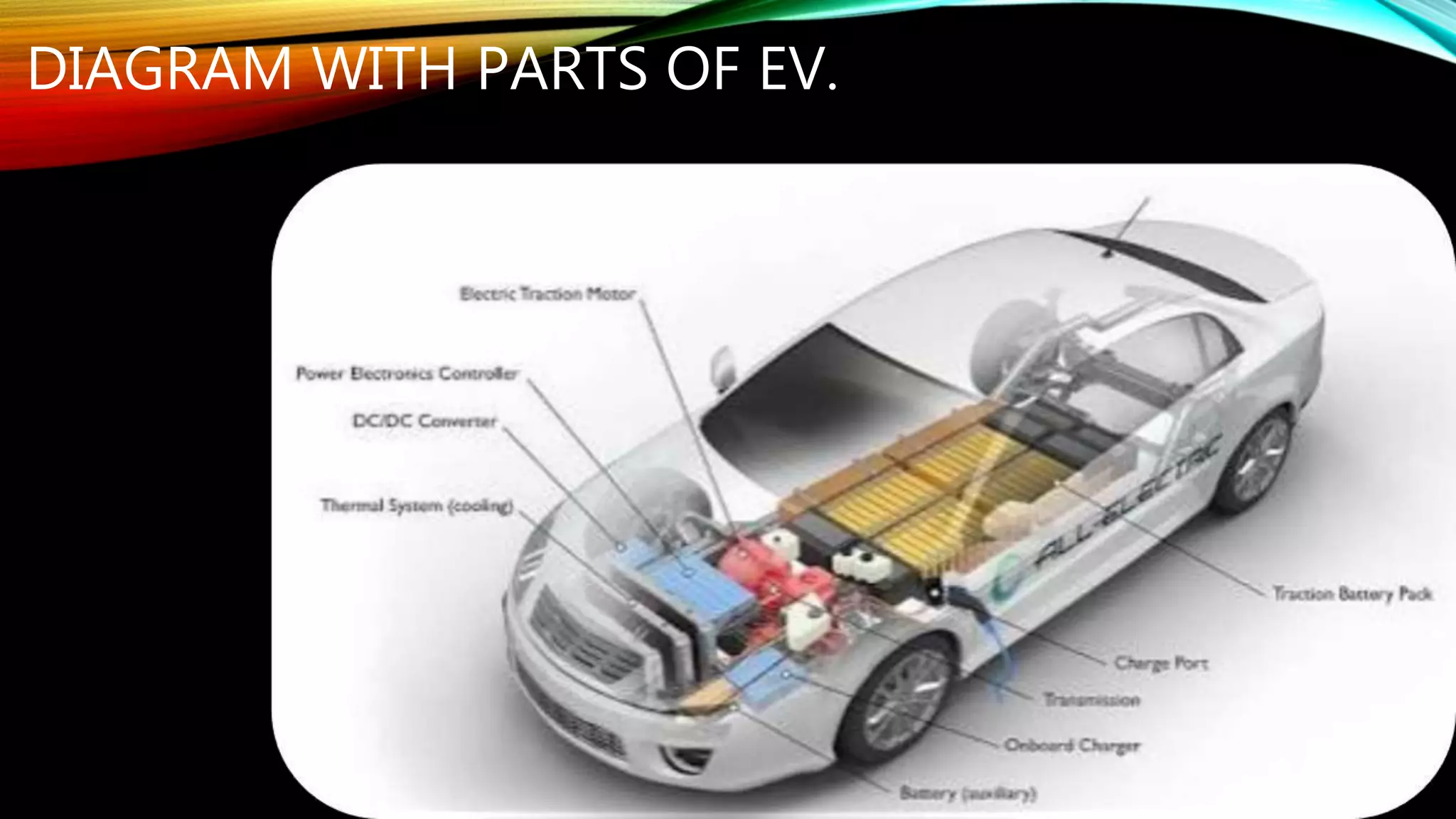

1) The document discusses the key parts of an electric vehicle, including electric motors, motor controllers, battery packs, transmissions, charging points, brakes, DC-DC converters, and joysticks for controlling modes.

