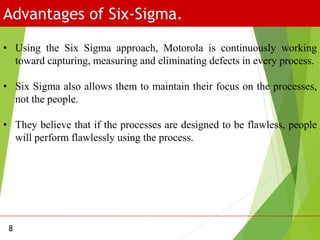

This document discusses how Motorola implemented Six Sigma and benchmarking to improve quality. It provides details on:

1. Motorola's implementation of Six Sigma, which reduced defects by 99.7% and costs by 84% while increasing productivity by 12% annually.

2. How benchmarking best practices from other industries helped Motorola develop a strategic quality plan focused on leadership, process management, and customer satisfaction.

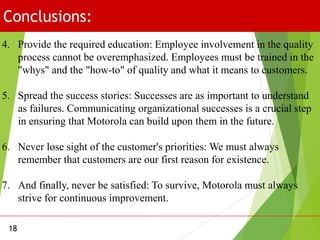

3. The conclusions that benchmarking enabled goal-setting and improvements, communication of successes was important, and continuous improvement is needed to maintain performance leadership.