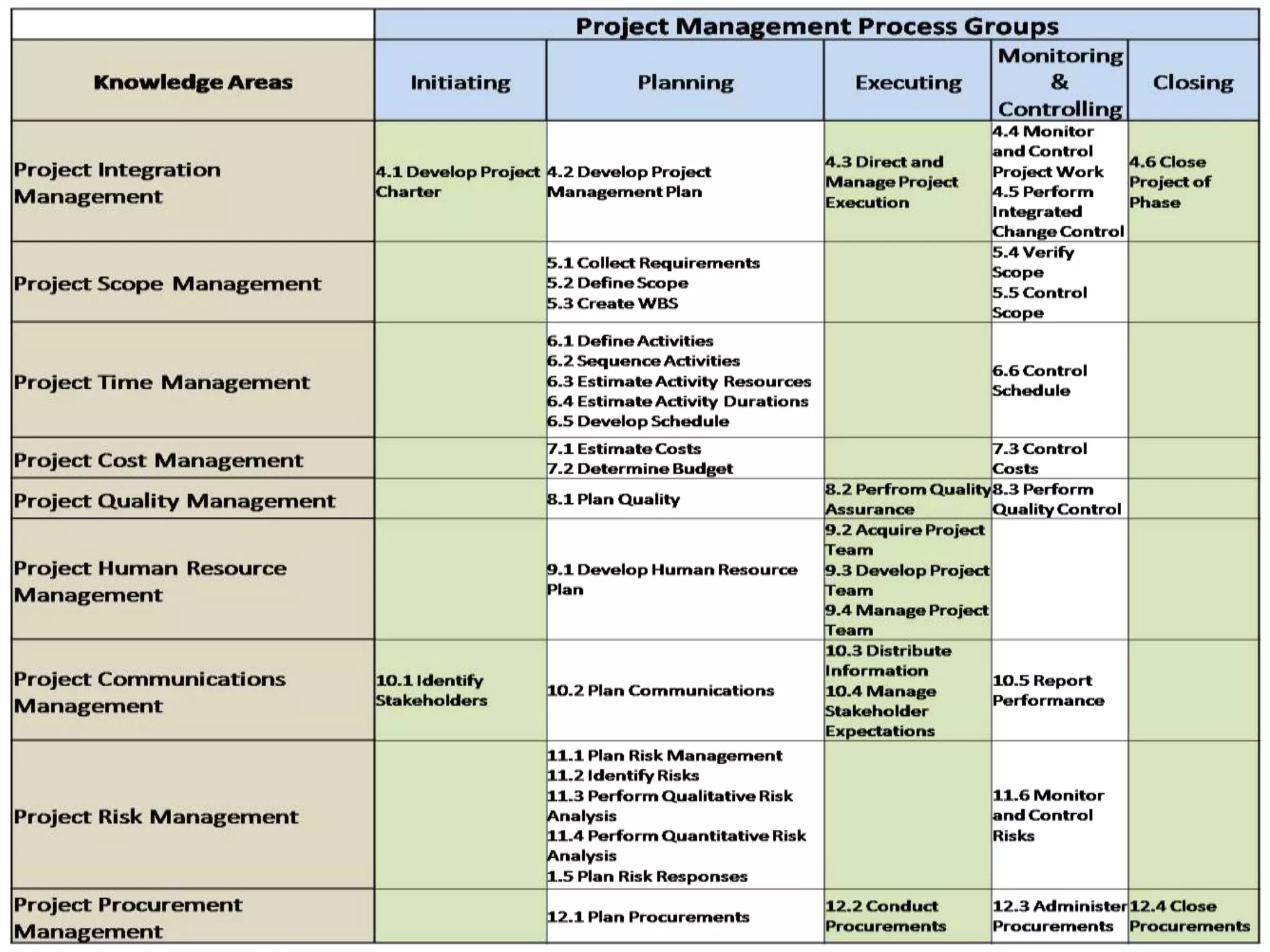

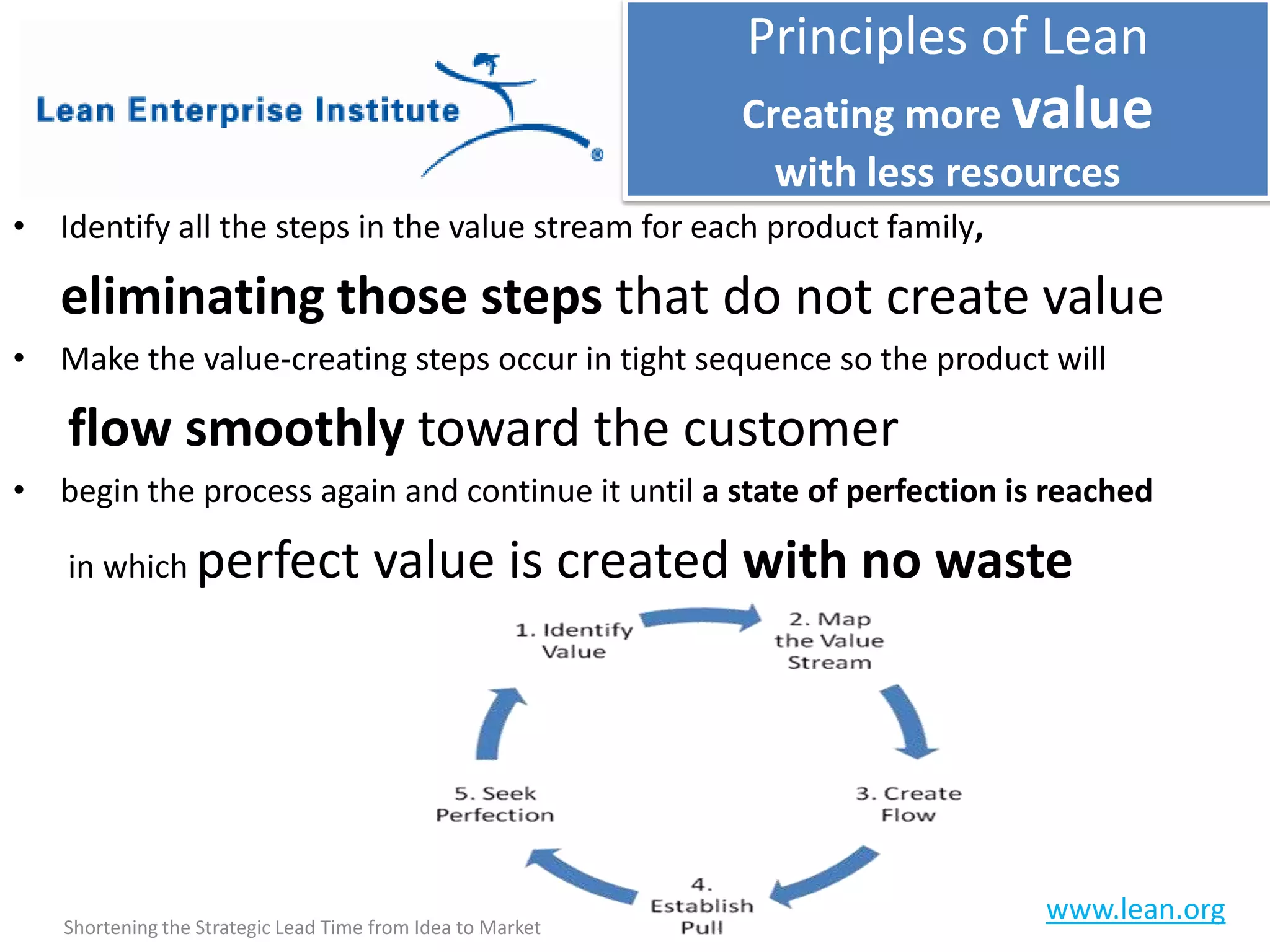

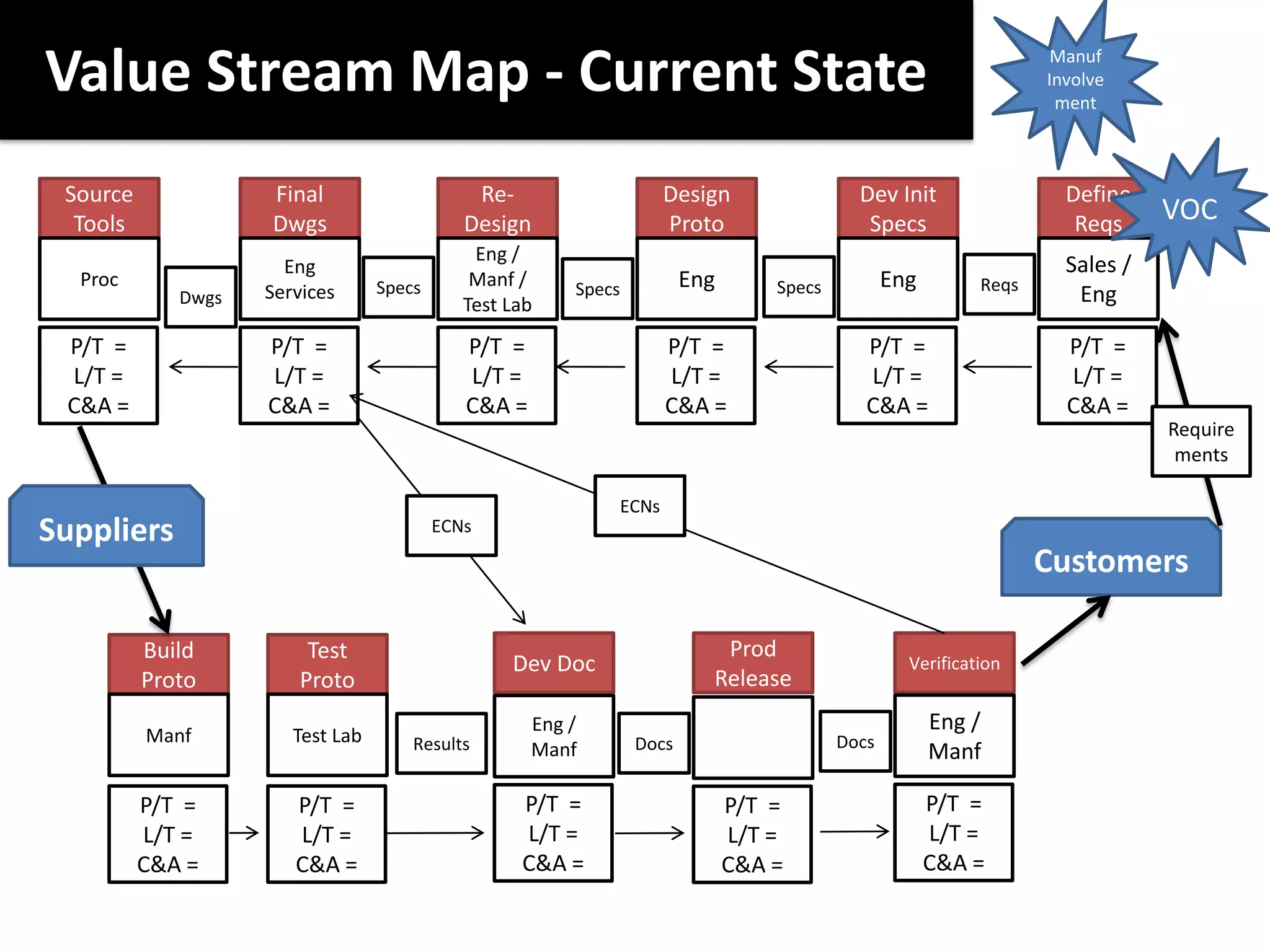

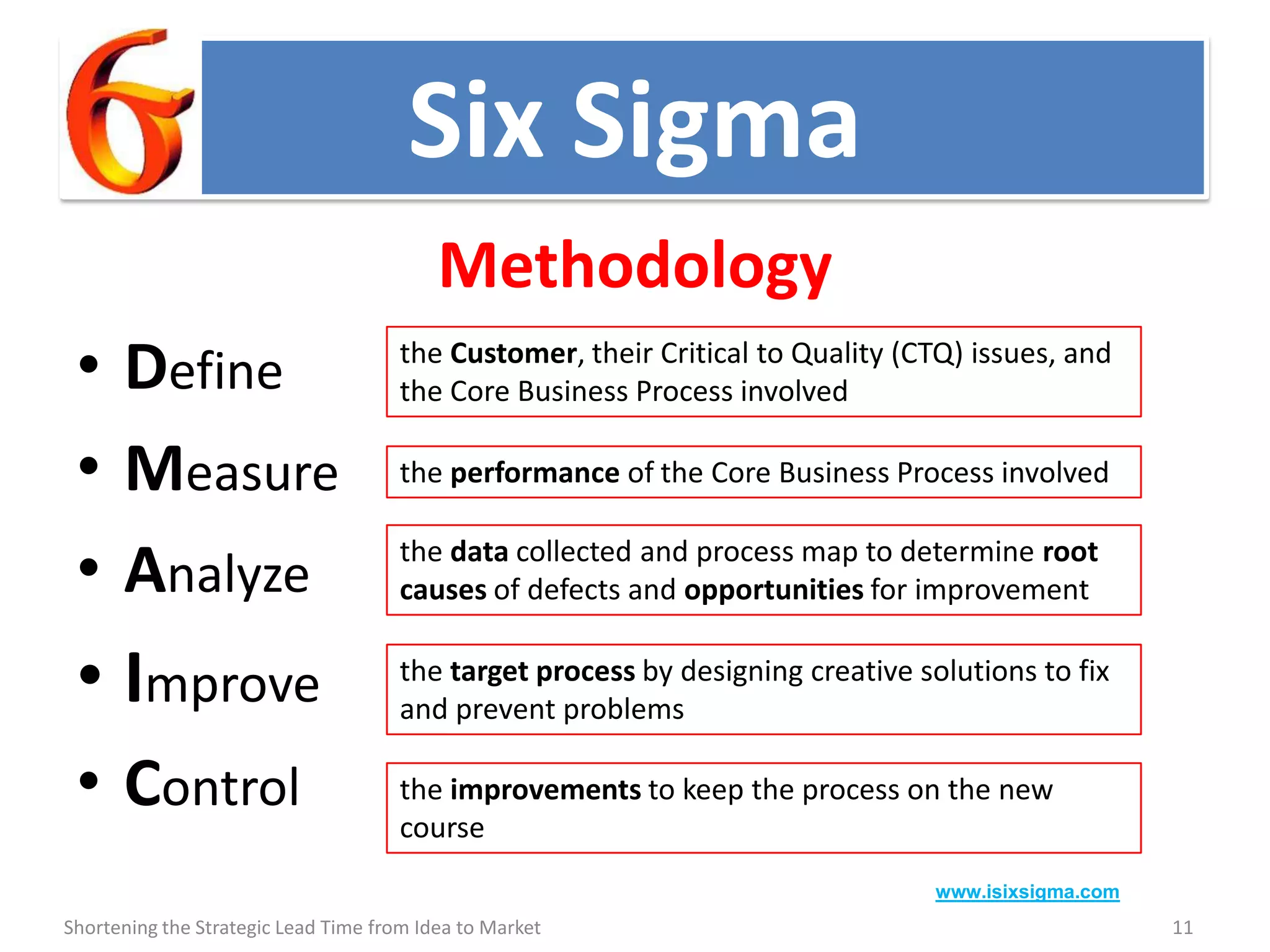

