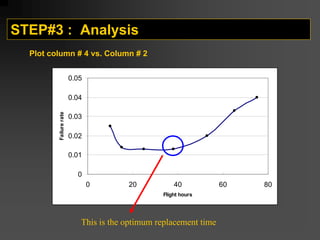

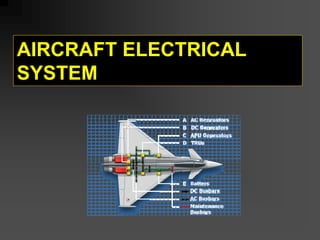

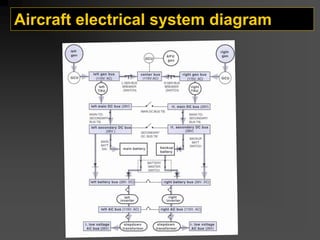

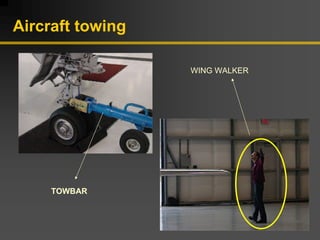

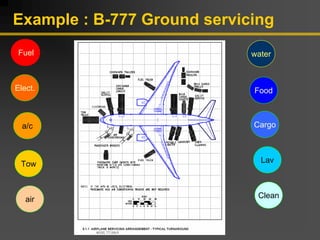

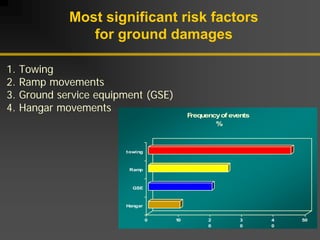

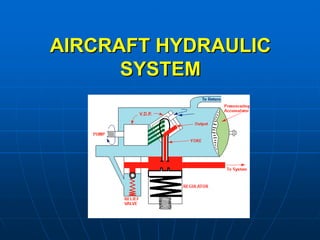

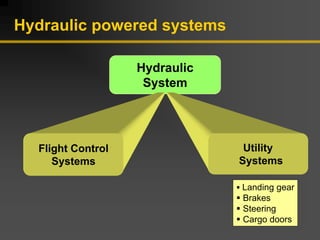

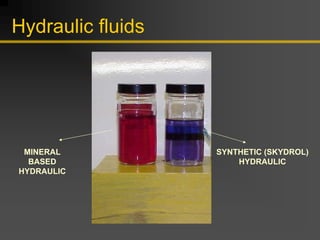

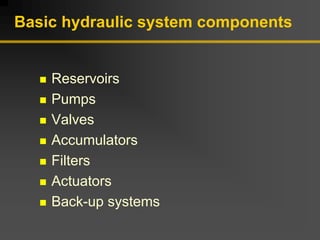

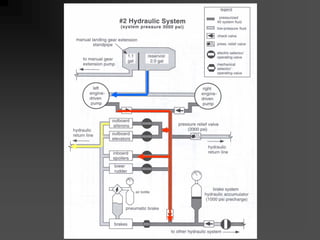

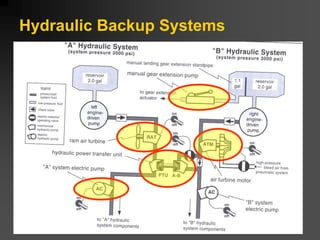

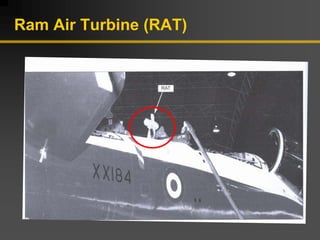

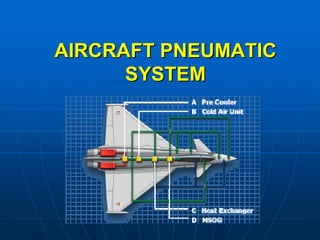

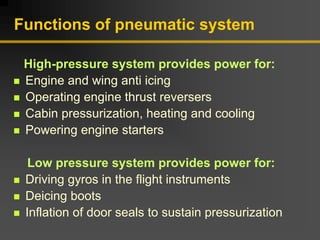

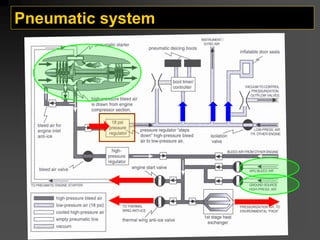

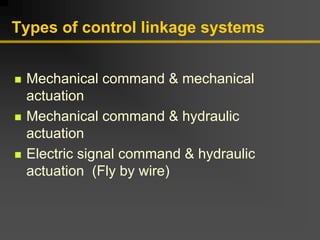

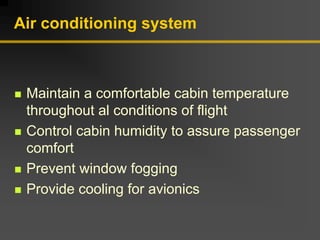

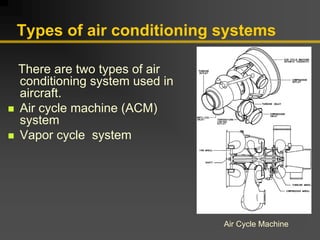

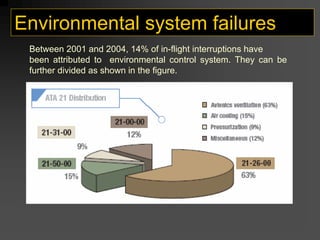

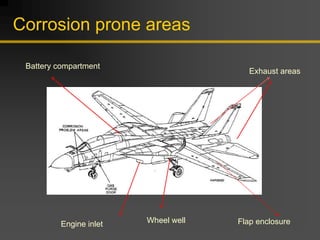

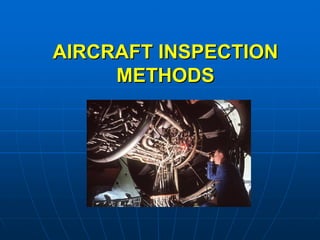

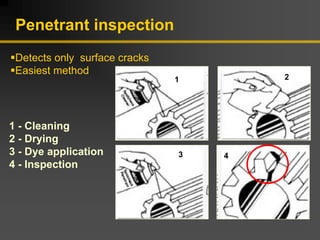

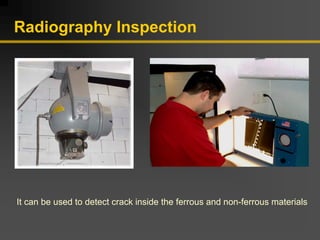

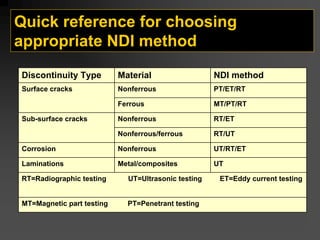

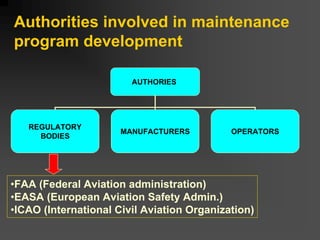