2) It explains that electric cars use electric motors powered by batteries rather than gasoline engines, and that they can use both AC and DC motors.

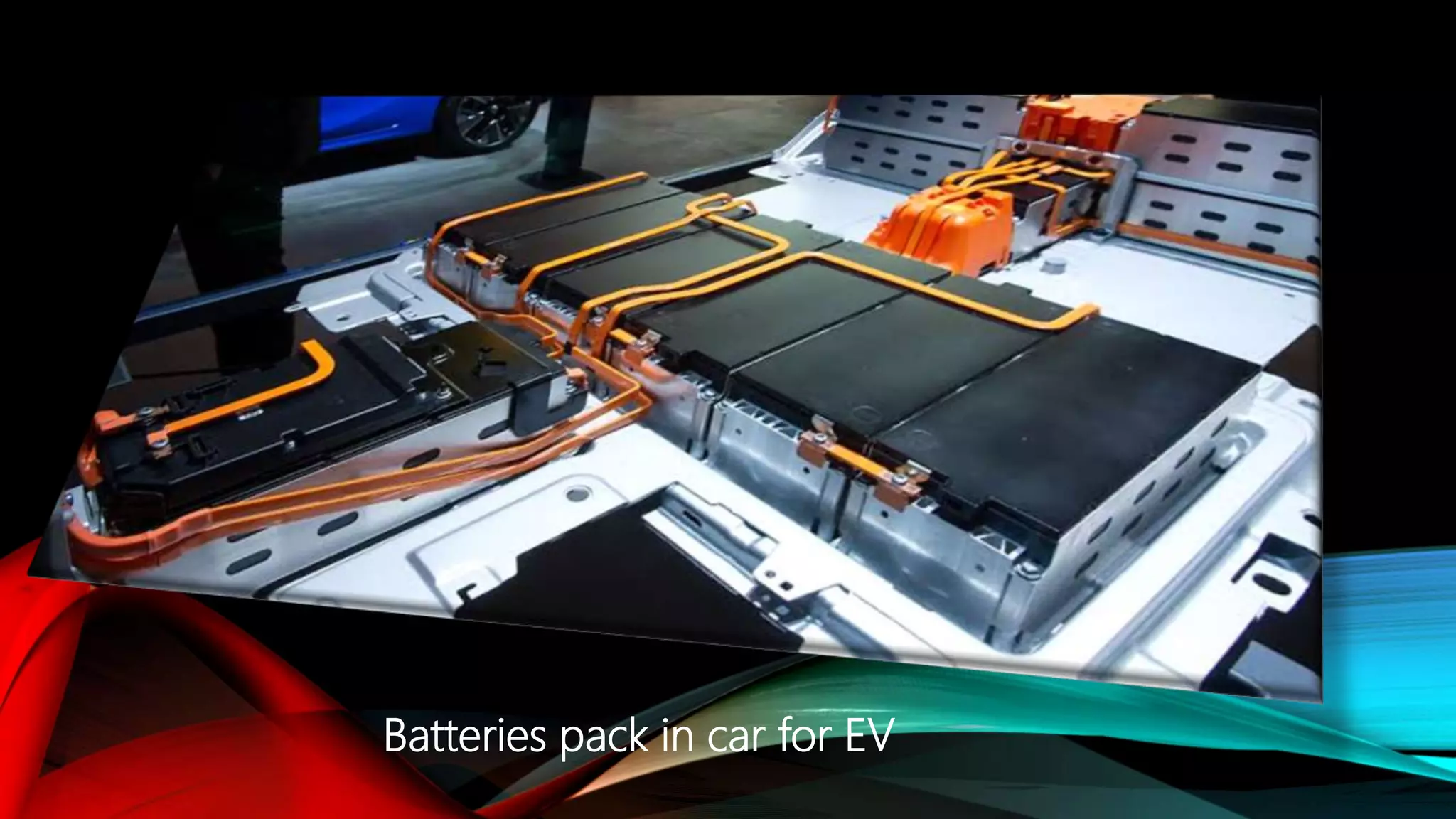

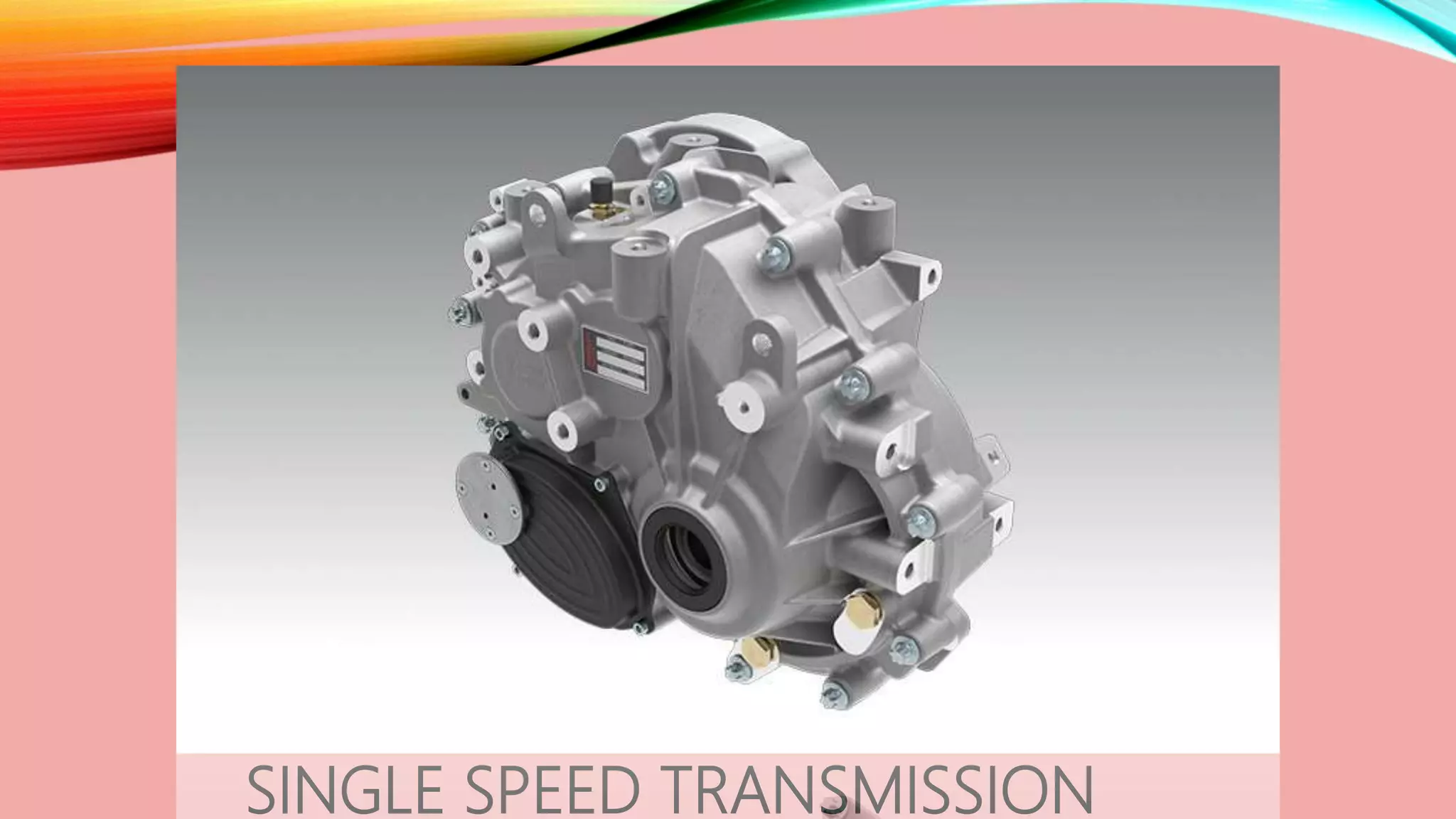

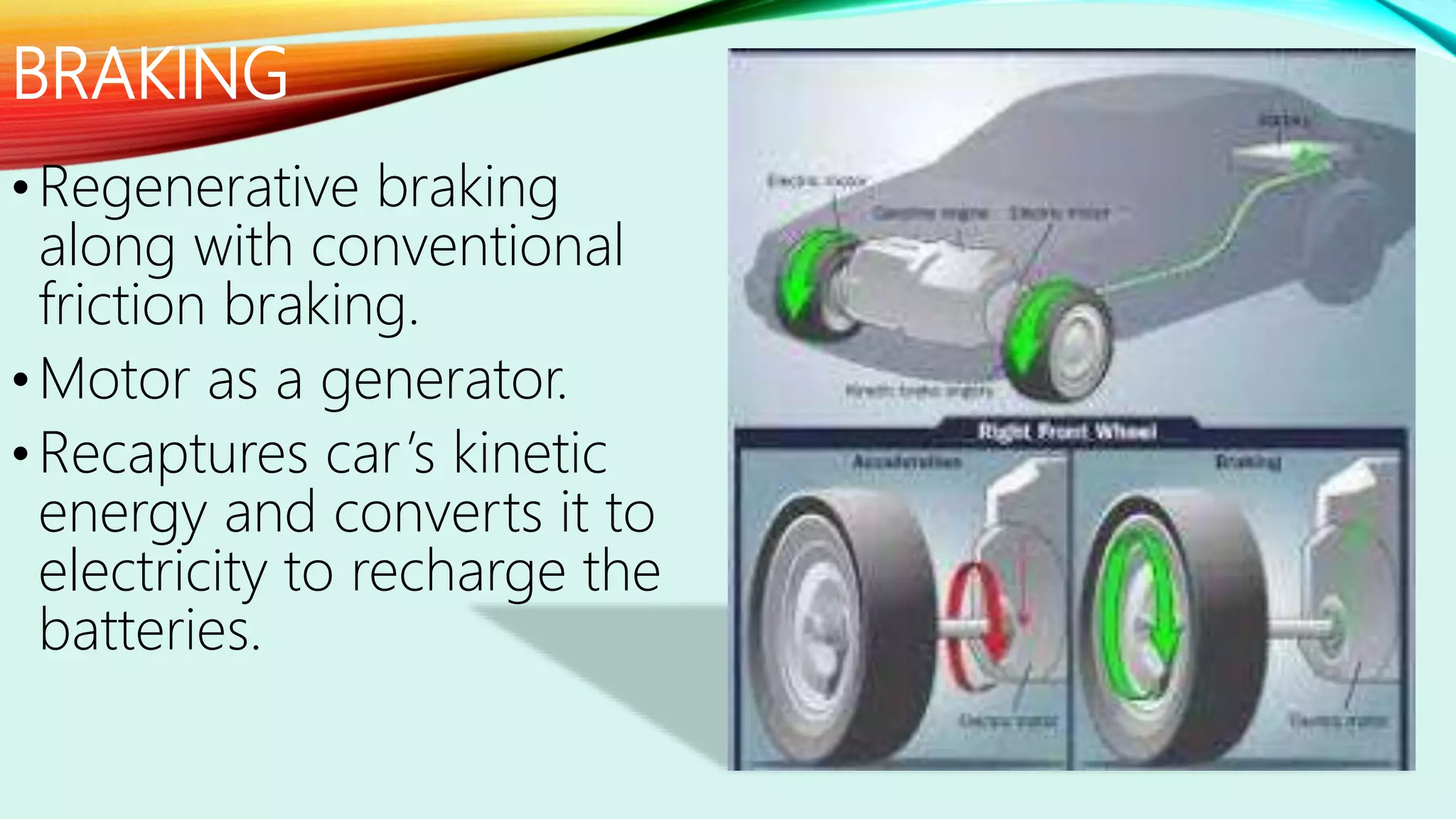

3) The document provides details on other components like single-speed transmissions, regenerative braking systems, lithium-ion batteries, charging stations, and DC-DC converters that convert voltages to power accessories.