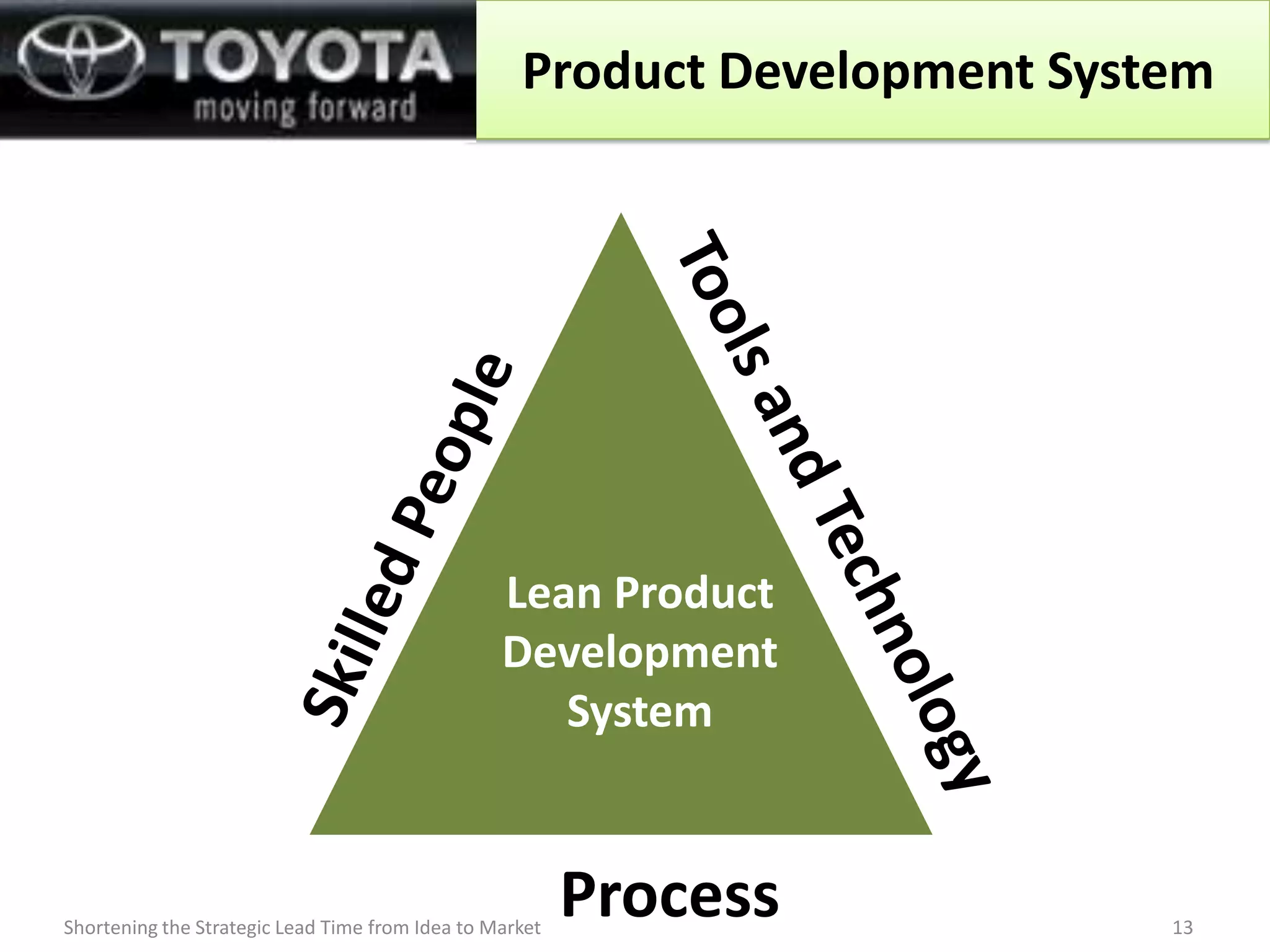

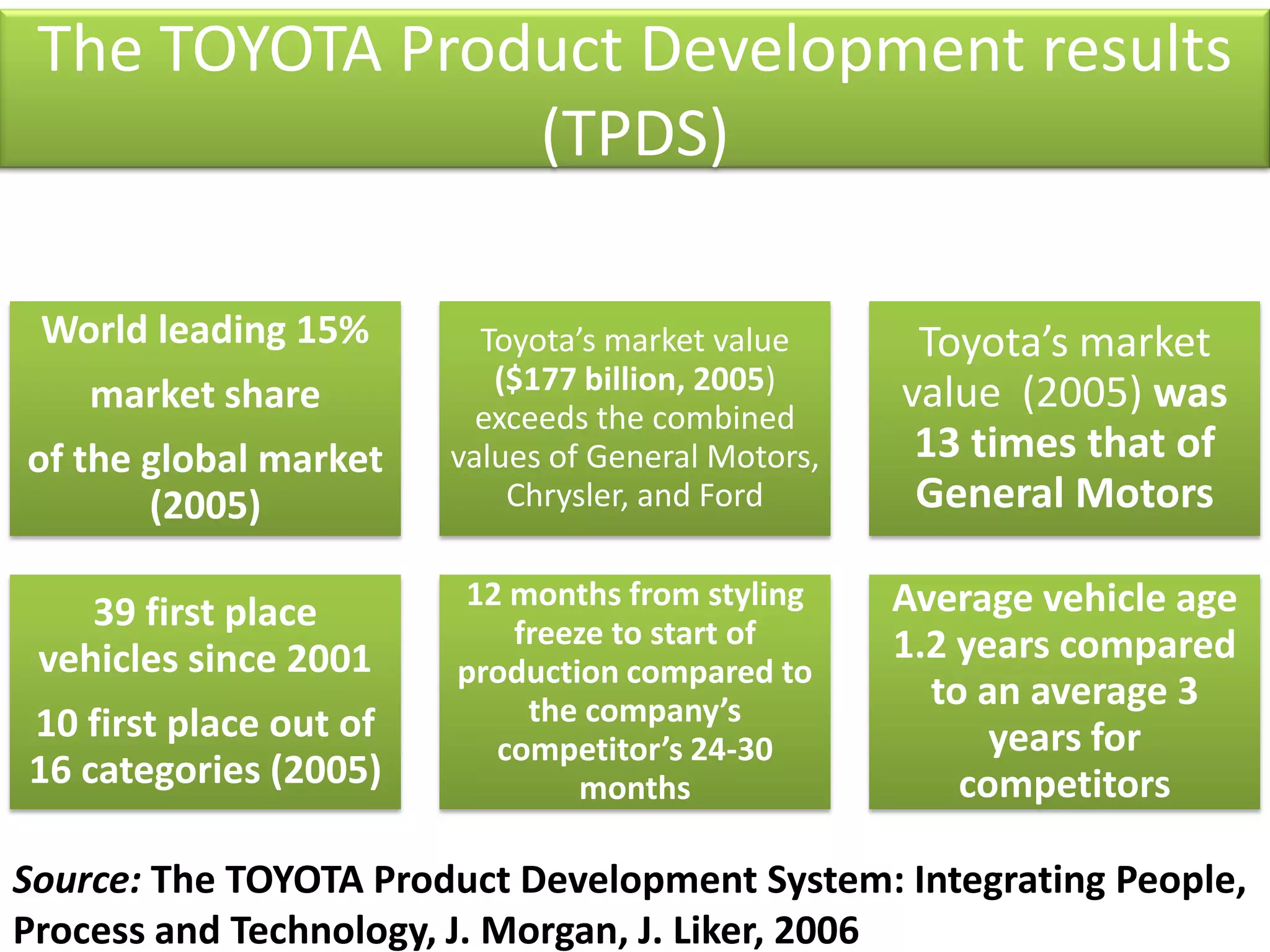

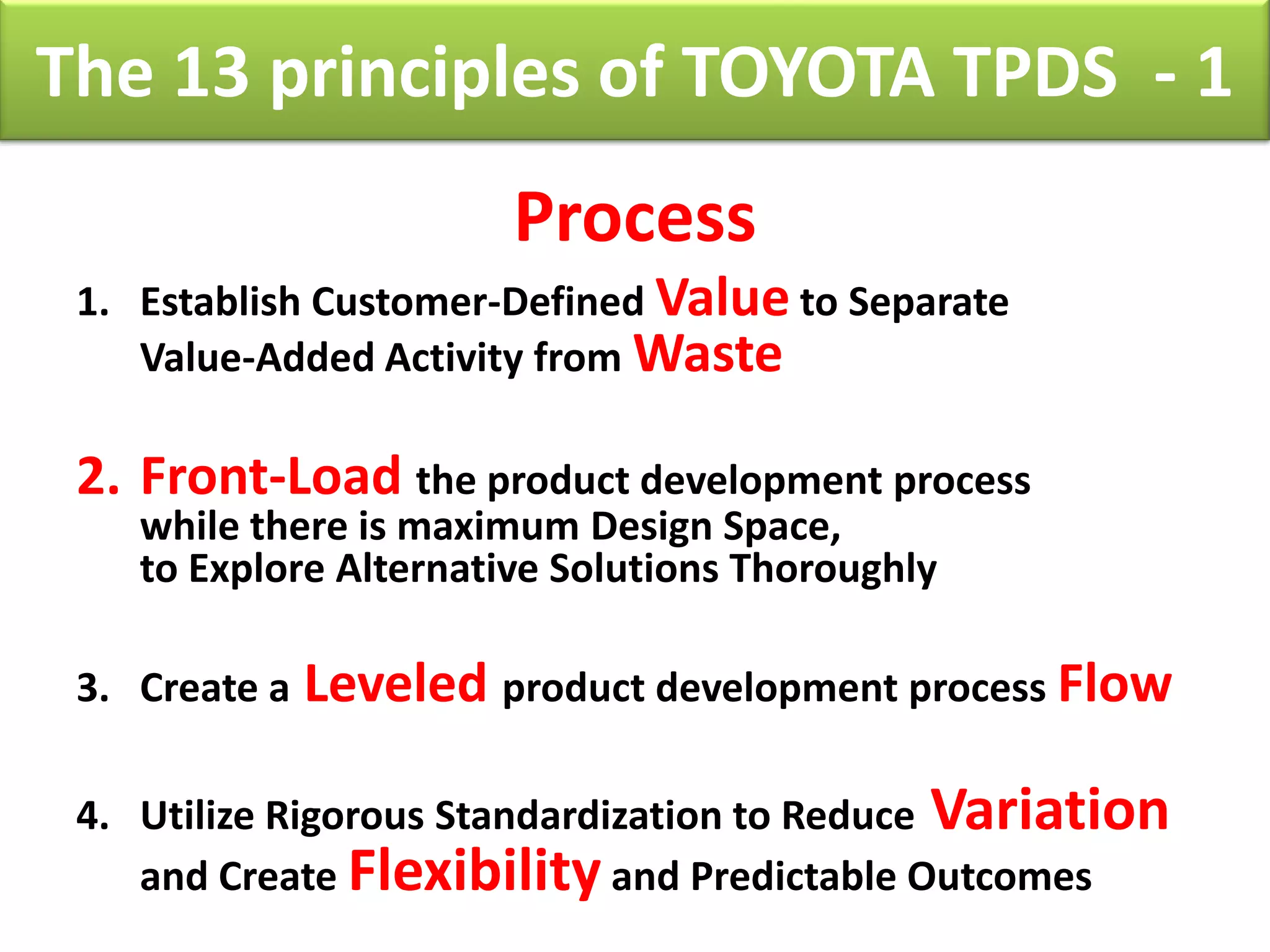

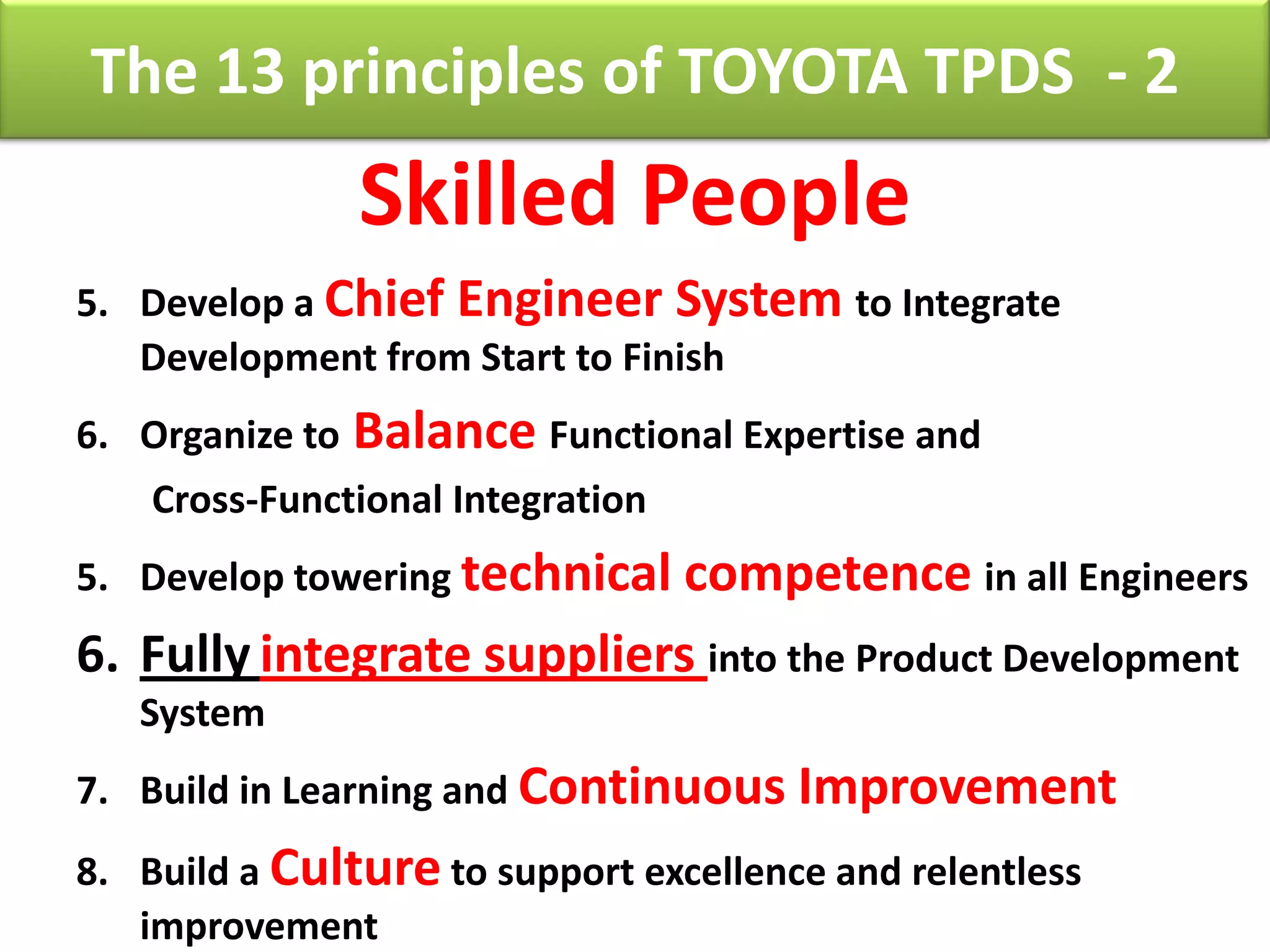

