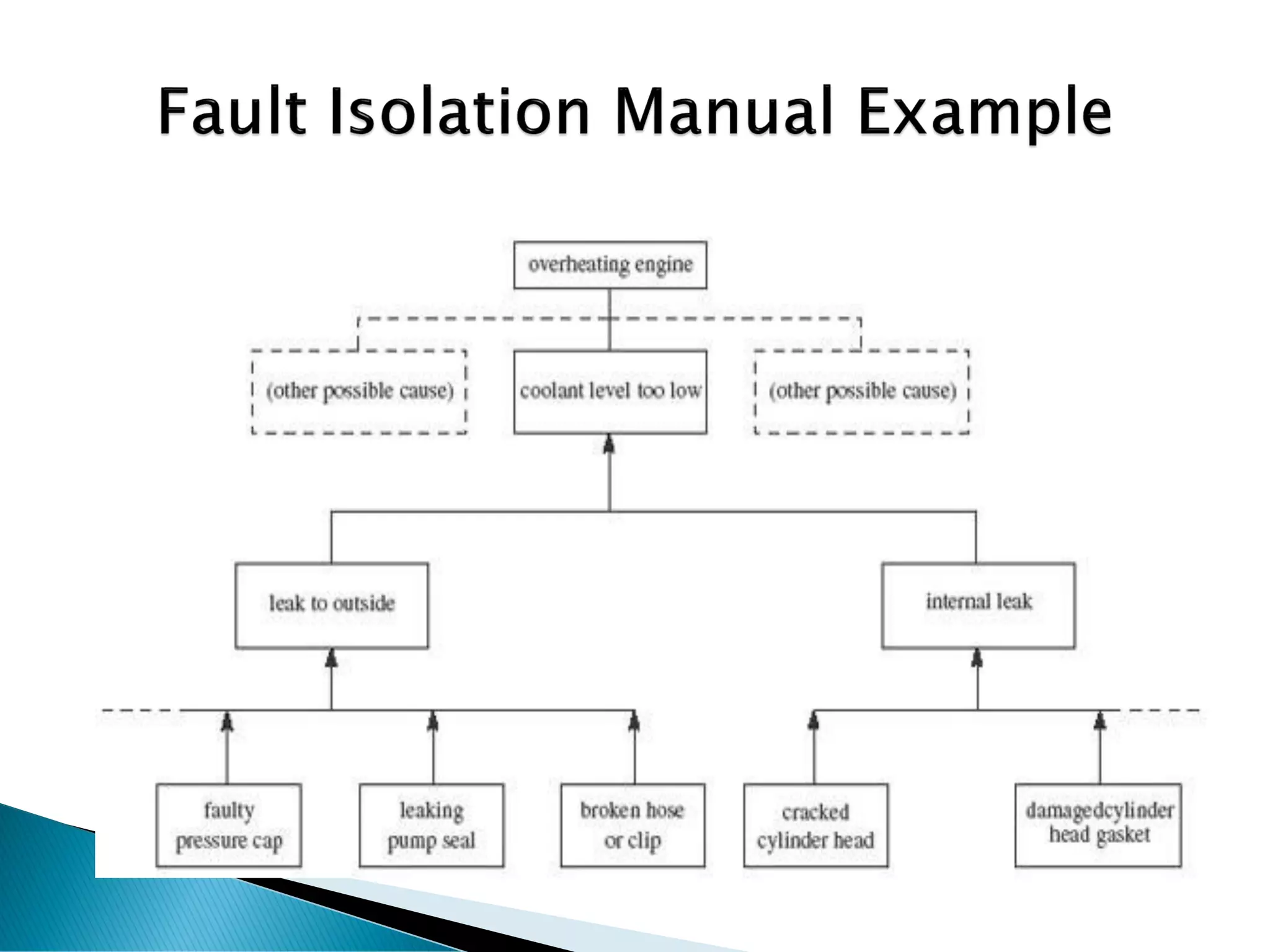

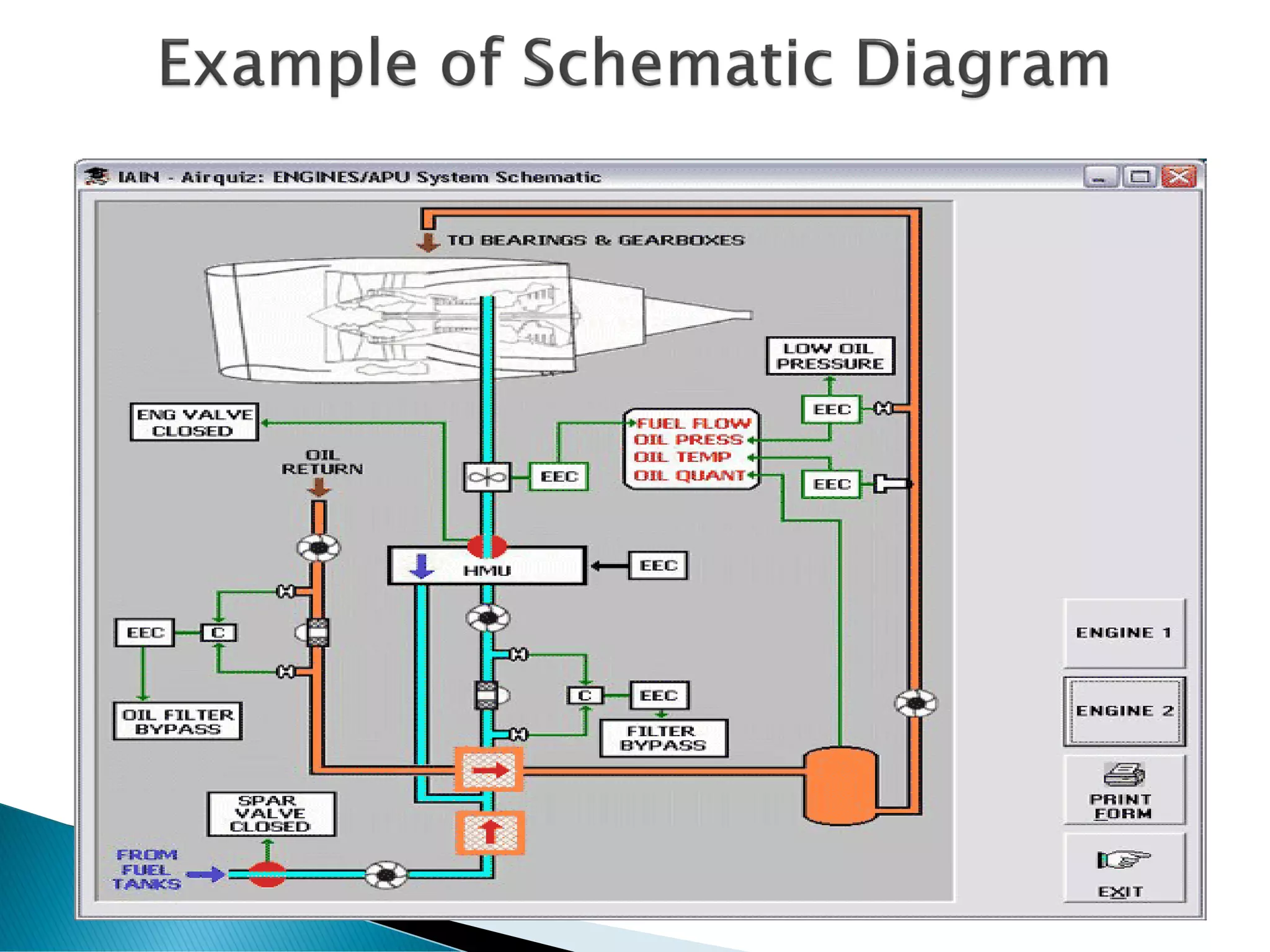

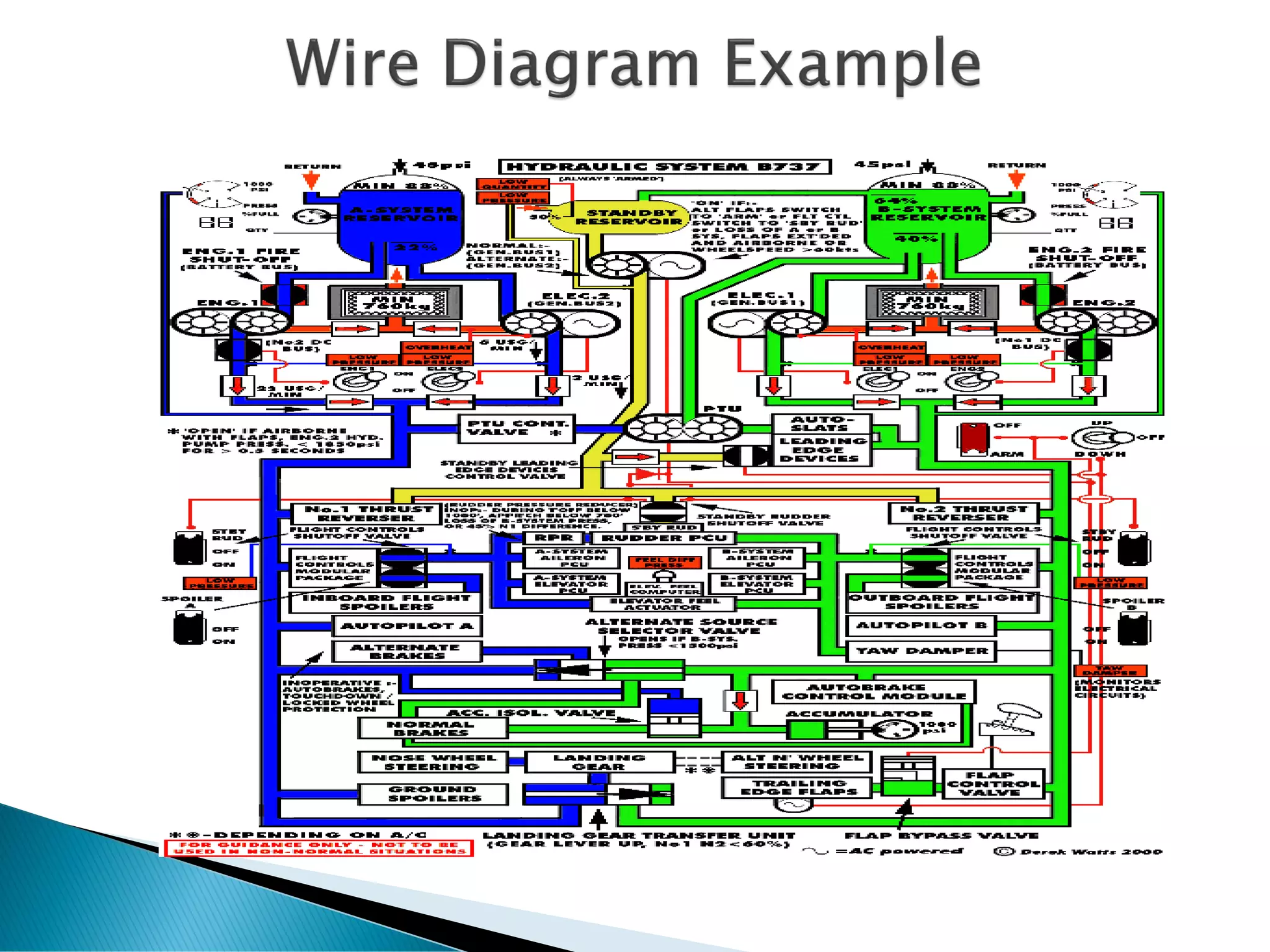

The document discusses various types of documentation used for aircraft maintenance, including manufacturer's documentation, regulatory documentation, and airline generated documentation. It describes documentation such as the maintenance manual, fault isolation manual, illustrated parts catalogue, wiring diagram manual, minimum equipment list, and more. It explains that proper documentation is essential for safely performing maintenance and troubleshooting aircraft systems.