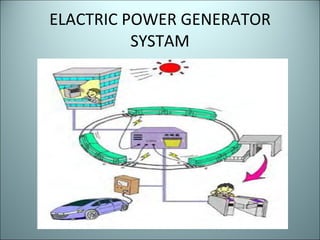

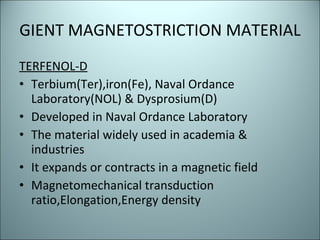

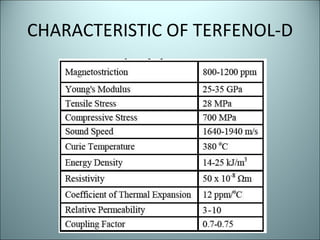

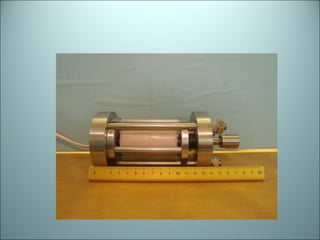

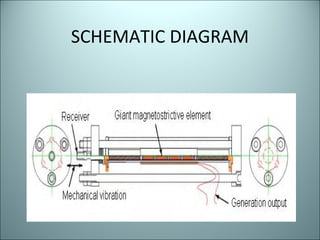

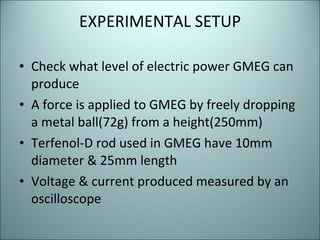

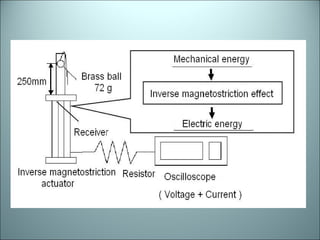

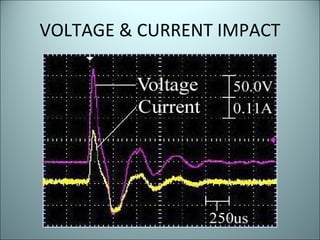

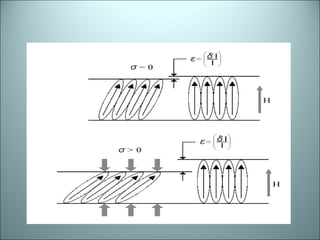

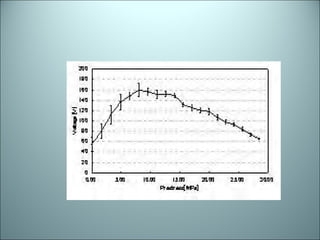

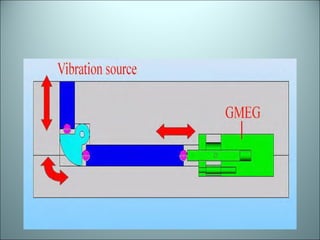

This document discusses the design and testing of a Giant Magnetostriction Electric power Generator (GMEG) that converts vibration energy into electricity. The GMEG uses a Terfenol-D giant magnetostrictive material which changes shape under magnetic fields. Experimental results showed the GMEG could generate over 100W of power from a dropped metal ball and that output voltage increased with an applied preload of 8MPa to the Terfenol-D. A vibration deflector was also designed to redirect vibrations to the GMEG from different angles.