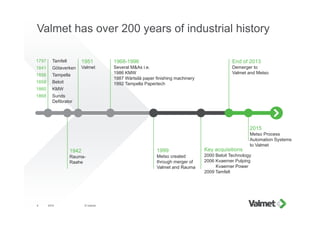

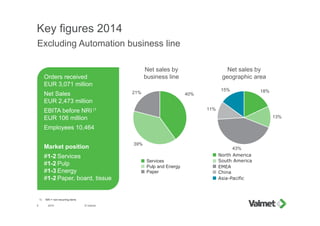

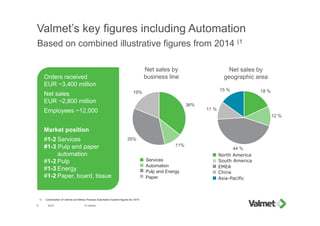

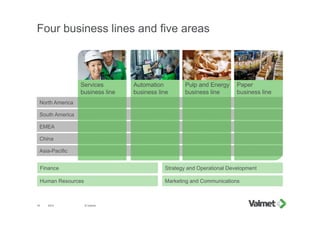

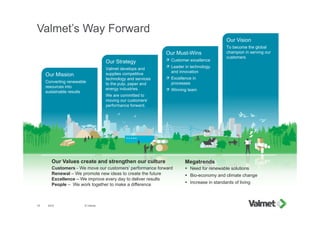

Valmet is a global company committed to moving customers' performance forward. It has over 200 years of industrial history and provides technology, automation solutions and services to pulp, paper and energy industries. In 2014, Valmet had net sales of EUR 2.473 billion and employs over 10,000 professionals serving customers globally. Valmet focuses its research and development on improving customers' processes through innovations like modularized products and more efficient energy solutions.