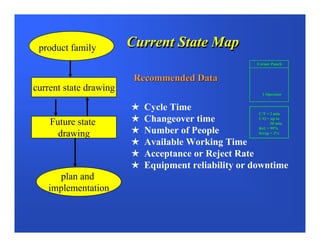

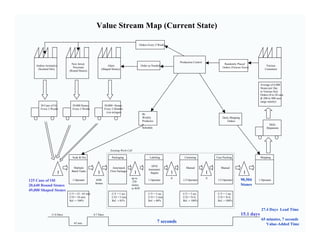

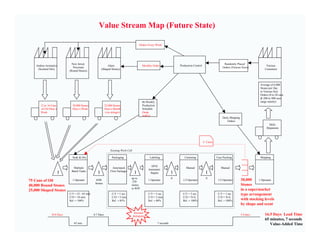

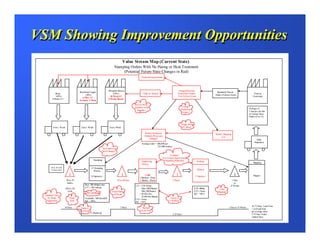

Value stream mapping is a lean manufacturing tool used to identify waste and opportunities for improvement. It visually maps the current and future state of processes by following the flow of products and information. Developing a current state map involves collecting data on cycle times, changeover times, staffing levels, and other metrics to understand how the production system currently operates. This data provides the foundation to design an improved future state map and implementation plan.