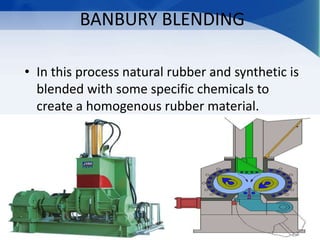

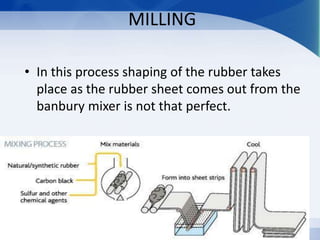

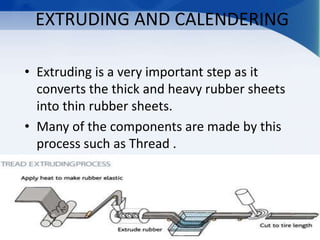

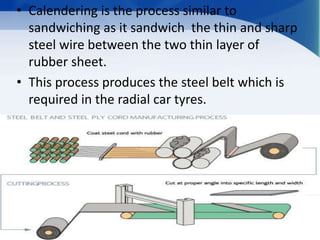

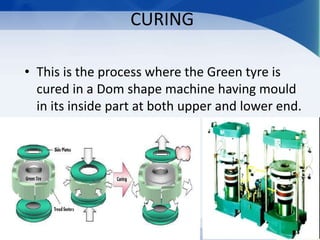

The document discusses the manufacturing process of General Tyres. It describes the raw materials used, which include natural rubber, synthetic rubber, and carbon. The manufacturing process involves several steps: banbury blending mixes the raw materials; milling shapes the rubber sheets; extruding and calendering thin the sheets and make components; components are assembled into green tires; curing forms the tires in a mold; finishing and inspection check quality; and finally, packing wraps the finished tires.