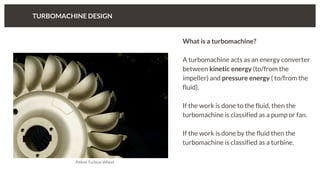

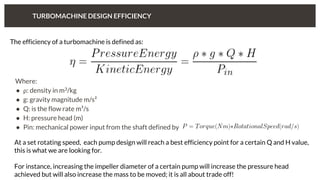

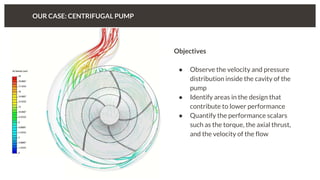

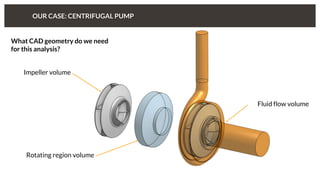

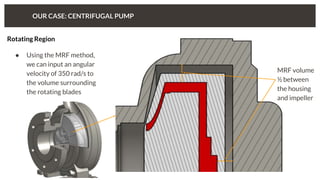

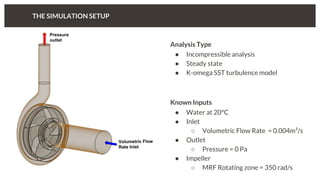

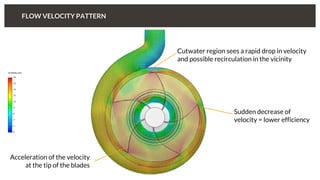

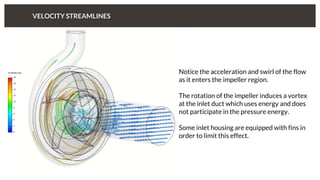

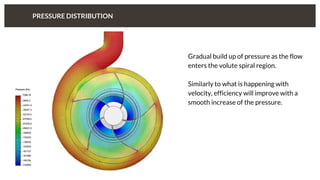

The document discusses turbomachinery design using cloud-based CFD optimization to enhance performance, durability, and design efficiency. It outlines key design efficiency factors, parameters affecting turbomachine performance, and the simulation workflow that aids in making informed design decisions. Additionally, it emphasizes the significance of CFD in reducing prototyping needs through rapid iteration and efficiency analysis.