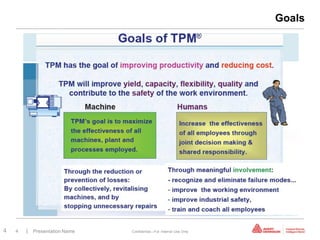

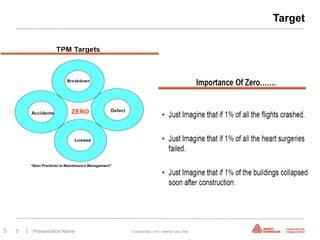

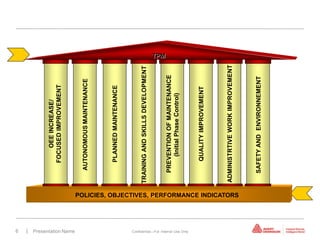

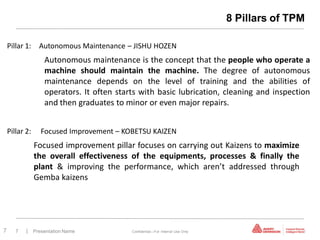

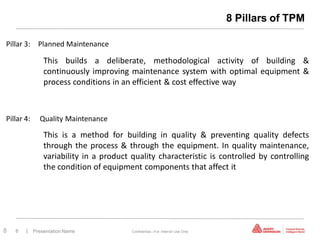

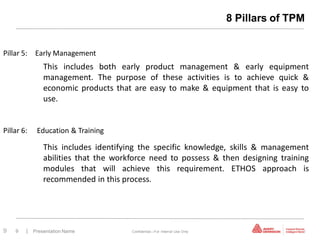

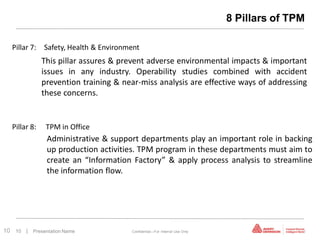

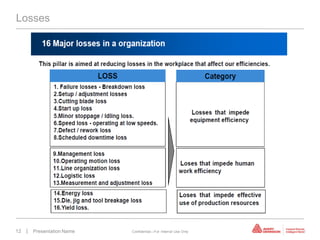

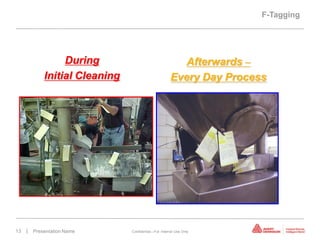

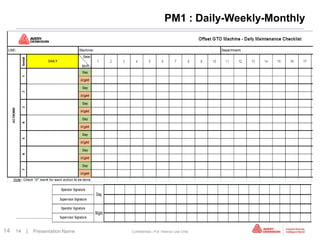

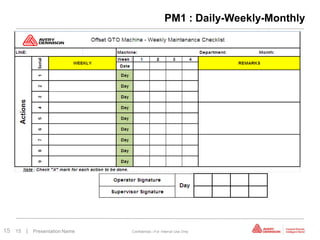

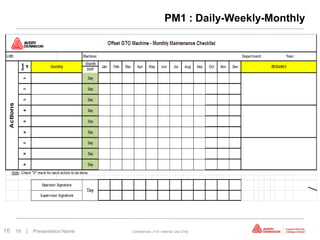

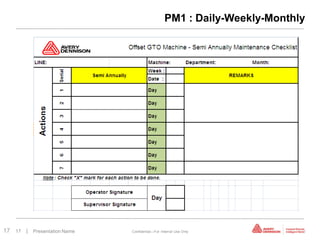

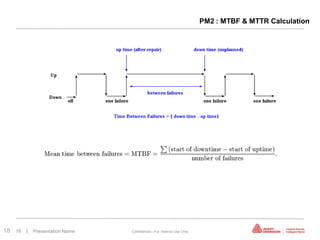

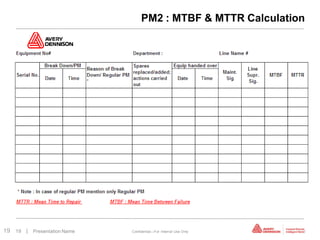

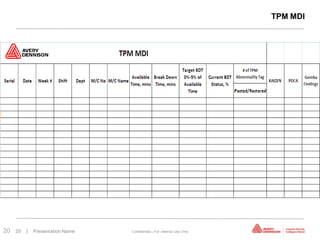

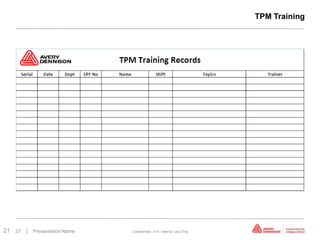

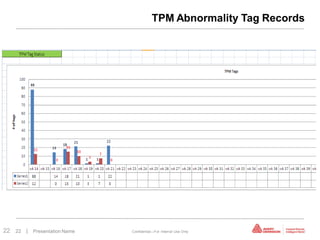

This document provides an introduction to Total Productive Maintenance (TPM). It defines TPM as combining productive and preventive maintenance with innovative management strategies and total employee involvement. The goals of TPM include increasing equipment effectiveness, focusing improvements, and developing employee skills. The presentation outlines the eight pillars of TPM which include autonomous maintenance, planned maintenance, quality maintenance, and education/training. It provides examples of TPM implementation including F-tagging equipment, preventative maintenance schedules, and using abnormality tags to track equipment issues.