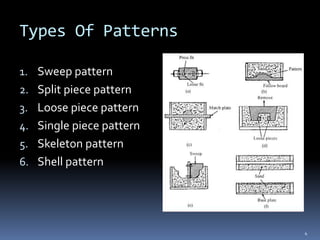

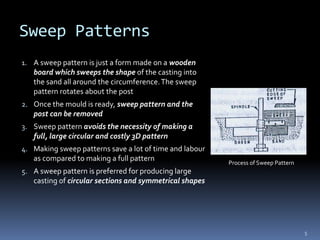

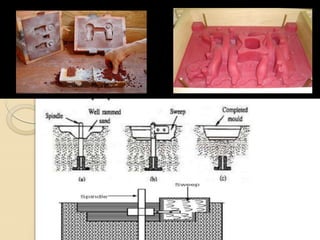

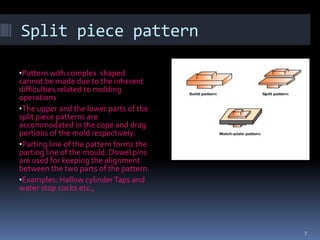

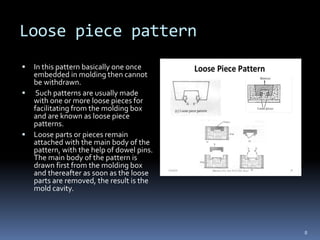

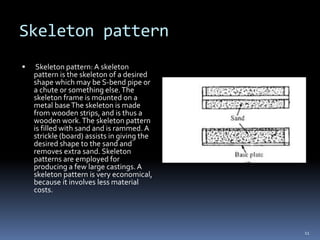

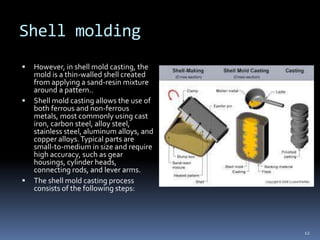

This document discusses different types of patterns used in casting processes. It describes sweep patterns, which involve a rotating form that sweeps the shape of the casting into sand all around a circumference. This avoids making a full circular pattern and saves time and labor for large circular castings. Split piece and loose piece patterns are used for complex shapes and involve separate pattern pieces that fit together. Single piece patterns are made from one solid piece for simple shaped castings. Skeleton patterns use a wooden frame structure filled with sand. Shell mold casting uses a thin resin-coated sand shell around a pattern to allow casting of various metals with high accuracy.