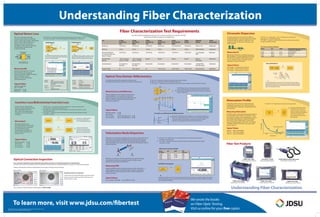

This document provides information on different optical fiber characterization tests including insertion loss, return loss, chromatic dispersion, polarization mode dispersion, and attenuation profile. It defines each test, describes typical test setups and methods, and lists reference standards. It also provides typical specification values for different fiber types and transmission systems. Finally, it includes a table outlining recommended fiber characterization tests for various bit rates.