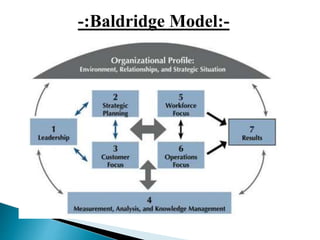

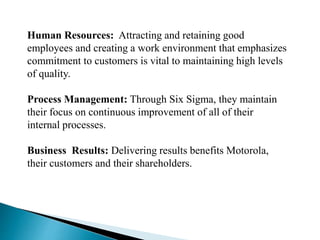

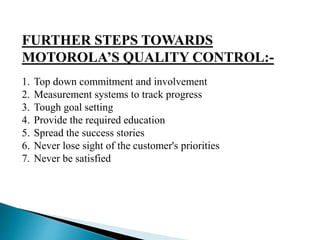

Motorola is committed to quality and innovation. It has R&D in 6 countries, manufacturing in 3 countries, and sells products in over 100 countries. Motorola originated Six Sigma and uses it to continuously improve quality and reduce costs. It aims for high quality at low cost to satisfy customers. Motorola's quality management involves quality planning, production, and self-evaluation. It was the first company to receive the Malcolm Baldridge National Quality Award and ISO 9001 certification, demonstrating its commitment to quality.