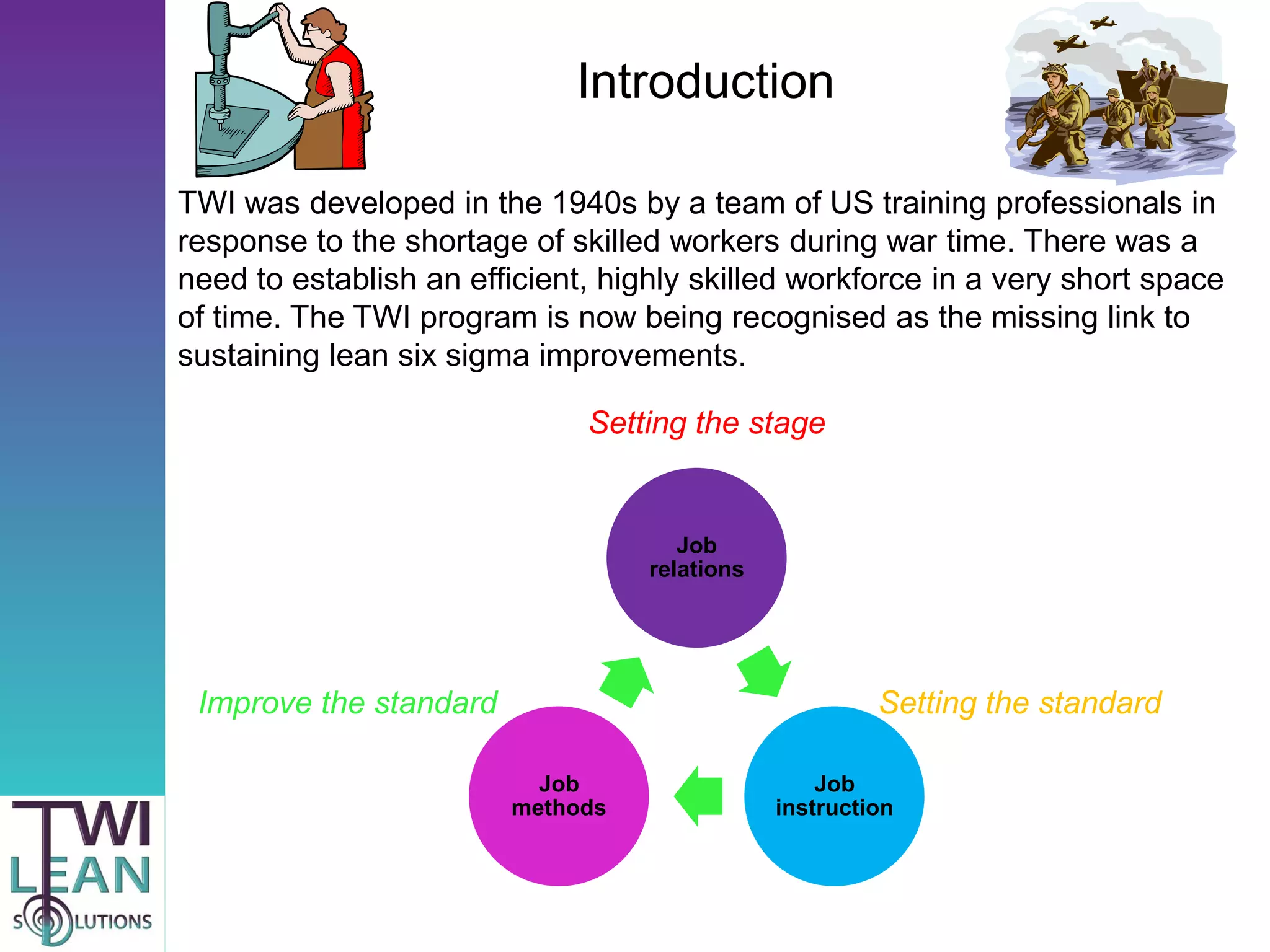

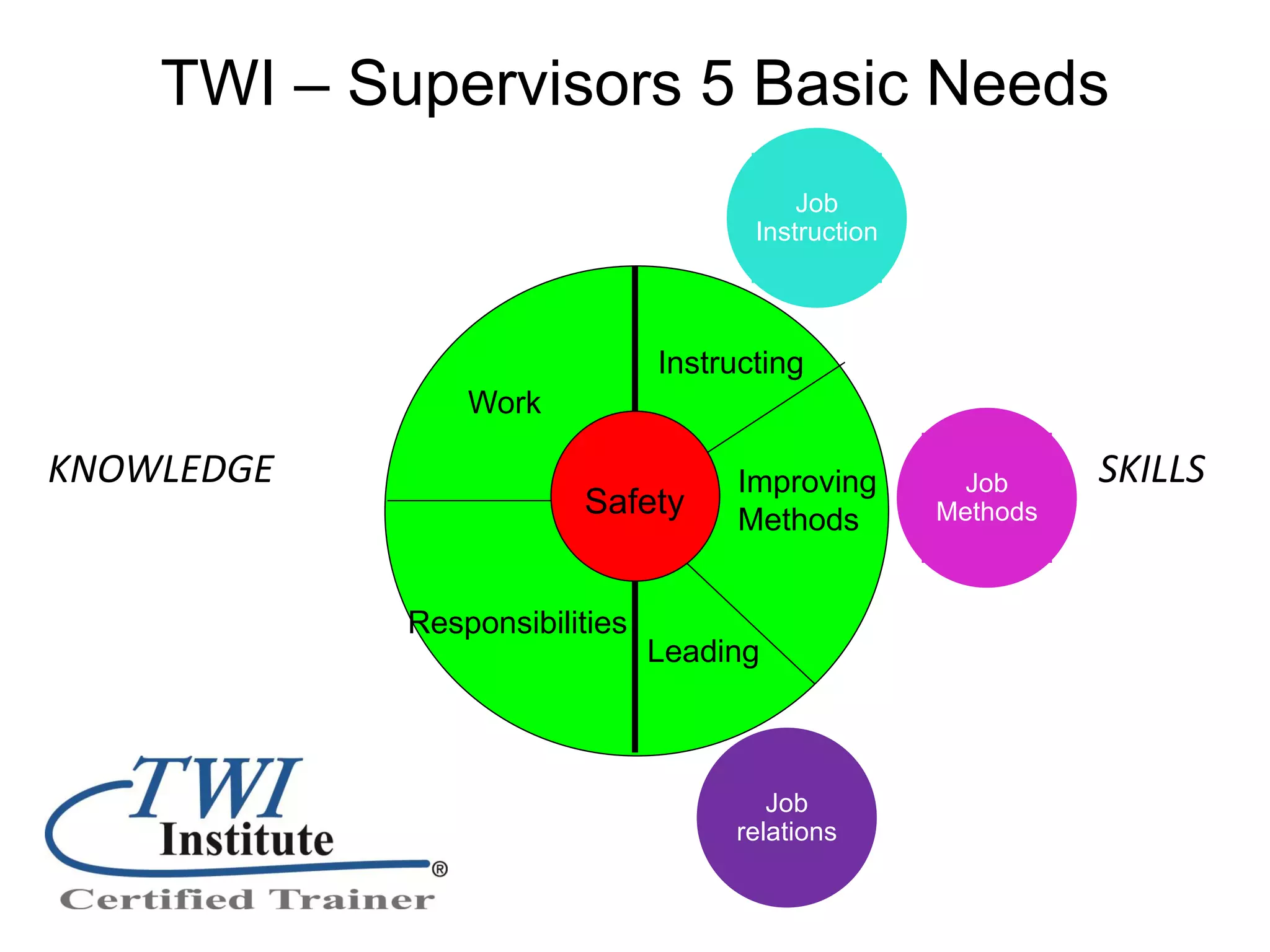

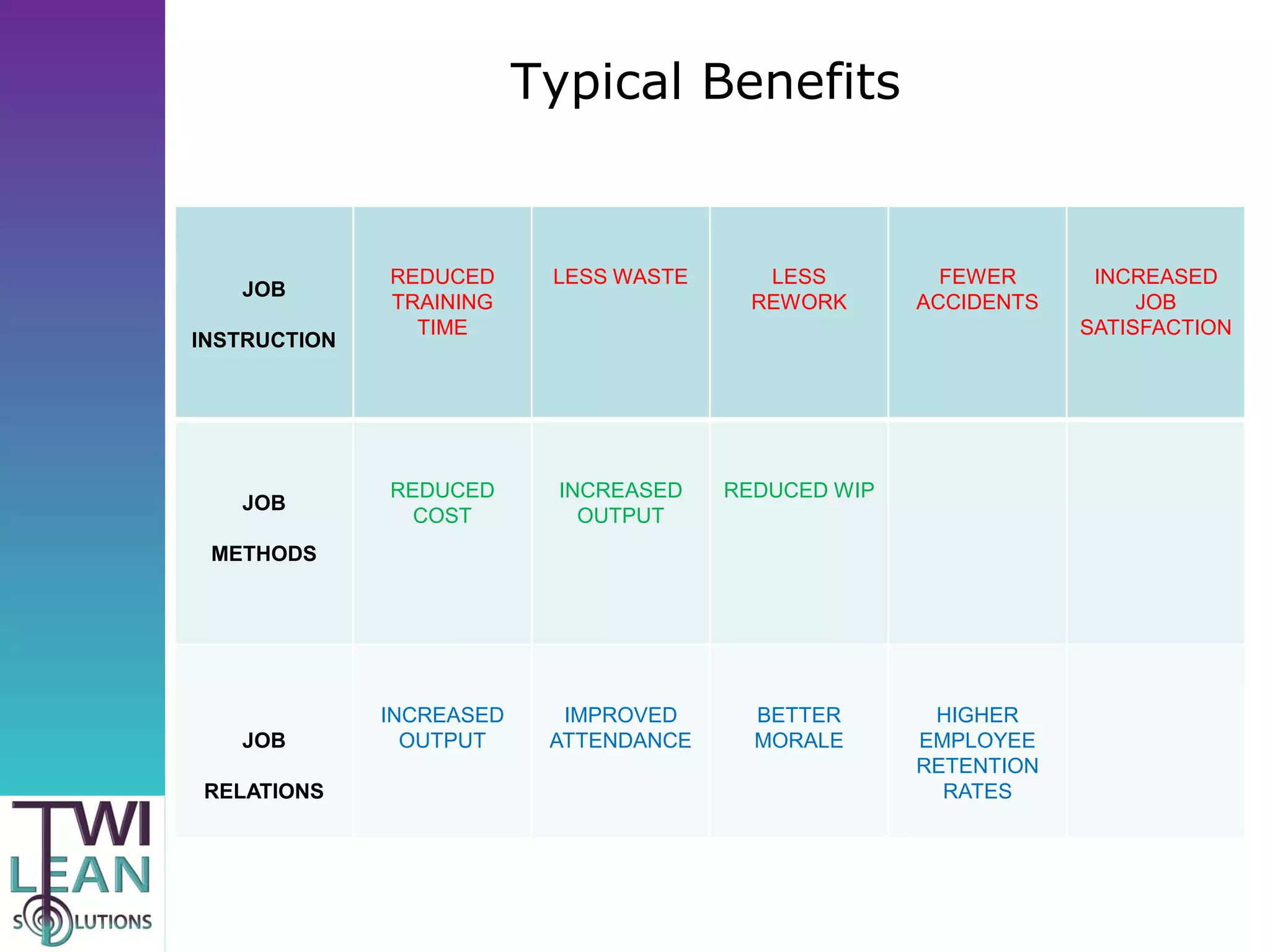

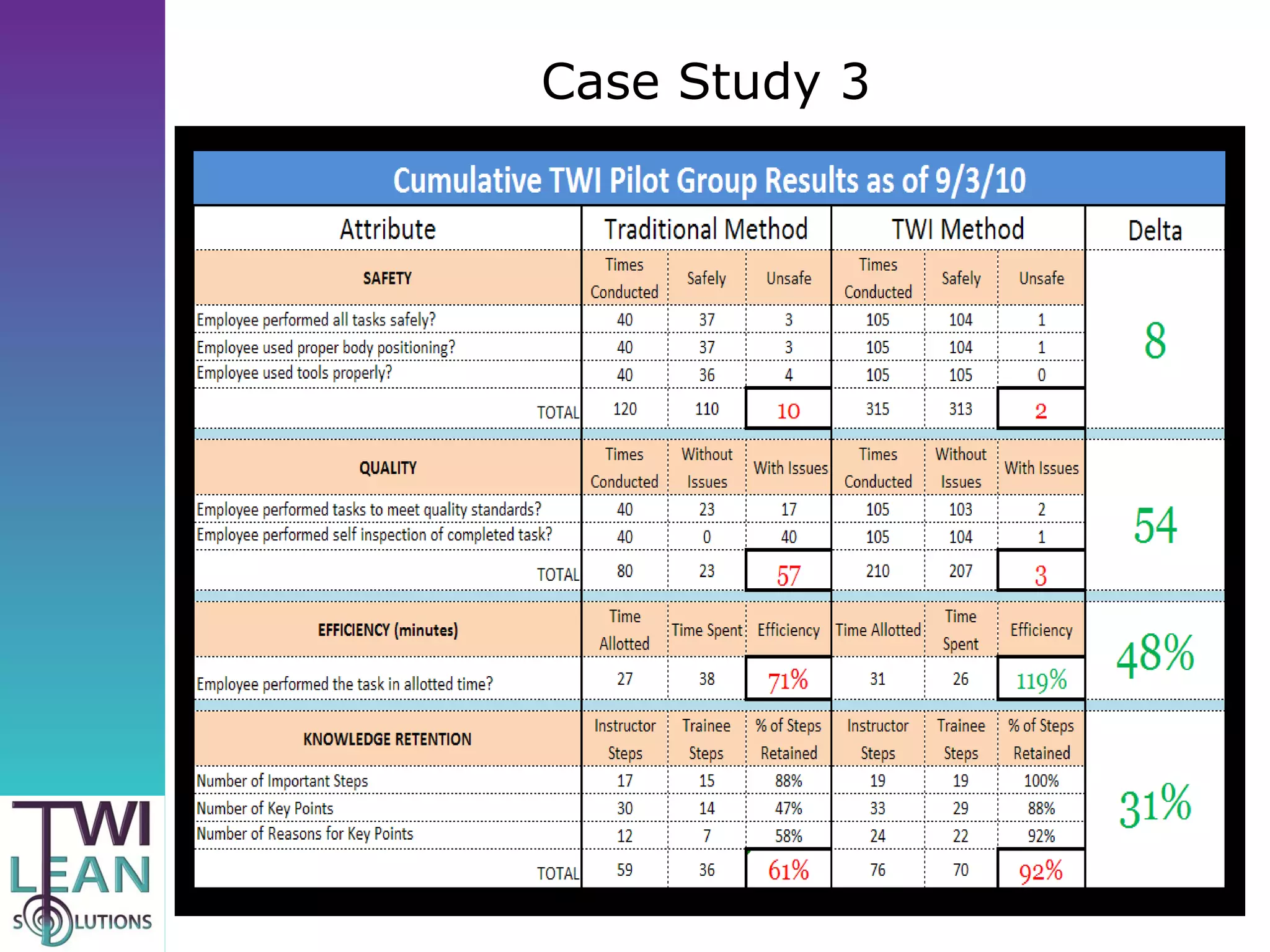

