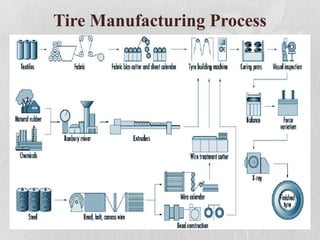

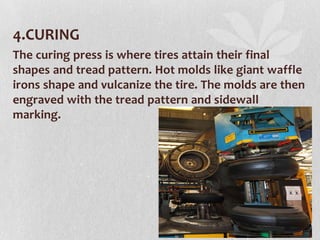

MRF is India's largest tire manufacturer, headquartered in Chennai. It was founded in 1946 and manufactures tires for cars, motorcycles, trucks, buses, tractors, and other vehicles. MRF also produces conveyor belts, toys, sports goods, and paints. The tire manufacturing process involves compounding and mixing rubber and other materials, preparing components like the tread and sidewall, building the tire, curing it in a mold under heat and pressure to set the shape and tread pattern, and inspecting the final product for quality.