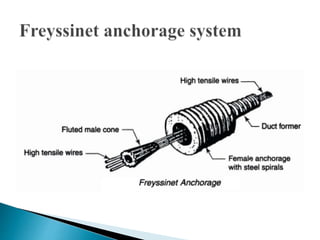

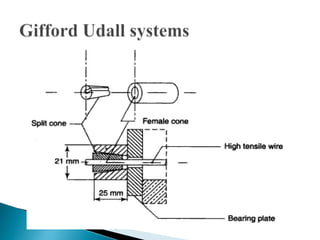

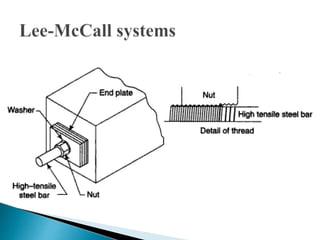

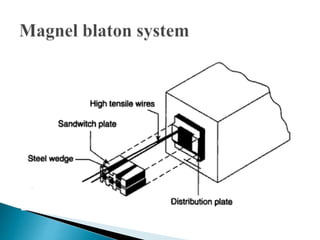

This document discusses different systems used for prestressing steel, which are grouped into four categories: mechanical, hydraulic, electrical/thermal, and chemical. It provides details on common tensioning devices within each category. Mechanical devices use weights, pulleys, and screw jacks. Hydraulic jacks ranging from 5-600 tonnes are widely used. Electrical/thermal heating of wires before concreting is another option. Chemical devices use expanding cement. The document also describes several popular prestressing systems including Freyssinet, Gifford Udall, Lee-McCall, Magnel Blaton, BBRV, and Baur Leonhardt.