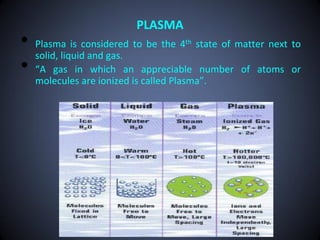

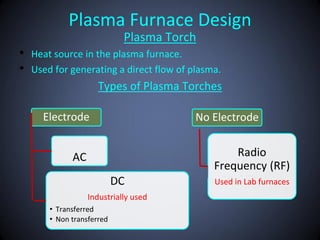

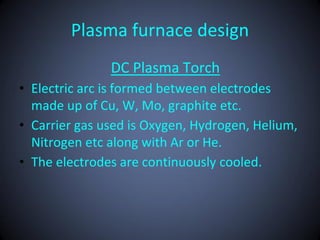

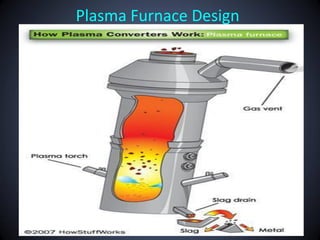

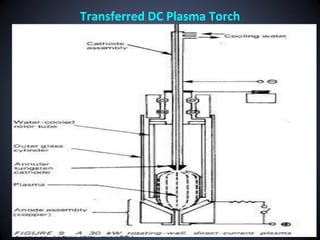

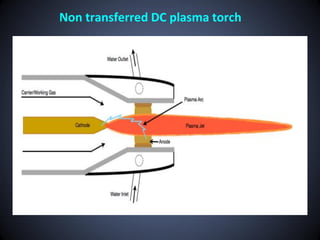

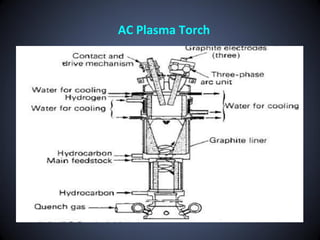

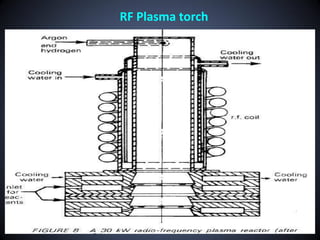

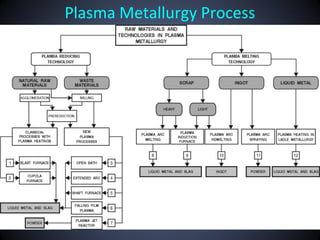

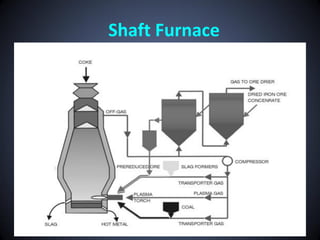

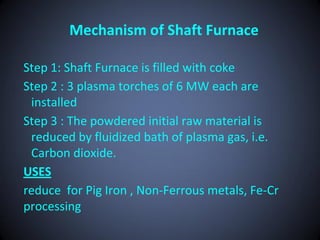

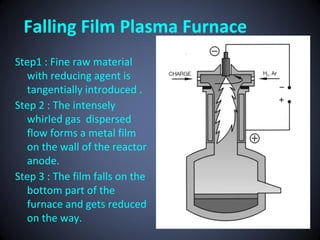

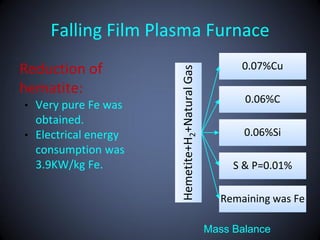

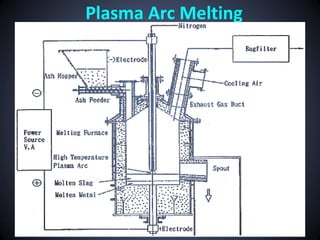

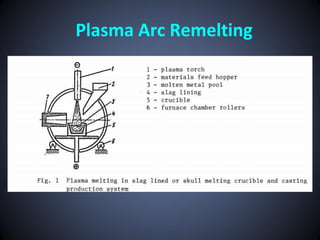

The document discusses plasma processing in extractive metallurgy. It describes plasma as the fourth state of matter and its properties. Plasma is used as both a heat source and carrier medium in materials processing. Different types of plasma torches and furnace designs are presented, including DC plasma torches, AC plasma torches, and RF plasma torches. Applications of plasma include plasma reducing technologies like shaft furnaces and falling film plasma furnaces. Plasma melting technologies such as plasma arc melting, plasma induction furnaces, and plasma arc remelting are also discussed.