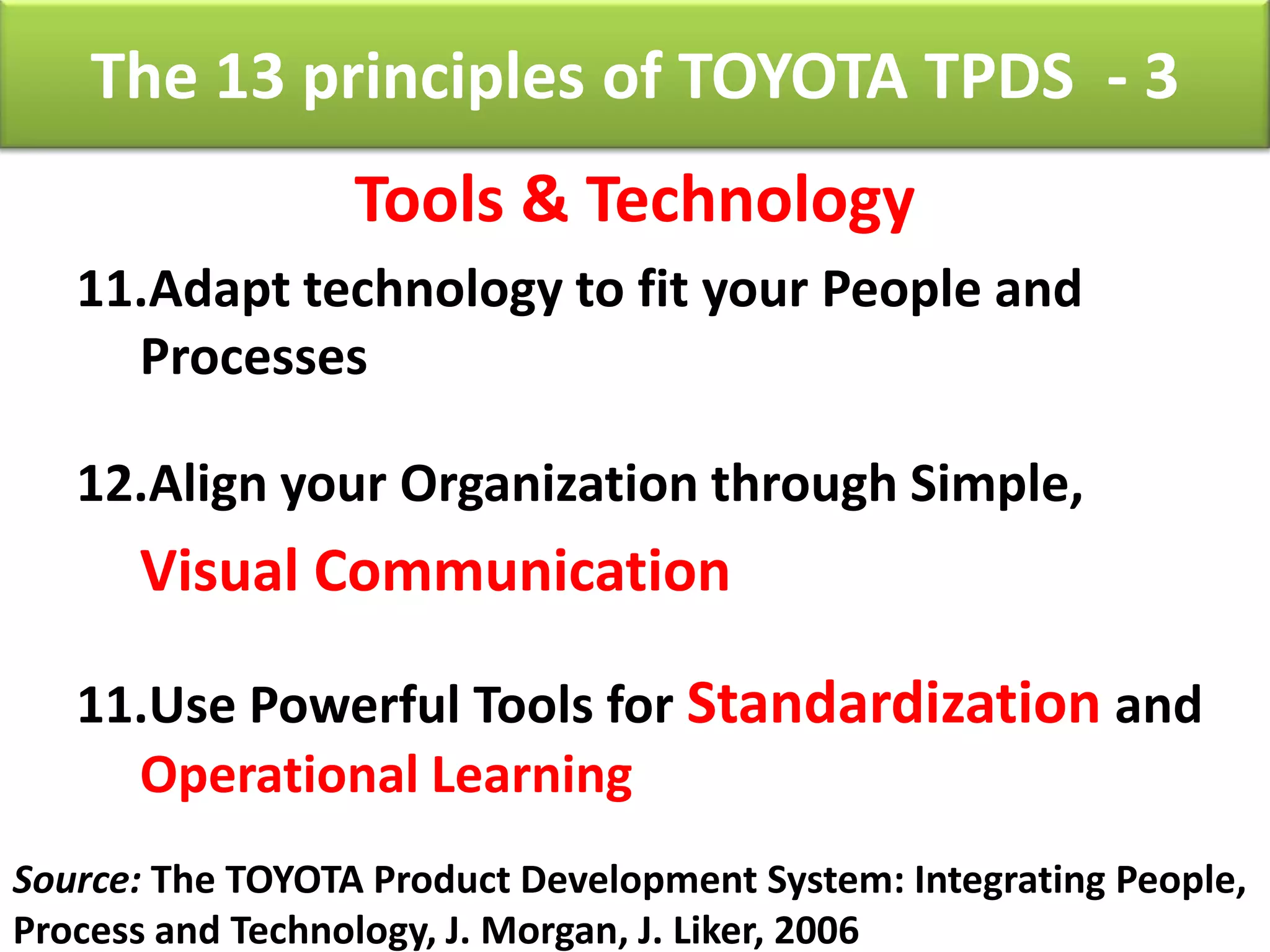

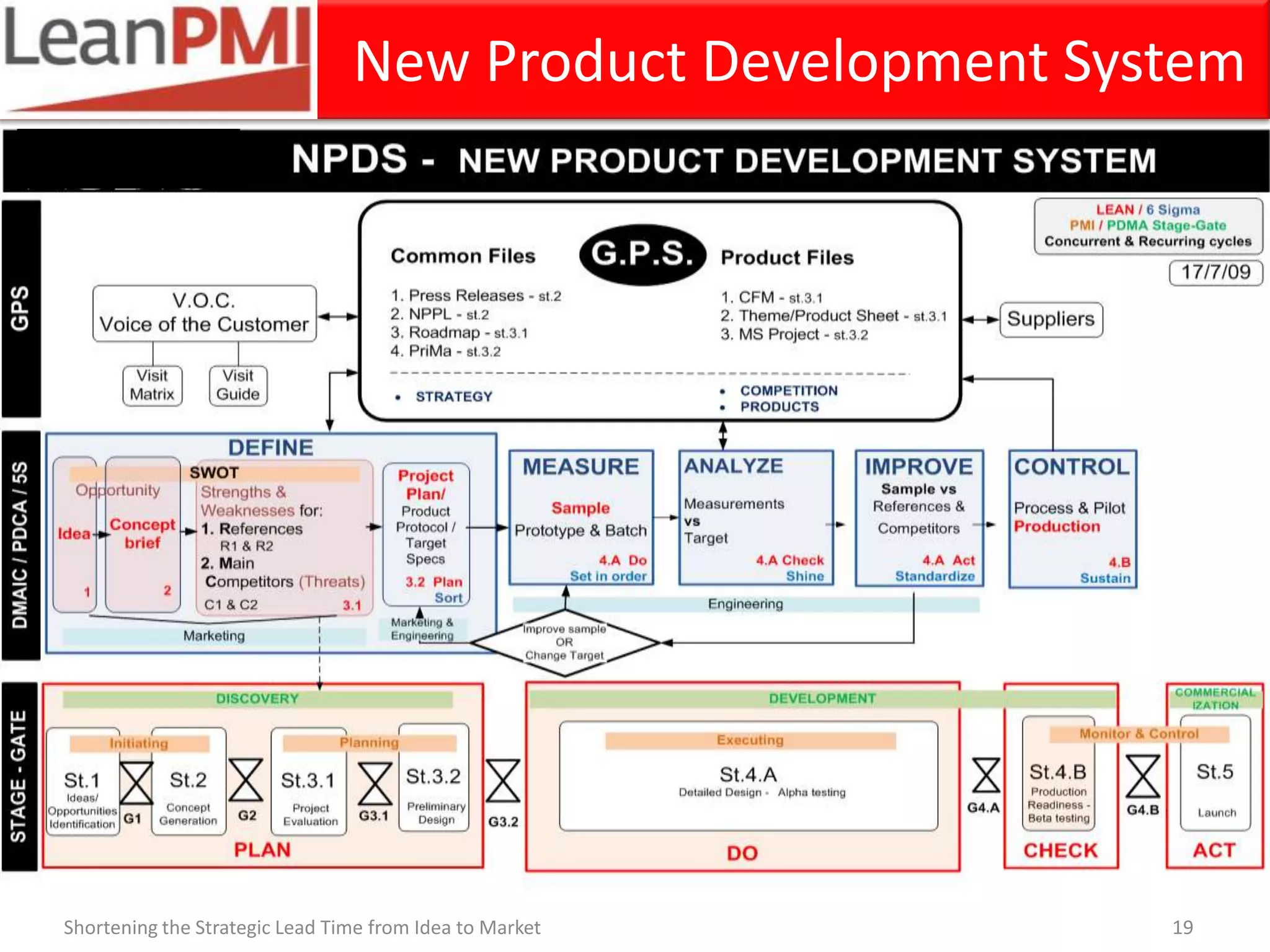

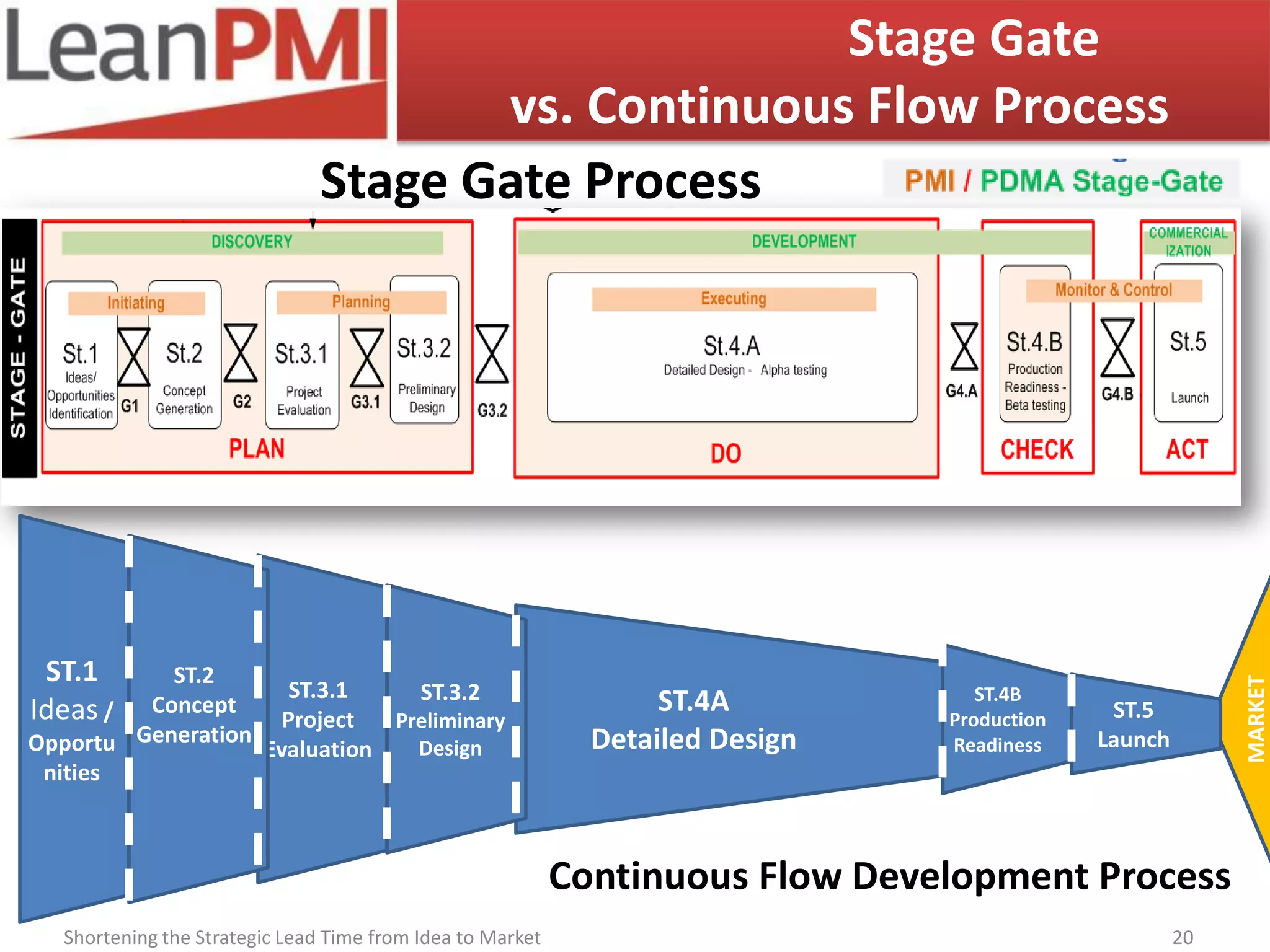

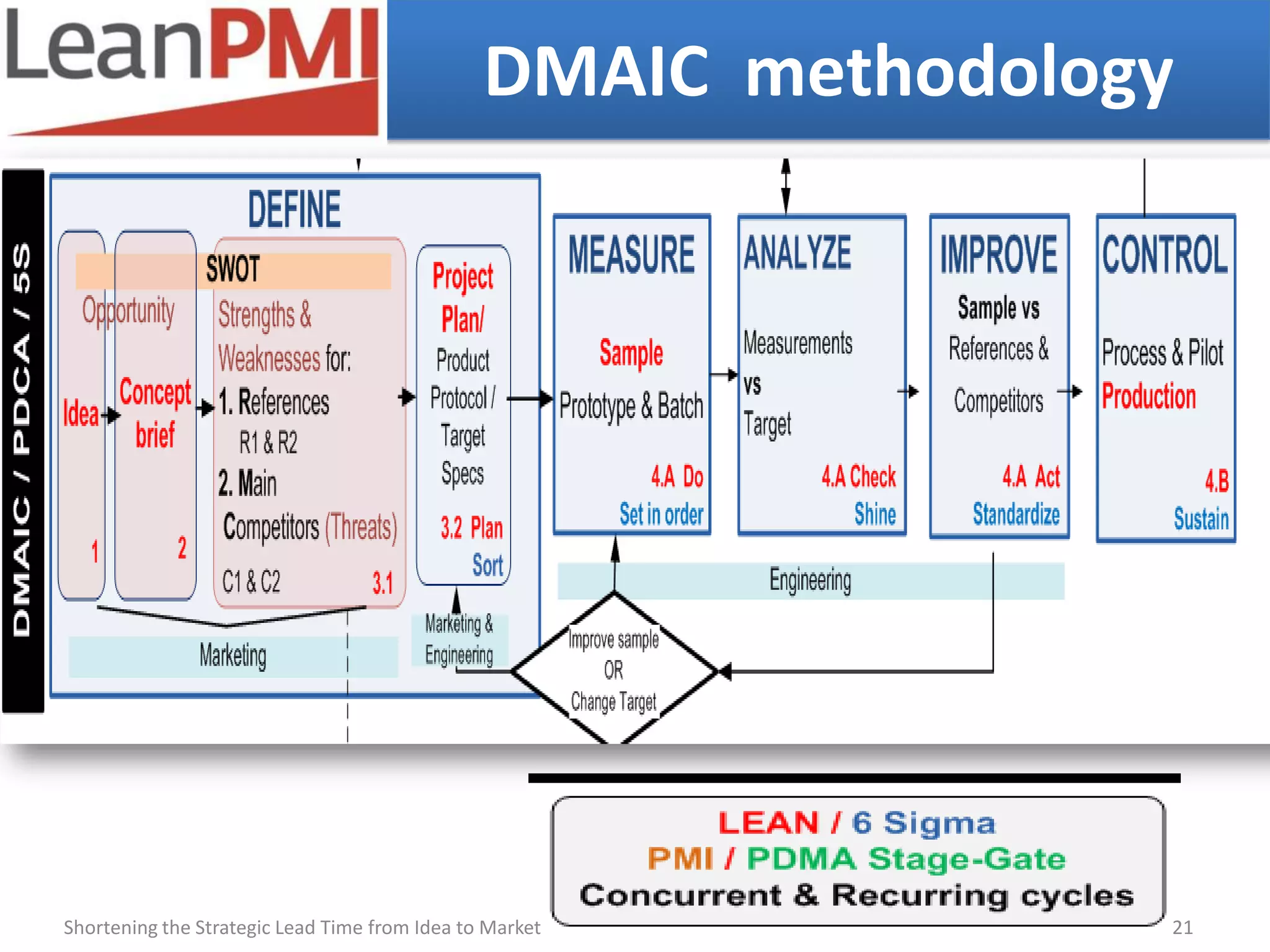