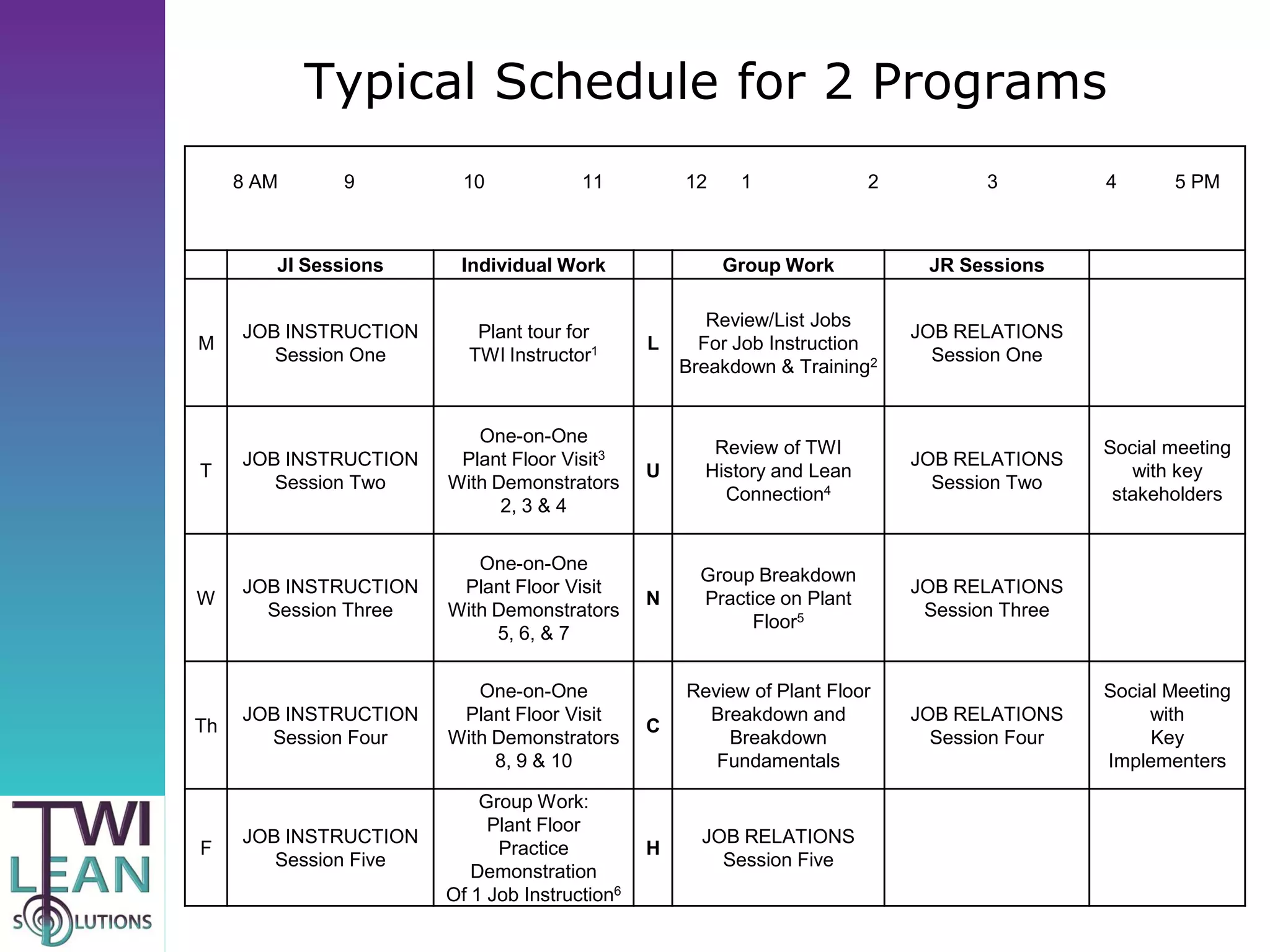

TWI was developed in the 1940s to efficiently train workers during wartime. It consists of three core programs: Job Relations, which creates a positive work environment; Job Instruction, which standardizes work methods through teaching workers how to learn tasks; and Job Methods, which improves work methods. Implementing TWI typically results in reduced training time, increased output and quality, improved attendance and morale, and higher employee retention. Case studies show companies achieving benefits such as decreased costs, increased productivity, and improved profitability after utilizing TWI training.