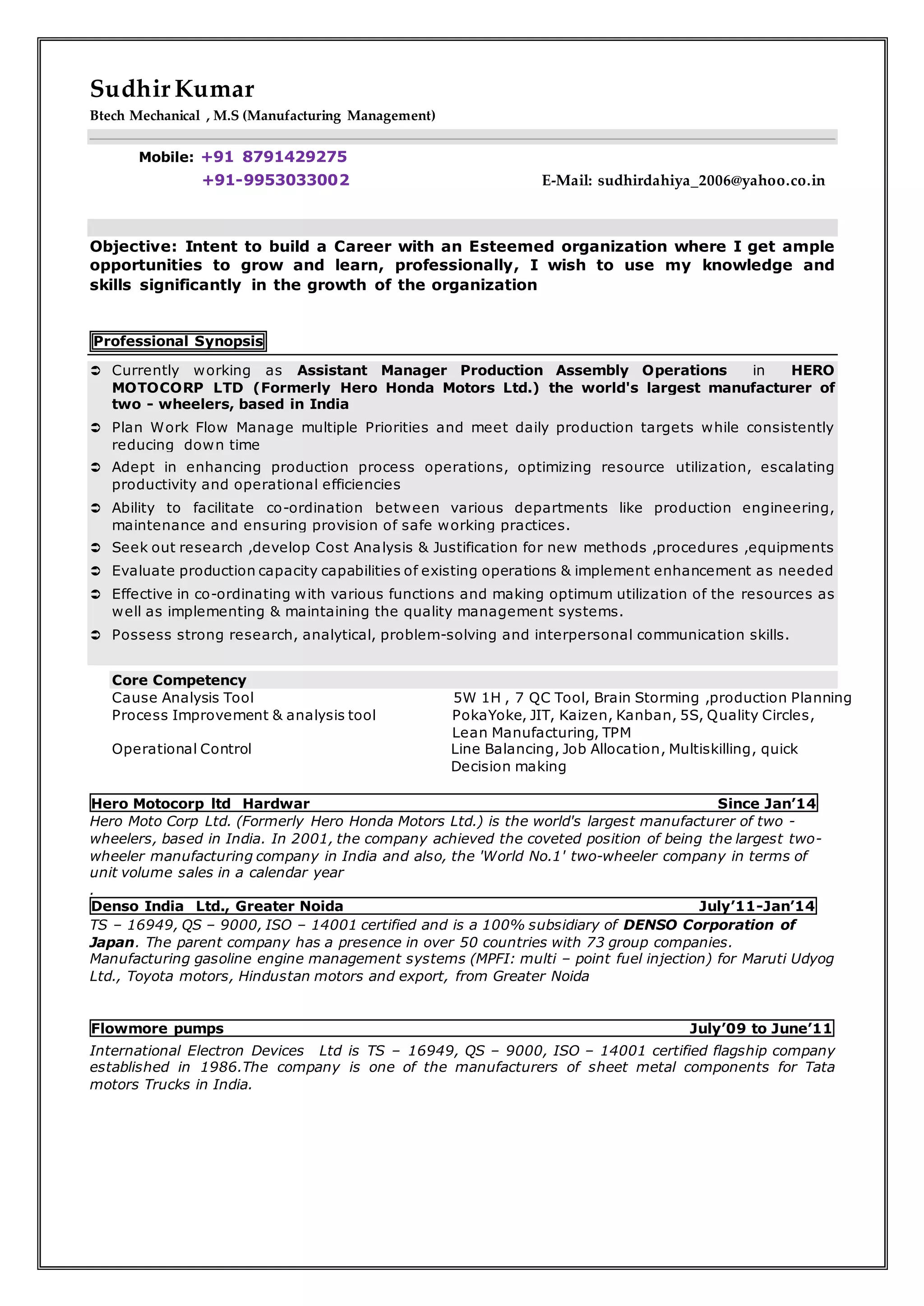

Sudhir Kumar has over 10 years of experience in production operations and management. He is currently the Assistant Manager of Production Assembly Operations at Hero Motocorp, the world's largest manufacturer of two-wheelers. He has a BTech in Mechanical Engineering and an MS in Manufacturing Management. His responsibilities include meeting daily production targets, enhancing production processes, and ensuring provision of safe working practices.