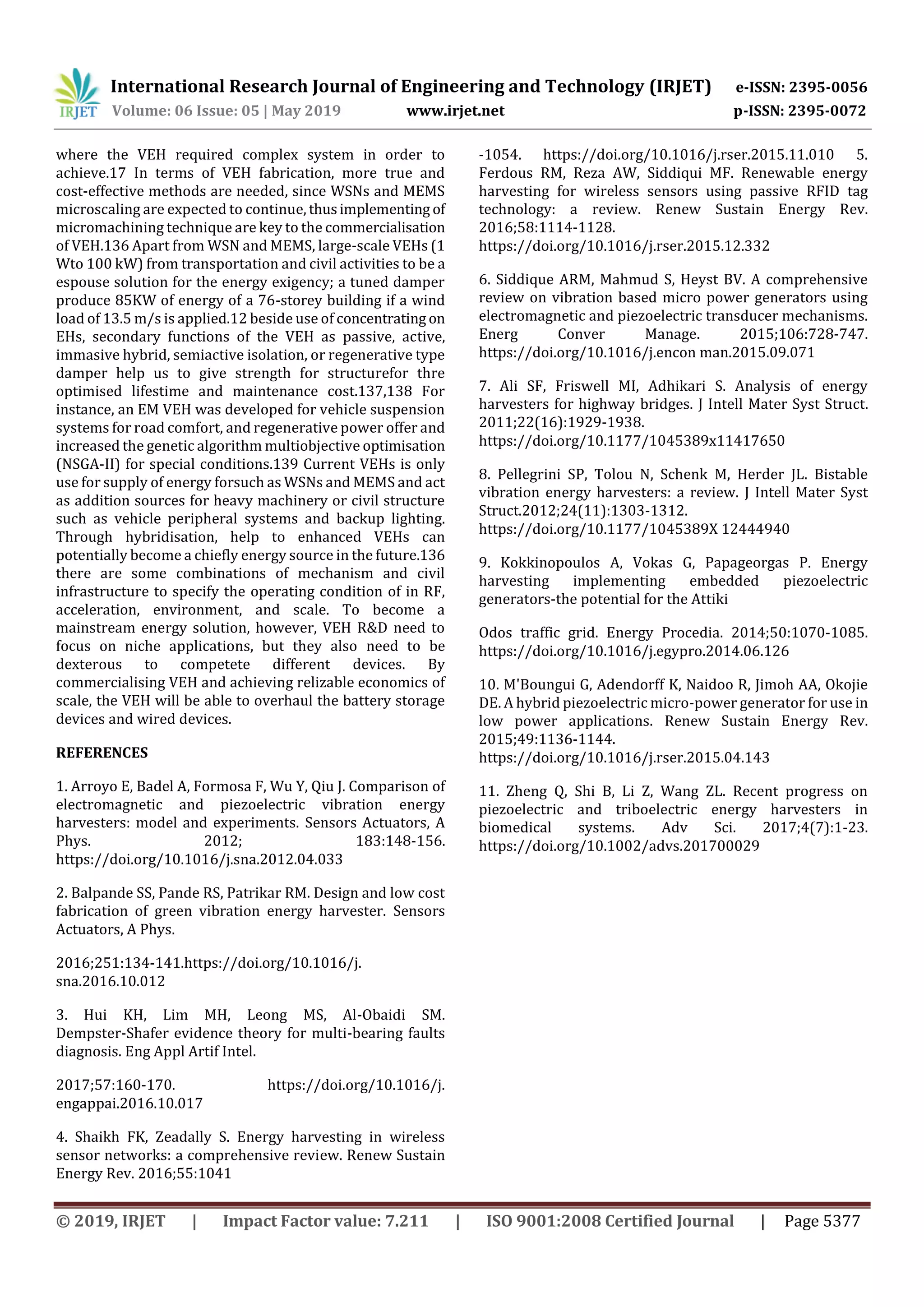

This document reviews different mechanisms for vibration-based energy harvesters, including piezoelectric, electromagnetic, electrostatic, magnetostrictive, and flexible/polymeric energy harvesters. It provides details on the operating principles, advantages, disadvantages, and recent advances of each mechanism. In particular, it discusses how hybrid energy harvesters combining two or more mechanisms can improve power output, efficiency, operational bandwidth, and load range compared to single mechanism harvesters. The review concludes that innovative designs, increased strain concentration, optimized timing circuits, adoption of nonlinear dynamics, and optimal energy harvesting materials can further advance vibration-based energy harvesting technologies.