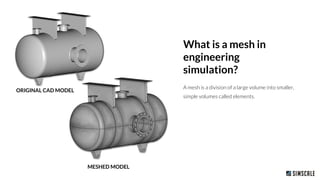

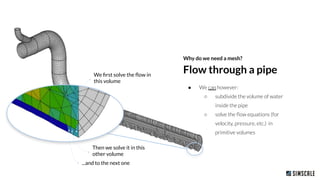

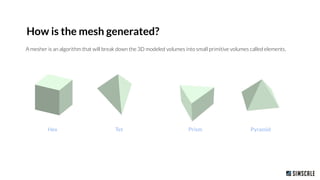

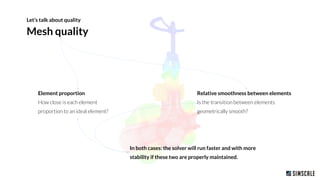

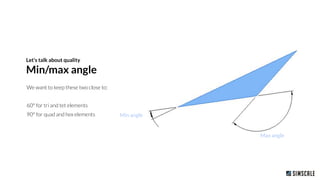

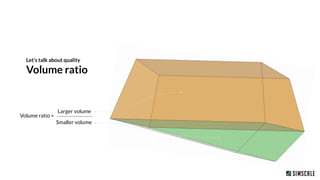

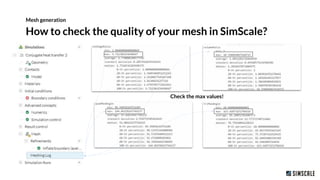

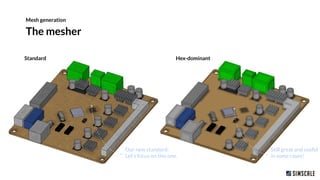

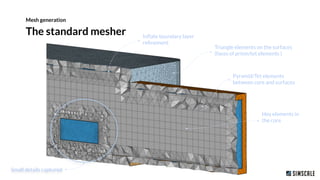

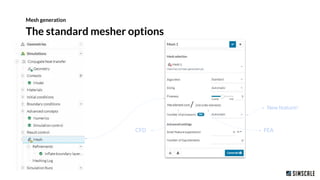

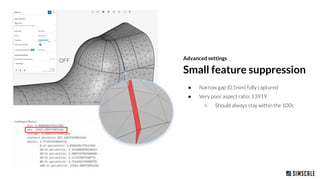

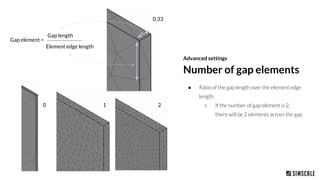

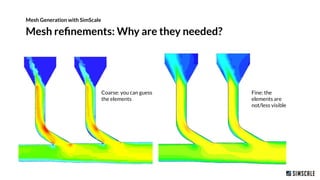

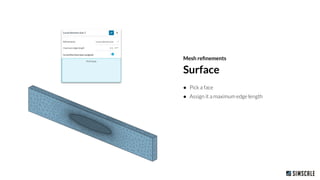

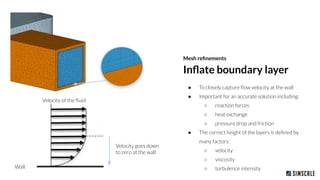

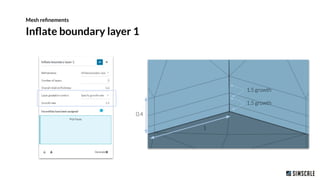

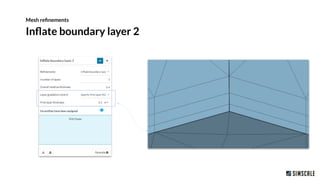

The document discusses a webinar on mesh generation using SimScale, a cloud-based engineering simulation platform founded in 2012. It covers the importance of meshing in engineering simulations, what constitutes a good quality mesh, and various practices and techniques for generating meshes effectively. It also highlights advanced mesh settings, including considerations for mesh refinements and quality factors that enhance simulation accuracy.