The document provides an overview of aircraft maintenance training. It covers topics like aircraft ground handling procedures, aircraft systems including hydraulic, pneumatic, flight control and landing gear systems, aircraft engines, and environmental control systems. The course outline includes sections on aircraft ground handling, aircraft systems, corrosion inspection methods, and aircraft maintenance planning. Key components and functions of different aircraft systems are described in further detail.

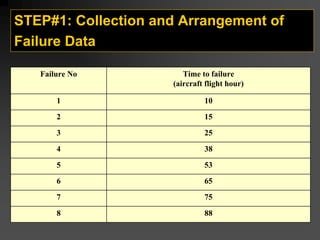

![STEP#2: Calculation of failure rate

Failure rate

Time

between

failures

∆t

Time

to

failure

(flight hour)

Failure Number

( i )

1 / [(5)(8+1-1)]=0.025

10

1

0.014

15

2

0.013

13

25

3

0.013

15

38

4

0.020

12

53

5

0.033

10

65

6

0.040

13

75

7

-

-

88

8

)

i

1

n

)(

t

(

1

FR

−

+

Δ

=

n= 8 (total number of failures)

15-10=5

25-15=10

?](https://image.slidesharecdn.com/methodsofmaintenance-230926102851-687dc483/85/methods-of-maintenance-pdf-161-320.jpg)