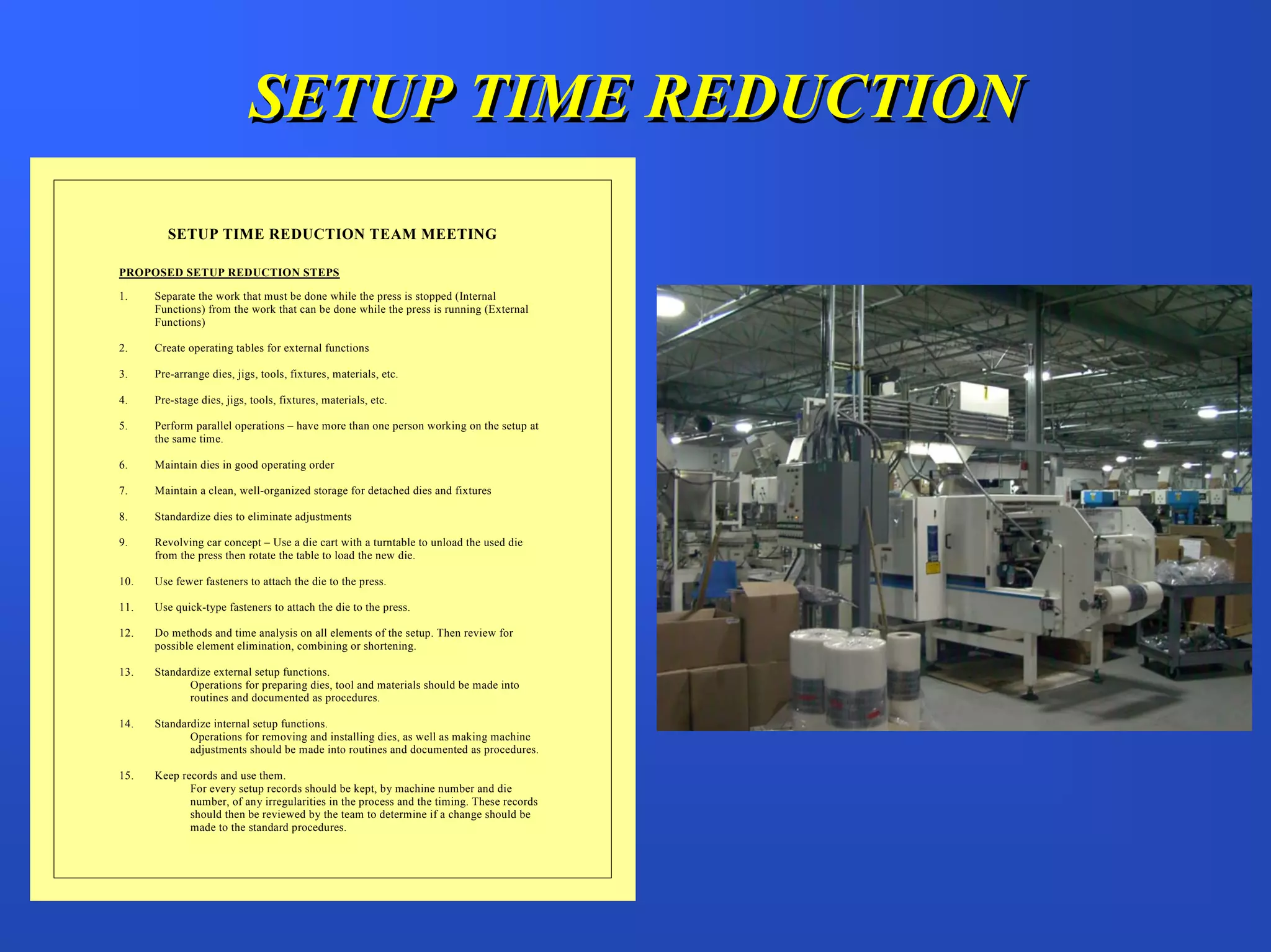

This document discusses a case study of a company that moved toy part bagging lines from the US to China to reduce costs. While labor rates in China were significantly lower, hidden costs began to emerge over time, such as quality issues, transportation costs, and inability to respond quickly to changes. The company implemented lean manufacturing techniques in their US operations to improve efficiency and reduce costs. A financial model was developed to quantify total costs, allowing some product lines to be moved back from China. The document advocates for continuous improvement and determining the best location based on long-term viability rather than just short-term profit.