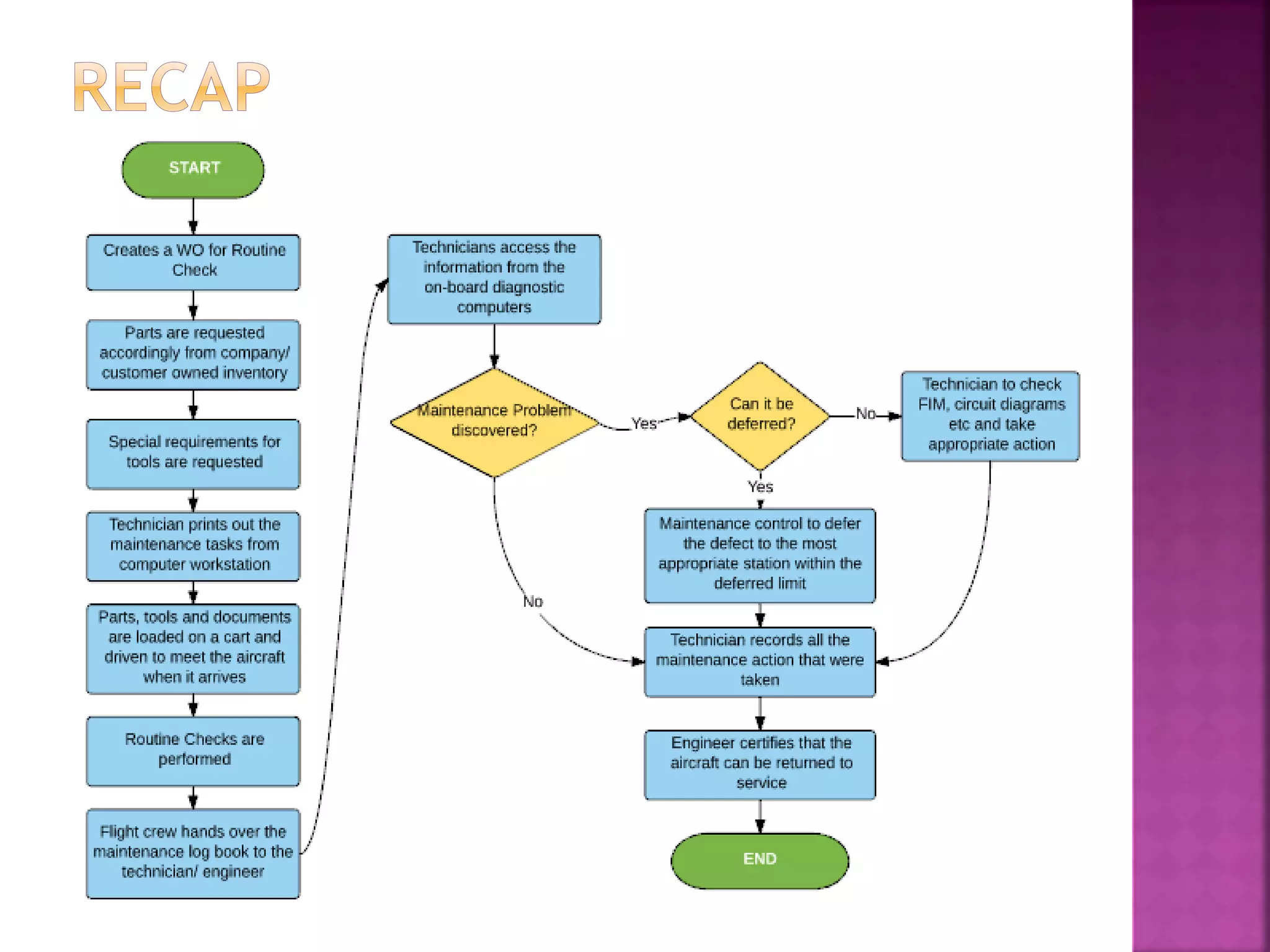

Neethu Nair is an aviation business analyst with experience working for airlines, MROs, and OEMs globally. The document discusses the processes for hangar and line maintenance. It describes the procedures for routine maintenance prior to aircraft arrival such as creating work orders and requesting parts. Upon arrival, technicians perform checks, access diagnostic information, and record maintenance actions before releasing the aircraft. Defects can either be deferred according to MEL or CDL guidelines or immediately solved depending on the situation.