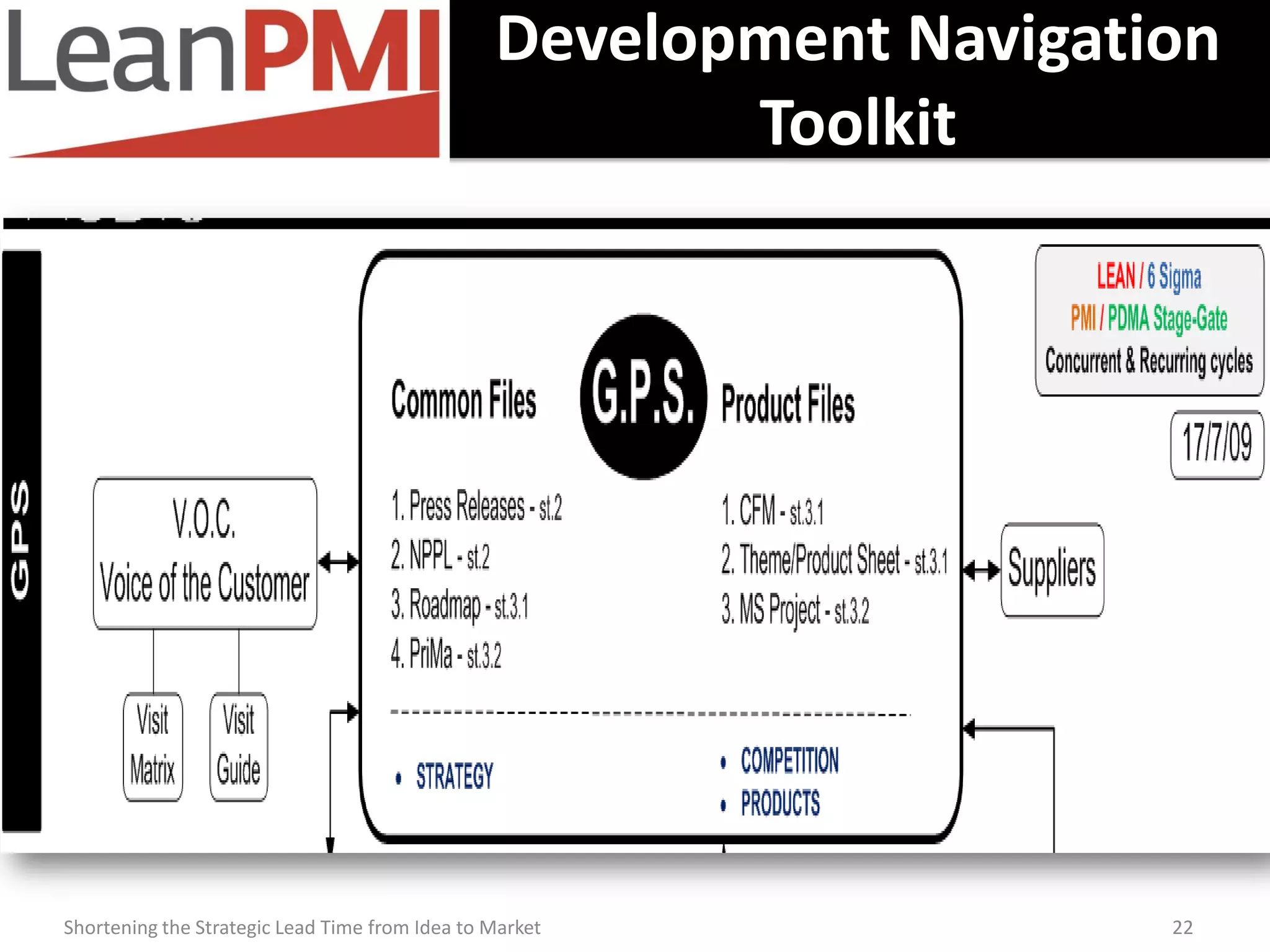

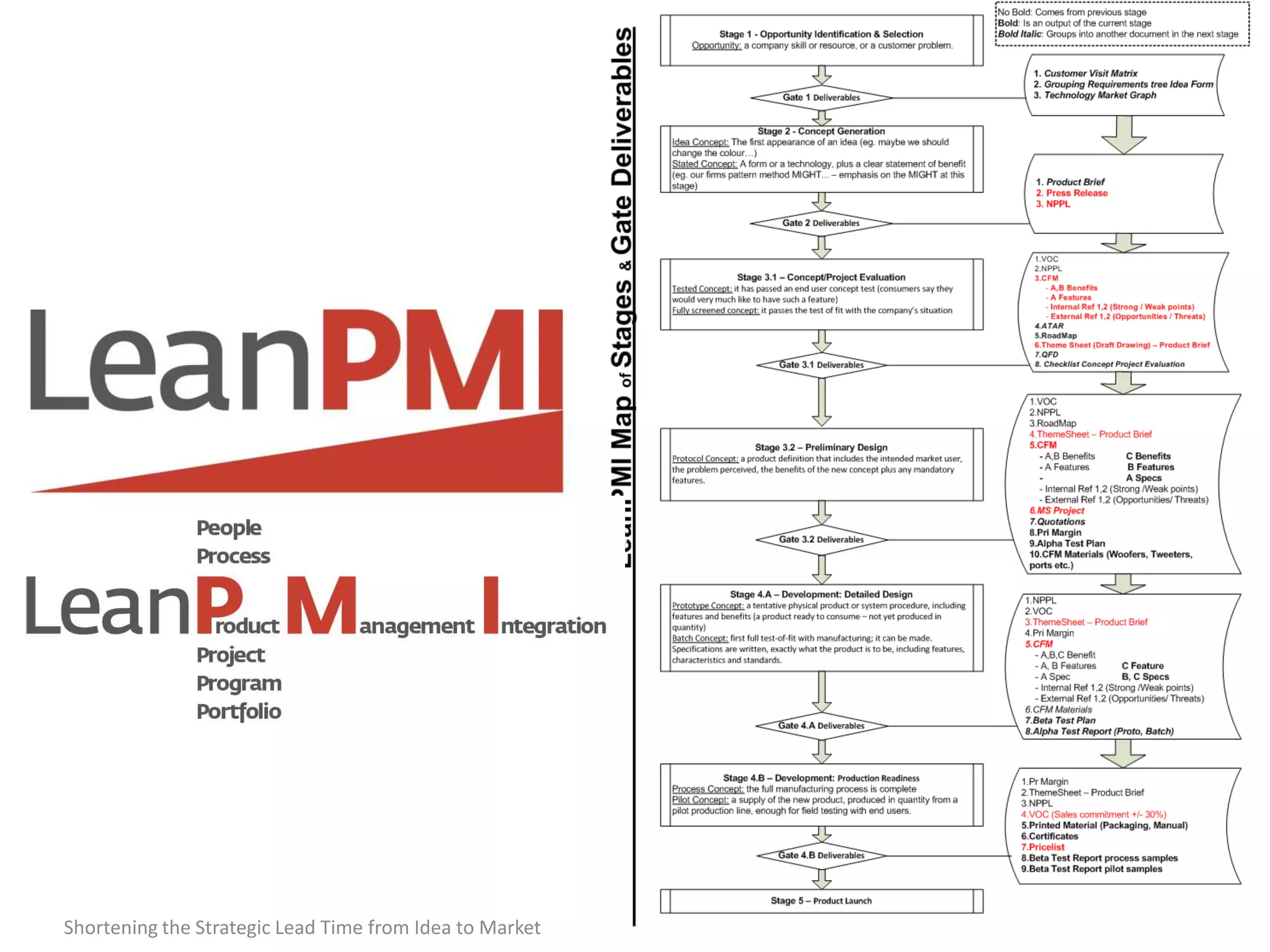

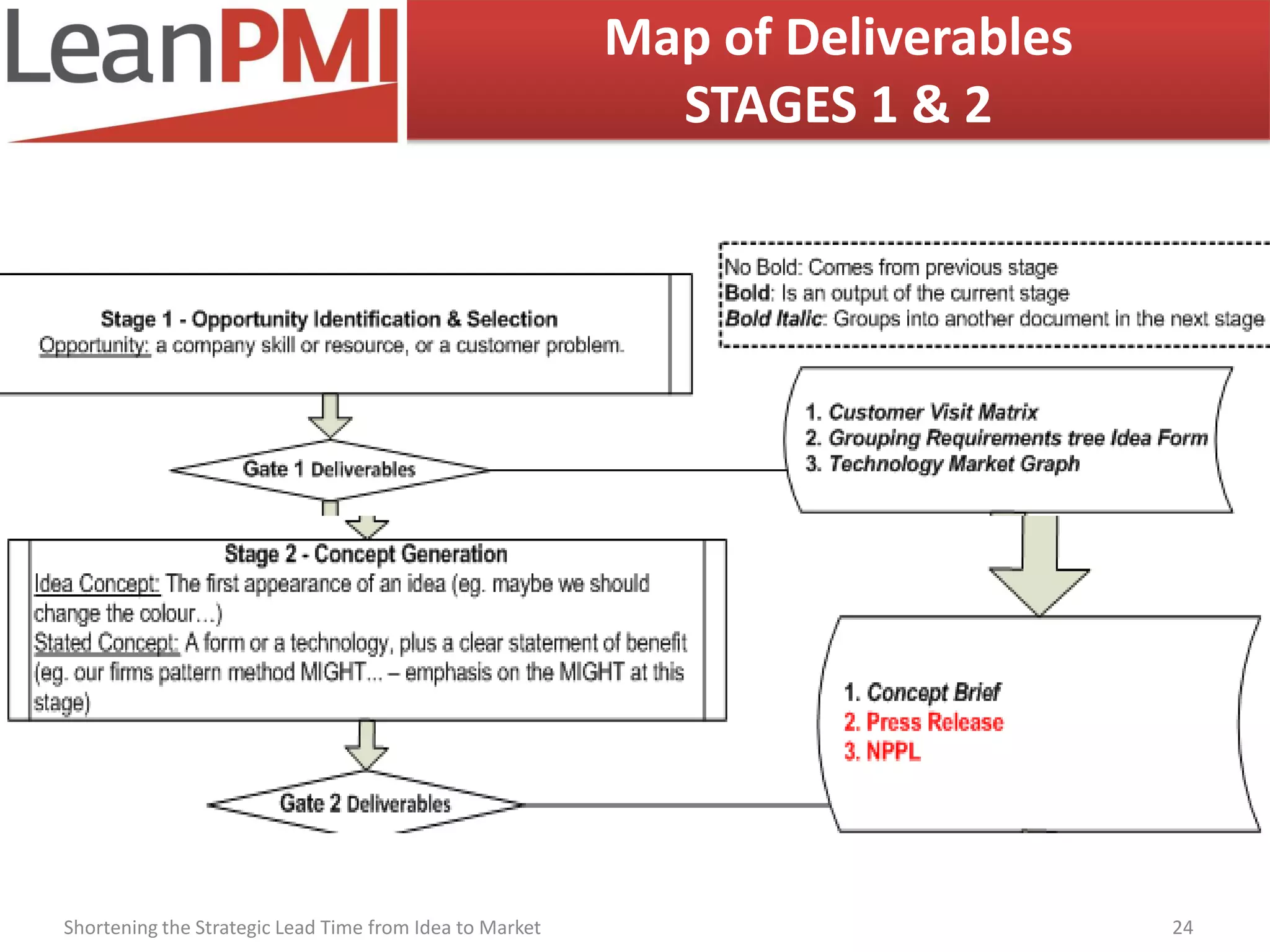

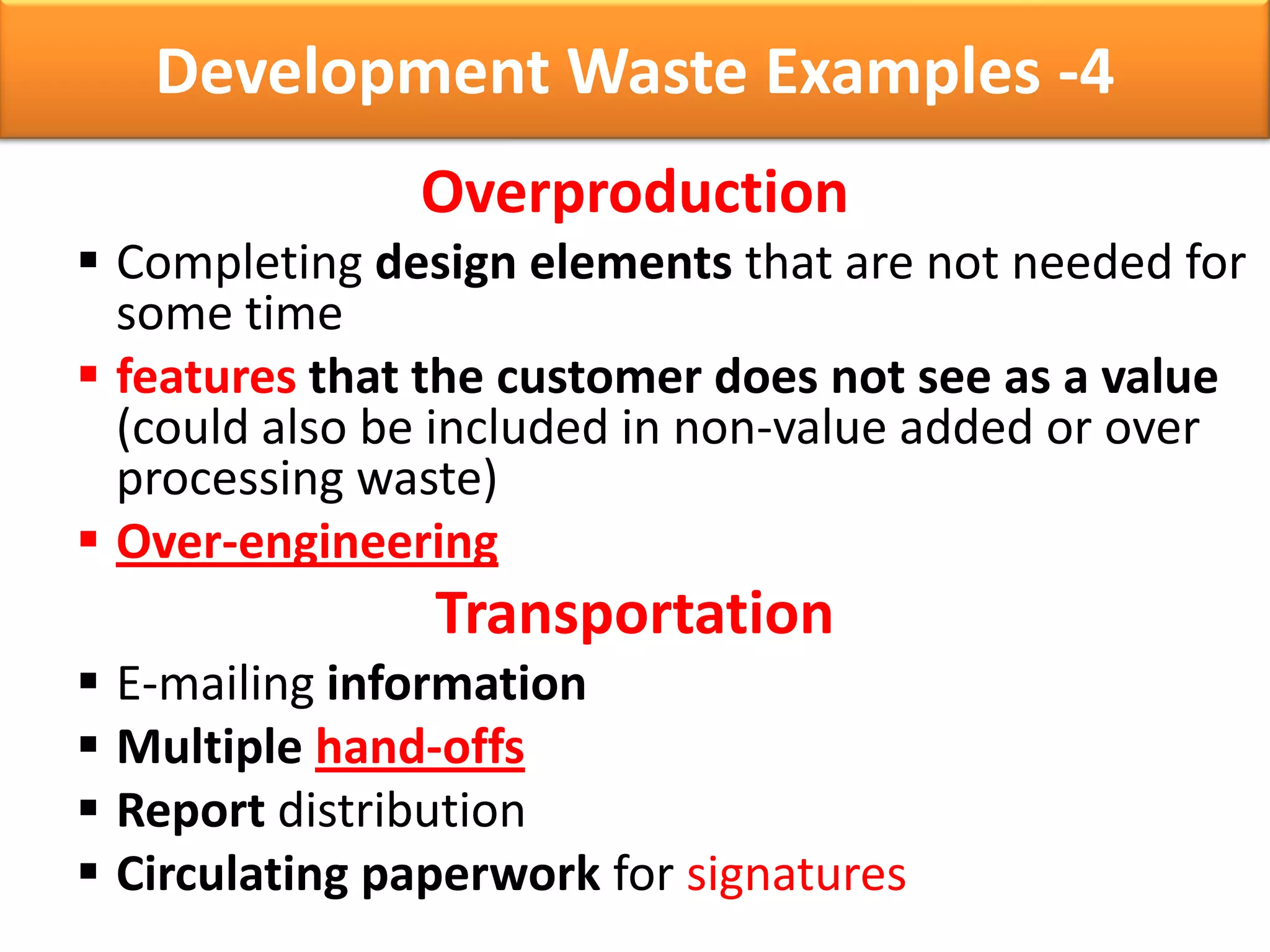

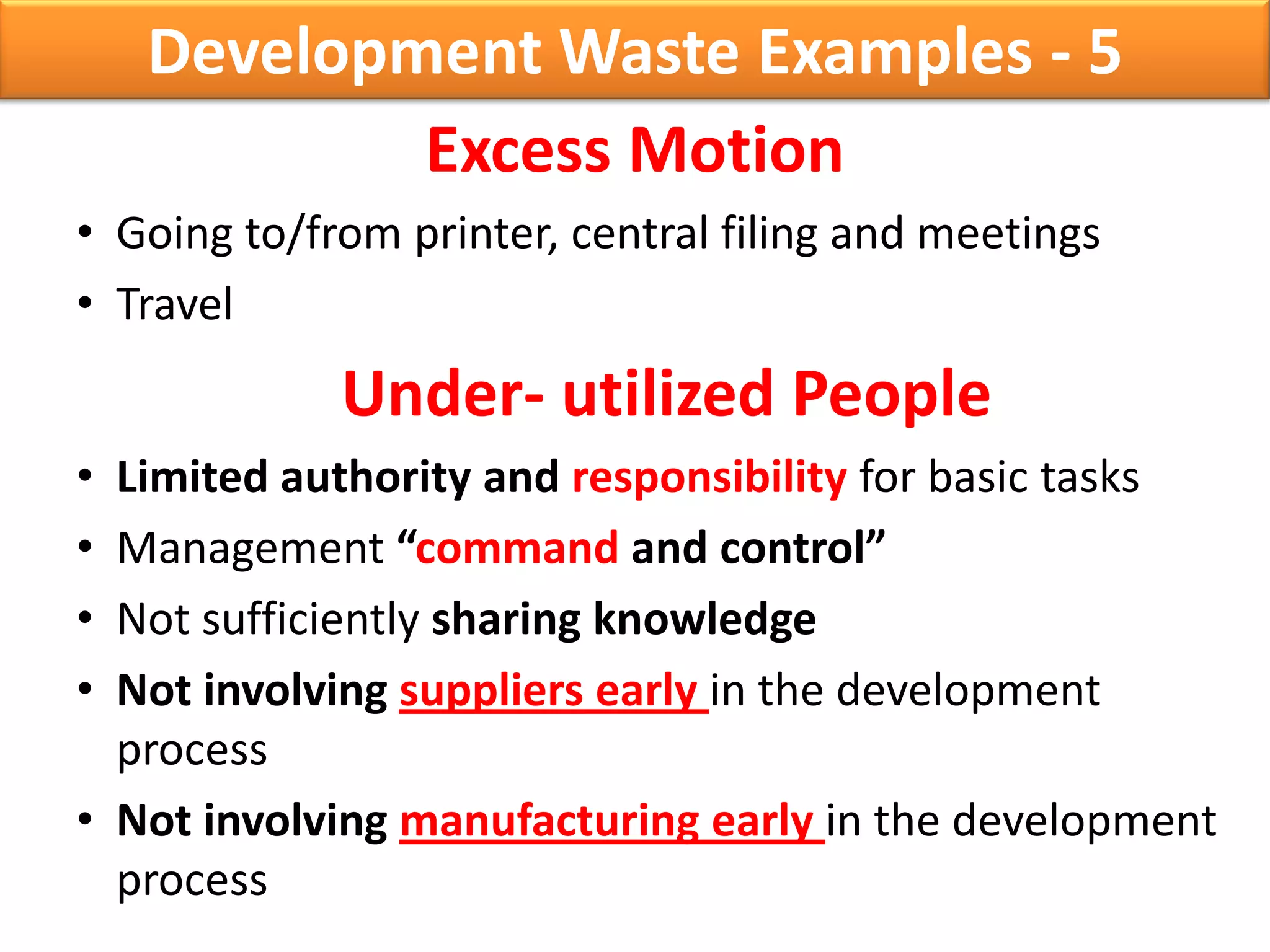

