The document discusses inventory management models and concepts including:

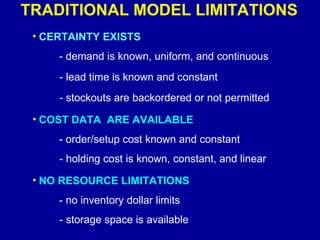

1) Traditional inventory models make simplifying assumptions about demand, lead times, and costs that may not reflect reality.

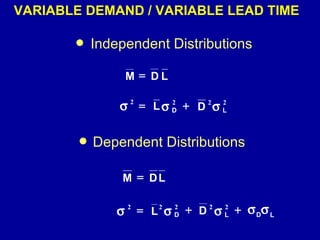

2) Probabilistic models use statistical distributions to represent uncertain demand and lead times. Safety stock is calculated based on the probability of stockouts.

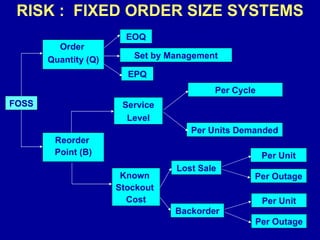

3) Service level goals can be set based on the probability of stockouts over an order cycle or per unit demanded. Imputed stockout costs are used to determine optimal reorder points.