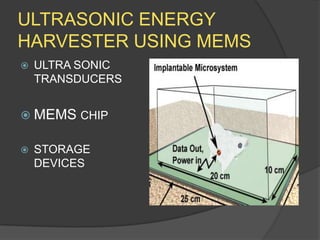

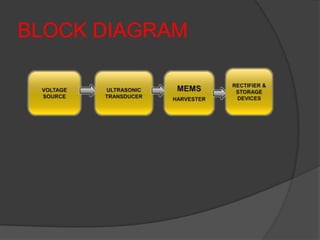

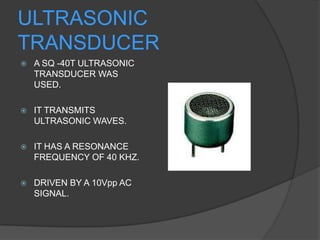

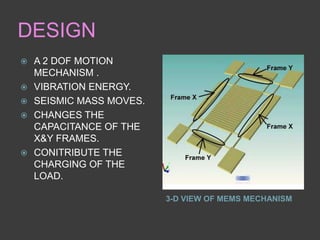

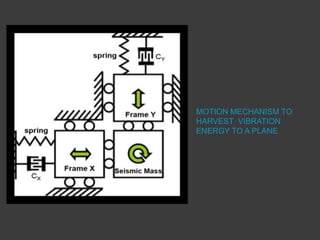

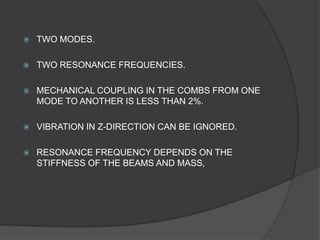

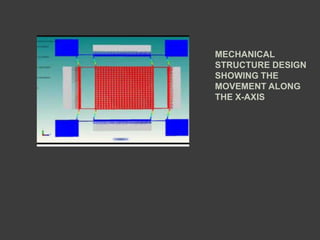

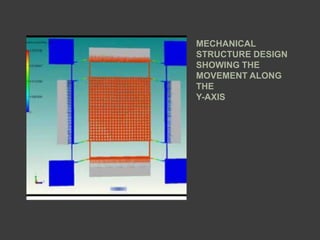

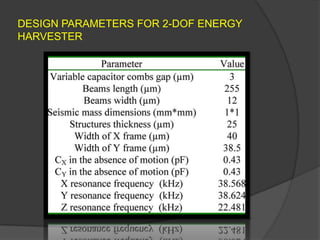

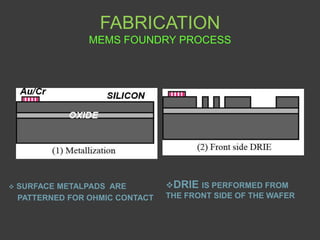

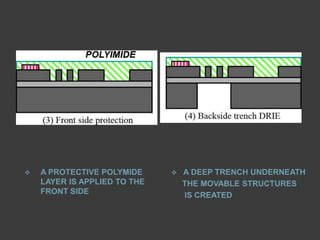

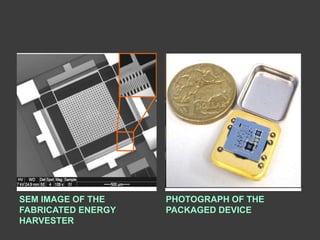

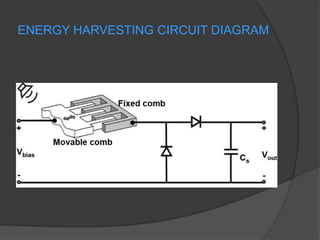

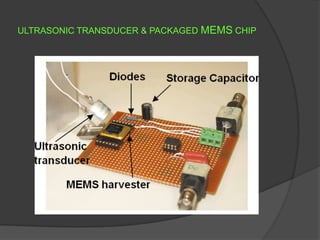

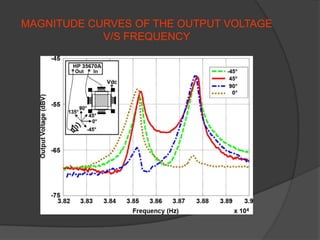

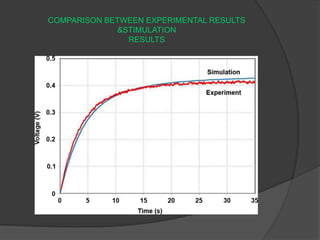

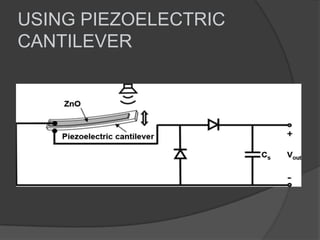

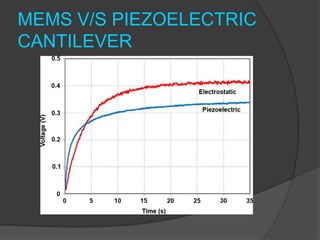

This document describes the design, fabrication, and testing of an ultrasonic energy harvester using MEMS technology. It uses a 2 degree-of-freedom motion mechanism in the MEMS chip to harvest vibration energy from two orthogonal directions. The MEMS chip is paired with an ultrasonic transducer that transmits ultrasonic waves to the chip. Experimental results show the device is able to charge a capacitor up to 21.4 nanowatts of power. The MEMS harvester provides advantages over piezoelectric cantilever harvesters such as smaller size, better sensitivity, and lower cost. Potential applications include powering implantable biomedical sensors.