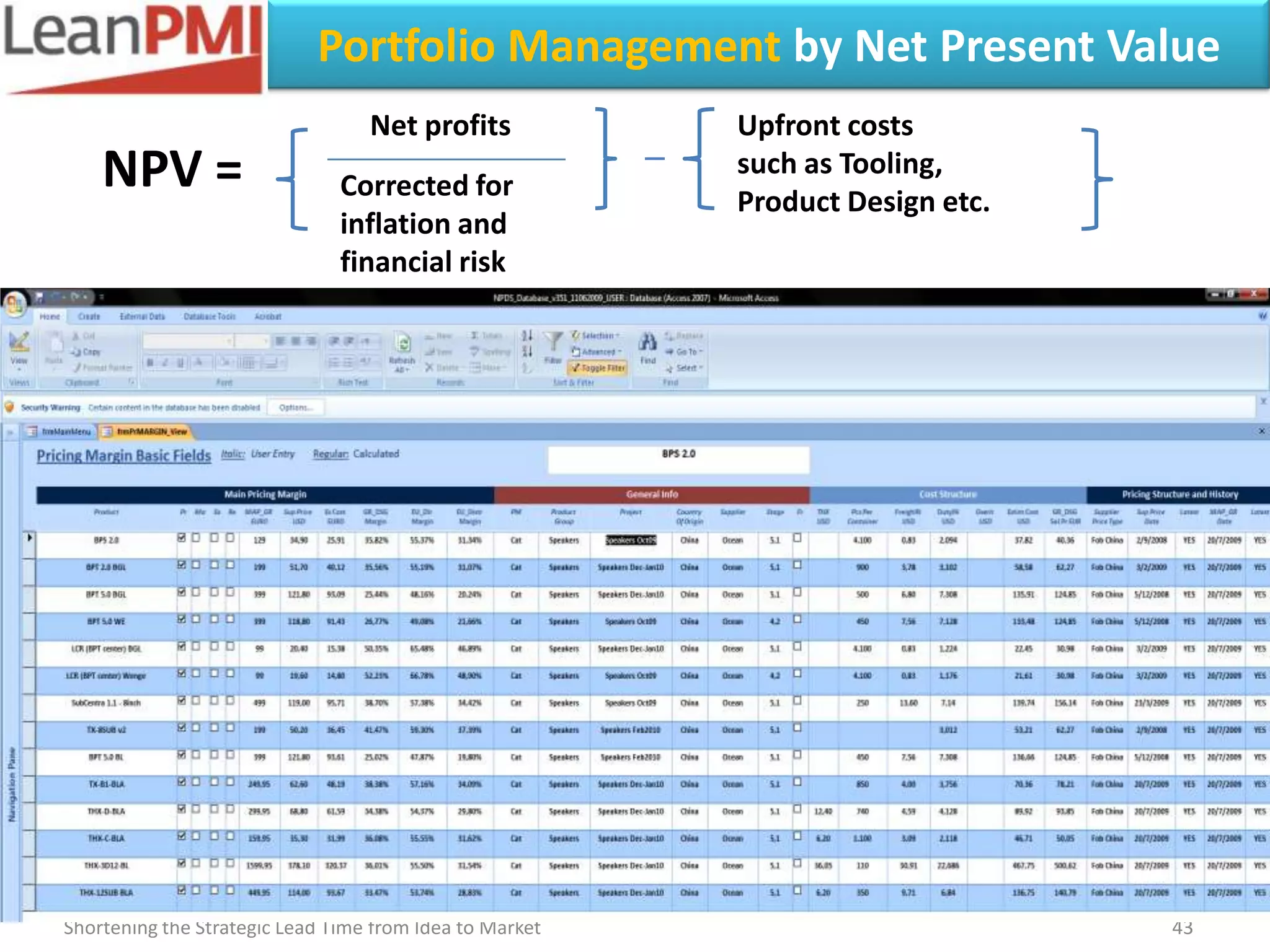

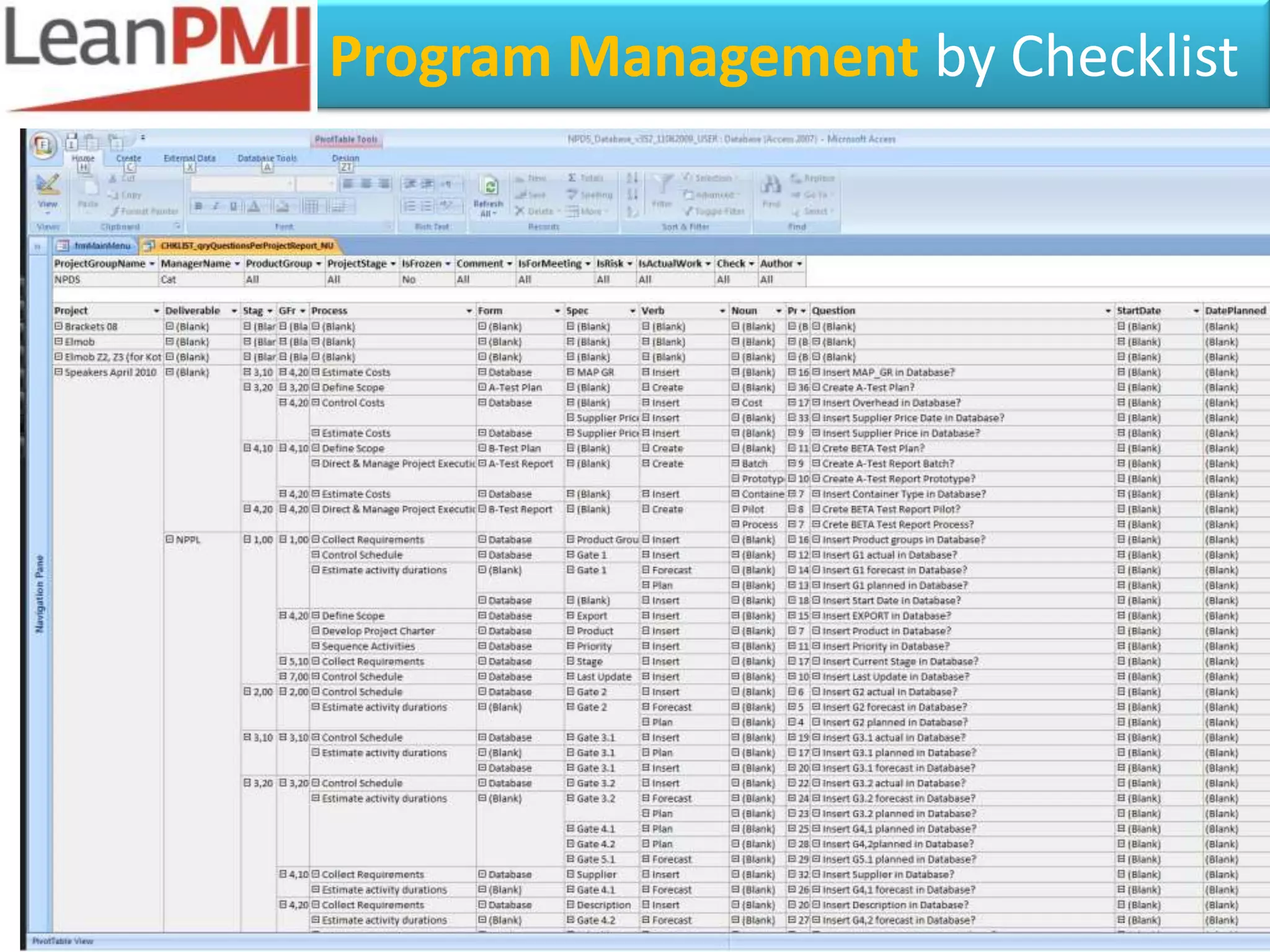

This document discusses various frameworks for shortening the strategic lead time from idea to market, including those from PDMA, PMI, Lean, Six Sigma, TOC, and Toyota's product development system. It provides overviews of the key aspects of each approach, such as PDMA's 3 phases of product development and 6 knowledge areas, PMI's processes and knowledge areas for project, program and portfolio management, and Lean's principles of eliminating waste and creating value. The overall message is that combining insights from these different approaches can help optimize the product development process.